Choosing between Programmable Logic Controllers (PLC) and Distributed Control Systems (DCS) requires a specific analysis of the situation, as the application scenarios differ and the requirements for control systems vary. When communicating with customers, we can approach the discussion from the following aspects!

1. From switch control to sequential control and transport processing, it evolves into multifunctional control such as continuous PID control from the bottom up, with PID in the interrupt station.

2. A single PC can serve as the master station, with multiple identical PLCs as slave stations.

3. A single PLC can also serve as the master, with multiple identical PLCs as slave stations, forming a PLC network. This is more convenient than using a PC as the master, as users do not need to know the communication protocol; they just need to follow the manual format.

4. The PLC grid can function as an independent DCS or as a subsystem of DCS.

5. PLCs are mainly used for sequential control in industrial processes, and new PLCs also have closed-loop control capabilities.

1. The Distributed Control System (DCS) integrates the 4C (Communication, Computer, Control, CRT) technology into a monitoring system.

2. It features a tree topology system from top to bottom, where communication is key.

3. PID is in the interrupt station, connecting computers with field instruments and control devices in a tree topology and parallel continuous link structure, with many cables running from the interrupt station to field instruments.

4. Analog signals, A/D—D/A, with microprocessor mixing. 5. Each instrument connects to I/O with a pair of wires, linked from the control station to the local area network (LAN). 6. DCS has a three-level structure of control (engineer station), operation (operator station), and field instruments (field measurement and control station). It is used for large-scale continuous process control, such as in petrochemicals.

Choosing between Programmable Logic Controllers (PLC) and Distributed Control Systems (DCS) requires a specific analysis of the situation, as the application scenarios differ and the requirements for control systems vary.

The platform of the control system will significantly influence how the automation system meets demands for optimized production, maintaining availability, and acquiring data. A lack of foresight in choosing a control system may also impact future scalability, process optimization, user satisfaction, and company profits.

Besides some basic principles (like how to control processes), the design team must also consider various factors such as installation, scalability, maintenance, and upkeep.

Currently, while PLC systems may be the most cost-effective for small devices, DCS systems offer more economical scalability and are more likely to yield a higher return on initial investment.

PLC is an industrial computer used to control production processes such as robotics, high-speed packaging, bottling, and motion control. Over the past 20 years, PLCs have added more functions, creating more benefits for small factories and installations. PLCs typically operate as standalone systems but can also integrate with other systems via communication. Each PLC has its own database, so integration requires some degree of mapping between controllers. This makes PLCs particularly suitable for small applications that do not have significant scalability demands.

DCS systems, on the other hand, distribute controllers throughout the automation system and provide universal interfaces, advanced control, system-level databases, and easily sharable information. Traditionally, DCS is mainly applied in process industries and larger factories, making large system applications easier to maintain throughout the lifecycle of the entire plant.

PLC is developed from relay control principles, storing instructions for executing logic operations, sequential control, timing, counting, and calculations; it controls various machinery or production processes through digital input and output operations. The control programs compiled by users express the process requirements of production and are pre-stored in the PLC’s user program memory. During operation, the program executes step by step according to the stored program to fulfill the requirements of the process flow.

The CPU of PLC has a program counter that indicates the stored address of the program steps. During program execution, the counter automatically increments by 1 after each step, executing from the starting step (step number zero) to the final step (usually the end instruction) and then returning to the starting step for cyclic operation.

The time required for PLC to complete one cycle of operation is called a scan cycle. Different models of PLCs have cycle scan times ranging from 1 microsecond to several tens of microseconds. The program counter’s cyclic operation is something that DCS does not have, which is also why PLC redundancy is not as robust as DCS.

DCS is developed based on operational amplifiers. It successfully creates functional blocks for all functions and relationships between process variables (some DCS systems refer to them as bloated blocks). The main differences in performance between DCS and PLC lie in the logic resolution of switch quantities and the calculations of analog quantities. Even though there has been some overlap between the two later on, distinctions still exist.

After the 1980s, PLCs enhanced algorithm capabilities for control loops significantly beyond just logic operations, but programming analog quantities in PLCs using ladder diagrams is not very intuitive and can be cumbersome. However, PLCs demonstrate advantages in logic resolution, operating at microsecond levels, resolving 1k logic programs in less than 1 millisecond. They treat all inputs as switch quantities, with 16 bits (and sometimes 32 bits) representing one analog quantity.

DCS treats all inputs as analog quantities, with 1 bit representing a switch quantity. The logic resolution time is in the hundreds of microseconds to milliseconds range. For PLC, resolving a PID operation takes several milliseconds, which is comparable to DCS’s operation time.

In terms of grounding resistance, requirements for PLC may not be very strict, but for DCS, it must be below several ohms (usually below 4 ohms). Analog signal isolation is also very important.

For systems with the same I/O point count, using PLC is generally cheaper than using DCS (approximately 40% savings). PLCs do not have dedicated operating stations, and both their software and hardware are generic, leading to significantly lower maintenance costs compared to DCS. If the controlled objects mainly involve equipment interlocking with relatively few loops, using PLC is more appropriate.

If the primary requirement is for analog quantity control with many functional calculations, DCS is the better choice. DCS outperforms PLC in aspects such as redundancy of controllers, I/O boards, communication networks, and in meeting some advanced computations and industry-specific requirements. Due to using generic monitoring software, PLC is easier to integrate into the management information systems of enterprises.

