Human-Machine Interface connects programmable logic controllers (PLC), variable frequency drives, DC speed controllers, instruments, and other industrial control devices, using a display screen to show information, and through input units (such as touch screens, keyboards, mice, etc.) to write working parameters or input operation commands, realizing digital devices that enable information interaction between humans and machines, consisting of hardware and software.

The human-machine interface product consists of hardware and software: the hardware part includes processors, display units, input units, communication interfaces, data storage units, etc., where the performance of the processor determines the performance level of the HMI product,which is the core unit of HMI. HMI software is generally divided into two parts, namely the system software running on HMI hardware and the screen configuration software running on PC under Windows operating system (such as JB-HMI screen configuration software).

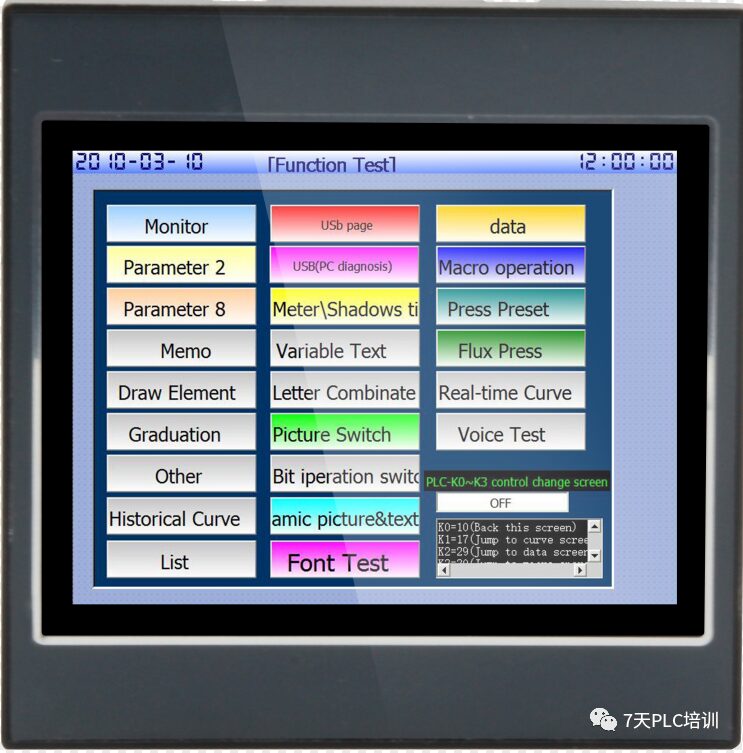

The basic functions of the human-machine interface include displaying the working status of the device, such as indicator lights, buttons, text, graphics, curves, etc.; data and text input operations, printing output; storing production formulas, recording equipment production data; simple logic and numerical calculations; connecting various industrial control devices in a network.

The selection indicators for human-machine interfaces include display screen size and color, resolution; the processing speed performance of the HMI; the input method of the human-machine interface, touch screen or membrane keyboard; screen storage capacity, noting whether the manufacturer’s marked capacity unit is in bytes (byte) or bits (bit); types and numbers of communication ports, whether printing functions are supported.

HMI with membrane keyboard input, display size less than 5.7 inches, with free screen configuration software, belongs to entry-level products. For example, POP-HMI small human-machine interface.

HMI with touch screen input, display size between 5.7 inches and 12.1 inches, with free screen configuration software, belongs to mid-level products.

High-performance HMI based on tablet PC, with multiple communication ports, display size greater than 10.4 inches, with paid screen configuration software, belongs to high-end products.

In a strict sense, there is an essential difference between the two.

The “touch screen” is merely a hardware component that may be used in human-machine interface products, serving as an input device installed in front of the display screen to replace some functions of the mouse and keyboard.

Human-machine interface products are devices that include both hardware and software for human-computer interaction. In industry, people often refer to human-machine interface products with touch input functionality as “touch screens,” but this is not scientifically accurate.

Human-Machine Interface includes HMI hardware and the corresponding dedicated screen configuration software. Generally, different manufacturers’ HMI hardware uses different screen configuration software, with PLC being the main type of connected device.

Configuration software is a general-purpose tool software product that runs on the PC hardware platform and Windows operating system. Together with a PC or industrial computer, it can also form an HMI product; general configuration software supports a wide variety of device types, such as various PLCs, PC boards, instruments, variable frequency drives, modules, etc., and due to the powerful performance of PC hardware platforms (mainly reflected in speed and storage capacity), the functionality of general configuration software is also much stronger, suitable for large monitoring systems.

Yes. Because general human-machine interface products provide a large number of commonly used device communication drivers for selection; generally, as long as the corresponding communication driver is selected in the screen configuration software of the human-machine interface, the communication connection between the HMI and the device can be completed.

The above are the 10 basic knowledge points about HMI. Have you learned them? If you want to know more about electricians, HMI, and PLC knowledge, you can scan the QR code below to join our group chat, where we have a lot of fun PLC programming, basic PLC knowledge, and electrical knowledge. Join us to happily learn PLC together!