The programming language for PLC software has distinct characteristics compared to general computer languages. It is neither a high-level language nor a typical assembly language, and it must meet the requirements for ease of writing and debugging.

Early PLCs supported only ladder diagram programming language and instruction list programming language. According to the International Electrotechnical Commission, five languages can now support PLC programming: Ladder Diagram (LD), Instruction List (IL), Function Block Diagram (FBD), Sequential Function Chart (SFC), and Structured Text (ST). Today, I will share some PLC control circuits and ladder diagrams, which are quite basic and practical. Let’s take a look!

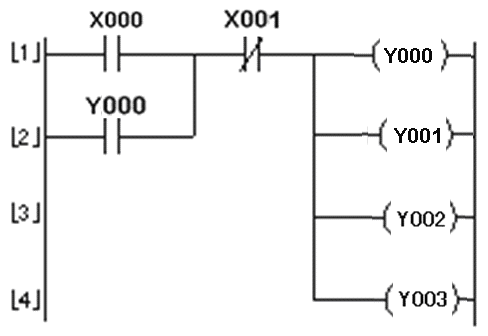

Starting, self-locking, and stopping control can be implemented using drive instructions (OUT) as well as set/reset instructions (SET, RST).

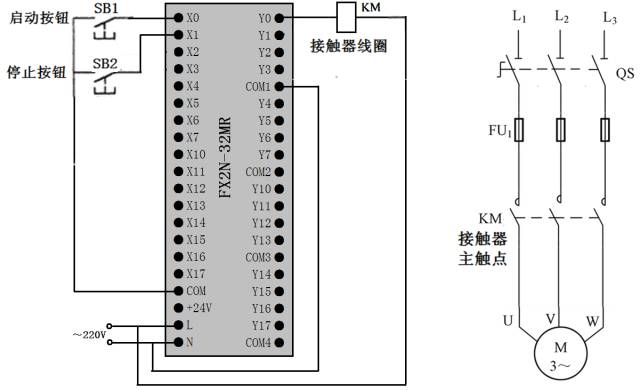

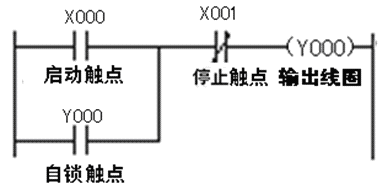

1. Using coil drive instructions to achieve starting, self-locking, and stopping control

Explanation of the circuit and ladder diagram:

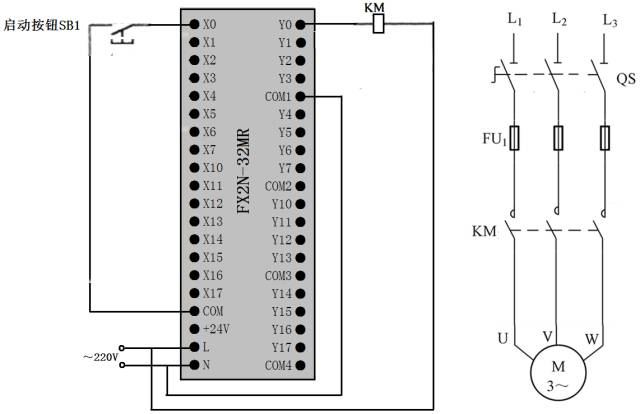

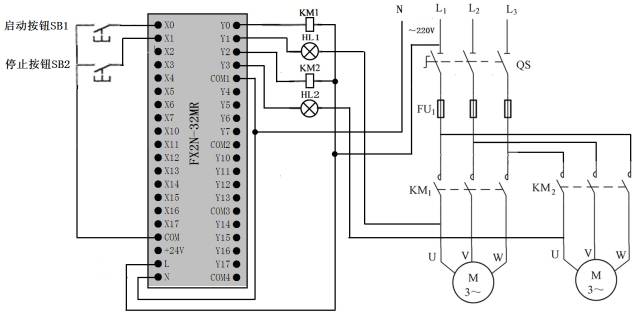

When the start button SB1 is pressed, the start contact X000 in the PLC internal ladder program closes, energizing the output coil Y000. The internal hard contact between output terminal Y0 and COM closes, energizing the contactor coil KM. The main contact KM in the main circuit closes, and the motor starts.

