Anyone engaged in electrical work knows that industrial production and technological development cannot do without the automation control of PLCs. PLC can be broadly understood as: a centralized relay extension control cabinet;

In actual production applications, PLCs greatly save the costs of industrial control and enhance the centralized management and automatic control of equipment. To learn PLC well, a solid foundation in PLC is essential.

(1) Input Interface: Accepts signals from controlled devices and drives the internal circuit to connect or disconnect via opto-isolators and input circuits.

(2) Output Interface: The execution results of the program are output through the opto-isolators and output components (relays, thyristors, transistors) of the output interface, controlling the connection or disconnection of external loads.

(1) CPU: The core component of the PLC that directs it to perform various tasks, such as accepting user programs and data, diagnostics, and executing programs;

(2) Memory: Stores the system and user programs and data;

(3) I/O Interface: The connecting component between the PLC and the controlled objects in the industrial production site, used to receive signals from controlled devices and output the execution results of the program;

(4) Communication Interface: Used for information exchange with other devices such as monitors and printers via the communication interface;

(5) Power Supply.

Thyristor Output Type: Generally can only carry AC loads, fast response speed, and high action frequency;

Transistor Output Type: Generally can only carry DC loads, fast response speed, and high action frequency;

Relay Output Type: Generally can carry AC and DC loads, but has a longer response time and lower action frequency.

(1) Integrated Type: The CPU, power supply, and I/O components are all concentrated in one chassis, compact structure, low price, generally used in small PLCs;

(2) Modular Type: The various parts of the PLC are divided into several separate modules, allowing for different modules to be selected according to needs to form a system, characterized by flexible configuration, easy expansion, and maintenance, generally used in medium and large PLCs. Modular PLCs consist of a frame or base and various modules, with modules installed in sockets on the frame or base.

(3) Stacked Type: Combines the characteristics of both integrated and modular types; the CPU, power supply, I/O interfaces, etc. are also independent modules, but they are connected via cables, making the system not only flexible in configuration but also compact in size.

The scanning process of a PLC includes five stages: internal processing, communication services, input processing, program execution, and output processing. The time required to scan once through these five stages is called the scanning cycle.

The scanning cycle is related to the CPU running speed, PLC hardware configuration, and the length of the user program.

PLC executes user programs in a cyclic scanning manner, and the execution process of the user program includes the input sampling stage, program execution stage, and output refresh stage.

(1) In terms of control methods: PLC uses programmed methods for control, making it easy to change or add control requirements, and PLC contacts are unlimited;

(2) In terms of working methods: PLC uses a serial working method, improving the system’s anti-interference ability;

(3) In terms of control speed: The contacts of the PLC are actually triggers, with instruction execution times in the microsecond range;

(4) In terms of timing and counting: PLC uses semiconductor integrated circuits as timers, clock pulses provided by crystal oscillators, with high delay accuracy and wide range. PLC has counting functions that relay systems do not have;

(5) In terms of reliability and maintainability: PLC uses microelectronic technology, with high reliability and built-in self-diagnosis functions to detect issues promptly.

Due to the PLC’s method of centralized sampling and centralized output in a cyclic scanning working mode, the status of the input terminal can only be read during the input sampling stage of each scanning cycle, and the execution results of the program are only sent out during the output refresh stage; additionally, the input and output delays of the PLC and the length of the user program can also cause output response lag.

To improve I/O input sampling and output refreshing, or to use direct input sampling and output refreshing, as well as interrupt input/output and intelligent I/O interfaces, among other methods.

Input relays, output relays, auxiliary relays, status registers, timers, counters, data registers.

(1) Model selection: Consider structural form, installation method, functional requirements, response speed, reliability requirements, and model uniformity;

(2) Capacity selection: Consider I/O point count and user storage capacity;

(3) I/O module selection: Include selection of digital and analog I/O modules, as well as special function modules;

(4) Selection of power supply modules and programmers, as well as other devices.

