A+PLUS Overview

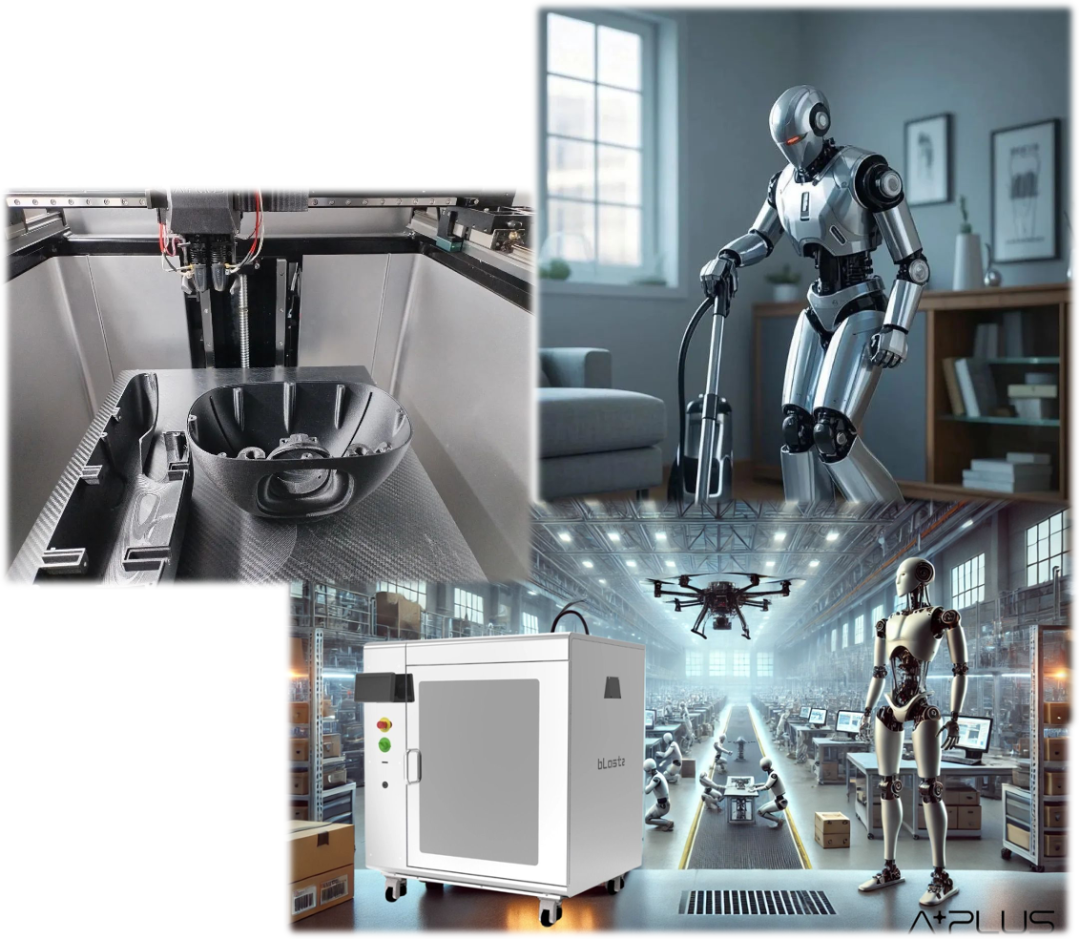

Based on the Aplus Blast2 FFF2.0 agile manufacturing platform, it ensures an end-to-end customized batch manufacturing model. Blast2, along with BlastMate high-throughput filament and BlastAcc (slicing software preset with optimal process parameters), forms the FFF2.0 intelligent manufacturing platform, focusing on continuous series production.

The A+ team possesses extensive knowledge and experience in precision equipment design, hardware, software, materials, and various vertical market applications. Based on semiconductor equipment precision motion control and direct drive technology, years of end-user experience enable the FFF2.0 system to embody both speed and precision.

