Multiple

How to Exchange Signals Between Multiple PLCs?

Previously, I discussed that in some large smart factories, a single or multiple large PLCs usually form the processing core.The advantage of a single PLC is that all important equipment needs to be controlled by this unified core, allowing for high integration of information. However, large PLCs cannot be used infinitely; they have capacity limits, and if there are too many programs, the response time naturally slows down. At this point, it is necessary touse multiple PLCs to complete the tasks together.

Due to some technical reasons or equipment supplier constraints, it is necessary to purchase multiple unrelated devices. They usually have separate processing units, which then need to be modified to integrate signals based on production requirements.

If usingmultiple PLCs, then the question arises: How to Exchange Signals Between Them?

There are generally two common methods:

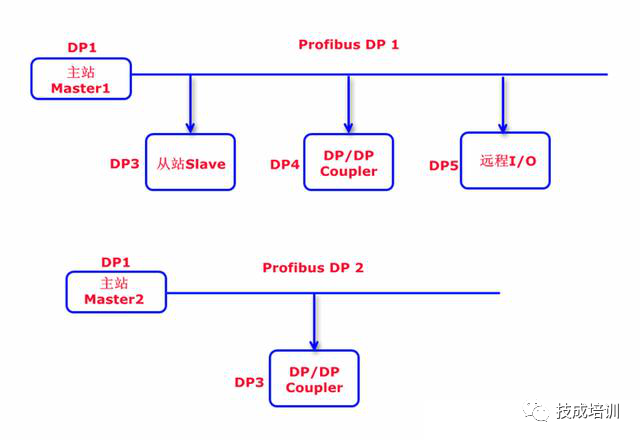

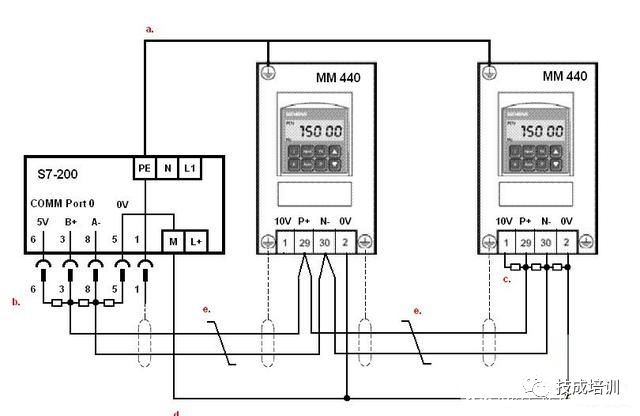

For example, PROFIBUS, PROFINET, Modbus, and free port communication are examples. This is a hardware + software approach. Generally speaking, PLCs of the same brand communicate more easily, but using them requires a certain understanding of PLCs, making it relatively difficult to get started.

The term hardwired here does not refer to the softness or hardness of the cable, but rather indicates a more rigid approach compared to communication methods. Hardwired methods are independent of the PLC brand; the signals from both sides can transition through relays. This method does not require software programming, only cables are needed, making it relatively easy to accept.

Due to the upgrade of factory equipment, in 2018, I commissioned several movable automation devices. The new equipment is a set of auxiliary devices that need to exchange signals with the main device. At the design stage, maintenance convenience and other issues were considered, and since the auxiliary devices need to be mobile, the signal exchange was designed as hardwired with aviation plugs, which operated well. However, I was always concerned about the hardwired connection, fearing that operational errors by workers could damage the aviation plugs, leading to cable short circuits and other issues. Fortunately, high-quality cables and aviation plugs were chosen during the design, and there have been no problems after over half a year of operation.

However, after a period of use, due to the overall process upgrade, it became necessary to integrate the equipment, which meant transmitting more information, including some analog signals, etc. Thus, I considered changing the hardwired connection to Ethernet communication, but this idea faced a lot of opposition.

The main device uses Siemens S1200, and the auxiliary device uses Siemens S7-200 SMART, both of which have Ethernet ports. The modification only requires removing the hardwired connection, adding a switch, and modifying the program to include S7 communication to change the connection method from hardwired to S7 communication.

However, maintenance engineers and electricians generally did not want this method…

1. Generally, maintenance personnel have lower skill levels, do not understand the principles of communication, feel that this method is unsafe, and that Ethernet cables (even category 6) do not appear as sturdy as dedicated cables with aviation plugs.

2. Maintenance electricians are accustomed to using multimeters to find faults, and hardwired cables are visible and tangible, making it more intuitive for them to check.

3. For devices like switches that belong to the internet category, some maintenance personnel feel these belong to the IT department, so they are unwilling to take over.

1. For communication,only one Ethernet cable is needed, making maintenance and installation very convenient; hardwired communication requires connectors, and generally, higher quality ones are metal aviation plugs, with cables soldered to the plugs, making repairs and replacements troublesome when damaged, while Ethernet cables can simply be replaced with a ready-made line.

2. Since both parties in communicationhave touch screens, the signals from both sides can be displayed clearly on the touch screens, making fault finding no more complicated than with hardwired connections.

3. Communication methods are safer than hardwired connections, as communication follows protocols. If an Ethernet cable is damaged, the PLC can identify it, while hardwired signals are independent; if a signal short-circuits, the system cannot recognize it.

4. Communication methodsare easier for system integration, which is a necessary condition for integrating existing equipment, allowing for smoother overall operation. Those who have worked on projects know that there are many ways to integrate two separate devices; simple logical processing can be done, but a more perfect solution involves deep information exchange, ensuring information flow, making the entire production process operate as a single system.

5. Compared to hardwired connections, communication is amore advanced technology; as the times progress, those in technology shouldstrengthen their learning, so even maintenance electricians at the grassroots level need to learn and enrich themselves.

Finally, at my strong suggestion, I attempted to modify the first device to Ethernet S7 connection,and it has been running smoothly for nearly a year without any issues, and hardwired connections sometimes experience minor signal interference. Therefore, to address this interference, I added a software filter in the program, which inadvertently increased production time and reduced efficiency. After switching to Ethernet, not only was stability guaranteed, but there was also no need to add filters, thereby shortening production cycles and improving efficiency.

Have you had similar experiences? How did you choose?

Source: Network, copyright belongs to the original author. If there are any copyright issues, please contact us promptly for deletion. Thank you!