In today’s rapidly developing digital age, the security of Industrial Control Systems (ICS) has become an important issue that enterprises cannot ignore. With technological advancements and increasingly cunning cyberattack methods, ensuring the secure operation of ICS is more urgent than ever. Therefore, implementing effective countermeasures is not only a necessary measure to protect corporate assets but also key to ensuring the stable operation of the entire industry. The following outlines five aspects of the strategies that should be adopted for ICS security.

Improve Industrial Control System Cybersecurity Regulations and Standards

We should formulate and improve relevant regulations and systems based on actual needs. At the same time, refer to the following standard documents: “IEC 62443 Industrial Communication Network Security”, “NIST SP800-82 Industrial Control System Security Guidelines”, “GB/T 26333-2010 Industrial Control Network Security Risk Assessment Standards”, “GB/T30976.1-2014 Industrial Control System Information Security Part 1: Assessment Specifications”, “GB/T30976.2-2014 Industrial Control System Information Security Part 2: Acceptance Specifications”, “Industrial Control System Cybersecurity Protection Guidelines” [2024] No. 14, “Implementation Plan for Enhancing Data Security Capabilities in the Industrial Sector (2024-2026)”, and “GB/T22239-2008 Information Security Technology Basic Requirements for Information System Security Level Protection”, etc. By drawing on these standards, we will further improve the industrial control system security standards applicable to various industry sectors, providing strong guarantees for ICS cybersecurity.

Establish a Corporate Industrial Control System Security Responsibility System

We should continuously improve the responsibility system for corporate information security. To this end, companies should establish leadership organizations and dedicated departments for information security, and equip them with dedicated technical personnel for ICS security. Regular network security training and emergency drills should be conducted for the corporate industrial internet. These personnel will be responsible for coordinating the security of industrial control systems and information systems, while also establishing corresponding network security management systems and emergency plans for security incidents. Additionally, sufficient funding for information security should be ensured to systematically carry out security management and technical protection work.

Comprehensively Promote Multi-Dimensional Security Protection for Industrial Control Systems

To ensure the security of industrial control systems, we must consider multiple aspects such as production safety, functional safety, and information security. Through coordinated planning, we can enhance the security performance of the system. Specifically, this involves improving the information security awareness of designers, construction personnel, users, operation and maintenance personnel, and management personnel. Furthermore, we need to pay attention to the issue that traditional protective measures (such as antivirus software) may not be suitable for industrial control systems, to prevent system paralysis or downtime accidents due to ineffective protective measures. Additionally, strengthening the security reliability of systems to prevent important information from being stolen or leaked is also crucial.

