Abstract

Introduction

Status of Multi-domain Electronic and Electrical Architecture Technology

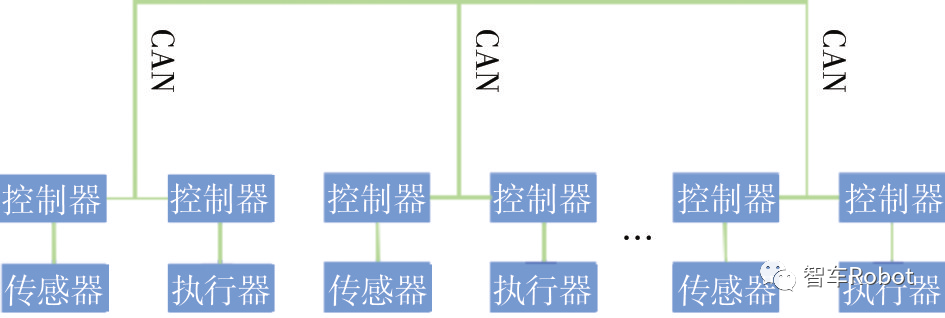

1.1 Distributed Architecture

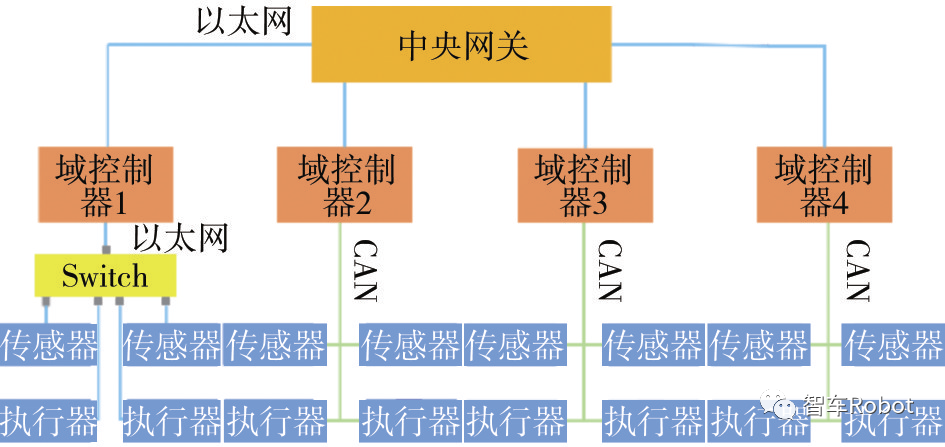

1.2 Domain-Centric Architecture

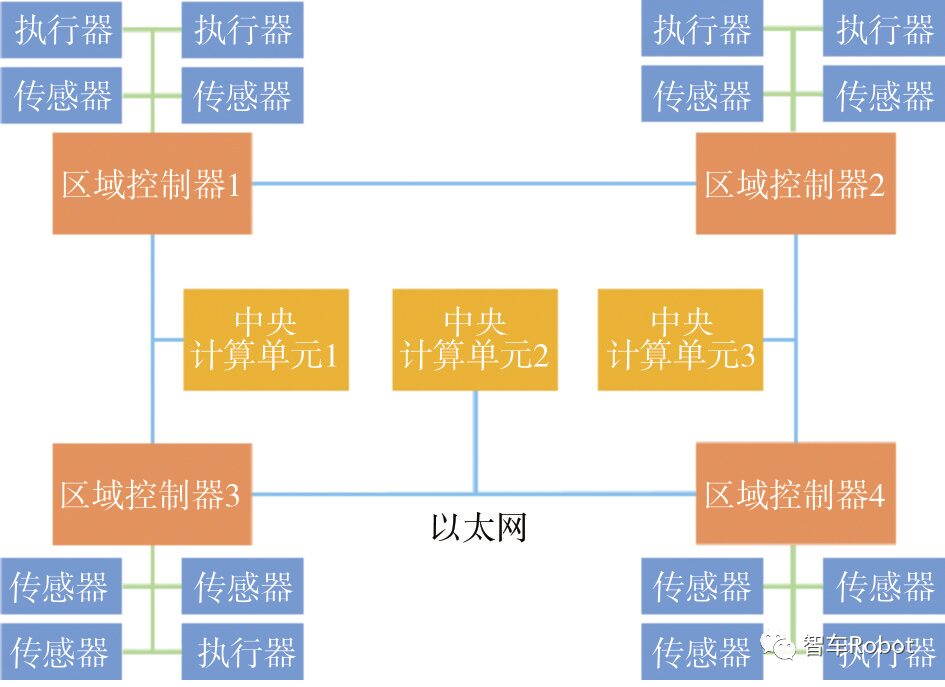

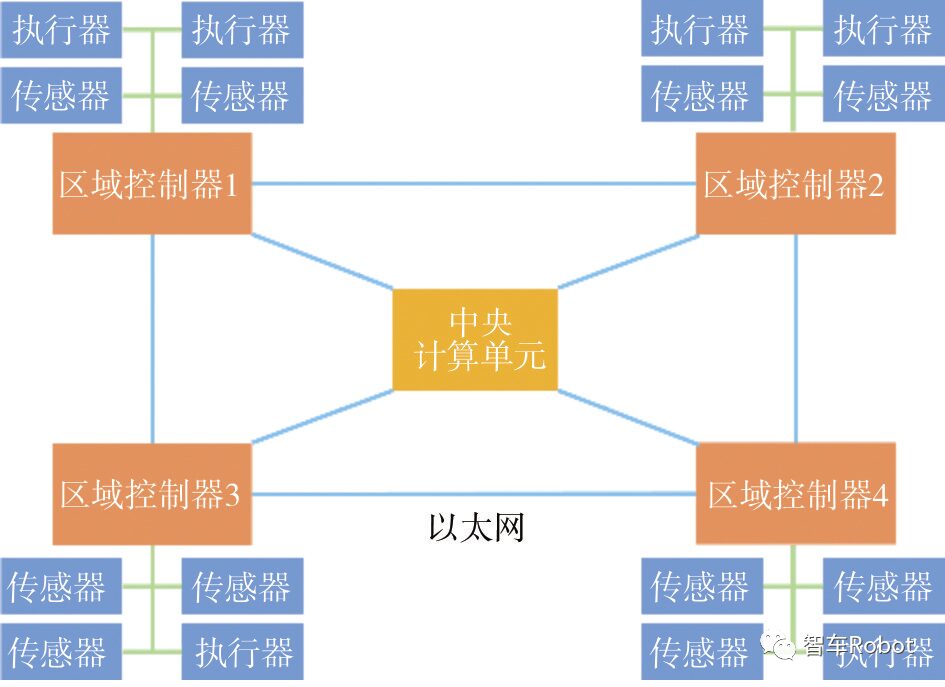