When the stop button SB2 is pressed, the stop contact X001 in the PLC internal ladder program opens, de-energizing the output coil Y000. The internal hard contact between Y0 and COM opens, de-energizing the contactor coil KM. The main contact KM in the main circuit opens, causing the motor to stop.

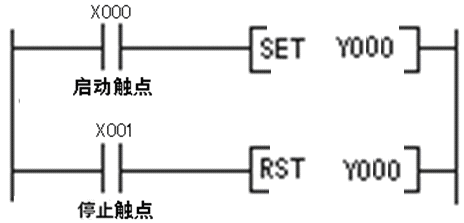

2. Using set/reset instructions to achieve starting, self-locking, and stopping control

The PLC wiring diagram is similar to the one above.

Explanation of the circuit and ladder diagram:

When the start button SB1 is pressed, the start contact X000 in the ladder diagram closes, and the [SET Y000] instruction is executed. The result of the instruction execution sets the output relay coil Y000 to 1, energizing it, connecting the internal hard contact between Y0 and COM, energizing the contactor coil KM, closing the main contact KM in the main circuit, and starting the motor.

When the stop button SB2 is pressed, the stop contact X001 in the ladder program closes, and the [RST Y000] instruction is executed. The result of the instruction execution resets the output coil Y000, de-energizing it, opening the internal hard contact between Y0 and COM, de-energizing the contactor coil KM, opening the main contact KM in the main circuit, and stopping the motor.

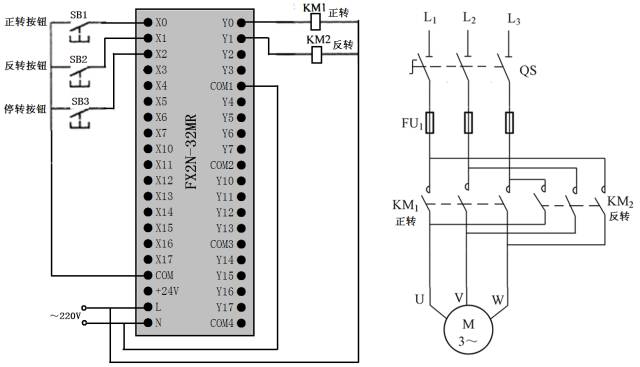

Explanation of the circuit and ladder diagram:

1) Forward interlocking control

Press the forward button SB1 → the forward contact X000 in the ladder program closes → the coil Y000 is energized → the self-locking contact Y000 closes, and the interlocking contact Y000 opens, closing the internal hard contact between Y0 and COM → the self-locking contact Y000 closes, allowing coil Y000 to remain energized even after X000 opens; the interlocking contact Y000 opens, preventing coil Y001 from being energized even if X001 closes (due to misoperation of SB2), achieving interlocking control; the internal hard contact between Y0 and COM closes, energizing the contactor KM1, closing the main contact KM1 in the main circuit, and energizing the motor for forward rotation.

2) Reverse interlocking control: Press the reverse button SB2 → the reverse contact X001 in the ladder program closes → the coil Y001 is energized → the self-locking contact Y001 closes, and the interlocking contact Y001 opens, closing the internal hard contact between Y1 and COM → the self-locking contact Y001 closes, allowing coil Y001 to remain energized even after X001 opens; the interlocking contact Y001 opens, preventing coil Y000 from being energized even if X000 closes (due to misoperation of SB1), achieving interlocking control; the internal hard contact between Y1 and COM closes, energizing the contactor KM2, closing the main contact KM2 in the main circuit, and energizing the motor for reverse rotation.

3) Stop control: Press the stop button SB3 → both stop contacts X002 in the ladder program open → coils Y000 and Y001 are de-energized → coils KM1 and KM2 are de-energized → both main contacts KM1 and KM2 in the main circuit open, causing the motor to stop.