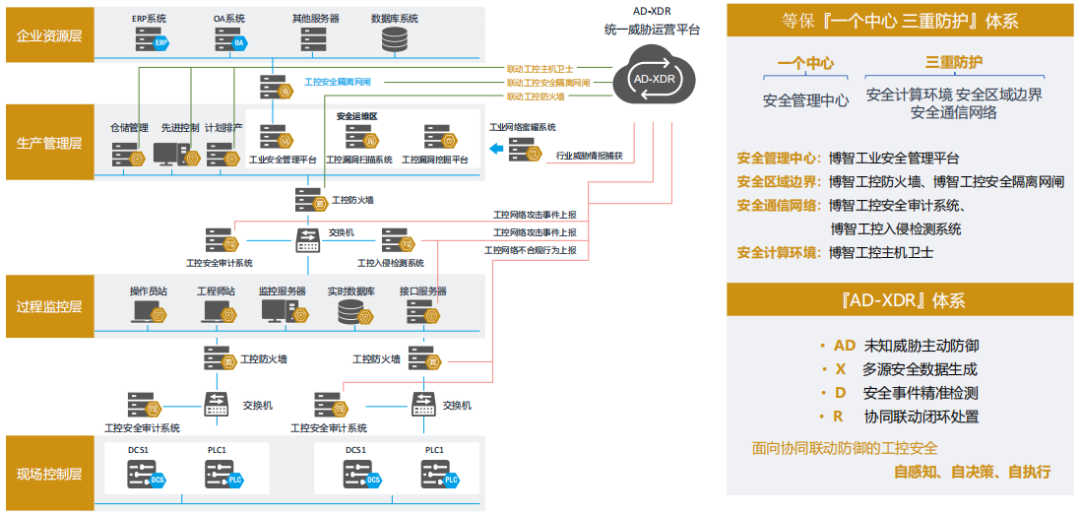

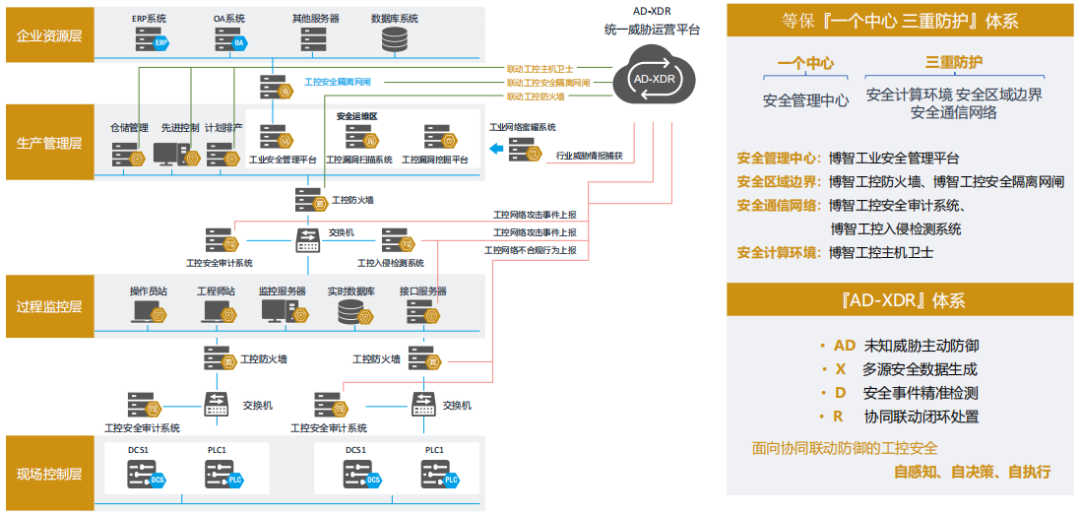

Bozhi Security Technology Co., Ltd. (hereinafter referred to as “Bozhi Security”) is driven by the security needs of the basic industries and industrial internet, relying on its accumulated assessment, testing, and protection capabilities in the field of industrial security to integrate and form an industrial network collaborative security protection solution based on AD-XDR.

Implement Network Testing and Control for Industrial Control Systems

To enhance the security reliability of the system, we need to implement strengthened testing and control measures at all stages of system requirement design, selection, bidding, construction, acceptance, operation and maintenance, and expansion. This includes strengthening the internal testing processes of manufacturers, such as factory testing and selection testing; at the same time, attention must be paid to testing work in key links such as trial operation, acceptance, security, networking, and online or version changes. Through these measures, we can effectively reduce potential issues that may arise during the requirements, design, development, and operation and maintenance processes.

Implement Security Risk Assessment for Industrial Control Systems

To improve the security protection level of industrial control systems, we need to conduct regular security testing and risk assessments. This can help us promptly identify security vulnerabilities and weak links in the network. Once these issues are identified, we can take corresponding management and technical measures to strengthen protection. Additionally, we should enhance guidance and supervision over the information security work of industrial control systems, including conducting security self-checks, regular inspections, and irregular spot checks to ensure that all security measures are effectively implemented. Through these measures, we can prevent major cybersecurity incidents and reduce their impact.

Bozhi Security relies on its accumulation in key industrial control knowledge bases such as the industrial control vulnerability database, industrial control fingerprint database, and industrial control protocol database to form a complete industrial control security product system covering risk assessment, security protection, and operation management.

Contact: 400-100-0298 ext 1