Airflow Sensor, Intake Temperature Sensor, Throttle Position Sensor, Water Temperature Sensor, Camshaft Position Sensor, Crankshaft Position Sensor, Knock Sensor, Oxygen Sensor

1、Airflow Sensor

The airflow sensor converts the incoming air into an electrical signal sent to the Engine Control Unit (ECU), serving as one of the basic signals for determining fuel injection. Depending on the measurement principle, it can be classified into four types: rotary vane airflow sensor (used in Toyota PREVIA), Karman vortex airflow sensor (used in Toyota Lexus LS400), hot wire airflow sensor (used in Nissan’s VG30E engine and Volvo B230F engine in domestic Tianjin Sanfeng buses), and hot film airflow sensor. The first two are volumetric flow types, while the latter two are mass flow types. Currently, the hot wire and hot film airflow sensors are the most commonly used.

2、Intake Pressure Sensor

The intake pressure sensor measures the absolute pressure in the intake manifold based on the engine load state and converts it into an electrical signal, which is sent to the computer along with the speed signal, serving as the basis for determining the basic fuel injection amount. This type of pressure sensor is used in domestic Audi 100 (V6 engine), Santana 2000, Beijing Cherokee (2.5L engine), and Toyota Crown 3.0. Currently, semiconductor pressure-sensitive resistors are widely used as intake pressure sensors.

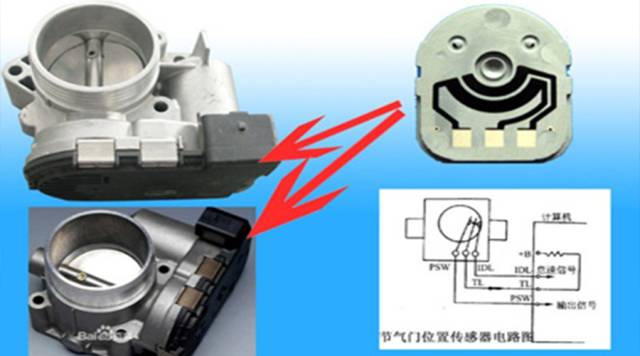

3、Throttle Position Sensor

The throttle position sensor is installed on the throttle body to detect the throttle opening. It is linked to the throttle via a lever mechanism, reflecting the different operating conditions of the engine. This sensor inputs the detected engine conditions into the ECU to control the varying fuel injection amounts. There are three types: switch contact throttle position sensor (used in Santana 2000 and Tianjin Sanfeng buses), linear variable resistor throttle position sensor (used in Beijing Cherokee), and integrated throttle position sensor (used in domestic Audi 100 V6 engine).

4、Crankshaft Position Sensor

Also known as the crankshaft angle sensor, it is the most important sensor in a computer-controlled ignition system. Its function is to detect the top dead center signal, crankshaft angle signal, and engine speed signal, and input them into the computer, allowing it to issue the best ignition timing command according to the cylinder’s ignition sequence. There are three types of crankshaft position sensors: electromagnetic pulse crankshaft position sensor, Hall effect crankshaft position sensor (used in Santana 2000 and Beijing Cherokee), and photoelectric effect crankshaft position sensor. The different types of crankshaft position sensors have varying control methods and precision. They are generally installed on the side of the crankshaft pulley or chain wheel, with some mounted at the front end of the camshaft or on the distributor (as in Santana 2000).

5、Knock Sensor

The knock sensor is installed on the engine block to monitor the engine’s knock condition at all times. Currently, there are two main types: resonant and non-resonant. When it rains, the windshield wipers of both large and small vehicles will operate simultaneously, with the two wiper blades swinging around a fixed pivot to clear rainwater from the windshield, providing the driver with a clear view.

The earliest windshield wipers consisted of a rocking arm with a rubber blade operated manually by the driver. Later, for visibility needs, wiper arms were installed on both sides, connected by a linkage, creating a manual dual wiper system, which is the original form of today’s automotive windshield wipers.

Subsequent wipers replaced manual operation with a vacuum system, known as vacuum wipers. A tube connected to the engine utilized the engine’s vacuum to drive a piston inside the wiper, moving the rocking arm and enabling the wiper blades to operate. In the early 1940s, electric wipers gradually replaced vacuum wipers in vehicles. However, until the early 1980s, some trucks and buses in China still used vacuum wipers. Now, all vehicles have switched to electric wipers.

Although windshield wipers seem simple, their construction is not. The wiper assembly includes a motor, gearbox, four-bar linkage, wiper arm pivot, and wiper blade assembly. When the driver presses the wiper switch, the motor starts, and its speed is reduced and increased through a worm gear, driving the rocking arm. The rocking arm moves the four-bar linkage, which swings the pivot mounted on the front panel left and right, ultimately moving the wiper blades to clear the windshield.

Currently, vehicles typically have two wiper arms, usually powered by a single motor, referred to as “single motor dual arms,” while some have a motor for each wiper, called “single motor single arm.” Some wiper arms also include a water hose connected to the washer, which sprays water onto the windshield when the switch is pressed. In some mid to high-end sedans, not only do the front and rear windshields have wipers, but the front headlights also have a small wiper blade to clear dust from the headlight glass.

When the driver turns off the wipers, the wiper arms often stop in an inappropriate position, obstructing the driver’s view. To solve this problem, wipers are equipped with a return switch that controls the wiper motor, ensuring that the wiper arms stop in a suitable position below the windshield when turned off.

Modern wipers commonly feature fast, slow, and intermittent control settings. The intermittent control setting typically uses the motor’s return switch contacts and the charging and discharging function of resistors and capacitors to make the wipers operate at set intervals, stopping for 2-12 seconds between sweeps, minimizing driver distraction. Some vehicles’ wipers are also equipped with electronic speed controllers that can automatically adjust the wiper arm’s swinging speed based on rainfall intensity; the wipers move faster in heavy rain and slower in light rain, stopping when it stops raining.