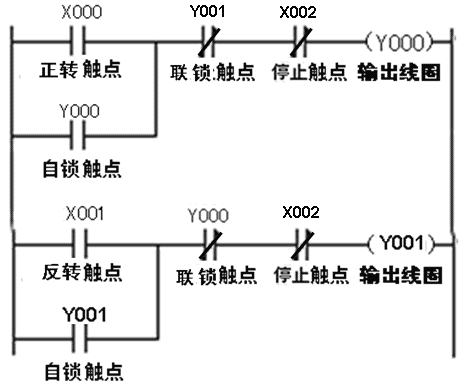

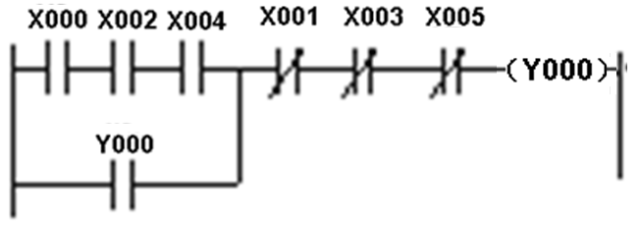

(1) Single Person Multi-Location Control

Starting control at location A. When the start button SB1 is pressed at location A → the normally open contact X000 closes → the coil Y000 is energized → the normally open self-locking contact Y000 closes, and the internal hard contact between Y0 closes → the normally open self-locking contact Y000 locks the power supply to coil Y000, closing the internal hard contact between Y0 and energizing the contactor coil KM → the main contact KM in the main circuit closes, and the motor operates.

Stopping control at location A. When the stop button SB2 is pressed at location A → the normally closed contact X001 opens → the coil Y000 is de-energized → the normally open self-locking contact Y000 opens, and the internal hard contact between Y0 opens → the contactor coil KM is de-energized → the main contact KM in the main circuit opens, causing the motor to stop.

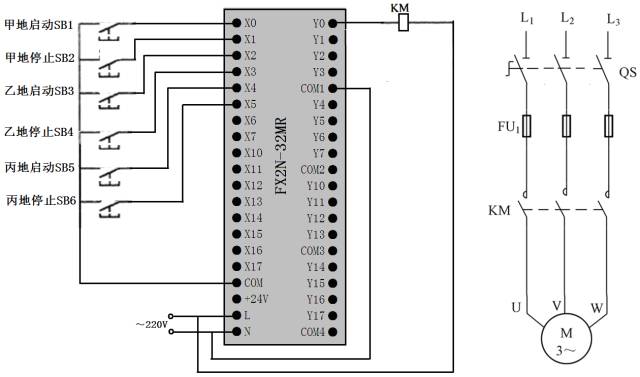

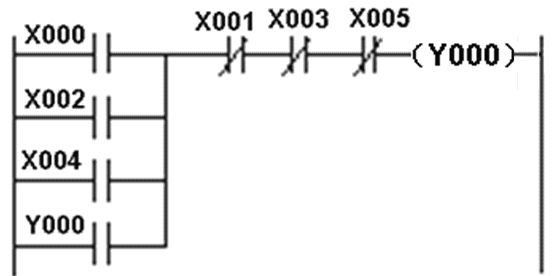

(2) Multi-Person Multi-Location Control

Starting control. When buttons SB1, SB3, and SB5 are pressed simultaneously at locations A, B, and C → the coil Y000 is energized → the normally open self-locking contact Y000 closes, and the internal hard contact between Y0 closes → the coil Y000 locks the power supply, energizing the contactor coil KM → the main contact KM in the main circuit closes, and the motor operates.

Stopping control. When any of the stop buttons SB2, SB4, or SB6 at locations A, B, or C is pressed simultaneously → the coil Y000 is de-energized → the normally open self-locking contact Y000 opens, and the internal hard contact between Y0 opens → the normally open self-locking contact Y000 opens, cutting off the power supply to coil Y000, and opening the internal hard contact between Y0, de-energizing the contactor coil KM → the main contact KM in the main circuit opens, causing the motor to stop.

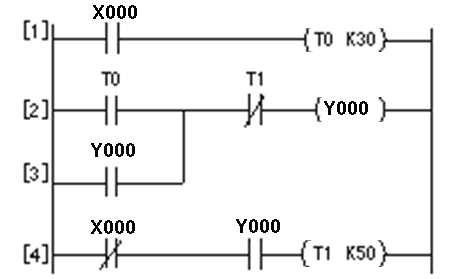

1. Delay Start Timing Control of PLC Circuits and Ladder Diagrams

This can achieve: pressing the start button for 3 seconds causes the motor to start working, and it will stop automatically after 5 seconds.

