Warm reminder: The article is about 3700 words long and will take about 10 minutes to read. You will definitely gain something after reading it. If you want to learn more professional and in-depth knowledge, you can join my Flat Panel Display Technology Learning Circle. The details link is as follows:Welcome to join the Flat Panel Display Technology Learning Circle

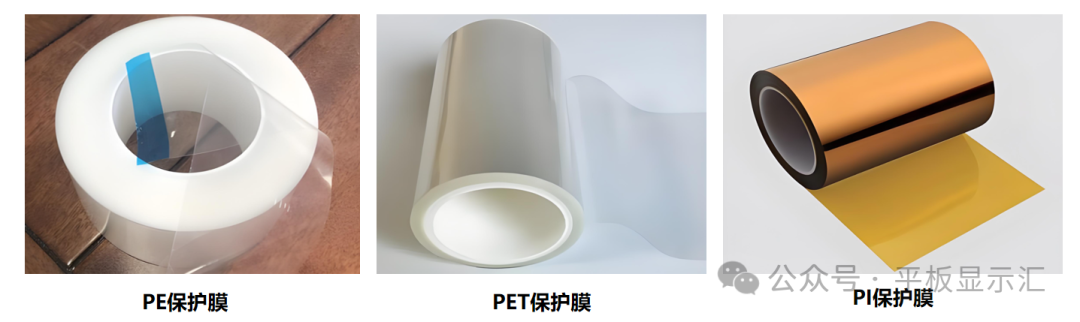

Readers who often read insightful articles and are relatively attentive should have noticed that most materials related to TFT-LCD display modules are introduced in insightful public account articles. Of course, this is just the first step in public account writing, and there will be continuous and in-depth explanations of these materials in the future.If readers are interested in any material or have encountered problems with any material, they can refer to the articles on the public account homepage or continue to follow subsequent articles.In the TFT-LCD display module, there is a very common and often overlooked material, yes, it is the front protective film attached to the surface of the fully bonded display module cover glass.Whenever protective films are mentioned, it usually gives people the impression of “Isn’t it just a protective film? What advanced technology can there be?”Of course, while it cannot be said to have “advanced technology”, there are still some requirements for the protective film attached to the glass cover surface, which will be explained in detail later in this article.In fact, protective films have different advantages and disadvantages and application scenarios based on different substrates and adhesive systems. Therefore, today’s article will focus on the classification and structure of protective films, key characteristics of protective films, and the manufacturing process of protective films.Of course, the protective film discussed in this article mainly refers to the front protective film, specifically the PET protective film, attached to the surface of the glass cover.01 Classification and Structure of Protective FilmsMany readers may not be very familiar with protective films if they do not read today’s article.There are many types of protective films, classified according to different application scenarios, different functional properties, different substrates, and different adhesive systems.There are actually many classifications of protective films; in this article, we will focus on different substrates and different adhesive systems.① Classification of Protective Films by SubstrateProtective films can be classified by substrate into many types, such as PE, PET, PI, PC, PVC, PP, TPU, etc. In fully bonded display modules, the three main and classic types we often use are: PE, PET, and PI.

Images of the three classic protective filmsa. PE Protective Film:PE stands for Polyethylene. PE protective film has high flexibility and extensibility, and it has high transparency, making it the lowest cost among these three protective films.However, PE protective film has poor mechanical properties, is very easy to scratch and tear, and has average temperature resistance, usually applied in glass cover shipping packaging films, wrapping films, etc.b. PET Protective Film:PET stands for Polyethylene Terephthalate. PET protective film has good mechanical properties and dimensional stability, showing superior performance in tear resistance, tensile strength, and wear resistance; at the same time, it has good transparency and excellent optical properties, with decent temperature resistance, usually applied as shipping protective films for backlight or fully bonded display modules.Additionally, due to the many advantages of PET substrate and its moderate cost, it is widely used in various optical materials, such as diffusion films, brightness enhancement films, OCA optical adhesive protective films/release films, etc.c. PI Protective Film:PI stands for Polyimide. PI protective film has many advantages, including excellent mechanical properties and chemical stability, such as high strength, good toughness, wear resistance, and good dimensional stability, while also being a “ceiling” in terms of high-temperature resistance.However, it also has some obvious disadvantages, mainly in terms of cost and transparency. PI protective film is usually applied in FPC cover films and protective tapes for components that can withstand high temperatures during SMT.The key advantages and disadvantages of PE, PET, and PI protective films are summarized as follows:

