First Public Disclosure of Water-Damaged Vehicle Circuit Board Disassembly: 85% of Hidden Hazards Can Be Fatal

Submerged for 10 minutes, hazards can linger for 3 years. This is the shocking data we obtained from the first disassembly of a water-damaged vehicle circuit board. While most people focus on the visible issues of water-damaged vehicles, the microscopic corrosion of circuits that is invisible to the naked eye is quietly becoming a “four-wheeled time bomb”.

Circuit Board: The “Unpredictable Bomb” of Water-Damaged Vehicles

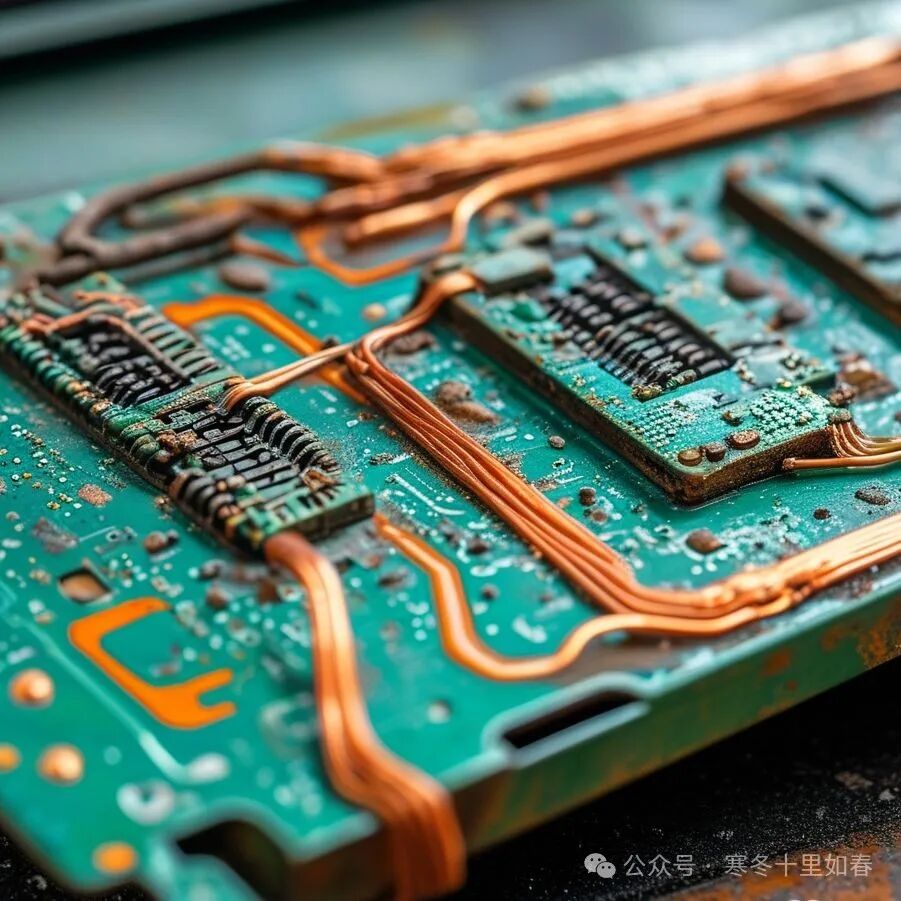

When a vehicle is submerged, the visible water stains may be dried, but the microscopic damage on the circuit board ispermanent. We disassembled the ECUs (Engine Control Units) of five vehicles with varying degrees of water damage and eight other critical electronic modules, discovering that 85% of the damage is completely undetectable by the naked eye.

Once moisture enters the circuit board, it forms anelectrolytic circuit between the microscopic metal wires. This is not a simple “water-in-dry-out-recover” process, but a slow “electronic corrosion war”. Ordinary lake water can cause gold-plated connectors to start leaching copper ions in just 20 minutes; impurities in seawater or floodwater can accelerate this process by 5-8 times.

“Just because you can’t see the danger doesn’t mean it doesn’t exist.” In onboard computers, there can be hundreds of microcircuits per square centimeter, with the narrowest lines measuring less than 0.1 millimeters. Once these lines are corroded, even a break as thin as a hair can cause the entire system to fail instantly under high temperature or vibration conditions.

Four years ago, I investigated a fire incident related to a water-damaged vehicle. The repaired vehicle appeared normal until the owner was driving at high speed, when a microcircuit in the BCM (Body Control Module) that had been corroded by water suddenly broke, causing a short circuit that led to a fire,with catastrophic consequences.