PLC and DCS systems are typically applied to discrete and process manufacturing, respectively. Discrete manufacturing facilities using PLC systems generally consist of separate production devices, primarily used for assembling components such as labeling, filling, or grinding. Process manufacturing facilities typically use automation systems to produce continuously and in batches according to recipes rather than by pieces. Large continuous processing equipment, such as refineries and chemical plants, employ DCS automation systems. Mixed applications often use both PLC and DCS systems simultaneously. Selecting a controller for a specific application requires consideration of factors such as the scale of the process, scalability, future upgrade plans, integration needs, functionality, high availability, and the return on investment over the entire lifecycle of the plant facilities.

Process Scale: How many input/output (I/O) points are needed? Small systems (less than 300 I/O points) may have a lower budget, making PLC systems more suitable. Applying DCS systems to smaller projects is generally not easy; conversely, they perform better in large plants. With a global database, DCS systems are easier to manage and upgrade, as any changes are global.

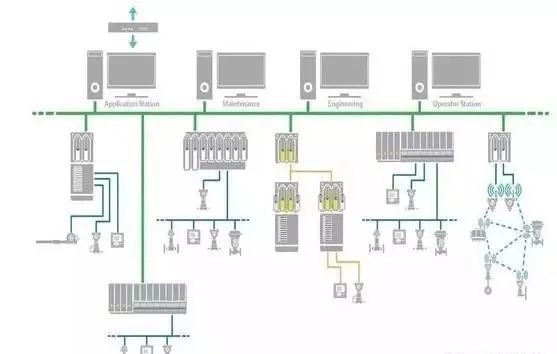

Upgrade Plans: Smaller industrial processes can use PLC systems, but if the process needs to expand or upgrade, more PLC hardware and databases will need to be added, requiring separate maintenance. This is a time-consuming and labor-intensive process that can easily lead to errors. DCS systems are easier to upgrade; for example, user access can be managed from a central hub, making maintenance and upkeep simpler (see Figure 1).

Integration Needs: For standalone devices, PLC systems are ideal. When a factory is configured with multiple PLC systems, interconnection requirements arise. This is generally difficult to achieve as it often requires using communication protocols for data mapping. Integration is certainly possible, but when changes are needed, users face difficulties: if one PLC system undergoes changes, it may disrupt communication between two PLCs due to affected data mapping. For DCS systems, mapping is not needed at all; configuration changes are a simple process, as controllers are built into the system.

High Availability: For processes requiring high availability, DCS systems can provide redundancy configurations (see Figure 2).

Efficiency and the ease of implementing redundancy are critical for keeping costs within budget.

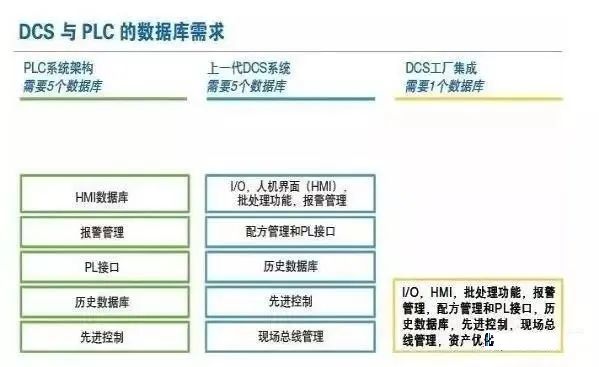

Functional Requirements: Certain industries and facilities require historical databases, streamlined alarm management, and centralized control rooms with universal user interfaces. Others may need integration with Manufacturing Execution Systems (MES), advanced control, and asset management. DCS systems have these applications built-in (see Figure 3), making it easy to add them to automation engineering applications without the need for additional servers or increased integration costs. From this perspective, DCS systems are more economical and can enhance productivity while reducing risks.

Lifecycle Return on Investment: Facility demands vary by industry. For smaller process engineering projects with no expansion needs and no requirement to integrate with other process areas, PLC systems offer better return on investment. DCS systems may have higher installation costs, but in terms of the entire lifecycle, the increased output and safety benefits provided by DCS systems can offset some of those costs. Balancing short-term needs with long-term vision is crucial for operational certainty and improving plant operations and maintenance.

Disclaimer: This article is sourced from the internet, and the copyright belongs to the original author. If there are copyright issues, please contact us for deletion. Thank you!

Complete Question Bank for 2022 Electrician Beginner Exam (with Answers)

Three Essential Tools for Electricians, Easily Accessible via WeChat!

[Collection] Secrets for a Decade-Long Electrician’s Career, Earning Over 10,000 Monthly!

Which of the Five Major Electrical Drafting Software (CAD, Eplan, CADe_simu…) Do You Prefer?

Latest Electrical Version CAD Drawing Software, with Detailed Installation Guide!

Latest Electrical Drawing Software EPLAN, with Detailed Installation Guide!

Common Issues for Beginners Using S7-200 SMART Programming Software (with Download Links)

Comprehensive Electrical Calculation EXCEL Sheets, Automatically Generated! No More Need for Help with Electrical Calculations!

Bluetooth Headphones, Books for Electricians/PLC Beginners Available? Come Claim Your Electrical Gifts!

Basic Skills in PLC Programming: Ladder Diagrams and Control Circuits (with 1164 Practical Cases for Mitsubishi PLC)

Still Can’t Understand Electrical Diagrams? Take the Basics of Electrical Diagram Reading and Simulation Software to Quickly Get Started!

12 Free Electrician Video Courses, 10GB Software/E-books, and 30 Days of Free Electrician Live Courses Available!