Images of the three classic protective filmsa. PE Protective Film:PE stands for Polyethylene. PE protective film has high flexibility and extensibility, and it has high transparency, making it the lowest cost among these three protective films.However, PE protective film has poor mechanical properties, is very easy to scratch and tear, and has average temperature resistance, usually applied in glass cover shipping packaging films, wrapping films, etc.b. PET Protective Film:PET stands for Polyethylene Terephthalate. PET protective film has good mechanical properties and dimensional stability, showing superior performance in tear resistance, tensile strength, and wear resistance; at the same time, it has good transparency and excellent optical properties, with decent temperature resistance, usually applied as shipping protective films for backlight or fully bonded display modules.Additionally, due to the many advantages of PET substrate and its moderate cost, it is widely used in various optical materials, such as diffusion films, brightness enhancement films, OCA optical adhesive protective films/release films, etc.c. PI Protective Film:PI stands for Polyimide. PI protective film has many advantages, including excellent mechanical properties and chemical stability, such as high strength, good toughness, wear resistance, and good dimensional stability, while also being a “ceiling” in terms of high-temperature resistance.However, it also has some obvious disadvantages, mainly in terms of cost and transparency. PI protective film is usually applied in FPC cover films and protective tapes for components that can withstand high temperatures during SMT.The key advantages and disadvantages of PE, PET, and PI protective films are summarized as follows: Comparison of key advantages and disadvantages of the three protective films② Classification of Protective Films by Adhesive SystemThe adhesive systems coated on protective films mainly include three types: Silicone (organic silicone),Acrylic (acrylic resin), and PU (polyurethane) adhesives.The adhesive systems used on protective films of different substrates will also vary, and it is crucial to comprehensively consider the curing temperature of the adhesive and the temperature resistance of the protective film substrate.For example, silicone and PU adhesives cannot be coated on PE protective films, as the curing temperatures of these two adhesives far exceed the temperature resistance of PE protective films.This article mainly focuses on the PET protective film attached to fully bonded display modules. Due to its good temperature resistance and excellent optical properties, PET protective film can accommodate the coating of these three types of adhesives.Due to the length of the article, we have summarized the key advantages and disadvantages of these three adhesive systems for PET protective films as follows:

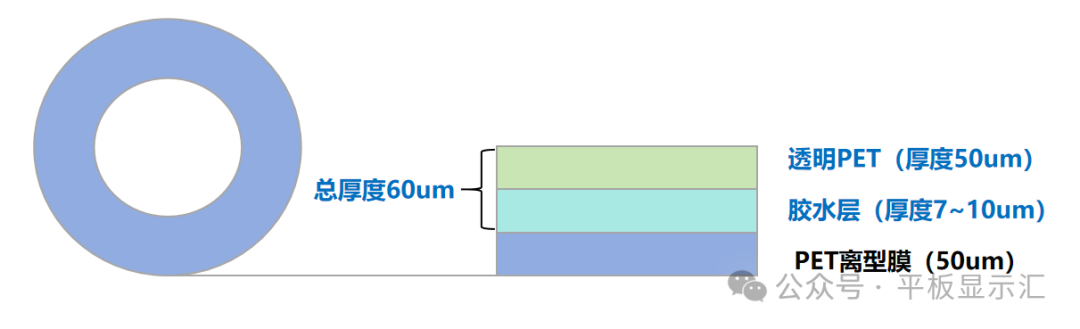

Comparison of key advantages and disadvantages of the three protective films② Classification of Protective Films by Adhesive SystemThe adhesive systems coated on protective films mainly include three types: Silicone (organic silicone),Acrylic (acrylic resin), and PU (polyurethane) adhesives.The adhesive systems used on protective films of different substrates will also vary, and it is crucial to comprehensively consider the curing temperature of the adhesive and the temperature resistance of the protective film substrate.For example, silicone and PU adhesives cannot be coated on PE protective films, as the curing temperatures of these two adhesives far exceed the temperature resistance of PE protective films.This article mainly focuses on the PET protective film attached to fully bonded display modules. Due to its good temperature resistance and excellent optical properties, PET protective film can accommodate the coating of these three types of adhesives.Due to the length of the article, we have summarized the key advantages and disadvantages of these three adhesive systems for PET protective films as follows: Comparison of key advantages and disadvantages of the three adhesive systems for PET protective films③ Structure of PET Protective FilmThe structure of PET protective film is relatively simple. The PET protective film body usually includes:transparent PET film and adhesive layer. The total thickness of PET protective films used on medium and small-sized display modules is generally about 60um, with the thickness of the transparent PET film being around 50um and the adhesive layer thickness being about 7-10um.One side of the PET protective film is adhesive, so it is usually attached to the base film, also known as the PET release film. The thickness of the PET release film is usually around 50um.Additionally, due to the high level of automation among current module manufacturers, PET protective films are usually shipped in rolls to meet the attachment requirements of automated equipment.

Comparison of key advantages and disadvantages of the three adhesive systems for PET protective films③ Structure of PET Protective FilmThe structure of PET protective film is relatively simple. The PET protective film body usually includes:transparent PET film and adhesive layer. The total thickness of PET protective films used on medium and small-sized display modules is generally about 60um, with the thickness of the transparent PET film being around 50um and the adhesive layer thickness being about 7-10um.One side of the PET protective film is adhesive, so it is usually attached to the base film, also known as the PET release film. The thickness of the PET release film is usually around 50um.Additionally, due to the high level of automation among current module manufacturers, PET protective films are usually shipped in rolls to meet the attachment requirements of automated equipment. Illustration of the structure of PET protective filmThe adhesive layer in the PET protective film is not only composed of the three types of adhesives mentioned above, known as the main adhesive, but also includes curing agents, antistatic agents, and solvents to meet the basic functions of PET protective films, such as: film tearing voltage, adhesive surface resistance, adhesion, and other functional indicators.02 Key Characteristics of Protective FilmsThe key characteristics of protective films vary based on different substrates and adhesive systems. The PET protective film attached to the cover glass of fully bonded display modules currently mainly uses PU adhesive-based PET protective films, and this section will focus on the key characteristics of PU adhesive-based PET protective films.The main key characteristics of PU adhesive-based PET protective films usually include: thickness, transmittance & haze, film tearing voltage, adhesion, and adhesive surface resistance. The thickness has been mentioned earlier; this section will discuss other key indicators.