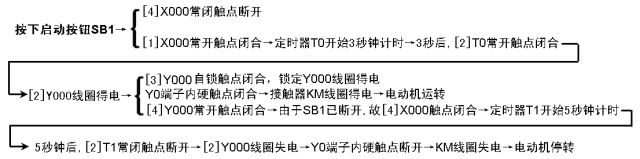

Explanation of the PLC circuit and ladder diagram is as follows:

2. Multiple Timer Combination Control of PLC Circuits and Ladder Diagrams

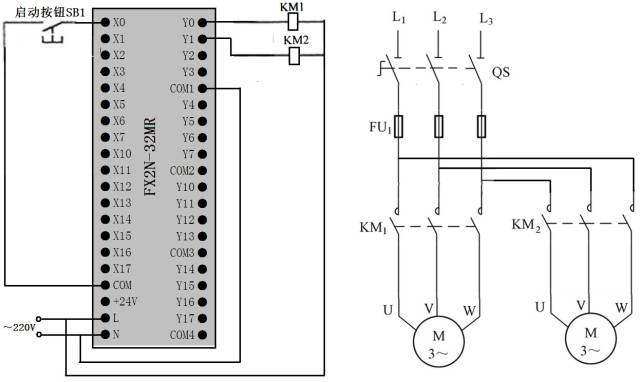

This can achieve: after pressing the start button, motor B runs immediately, motor A starts after 30 seconds, motor B stops after 70 seconds, and motor A stops after 100 seconds.

Explanation of the PLC circuit and ladder diagram is as follows:

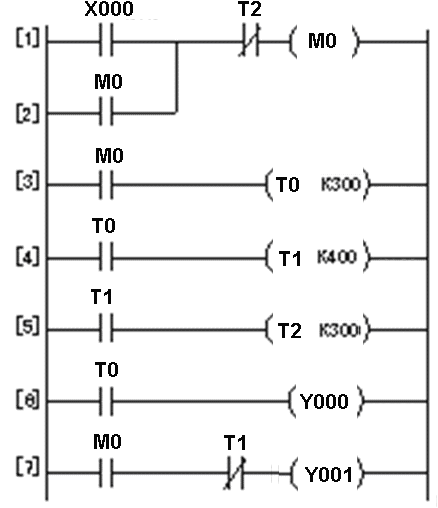

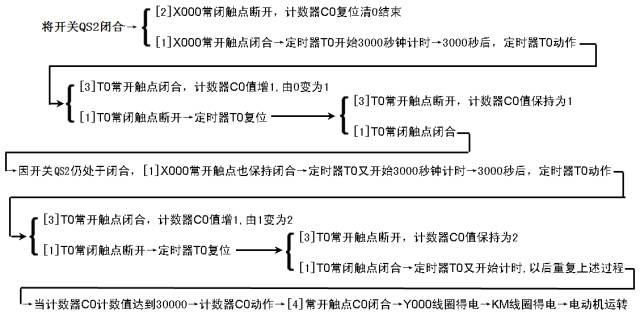

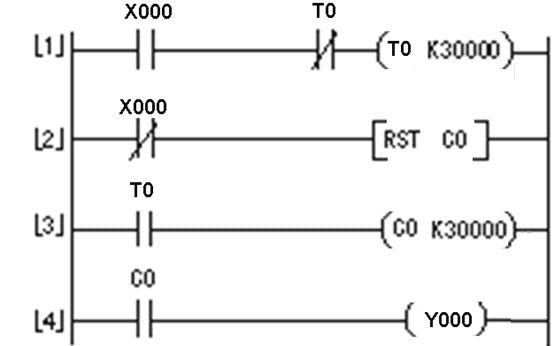

The longest timing time for Mitsubishi FX series PLC is 3276.7 seconds (about 54 minutes). Using timers and counters can extend the timing time.