Centralized Sampling: In a scanning cycle, input status sampling only occurs during the input sampling stage, and the input terminal will be locked during the program execution stage.

Centralized Output: In a scanning cycle, the output image register states related to output are only transferred to the output latch during the output refresh stage, refreshing the output interface, while in other stages the output status remains in the output image register. This working method can improve the system’s anti-interference ability and enhance system reliability, but may cause lag in PLC input/output response.

PLC adopts centralized sampling, centralized output, and cyclic scanning working methods.

Characteristics: Centralized sampling means that in a scanning cycle, PLC samples the input status only during the input sampling stage, and the input terminal will be locked during the program execution stage.

Centralized output means that in a scanning cycle, PLC only transfers the output image register states related to output to the output latch during the output refresh stage, refreshing the output interface, while in other stages the output status remains in the output image register.

Cyclic scanning means that PLC needs to perform multiple operations within a scanning cycle, executing them one by one in a time-sharing manner, repeatedly running.

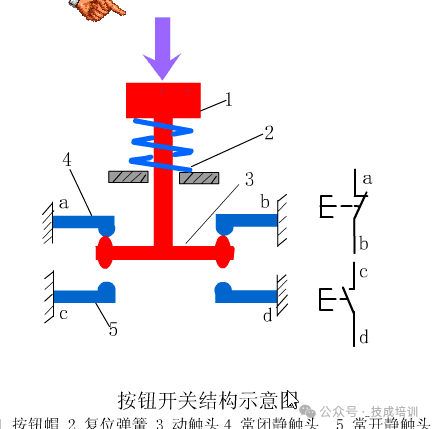

An electromagnetic contactor generally consists of electromagnetic mechanism, contacts, arc extinguishing device, release spring mechanism, bracket, and base.

The contactor works based on electromagnetic principles: when the electromagnetic coil is powered, the coil current generates a magnetic field, causing the static iron core to produce electromagnetic attraction, pulling the armature and causing the contacts to act, opening the normally closed contacts and closing the normally open contacts, which are interconnected. When the coil is de-energized, the electromagnetic force disappears, and the armature falls back under the action of the release spring, restoring the contacts, i.e., the normally open contacts open and the normally closed contacts close.

A Programmable Logic Controller (PLC) is an electronic device designed for digital operation in industrial environments.

It uses programmable memory to store instructions for performing logical operations, sequential operations, timing, counting, and arithmetic operations, and can control various types of machinery or production processes through digital or analog inputs and outputs.

PLCs and their related peripheral devices should be designed according to the principles of easy integration with industrial control systems and easy expansion of their functions.

① Different component devices; ② Different contact quantities; ③ Different methods of implementing control.

Disclaimer: This article is reprinted from the internet, and the copyright belongs to the original author. If there are any copyright issues, please contact us for deletion, thank you!

Complete question bank for the 2022 junior electrician exam (includes answers)

Three essential tools for electrical workers, easily accessible with WeChat!

【Collection】 The “path” of a ten-year veteran electrician, the secret to earning over ten thousand a month!

Which of the five major electrical drawing software (CAD, Eplan, CADe_simu…) do you pick?

Latest electrical CAD drawing software, with a super detailed installation tutorial!

Latest electrical drawing software EPLAN, with a super detailed installation tutorial!

Common issues for beginners using S7-200 SMART programming software (with download link)

Comprehensive electrical calculation EXCEL spreadsheet, automatically generated! No need to seek help for electrical calculations!

Bluetooth headsets, electrical/PLC introductory books for you to claim? Come and get your electrical gifts!

Basic skills in PLC programming: Ladder diagrams and control circuits (includes 1164 practical cases of Mitsubishi PLC)

Still can’t understand electrical diagrams? Grab the basics of electrical diagram reading and simulation software, theory and practice quickly!

12 free electrical video courses, 10GB of software/e-book materials, and 30 days of free electrical live classes are available!