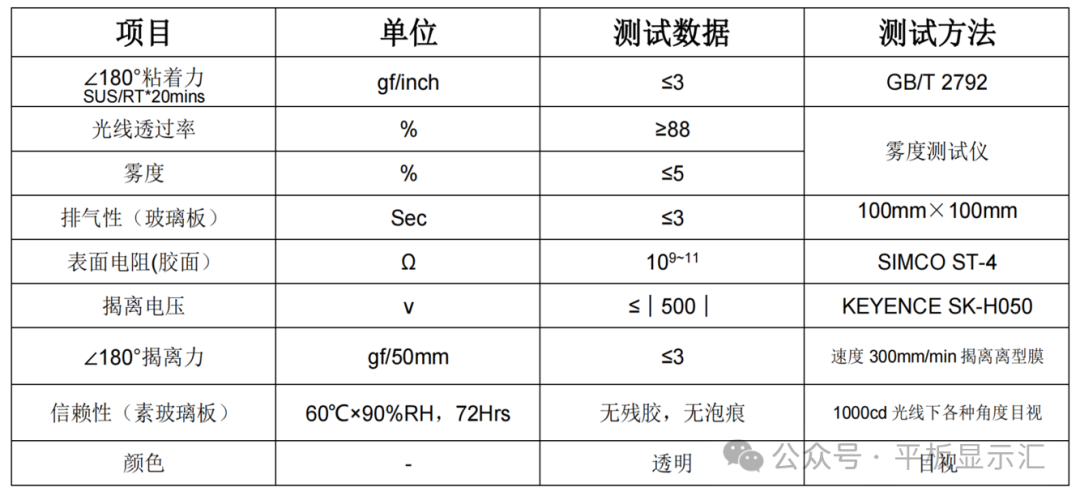

Illustration of the structure of PET protective filmThe adhesive layer in the PET protective film is not only composed of the three types of adhesives mentioned above, known as the main adhesive, but also includes curing agents, antistatic agents, and solvents to meet the basic functions of PET protective films, such as: film tearing voltage, adhesive surface resistance, adhesion, and other functional indicators.02 Key Characteristics of Protective FilmsThe key characteristics of protective films vary based on different substrates and adhesive systems. The PET protective film attached to the cover glass of fully bonded display modules currently mainly uses PU adhesive-based PET protective films, and this section will focus on the key characteristics of PU adhesive-based PET protective films.The main key characteristics of PU adhesive-based PET protective films usually include: thickness, transmittance & haze, film tearing voltage, adhesion, and adhesive surface resistance. The thickness has been mentioned earlier; this section will discuss other key indicators. Illustration of key characteristics in a PET protective film specification sheet① Transmittance & HazeThe transmittance of PET protective films is generally required to be >88%, while some manufacturers may conservatively control it at >85%. The haze of PET protective films is generally within the range of <2%-5%, with specifics depending on the specifications provided by the protective film manufacturer.a. Transmittance:It refers to the amount of light that passes through the transparent PET protective film when light is vertically incident on it, where scattering occurs both inside and on the surface of the material. Transmittance is the ratio of the luminous flux passing through the PET protective film to the incident luminous flux, mainly evaluating the ability of light to penetrate the PET protective film, expressed as T%=Tt/T0 %.b. Haze: It refers to the ratio of the scattered luminous flux (deviating from the incident light direction by 2.5°) to the total luminous flux passing through the PET protective film, mainly evaluating the scattering ability of the PET protective film, expressed as H%=Td/Tt %.