Explanation of the PLC circuit and ladder diagram is as follows:

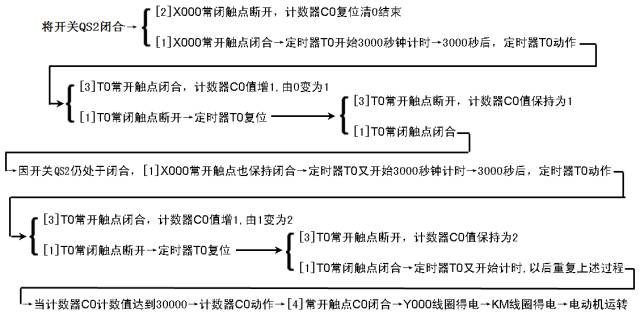

The timer T0 in the figure has a timing unit of 0.1 seconds (100ms), and when used with the counter C0, its timing time T = 30000 × 0.1 seconds × 30000 = 90000000 seconds = 25000 hours. If you need to reset the timing, you can disconnect switch QS2 to close the normally closed contact [2] X000, then execute the “RST C0” instruction. After the counter C0 is reset, close QS2 again to restart the 250000-hour timing.

Explanation of the PLC circuit and ladder diagram is as follows:

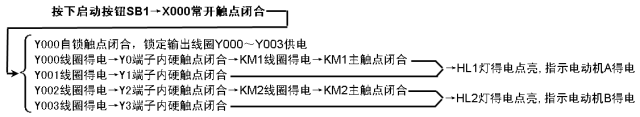

(1) Starting control

(2) Stopping control

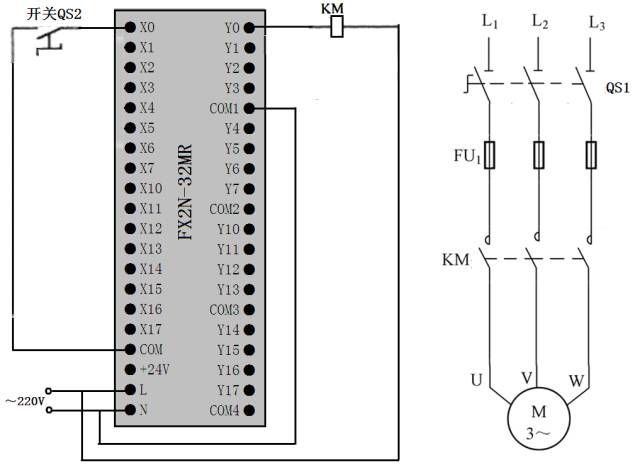

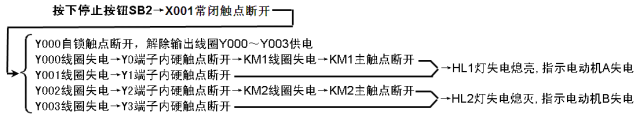

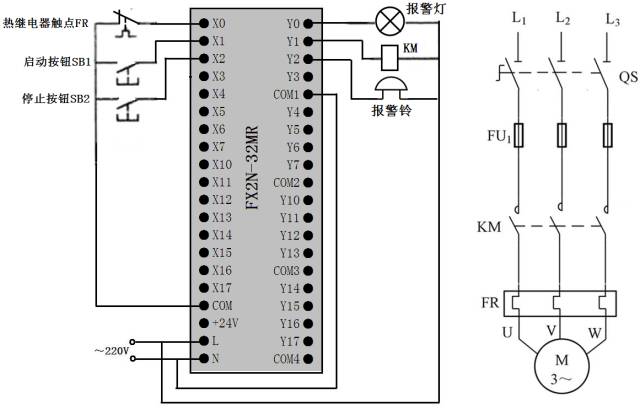

Explanation of the PLC circuit and ladder diagram:

(1) Starting control

Press the start button SB1 → the normally open contact [1] X001 closes → the [SET Y001] instruction is executed → the Y001 coil is set, meaning the Y001 coil is energized → the internal hard contact of terminal Y1 closes → the contactor KM coil is energized → the main contact KM closes → the motor operates.

(2) Stopping control

Press the stop button SB2 → the normally open contact [2] X002 closes → the [RST Y001] instruction is executed → the Y001 coil is reset, meaning the Y001 coil is de-energized → the internal hard contact of terminal Y1 opens → the contactor KM coil is de-energized → the main contact KM opens → the motor stops.

