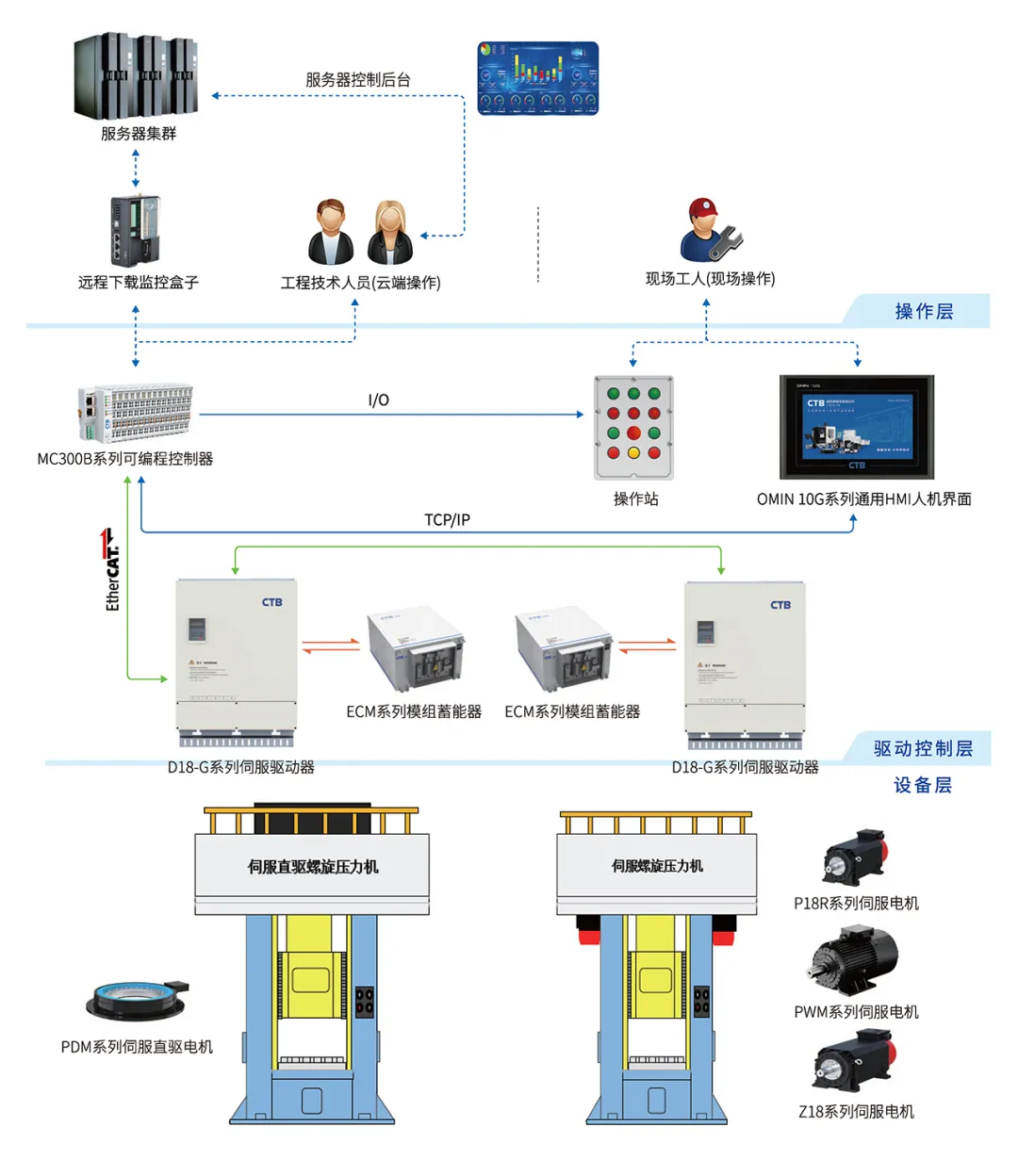

Servo Spiral Press Machine Control System,

Features a complete range of functions, simple operation, energy efficiency,

reduces labor costs, improves product quality,

adapts to changing process conditions,

and offers higher versatility, flexibility, and intelligence.

