Raymo Technology is a high-tech enterprise focused on the deep application of metal 3D printing technology in mold manufacturing and application fields, providing global mold users with comprehensive 3D printing application solutions.

Raymo Technology is a high-tech enterprise focused on the deep application of metal 3D printing technology in mold manufacturing and application fields, providing global mold users with comprehensive 3D printing application solutions.

In the injection production of automotive exterior parts, ensuring consistent product quality is a focal point for manufacturers. Due to the complexity of the injection molding process and the varying properties of materials, some seemingly unsolvable quality issues often arise.As a professional provider of 3D printing solutions for molds, Raymo Technology has leveraged mold printing technology to help numerous clients overcomethe major challenges encountered in the production of automotive injection molded exterior parts, enhancingthe product quality and production efficiency of automotive injection parts.

Challenge 1: Local Defects Caused by Poor Venting

In the early stages of injection molding, when molten plastic rapidly fills the cavity, if the venting channel design is unreasonable, residual gas in the cavity cannot be expelled in time, leading to the formation of high-pressure zones in certain areas of the cavity, resulting indefects such asbloating, gas streaks, and burning marks. This issue is particularly pronounced in large and complex curved components such as front bumpers and side skirts.

*Image from the internet

*Image from the internet

Solution

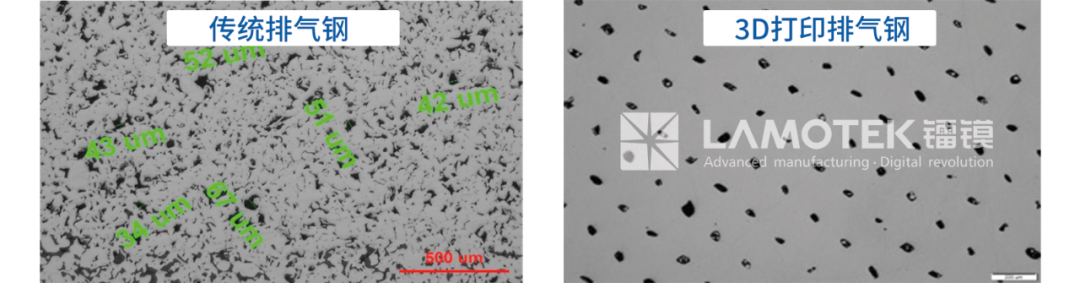

Using 3D printing technology, it is possible to create conformal venting channels, achieving precise directional design and rapid iterative optimization of the venting system:

(1) Free design of vent holes: Depending on the shape of different parts and the properties of different plastics, the distribution location and diameter of vent holes can be customized, ensuring no glue leakage while significantly improving venting efficiency.

(2) Rapid manufacturing of vent blocks: 3D printing technology allows for quick modifications to vent designs, enabling rapid design and delivery, helping clients quickly find the best solutions.

Challenge 2: Surface Defects Caused by Uneven Cooling

Challenge 2: Surface Defects Caused by Uneven Cooling

Injection molded products often require rapid and uniform cooling, and uneven local cooling can lead to the following issues:

– Surface roughness: When the local temperature distribution is uneven, the surface of the melt solidifies too quickly while the internal temperature remains high, resulting in uneven thermal stress.

– Sink marks and warping: Inconsistent plastic shrinkage in different areas often results in noticeable sink marks or warping in large or thin-walled components (such as headlight covers and emblems).