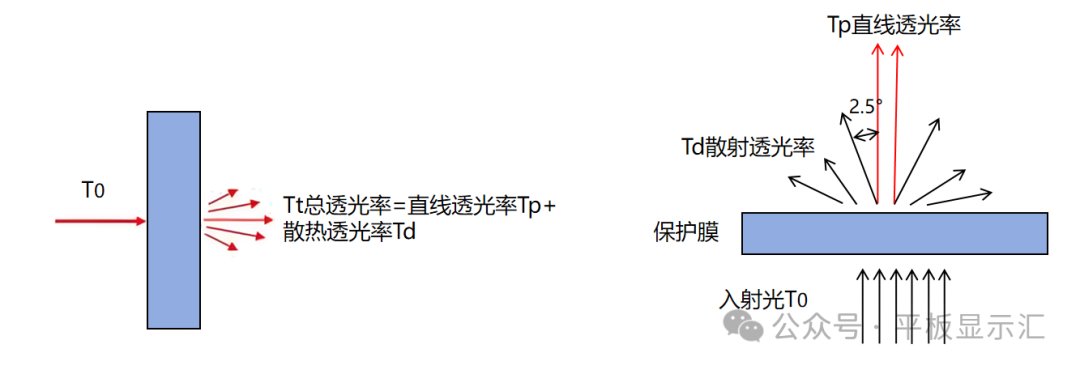

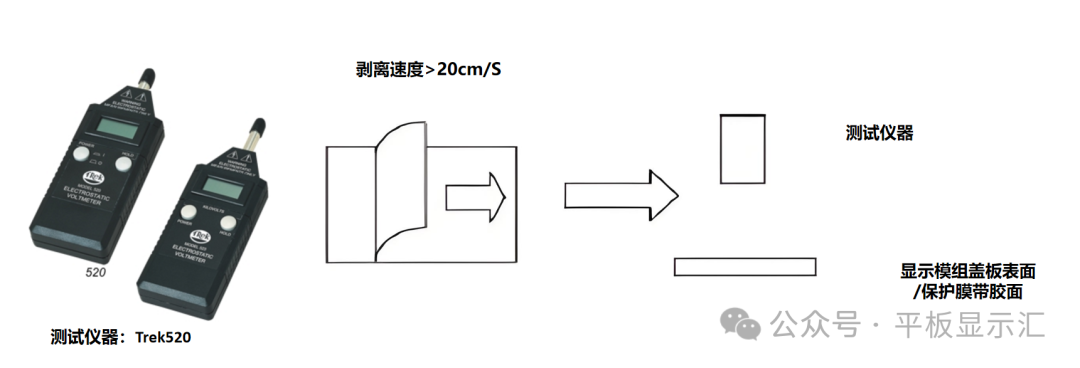

Illustration of key characteristics in a PET protective film specification sheet① Transmittance & HazeThe transmittance of PET protective films is generally required to be >88%, while some manufacturers may conservatively control it at >85%. The haze of PET protective films is generally within the range of <2%-5%, with specifics depending on the specifications provided by the protective film manufacturer.a. Transmittance:It refers to the amount of light that passes through the transparent PET protective film when light is vertically incident on it, where scattering occurs both inside and on the surface of the material. Transmittance is the ratio of the luminous flux passing through the PET protective film to the incident luminous flux, mainly evaluating the ability of light to penetrate the PET protective film, expressed as T%=Tt/T0 %.b. Haze: It refers to the ratio of the scattered luminous flux (deviating from the incident light direction by 2.5°) to the total luminous flux passing through the PET protective film, mainly evaluating the scattering ability of the PET protective film, expressed as H%=Td/Tt %. Illustration of the calculation method for transmittance and haze of PET protective films② Film Tearing VoltageThe film tearing voltage of the protective film is a very critical indicator for evaluating the static electricity release capability of the PET protective film, representing the risk of static electricity accumulation during the tearing process; the higher the film tearing voltage, the greater the risk of damage to devices during static electricity release.Generally speaking, the lower the film tearing voltage of the protective film, the stronger its static electricity release capability, and the lower the risk of tearing white spots or tearing patterns occurring on the display module after the protective film is attached to the surface of the fully bonded display module glass cover.Ordinary PET protective films are generally controlled at ≤±500V for film tearing voltage, while low film tearing voltage protective films can achieve ≤±300V.Of course, it is also important to note that “For the same PET protective film, the film tearing voltage will vary depending on the type of glass cover it is attached to and whether the glass cover surface has undergone AF film treatment.”This point is very critical and must be remembered; the specific mechanism will be explained in detail in subsequent articles.