High Synchronization Provides Complete Servo Application Solutions

High Synchronization offers a full range of products including HMI human-machine interface, programmable controllers, servo drives, servo motors, direct drive motors, energy-saving modules, etc. It realizes a complete solution from control layer, drive layer, execution layer to energy management.

Since entering the spiral press machine industry in 2008, High Synchronization has been deeply engaged in research for over a decade, continuously iterating and updating products and control solutions through practical verification. With reliable product quality and advanced control solutions, it has achieved mass cooperation with major domestic manufacturers and leading enterprises. High Synchronization will continue to deepen industry applications, understand the development technologies at the forefront of the market, actively explore higher and better system solutions, and promote high-quality development of servo technology in the stamping industry.

Solution Features▲

-

Integrated solution provided, worry-free after-sales;

-

Industry-specific product development and design, continuously improving equipment performance while meeting extreme adverse environmental conditions;

-

Various combination solutions available including asynchronous servo, synchronous servo, high seismic resistance servo, direct drive servo;

-

Excellent multi-machine synchronization control solutions, with speed, torque, and current synchronization errors achieving industry-leading levels;

-

Rich experience in control and debugging of unmanned automated workshops;

-

The overall solution includes complete automated loading and unloading, hydraulic ejection, robotic loading and unloading, automatic conveying, and other peripheral automation functions, meeting users’ continuous upgrade needs;

-

More than ten years of industry experience with a complete protection mechanism;

-

Supports customized development.