1.3 Centralized Architecture

Overall Design Technology of Multi-domain Electronic and Electrical Architecture

2.1 Main Tasks of Overall Architecture Design

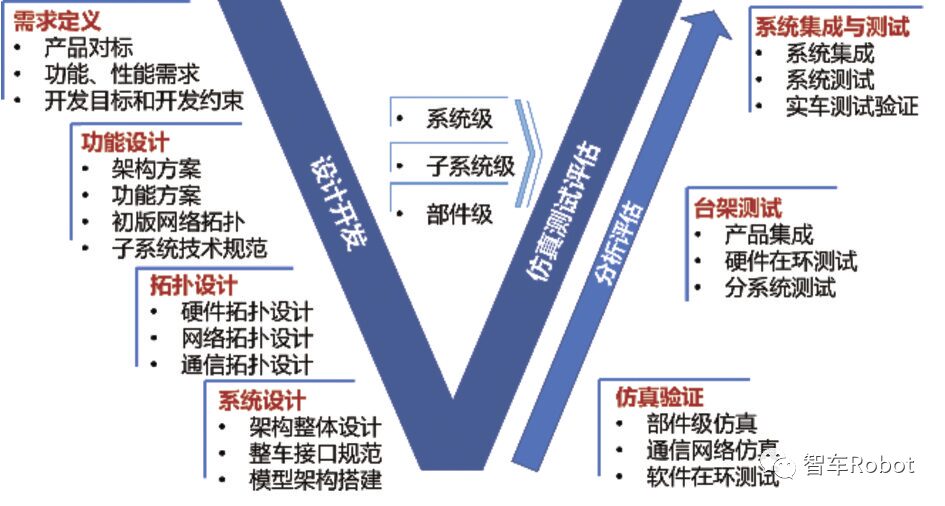

2.2 Overall Architecture Design and Evaluation Methods

2.2.1 Architecture Requirement Definition