In modern industrial manufacturing, EHS (Environmental, Health, and Safety) is a key factor for enterprises to achieve sustainable development and efficient production.The FFF2.0 technology represented by A+PLUS, with its advanced processes and intelligent features, can be smoothly integrated into industrial continuous manufacturing processes while complying with EHS standards, enhancing production efficiency and safety from multiple aspects.1. Environmental: Reducing Waste and Improving Material Utilization

- Efficient Material Management:A+PLUS’s BlastMate PPS-CF and other high-performance composite materials achieve precise extrusion and low loss under FFF2.0 technology, ensuring a high printing success rate, saving materials, and reducing waste generation.

- Intelligent Temperature Control and Energy Efficiency Optimization:Efficient heating methods with precise temperature control combined with linear motor direct drive reduce energy waste while lowering overall carbon emissions.

- Sustainable Production:FFF2.0 is compatible with recyclable engineering plastics, such as high-performance polymers (PPS-CF, PAHT-CF), aiding the manufacturing industry in moving towards environmentally friendly practices.

2. Health: Reducing Hazards and Improving Operational Safety

2. Health: Reducing Hazards and Improving Operational Safety

- Low Volatile Emission:A+PLUS employs optimized heating and melting control, combined with a closed printing environment and filtration system, significantly reducing VOC (volatile organic compounds) and ultrafine particulate emissions, making it more compliant with occupational health standards compared to traditional FDM.

- Intelligent Operation, Reducing Manual Intervention:

- Automatic Leveling & Material Detection:Reduces manual intervention, avoiding equipment damage or safety accidents caused by operational errors.

- Remote Monitoring and Management:Based on Blast-Scada remote control printing, it reduces the risk of operators being exposed to high temperatures and high-speed moving parts.

- Compliance with Industrial Safety Standards:All hardware designs comply with CE and ISO safety standards, ensuring health in factory and laboratory environments.

3. Safety: High Reliability Supporting Industrial Continuous Production

3. Safety: High Reliability Supporting Industrial Continuous Production

- Linear Motor + High-Precision Motion Control System:

- Compared to traditional belt drives, linear motors reduce mechanical friction, improve printing stability, and achieve long-term continuous high-precision manufacturing.

- Precision up to ±0.01mm ensures part consistency, making FFF2.0 suitable for industrial-grade continuous production.

- Intelligent Detection & Self-Diagnosis of Equipment:

- Material shortage detection prevents material waste and workpiece scrapping.

- Machine status self-checks prevent production stoppages or safety accidents due to equipment failures.

- Regular warning replacement mechanism for consumable and worn parts.

- Modular Design, Easy Maintenance:

- Core components of the equipment (nozzle, heating module, cooling system) support quick replacement, reducing downtime and improving equipment availability.

- Compared to traditional industrial equipment, A+PLUS’s FFF2.0 solution is more flexible and suitable for various manufacturing scenarios.

A+PLUS’s FFF2.0 FDM technology has quickly become part of industrial continuous manufacturing due to its higher precision, more stable production capabilities, and compliance with EHS (Environmental, Health, and Safety) characteristics. In 2024, it will bring disruptive application cases in three areas: drones (UAVs), embodied intelligence (Embodied AI), and industrial jigs & fixtures.1. Drones (UAVs) — Lightweight, High-Temperature Resistant, Rapid CustomizationDrones have a high demand for lightweight, high-strength materials, and strict requirements for high-temperature resistance, impact resistance, and aerodynamic optimization design. Traditional manufacturing methods (such as CNC and mold manufacturing) are costly and time-consuming, making it difficult to meet the iterative and customized needs of drone development, thus requiring reduced manual assembly and increased production automation.WHY A+PLUS FFF2.0?