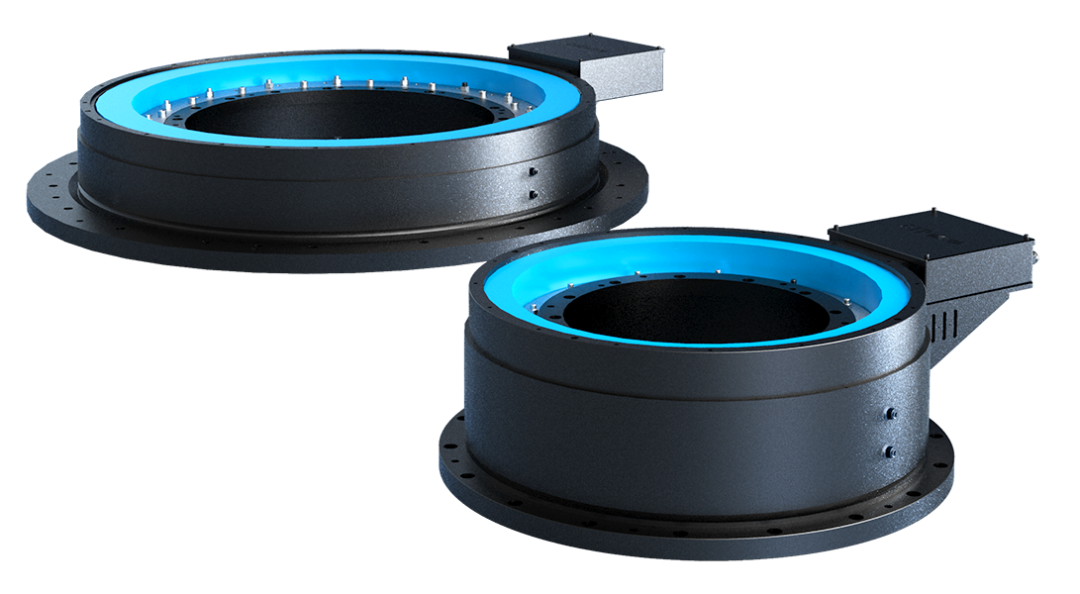

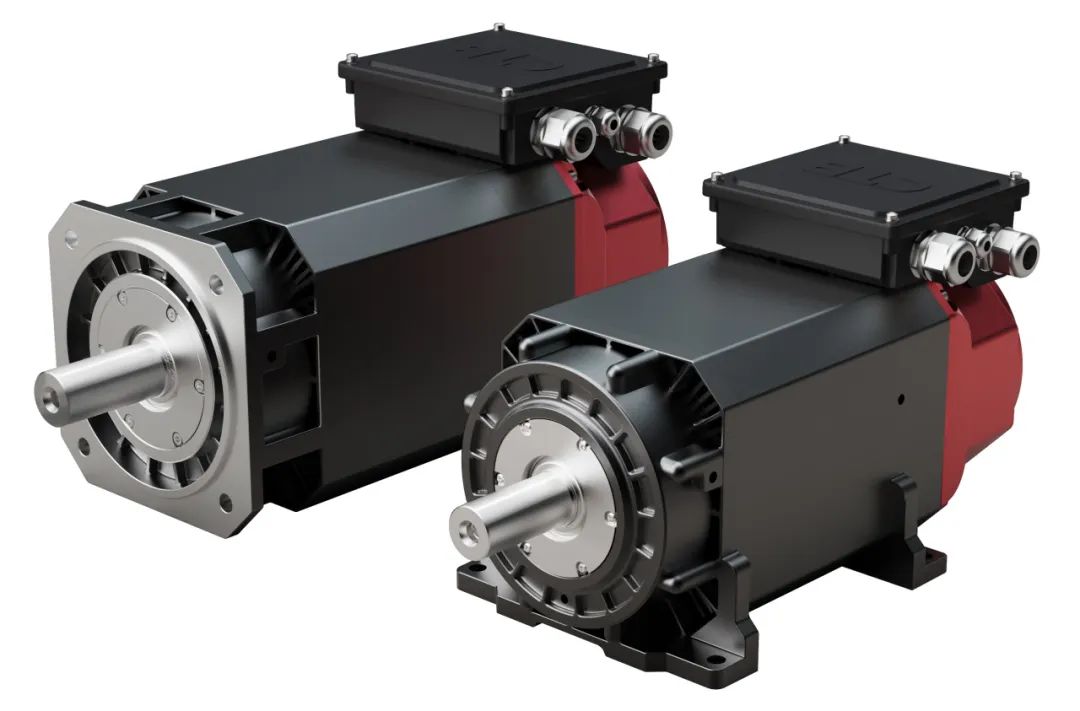

Special Direct Drive Motors for Spiral Press Machines PDM Series

|

◆ Equipment Tonnage |

400 ~ 1600 T (other specifications under development) |

|

◆ Cooling Method |

Water Cooling |

|

◆ Speed Detection |

High precision magnetic encoder, optional rotary transformer |

|

◆ Built-in motor parameter smart card, no debugging required |

|

|

◆ Supports customized development |

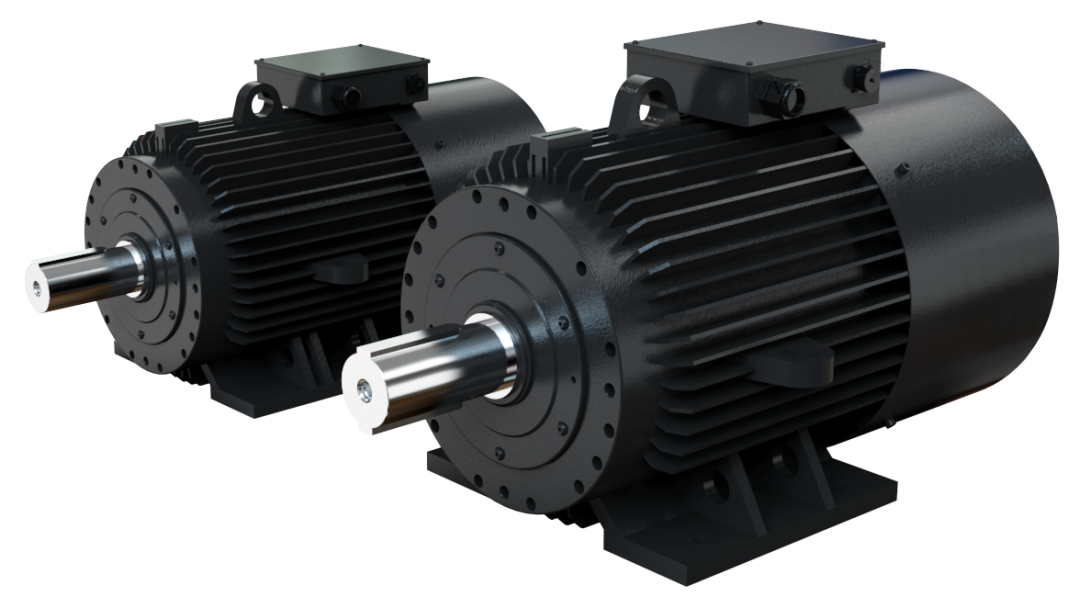

Permanent Magnet Synchronous Servo Motor P18R Series

|

◆ Power Range |

30 ~ 110 kW |

|

◆ Torque Range |

573 ~ 2101 N·m (rated torque) |

|

◆ Maximum Speed |

1000 r/min |

|

◆ Speed Detection |

Rotary transformer, bus-type high-precision encoder |

|

◆ Built-in motor parameter smart card, no debugging required |

|

|

◆ Integrated design of stator air duct, greatly improving overall heat dissipation efficiency |

|

|

◆ Embedded electromagnetic design and integrated design of foot, greatly enhancing overall rigidity, effectively addressing equipment vibration characteristics |

AC Permanent Magnet Synchronous Servo Motor PWM Series

|

◆ Power Range |

45 ~ 280 kW |

|

◆ Speed Range |

600 ~ 1500 r/min |

|

◆ Speed Detection |

High precision magnetic encoder, rotary transformer optional |

|

◆ Built-in motor parameter smart card, no debugging required |

|

|

◆ The machine adopts steel plate welded shell and other high seismic resistance designs, meeting the needs of the forging industry |

AC Asynchronous Servo Motor Z18 Series

|

◆ Power Range |

1.1 ~ 400 N·m |

|

◆ Rated Speed |

375 / 500 / 750 / 1000 / 1500 / 2000 / 3000 r/min |

|

◆ Speed Detection |

Magnetic encoder, incremental encoder, rotary transformer, sine-cosine encoder, absolute encoder optional |

|

◆ Built-in motor parameter smart card, no debugging required |

Servo Drives

|

☑ High Protection |

High protection level, suitable for various harsh conditions |

|

☑ High Performance |

Integrates position, speed, and torque control, drives the entire series of servo motors |