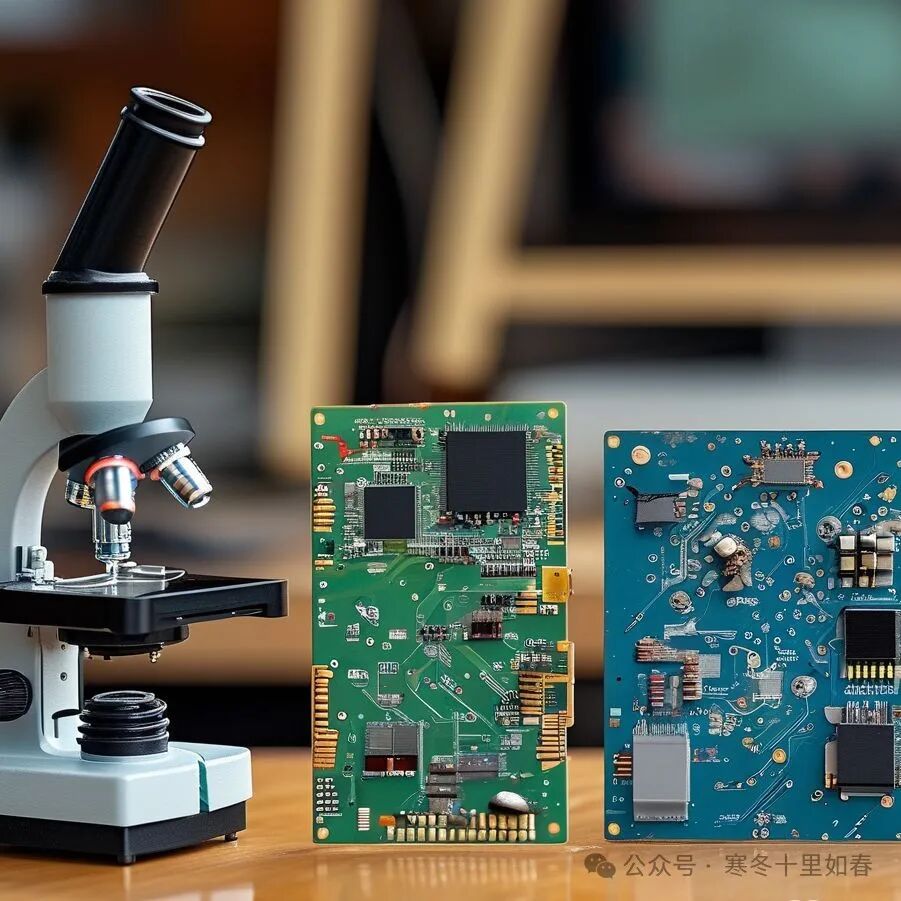

Stunning Comparison: Dissection Experiment of New and Old Circuit Boards

To visually demonstrate the hazards brought by water damage, we conducted a comparative experiment.

We took three identical Mercedes-Benz C-Class ABS control module circuit boards: one brand new, one lightly water-damaged (professionally dried after 30 minutes of immersion), and one heavily water-damaged (naturally air-dried after 24 hours of immersion). Externally, the lightly water-damaged circuit board looked almost identical to the new one and even functioned normally. However, under a microscope at 50x magnification, green oxidation was clearly visible at the edges of the copper wires, and there were signs of microscopic corrosion at the pins of the main control chip.

The most alarming finding was that we subjected the lightly water-damaged circuit board to thermal cycling tests—after 20 cycles in an environment ranging from -20°C to 85°C, those “almost invisible” micro-corrosion areas had significantly expanded, with some circuit resistance values increasing by 28 times! This means that even a “professionally repaired” water-damaged vehicle could suddenly fail under extreme weather conditions.

The airbag control module is even more dangerous—of the five water-damaged samples we tested, all exhibited trigger delays or complete failures after high humidity and high temperature testing. Imagine when you need airbag protection the most, it just “fails to operate”.

Those “Electronic Corrosions” You Will Never See

Don’t be deceived by appearances. The most terrifying aspect of water-damaged vehicles is not the visible mold and rust, but the damage to electronic components that ishidden inside sealed enclosures.

The disassembly of water-damaged vehicle circuit boards reveals four types of irreparable hidden damage:

- Microscopic Coating Loss: The coating on electronic component contacts is corroded, increasing contact resistance between pins and pads.

- Latent Short Circuit Risk: Ions from moisture remain in the gaps of the circuit board, potentially reactivating in high humidity environments.

- Insulation Layer Penetration: The insulation layers inside multilayer circuit boards are damaged by moisture, causing inter-layer short circuits.

- Increased Sensitivity to Static Electricity: Moisture-affected electronic components are 3-5 times more sensitive to static electricity than normal values.

What is most surprising is that even circuit boards that have only been “fogged” by steam can develop undetectable corrosion. Some vehicle owners believe that as long as the car has not been completely submerged, it is fine, not realizing that the high-temperature environment of the engine compartment can cause moisture to condense and seep into various electronic control modules.

How to Identify “Repaired” Water-Damaged Vehicle Circuits

The second-hand car market is rife with water-damaged vehicles, especially after annual floods. Modifications, cleaning, and replacements—unscrupulous dealers always find ways to cover up water damage. However, issues with the circuit system arethe hardest to completely repair.

Here are a few identification techniques that only experts know:

-

Check ECU Coding Date: Remove the ECU or other computer modules and check the production date code on the back. If it differs from the vehicle’s manufacturing date by more than six months, it is likely a replacement.

-

Observe Metal Terminals of Connectors: Shine a flashlight inside the computer connector. True water damage traces are often hidden here. Original factory terminals have a uniform coating luster, while those that have been water-damaged will show uneven dull areas.

-

Inspect the Fuse Box: The fuse box is an overlooked evidence repository for water damage. Slight green oxidation in the seams is nearly impossible to completely remove.

-

Microcomponent Symmetry Check: The micro-capacitor arrays on key computers such as the body control module and engine ECU should have consistent colors. If some components are darker in color, it is likely a result of oxidation from water immersion.

Veterans know that when buying a car, it is better to spend more time checking the electronic systems than to take a small risk and buy a vehicle with hidden dangers.

Conclusion: A Risk Not Worth Taking

A water-damaged vehicle, even if it appears problem-free on the surface, has hidden circuit hazards like buried landmines. Perhaps today, tomorrow, or even a year later, everything seems fine, but that microscopic corrosion continues to spread in the dark.

How many vehicle owners have told me, “My car just stalled suddenly, with no warning at all.” Perhaps this is the moment when the neglected water damage hazard finally “explodes”.

For consumers, the best advice is:It is better to miss out on a good car than to buy a water-damaged vehicle. If you suspect your vehicle has been water-damaged, be sure to have a professional technician conduct a thorough inspection, especially of those invisible circuit systems.

Safe driving starts with rejecting water-damaged vehicles. Because 85% of the hazards are invisible, but they can be fatal.