A+PLUS’s FFF2.0 FDM technology has quickly become part of industrial continuous manufacturing due to its higher precision, more stable production capabilities, and compliance with EHS (Environmental, Health, and Safety) characteristics. In 2024, it will bring disruptive application cases in three areas: drones (UAVs), embodied intelligence (Embodied AI), and industrial jigs & fixtures.1. Drones (UAVs) — Lightweight, High-Temperature Resistant, Rapid CustomizationDrones have a high demand for lightweight, high-strength materials, and strict requirements for high-temperature resistance, impact resistance, and aerodynamic optimization design. Traditional manufacturing methods (such as CNC and mold manufacturing) are costly and time-consuming, making it difficult to meet the iterative and customized needs of drone development, thus requiring reduced manual assembly and increased production automation.WHY A+PLUS FFF2.0? ✅ High-Performance Materials Empowering Drone Component Manufacturing• A+PLUS’s BlastMate PPS-CF (carbon fiber reinforced polyphenylene sulfide) material is lighter than traditional plastics while possessing high strength and high heat resistance (>260°C), chemical resistance, suitable for critical drone components such as frames, shells, arms, and propeller guards.• Carbon fiber reinforced materials improve structural strength by 30%-50% compared to traditional FDM, meeting the long-term operational needs of aircraft.✅ Topology Optimization + 3D Printing Achieving Lightweight Structures• Combined with AI topology optimization design, FFF2.0 can manufacture honeycomb structures or biomimetic designs, reducing weight by over 30% compared to CNC structural parts, enhancing endurance and load capacity.• FFF2.0 can achieve integrated manufacturing (monolithic structure), reducing screws and adhesives required for traditional assembly, improving overall reliability.✅ Rapid Prototyping and Batch Manufacturing Coexist• FFF2.0 allows UAV manufacturers to complete new part printing within hours, shortening the development cycle by 80% compared to CNC, enabling rapid iteration and validation.• Suitable for small batch custom production, eliminating mold costs, and can be directly used for batch manufacturing of drone components or repair replacement parts.

✅ High-Performance Materials Empowering Drone Component Manufacturing• A+PLUS’s BlastMate PPS-CF (carbon fiber reinforced polyphenylene sulfide) material is lighter than traditional plastics while possessing high strength and high heat resistance (>260°C), chemical resistance, suitable for critical drone components such as frames, shells, arms, and propeller guards.• Carbon fiber reinforced materials improve structural strength by 30%-50% compared to traditional FDM, meeting the long-term operational needs of aircraft.✅ Topology Optimization + 3D Printing Achieving Lightweight Structures• Combined with AI topology optimization design, FFF2.0 can manufacture honeycomb structures or biomimetic designs, reducing weight by over 30% compared to CNC structural parts, enhancing endurance and load capacity.• FFF2.0 can achieve integrated manufacturing (monolithic structure), reducing screws and adhesives required for traditional assembly, improving overall reliability.✅ Rapid Prototyping and Batch Manufacturing Coexist• FFF2.0 allows UAV manufacturers to complete new part printing within hours, shortening the development cycle by 80% compared to CNC, enabling rapid iteration and validation.• Suitable for small batch custom production, eliminating mold costs, and can be directly used for batch manufacturing of drone components or repair replacement parts. 2. Embodied Intelligence (Embodied AI) — Structural Optimization, Rapid Customization, Durable MaterialsEmbodied intelligent robots require highly biomimetic motion structures and materials that are impact-resistant, fatigue-resistant, shock-absorbing, and capable of high-precision repeatable manufacturing. Traditional robot manufacturing methods are limited by high-cost CNC processing and mold manufacturing, making it difficult to adapt to small batch customization needs, thus requiring lightweight components while maintaining high strength to support long-term operation.WHY A+PLUS FFF2.0?

2. Embodied Intelligence (Embodied AI) — Structural Optimization, Rapid Customization, Durable MaterialsEmbodied intelligent robots require highly biomimetic motion structures and materials that are impact-resistant, fatigue-resistant, shock-absorbing, and capable of high-precision repeatable manufacturing. Traditional robot manufacturing methods are limited by high-cost CNC processing and mold manufacturing, making it difficult to adapt to small batch customization needs, thus requiring lightweight components while maintaining high strength to support long-term operation.WHY A+PLUS FFF2.0? ✅ Custom Manufacturing of Robot Shells & Structural Parts• Using BlastMate PAHT-CF to print high-strength parts, such as robot limb joints, shells, and skeletal support structures, achieving lightweight design while enhancing structural rigidity and impact resistance.• Topology optimization generates structures more aligned with robotic kinematics, improving motion flexibility and energy efficiency.✅ Composite Material Printing Enhances Durability• Robot components may endure repeated loads during long-term operation; FFF2.0 printed short-fiber reinforced composites can provide metal-like mechanical properties while reducing weight by over 50%.• Suitable for manufacturing connecting parts, sensor brackets, surface coverings, and other critical structures.✅ Low-Cost, Flexible Manufacturing & Small Batch Customization• During robot development, FFF2.0 can achieve rapid prototyping, avoiding the long cycle production issues of CNC.• Custom structural parts of different sizes and functions can be tailored for various application scenarios (such as medical robots, warehouse robots, service robots), flexibly responding to market demands.