2.2.2 Architecture Functional Design

2.2.3 Architecture Topology Design

2.2.4 Architecture System Design

2.2.5 Architecture Analysis and Evaluation

Hardware Systems of Multi-domain Electronic and Electrical Architecture

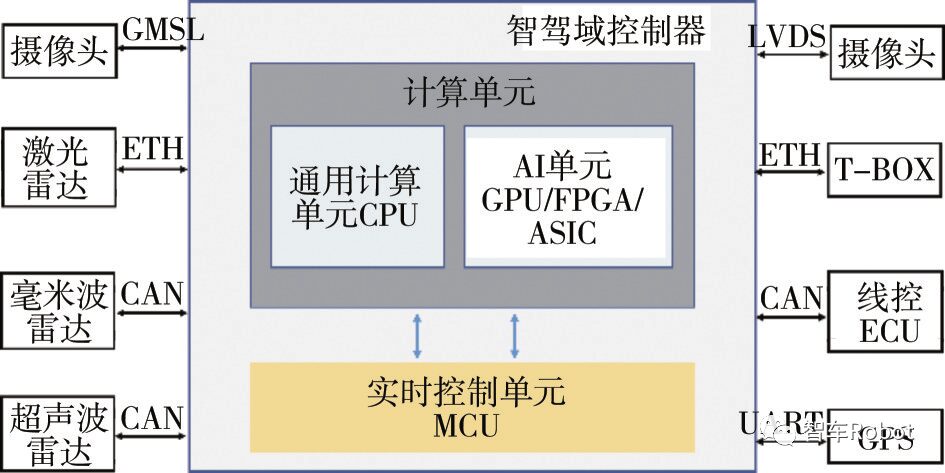

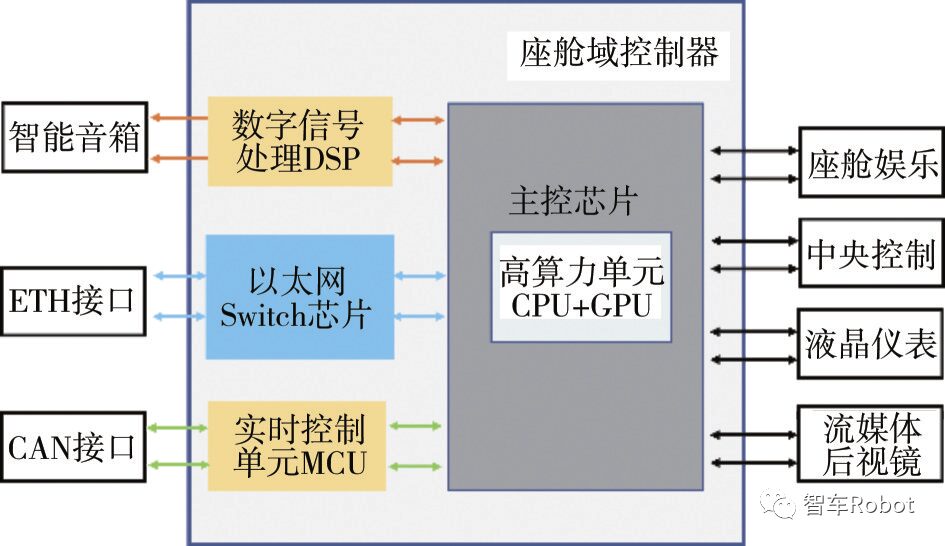