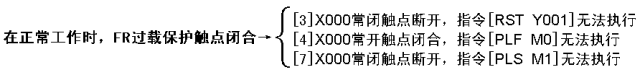

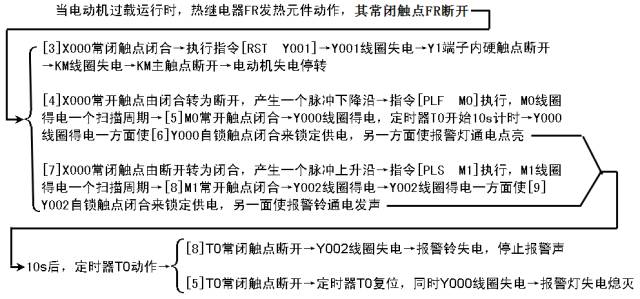

(3) Overload protection and alarm control

Explanation of the circuit and ladder diagram:

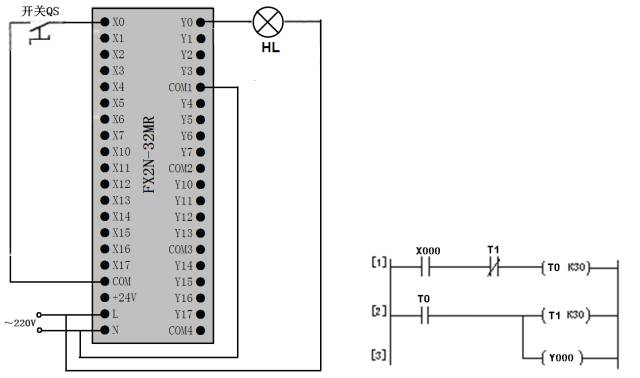

Close switch QS → the normally open contact X000 closes → timer T0 starts a 3s countdown → after 3s, timer T0 activates, and its normally open contact closes → timer T1 starts a 3s countdown, meanwhile Y000 is energized, closing the internal hard contact of terminal Y0, lighting lamp HL → after 3s, timer T1 activates, its normally closed contact opens → timer T0 resets, its normally open contact opens → coil Y000 is de-energized, simultaneously resetting timer T1 → de-energizing coil Y000 turns off lamp HL; resetting timer T1 closes T1, and since switch QS remains closed, the normally open contact X000 also remains closed, timer T0 restarts the 3s countdown.

The above process repeats, causing lamp HL to blink with a frequency of 3s on, 3s off.

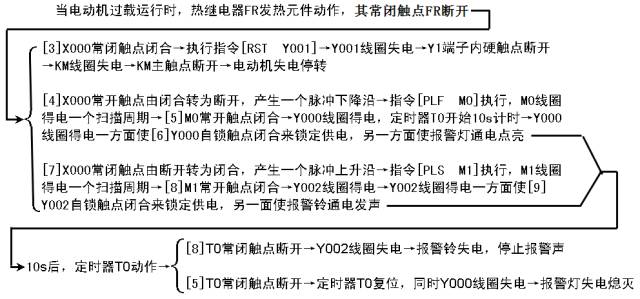

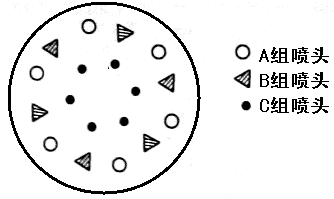

PLC Control of a Fountain

The system requires two buttons to control the operation of three groups of nozzles (by controlling the motors of the three groups of nozzles). The three groups of nozzles are arranged as shown in the figure. The specific control requirements are as follows:

When the start button is pressed, group A sprays for 5 seconds and then stops, followed by groups B and C spraying simultaneously. After 5 seconds, group B stops, group C continues to spray for another 5 seconds and then stops. Then groups A and B spray for 7 seconds, with group C stopping during the first 2 seconds of those 7 seconds and spraying during the last 5 seconds. After that, all three groups of nozzles stop spraying for 3 seconds, and the previous process repeats. When the stop button is pressed, all three groups of nozzles stop spraying.