✅ Custom Manufacturing of Robot Shells & Structural Parts• Using BlastMate PAHT-CF to print high-strength parts, such as robot limb joints, shells, and skeletal support structures, achieving lightweight design while enhancing structural rigidity and impact resistance.• Topology optimization generates structures more aligned with robotic kinematics, improving motion flexibility and energy efficiency.✅ Composite Material Printing Enhances Durability• Robot components may endure repeated loads during long-term operation; FFF2.0 printed short-fiber reinforced composites can provide metal-like mechanical properties while reducing weight by over 50%.• Suitable for manufacturing connecting parts, sensor brackets, surface coverings, and other critical structures.✅ Low-Cost, Flexible Manufacturing & Small Batch Customization• During robot development, FFF2.0 can achieve rapid prototyping, avoiding the long cycle production issues of CNC.• Custom structural parts of different sizes and functions can be tailored for various application scenarios (such as medical robots, warehouse robots, service robots), flexibly responding to market demands. 3. Industrial Jigs & Fixtures — High Precision, Automation Integration, High Load ResistanceTraditional jigs (such as CNC machined or cast jigs) have high manufacturing costs, long delivery cycles, and inconvenient adjustments, making it difficult to adapt to changes in production processes. Jigs need to withstand high intensity and high-temperature environments while maintaining long-term precision stability. Therefore, production lines hope to reduce manual intervention and improve automation levels through intelligent jigs.WHY A+PLUS FFF2.0?

3. Industrial Jigs & Fixtures — High Precision, Automation Integration, High Load ResistanceTraditional jigs (such as CNC machined or cast jigs) have high manufacturing costs, long delivery cycles, and inconvenient adjustments, making it difficult to adapt to changes in production processes. Jigs need to withstand high intensity and high-temperature environments while maintaining long-term precision stability. Therefore, production lines hope to reduce manual intervention and improve automation levels through intelligent jigs.WHY A+PLUS FFF2.0? ✅ Rapid Manufacturing of High-Strength Jigs & Low-Cost Iteration• Through BlastMate PPS-CF, PAHT-CF, PET-CF 3D printing, lightweight yet high-strength jigs can be manufactured to withstand mechanical stress and chemical corrosion in industrial production environments.• Using 3D printing to manufacture jigs shortens the production cycle by 60%-80%, reducing costs by over 50% compared to traditional CNC processing.• Suitable for high-precision clamping and positioning tools in industries such as automotive, aerospace, and electronics manufacturing.✅ Intelligent Jigs and Automation Integration• Combined with the Blast-Scada remote intelligent monitoring system, intelligent jigs can be manufactured to automatically adjust clamping force and sense workpiece position, improving production line automation levels.• Multi-material printing (combining rigid and flexible materials) can produce jigs with shock-absorbing functions, suitable for precision assembly.✅ Adaptation to Complex Geometries and Customized Production• Traditional jigs struggle to adapt to irregular workpieces or non-standard products; FFF2.0 can directly print customized jigs that adapt to different workpieces based on 3D scanning data, avoiding repetitive design and high manufacturing costs.A+PLUS’s FFF2.0 FDM 3D printing technology brings a new manufacturing model to drones, embodied intelligent robots, and industrial jigs and fixtures through high-performance materials, intelligent manufacturing, and low-cost rapid iteration.