3.1 Domain Control Units and Key Technologies

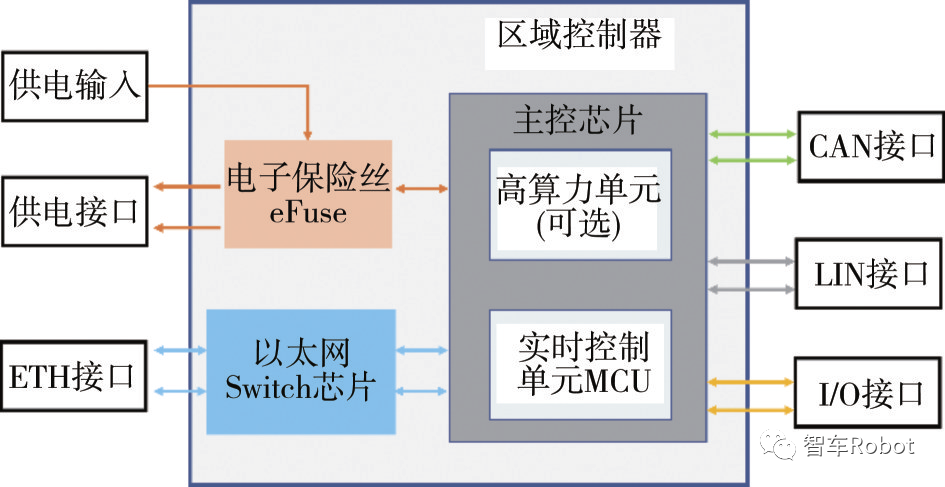

3.2 Zone Controllers and Key Technologies

3.3 Central Computing Units and Key Technologies

3.4 Power Supply Systems and Key Technologies

3.5 Wiring Harness Systems and Key Technologies

Communication Systems of Multi-domain Electronic and Electrical Architecture