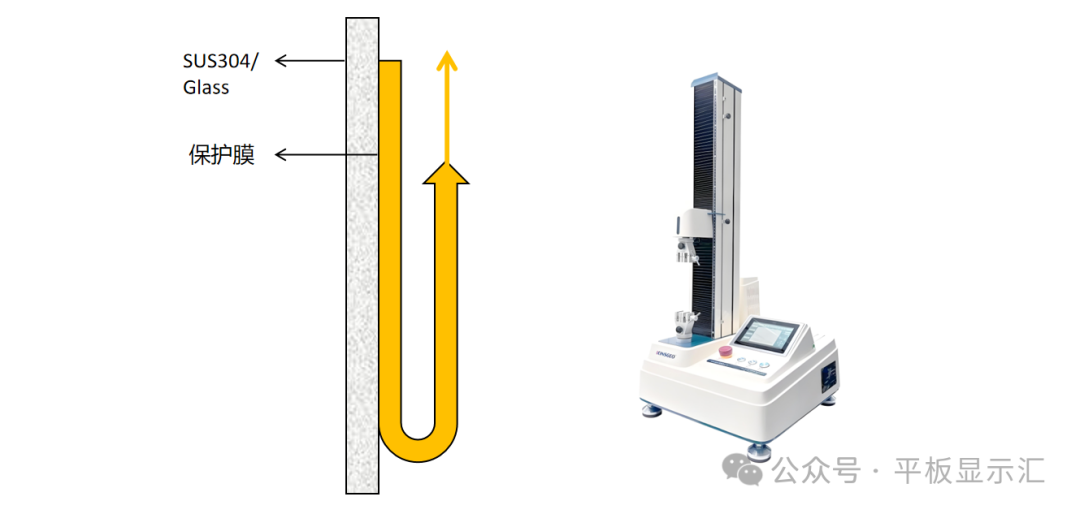

Illustration of the calculation method for transmittance and haze of PET protective films② Film Tearing VoltageThe film tearing voltage of the protective film is a very critical indicator for evaluating the static electricity release capability of the PET protective film, representing the risk of static electricity accumulation during the tearing process; the higher the film tearing voltage, the greater the risk of damage to devices during static electricity release.Generally speaking, the lower the film tearing voltage of the protective film, the stronger its static electricity release capability, and the lower the risk of tearing white spots or tearing patterns occurring on the display module after the protective film is attached to the surface of the fully bonded display module glass cover.Ordinary PET protective films are generally controlled at ≤±500V for film tearing voltage, while low film tearing voltage protective films can achieve ≤±300V.Of course, it is also important to note that “For the same PET protective film, the film tearing voltage will vary depending on the type of glass cover it is attached to and whether the glass cover surface has undergone AF film treatment.”This point is very critical and must be remembered; the specific mechanism will be explained in detail in subsequent articles. Illustration of the testing equipment and process for PET protective film tearing voltage③ Adhesive Surface ResistanceThe adhesive surface resistance of the protective film represents the ability of the adhesive layer to conduct static electricity. The higher the adhesive surface resistance, the better the insulation, making it difficult to eliminate static electricity, thus increasing the risk of ESD damage to devices; conversely, the lower the adhesive surface resistance, the easier it is to form a channel for static electricity release, thus reducing the risk of ESD damage to devices.Generally, the adhesive surface resistance of PET protective films is usually controlled within the range of <10^7~10^11, and different protective film manufacturers may have different specifications for adhesive surface resistance control, but within this range, there are generally no major issues.The adhesive surface resistance and film tearing voltage of protective films jointly affect static electricity accumulation and release. Antistatic agents are added to the protective films to lower the adhesive surface resistance, which also reduces the film tearing voltage of the protective films.④ AdhesionThe adhesion of the protective film is generally evaluated using the 180° peel strength method, which involves attaching the protective film to a standard substrate (such as SUS304 or glass substrate) and then using a universal testing machine to peel the protective film from the standard substrate at a 180° angle. The magnitude of the peel strength is the adhesion of the protective film.Generally, the adhesion of protective films attached to the surface of fully bonded display module glass covers is usually around 1-3g, although there may be some differences in the adhesion specified by different protective film manufacturers.

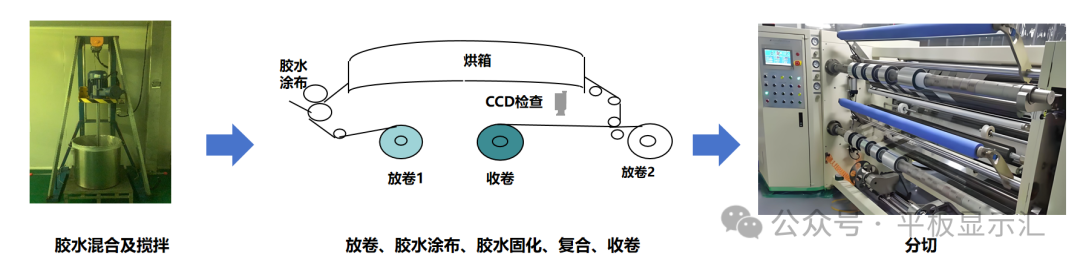

Illustration of the testing equipment and process for PET protective film tearing voltage③ Adhesive Surface ResistanceThe adhesive surface resistance of the protective film represents the ability of the adhesive layer to conduct static electricity. The higher the adhesive surface resistance, the better the insulation, making it difficult to eliminate static electricity, thus increasing the risk of ESD damage to devices; conversely, the lower the adhesive surface resistance, the easier it is to form a channel for static electricity release, thus reducing the risk of ESD damage to devices.Generally, the adhesive surface resistance of PET protective films is usually controlled within the range of <10^7~10^11, and different protective film manufacturers may have different specifications for adhesive surface resistance control, but within this range, there are generally no major issues.The adhesive surface resistance and film tearing voltage of protective films jointly affect static electricity accumulation and release. Antistatic agents are added to the protective films to lower the adhesive surface resistance, which also reduces the film tearing voltage of the protective films.④ AdhesionThe adhesion of the protective film is generally evaluated using the 180° peel strength method, which involves attaching the protective film to a standard substrate (such as SUS304 or glass substrate) and then using a universal testing machine to peel the protective film from the standard substrate at a 180° angle. The magnitude of the peel strength is the adhesion of the protective film.Generally, the adhesion of protective films attached to the surface of fully bonded display module glass covers is usually around 1-3g, although there may be some differences in the adhesion specified by different protective film manufacturers. Illustration of the adhesion testing of PET protective films03 Manufacturing Process of Protective FilmsThe manufacturing process of PET protective films is relatively simple and can be roughly divided into seven key manufacturing processes: adhesive mixing, unwinding of PET base film, adhesive coating, adhesive curing & aging, PET release film lamination, winding of PET protective film, and slitting.It is important to note that adhesive curing generally involves multiple stages of ovens, each with different temperatures; adhesive aging typically involves placing the adhesive in a 50°C aging room for about 48 hours, and some may use a method of resting at room temperature for a week.Of course, the above manufacturing processes for protective films are just general; there may be some differences between different protective film manufacturers.