✅ Rapid Manufacturing of High-Strength Jigs & Low-Cost Iteration• Through BlastMate PPS-CF, PAHT-CF, PET-CF 3D printing, lightweight yet high-strength jigs can be manufactured to withstand mechanical stress and chemical corrosion in industrial production environments.• Using 3D printing to manufacture jigs shortens the production cycle by 60%-80%, reducing costs by over 50% compared to traditional CNC processing.• Suitable for high-precision clamping and positioning tools in industries such as automotive, aerospace, and electronics manufacturing.✅ Intelligent Jigs and Automation Integration• Combined with the Blast-Scada remote intelligent monitoring system, intelligent jigs can be manufactured to automatically adjust clamping force and sense workpiece position, improving production line automation levels.• Multi-material printing (combining rigid and flexible materials) can produce jigs with shock-absorbing functions, suitable for precision assembly.✅ Adaptation to Complex Geometries and Customized Production• Traditional jigs struggle to adapt to irregular workpieces or non-standard products; FFF2.0 can directly print customized jigs that adapt to different workpieces based on 3D scanning data, avoiding repetitive design and high manufacturing costs.A+PLUS’s FFF2.0 FDM 3D printing technology brings a new manufacturing model to drones, embodied intelligent robots, and industrial jigs and fixtures through high-performance materials, intelligent manufacturing, and low-cost rapid iteration. In the field of drones, FFF2.0 provides lightweight, high-strength components to enhance flight performance.In the field of embodied intelligence, FFF2.0 allows for the manufacturing of complex structures, enabling customized production of robots.In the field of industrial jigs, FFF2.0 reduces manufacturing costs and improves automation production efficiency.FFF2.0 is becoming an important part of industrial continuous manufacturing, making intelligent manufacturing more flexible and efficient, and promoting the rapid development of the next generation of drones, robots, and smart factories.At the same time, it also complies with EHS standards and can be smoothly integrated into industrial continuous manufacturing processes:Through low energy consumption, low emissions, and high material utilization, it meets environmental (E) requirements.Using a closed structure, remote operation, and low volatile materials enhances health (H) protection.Relying on high-precision linear motors, automated control, and self-check systems enhances safety (S) assurance.This not only enhances the feasibility of 3D printing in unmanned production lines, precision manufacturing, aerospace, automotive parts, and other industrial fields but also marks that FFF2.0 is becoming one of the core technologies of industrial-grade continuous manufacturing.

In the field of drones, FFF2.0 provides lightweight, high-strength components to enhance flight performance.In the field of embodied intelligence, FFF2.0 allows for the manufacturing of complex structures, enabling customized production of robots.In the field of industrial jigs, FFF2.0 reduces manufacturing costs and improves automation production efficiency.FFF2.0 is becoming an important part of industrial continuous manufacturing, making intelligent manufacturing more flexible and efficient, and promoting the rapid development of the next generation of drones, robots, and smart factories.At the same time, it also complies with EHS standards and can be smoothly integrated into industrial continuous manufacturing processes:Through low energy consumption, low emissions, and high material utilization, it meets environmental (E) requirements.Using a closed structure, remote operation, and low volatile materials enhances health (H) protection.Relying on high-precision linear motors, automated control, and self-check systems enhances safety (S) assurance.This not only enhances the feasibility of 3D printing in unmanned production lines, precision manufacturing, aerospace, automotive parts, and other industrial fields but also marks that FFF2.0 is becoming one of the core technologies of industrial-grade continuous manufacturing.

Disclaimer: Some content in this public account comes from cooperative media, enterprises, netizens, and publicly available information on the internet, for reference only. This public account maintains neutrality regarding all information, opinions, and does not provide any express or implied guarantees regarding the accuracy, reliability, or completeness of the content. If there are any infringement issues, please contact us in a timely manner, and we will handle the relevant content promptly upon receiving notification.

Previous Highlights:

1. The National Development and Reform Commission publicly shares carbon peak construction experiences; what can we expect from the new batch of 62 pilot projects?

2.EcoVadis 2025 Methodology Update: Practical Requirements Aligning with EU Regulatory Trends

3.Exploring Zero Carbon Parks! Including reward policies and evaluation standards for zero carbon parks in 17 provinces

4.How to Build a World-Class Sustainable Brand through Narrative?

5. It is already 2025; which industries will peak carbon emissions first?