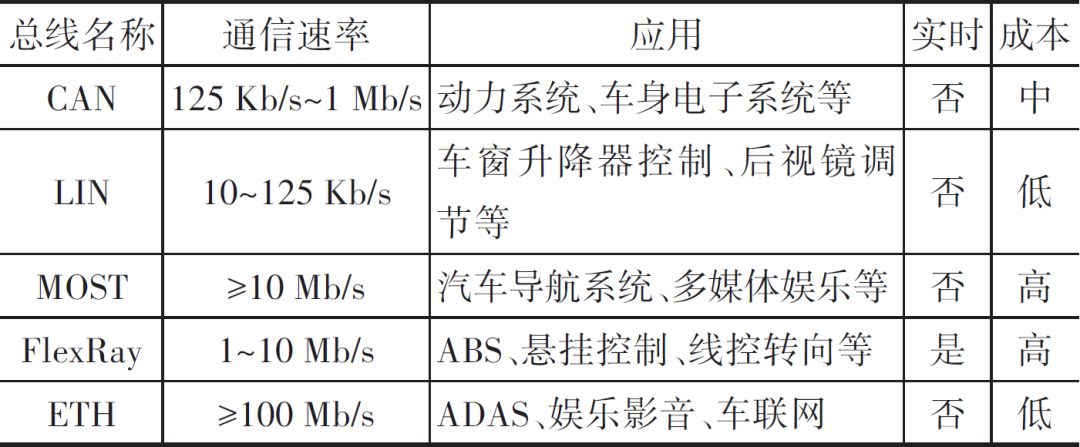

4.1 Development and Status of On-board Communication Systems

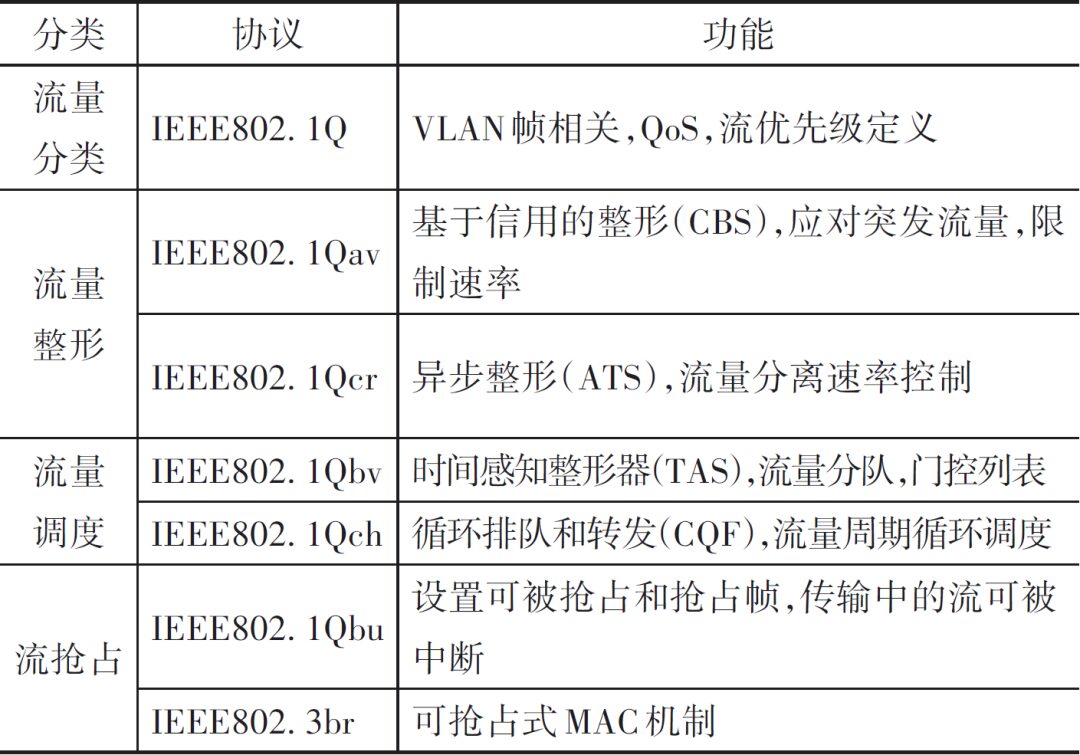

4.2 Analysis and Research of Time-Sensitive Network Communication Protocols

4.2.1 Time Synchronization Protocols