*Image from the internet

*Image from the internet

Solution

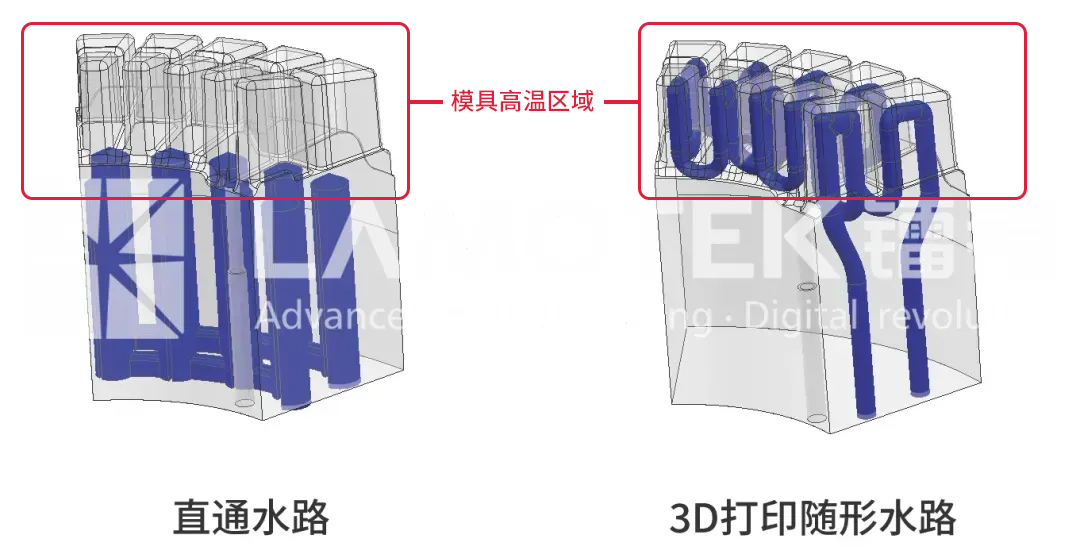

3D printing can easily create complex and flexible conformal cooling channels, achieving precise temperature control:

(1) Improved mold temperature control: By adjusting the distribution, shape, and size of the cooling channels, precise control of the cavity surface temperature can be achieved, effectively enhancing injection efficiency and production yield.

(2) Wide applicability: Any injection mold can enhance its performance through conformal cooling channels, particularly suitable for dimension-sensitive or high-shape-requirement components, such as headlight covers and interior trim panels.

Challenge 3: Fiber Float Phenomenon in Glass Fiber Reinforced Plastics

Challenge 3: Fiber Float Phenomenon in Glass Fiber Reinforced Plastics

Although glass fiber reinforced plastics have low shrinkage rates and high impact resistance, they exhibit poor flowability. When the mold temperature is too low, the melt quickly forms a hardened skin upon contact with the cavity surface, combined with insufficient venting, creates a gas flow layer, leading to deviations in the position of the glass fibers during the injection process, often manifested as:

– Fiber float phenomenon: In high flow rate areas (such as side skirts and radiator covers), glass fibers tend to concentrate in the middle, while in low flow rate areas, they remain on the product surface, creating a poking effect.

*Image from the internet

Solution

3D printed molds can effectively control the fiber float issue:

(1) Optimize temperature control design: Flexible adjustment of mold temperature can improve flowability by regulating the mold temperature, alleviating the issue of rapid hardening of the melt.

(2) Improve venting structure: Design a more reasonable venting system to ensure timely expulsion of gases from the cavity, reducing the formation of gas flow layers.

(3) Precise flow rate management: Utilizing digital simulation and precision manufacturing to achieve accurate control of melt flow rates, ensuring uniform distribution of glass fibers.

The limitations in the design and manufacturing methods of molds are often the root causes of production issues such as insufficient venting, uneven cooling, and fiber float phenomena in the injection molding process of automotive exterior parts. The 3D printing technology for molds provides new solutions to these challenges through free design, rapid iteration, and flexible manufacturing advantages. Relying on digital design and manufacturing methods significantly enhances injection quality, shortens production cycles, and achieves efficient and intelligent production.

*This article was originally published by Raymo Technology on the WeChat public platform, and is strictly prohibited from being copied! Unauthorized reproduction is not allowed. The company reserves the right to pursue legal responsibility for violations.(For reprints, please contact the staff through the backend) Looking forward to discussing more possibilities of 3D printing with everyone!

Looking forward to discussing more possibilities of 3D printing with everyone!