Illustration of the adhesion testing of PET protective films03 Manufacturing Process of Protective FilmsThe manufacturing process of PET protective films is relatively simple and can be roughly divided into seven key manufacturing processes: adhesive mixing, unwinding of PET base film, adhesive coating, adhesive curing & aging, PET release film lamination, winding of PET protective film, and slitting.It is important to note that adhesive curing generally involves multiple stages of ovens, each with different temperatures; adhesive aging typically involves placing the adhesive in a 50°C aging room for about 48 hours, and some may use a method of resting at room temperature for a week.Of course, the above manufacturing processes for protective films are just general; there may be some differences between different protective film manufacturers. Illustration of the manufacturing process of PET protective filmsWelcome to join my knowledge circle for more comprehensive and professional content, enjoy more benefits, and communicate and progress together with me.Alright,that concludes today’s sharing.This is a content-rich public account, adhering to the principle of “speak without reservation, and say everything”, follow me,and I hope it helps you.Author Profile:I am Unfan, with over 10 years of experience in the display industry, having progressed from a technical novice to a technical director and product technology expert. I specialize in addressing various technical issues related to display products and hope to help everyone avoid the pitfalls I have encountered. Follow my public account, add me as a friend, and let me help you navigate the field of flat panel display technology more smoothly. Remember to set it as a star so you can see articles as soon as they are published.

Illustration of the manufacturing process of PET protective filmsWelcome to join my knowledge circle for more comprehensive and professional content, enjoy more benefits, and communicate and progress together with me.Alright,that concludes today’s sharing.This is a content-rich public account, adhering to the principle of “speak without reservation, and say everything”, follow me,and I hope it helps you.Author Profile:I am Unfan, with over 10 years of experience in the display industry, having progressed from a technical novice to a technical director and product technology expert. I specialize in addressing various technical issues related to display products and hope to help everyone avoid the pitfalls I have encountered. Follow my public account, add me as a friend, and let me help you navigate the field of flat panel display technology more smoothly. Remember to set it as a star so you can see articles as soon as they are published. Previous Article Recommendations:[Practical Guide] Discussing the Six Major Causes of Peeling Light Leakage Caused by BLU Adhesive and Improvement Countermeasures[Case Sharing] Mechanism of Color Shift in TFT-LCD Display Modules and Improvement Countermeasures[Practical Guide] Discussing What to Focus on in the DPA Slicing of Flexible Circuit Boards (FPCA)[Case Sharing] Detailed Explanation of the Mechanism of Bubbles (Black Spots) in TFT-LCD Displays and Improvement Countermeasures[Technical Insights] Understanding the Key Performance Parameters and Practical Significance of Polarizers (POL)[Practical Guide] Discussing What to Focus on in the DPA Slicing of Flexible Circuit Boards (FPCA)

Previous Article Recommendations:[Practical Guide] Discussing the Six Major Causes of Peeling Light Leakage Caused by BLU Adhesive and Improvement Countermeasures[Case Sharing] Mechanism of Color Shift in TFT-LCD Display Modules and Improvement Countermeasures[Practical Guide] Discussing What to Focus on in the DPA Slicing of Flexible Circuit Boards (FPCA)[Case Sharing] Detailed Explanation of the Mechanism of Bubbles (Black Spots) in TFT-LCD Displays and Improvement Countermeasures[Technical Insights] Understanding the Key Performance Parameters and Practical Significance of Polarizers (POL)[Practical Guide] Discussing What to Focus on in the DPA Slicing of Flexible Circuit Boards (FPCA)