4.2.3 Reliability Protocols

4.2.4 Resource Management Protocols

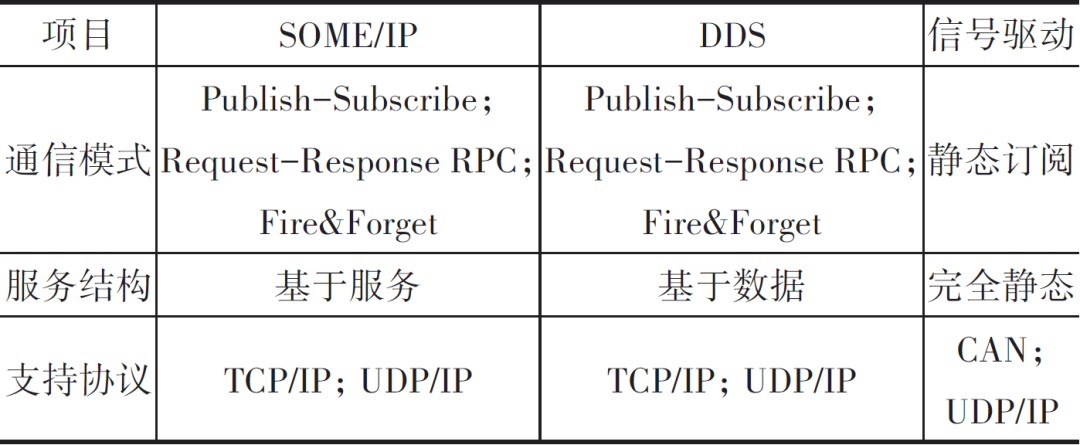

4.3 Service-Oriented Software-Defined Networks

Software Systems of Multi-domain Electronic and Electrical Architecture

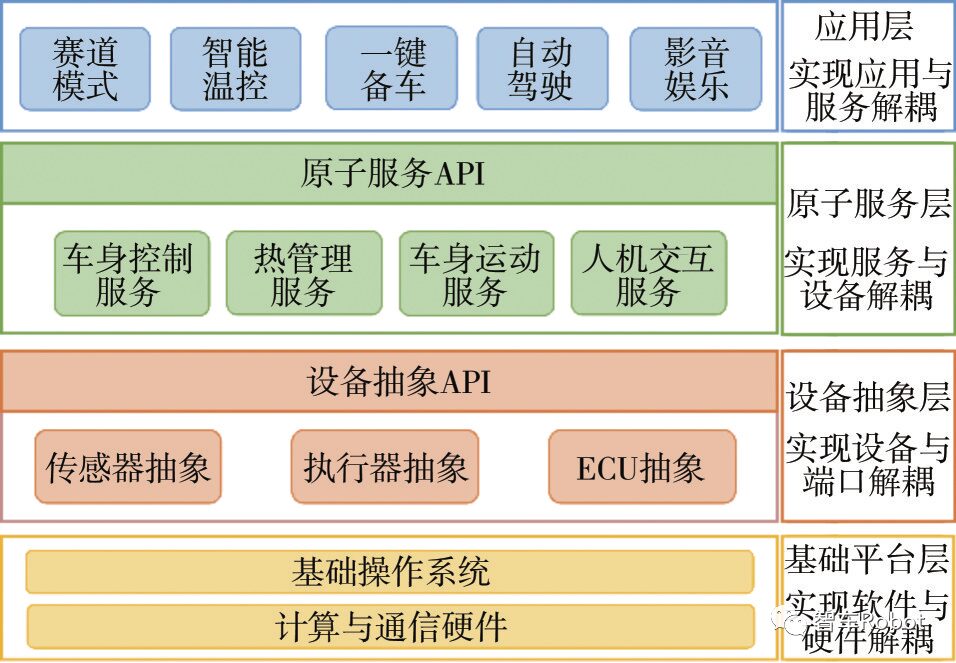

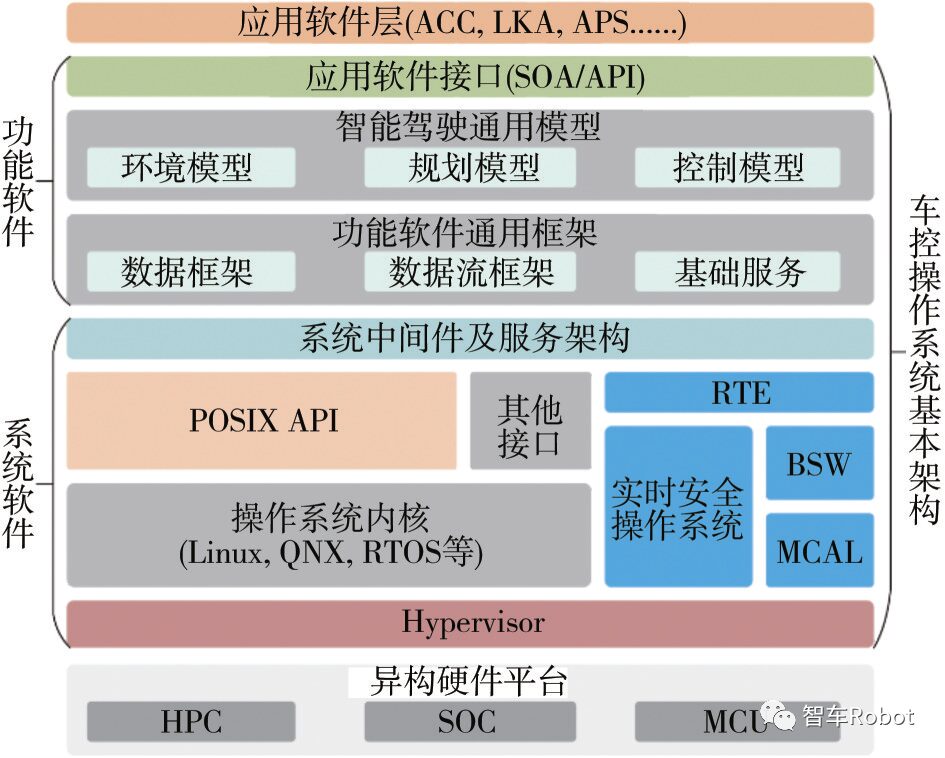