|

☑ High Overload |

Can achieve 2 times or more overload capacity |

|

☑ High Compatibility |

TTL, 1VPP, BISS-C, ENDATA2.2, SSI, RESOLVER, RS485 |

|

☑ Precise Control |

Enhances equipment processes, improves processing efficiency |

|

☑ Multiple Communication |

Supports ModbusTCP, EtherCAT, Profinet and other bus communications |

ECM Series Module Accumulator

|

☑ Input Voltage |

DC 350 ~ 800V |

|

☑ Product Specifications |

32mF, 72mF |

|

☑ Product Features |

Short charging time, long service life, good temperature characteristics |

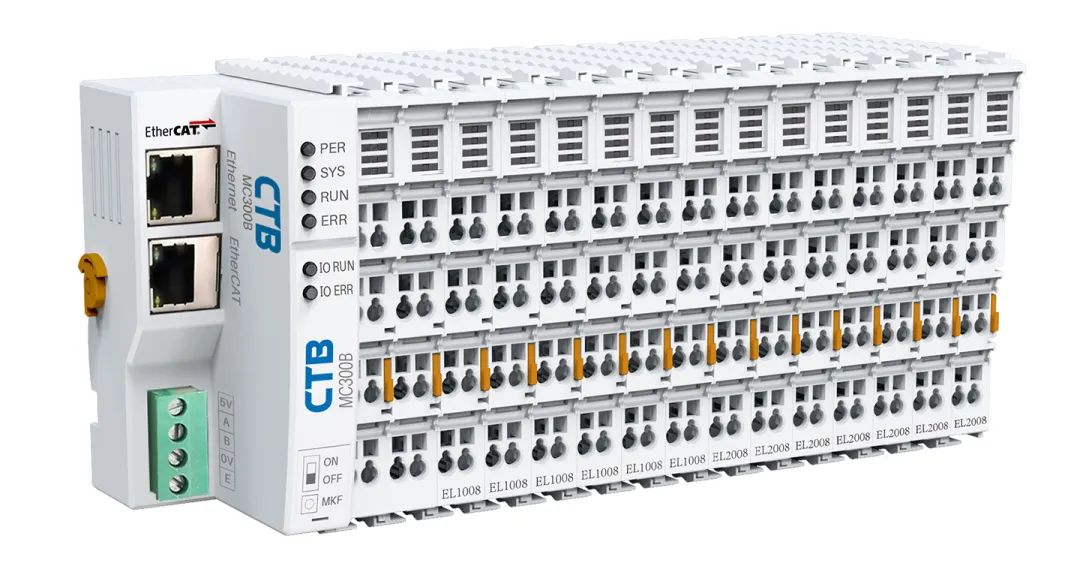

Programmable Controller

|

☑ Supports various types, compatible with EtherCAT bus and industrial Ethernet |

|

☑ Integrated motion control commands, can connect 20 axes of servo, 12 axes of electronic cam control synchronized with a cycle of 4ms |

|

☑ Programming environment: OpenPCS (compliant with IEC-61131-3) supports ST, SFC, LD, FBD, IL five programming languages |

|

☑ Maximum adaptable I/O module quantity: 32 (up to 32×8 I/O points) |

|

☑ Compact size, saves installation space |

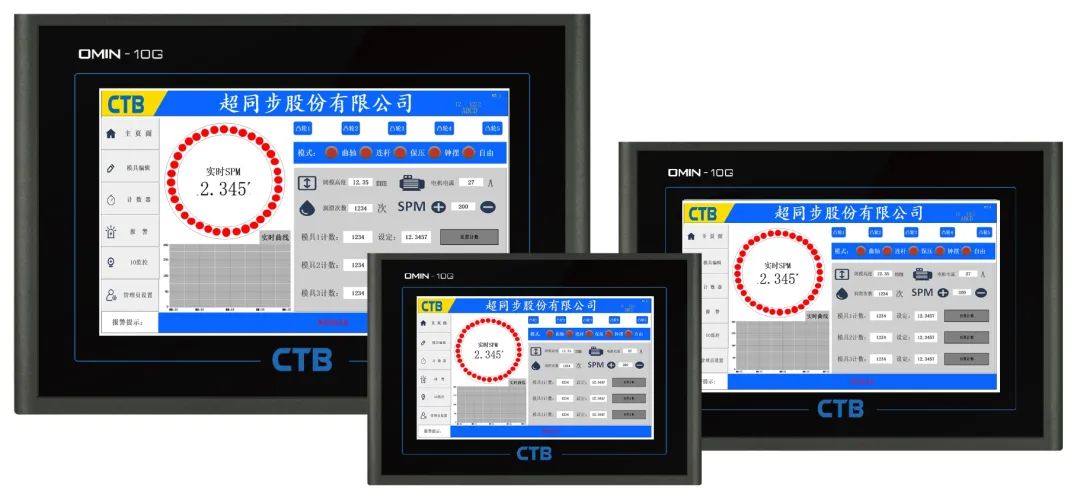

Integrated Display Control Machine

|

☑ PLC, touch display, view, motion control integrated, real-time display control |

|

☑ ARM quad-core 1G CPU, real-time Linux operating system, powerful performance |

|

☑ EtherCAT bus master, controls multiple slave devices |

|

☑ Supports multi-channel I/O control, small I/O scenarios do not require external I/O modules |

|

☑ DDR memory (2G), EMMC storage (8G), Gigabit Ethernet |

|

☑ Complete PC-side development software support |

High Response All-around Technical Service

Application Scenarios