5.1 Software-Defined Vehicles

5.1.1 Basic Concept of SDVs

5.1.2 Decoupling and Mapping of Software and Hardware

5.2 Service-Oriented Software Design

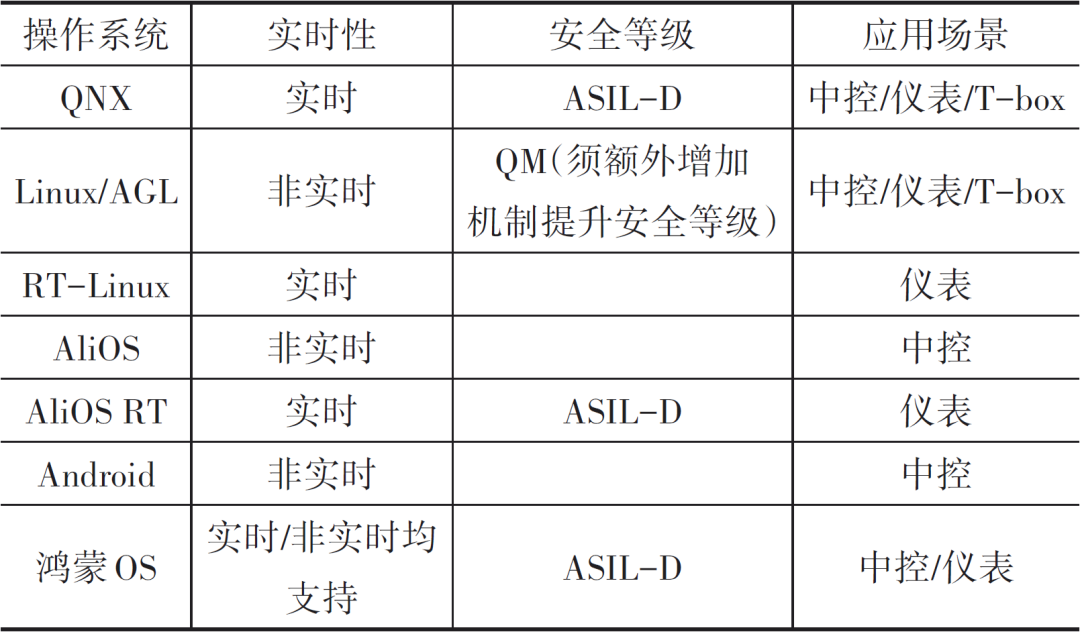

5.3 Vehicle Operating Systems

5.3.1 Vehicle Control Operating Systems

5.3.2 On-board Operating Systems

Research Outlook

Conclusion