Banner | Promotion

E-Paper is a paper-like display that is lightweight and portable, utilizing reflected ambient light for display, featuring unique readability in bright light, low visual fatigue, longer battery life, and lower power consumption for static images. It is considered an important product for future new types of displays. In flexible e-paper displays, thin film transistors (TFT) serve as the switching components for pixels, making their flexibility, stability, and electrical performance critical.

Recently, a team led by researcher Ning Honglong from South China University of Technology published a review article titled “Research Progress on Flexible Thin Film Transistors for E-Paper” in Liquid Crystal and Display (ESCI, Scopus indexed, core Chinese journal).

The article reviews the research progress of thin film transistors in flexible e-paper displays, focusing on the device’s flexibility, electrical characteristics, and stability. It concludes with a comparative analysis suggesting that MOTFT is likely to become the best candidate for driving the next generation of flexible e-paper displays due to its excellent electrical characteristics, high optical transparency, and relatively low processing temperature.

There are two main driving methods for display pixels: passive matrix (PM) and active matrix (AM). The former requires more complex peripheral designs, making flexibility difficult, while the latter has simpler peripherals and higher array performance, which is why flexible e-paper displays usually adopt active driving methods. In this driving method, thin film transistors (TFT) are crucial as the switching components for pixels.

Firstly, and most importantly, they must exhibit excellent flexibility, which requires avoiding high-temperature processes during fabrication to be compatible with flexible substrates. Secondly, the mechanical stress from bending and the electrical stress generated when updating content on the e-paper impose higher demands on the stability and durability of the TFT devices. Additionally, in the display driving array, TFTs should also possess excellent uniformity to ensure the display operates normally. For reflective e-paper displays, the opaque parts of the light path, such as the TFT structure, can adversely affect the final display effect; therefore, the optical transparency of TFTs is also very important.

The article focuses on the flexibility, performance uniformity, and other characteristics of the devices, detailing the research progress of TFT applications in e-paper displays, providing reference directions for the development of the next generation of high-performance flexible e-paper displays.

2. Flexible TFTs in E-Paper

The main types of TFTs applied in e-paper displays can be classified into three categories based on the active layer material: organic thin film transistors (OTFT), amorphous silicon thin film transistors (a-Si TFT), and metal oxide thin film transistors (MOTFT).

Organic thin film transistors typically have a mobility of 0.1~10 cm²·V⁻¹·s⁻¹, with higher manufacturing costs and complexity, and a processing temperature ranging from room temperature to 250 ℃; amorphous silicon thin film transistors generally have a mobility of 0.5~1 cm²·V⁻¹·s⁻¹, with lower manufacturing costs and complexity, but a higher processing temperature of 250~350 ℃; metal oxide thin film transistors can achieve mobilities as high as 10~100 cm²·V⁻¹·s⁻¹, with low complexity and a processing temperature of room temperature to 350 ℃.

2.1 OTFT Applications in E-Paper Displays

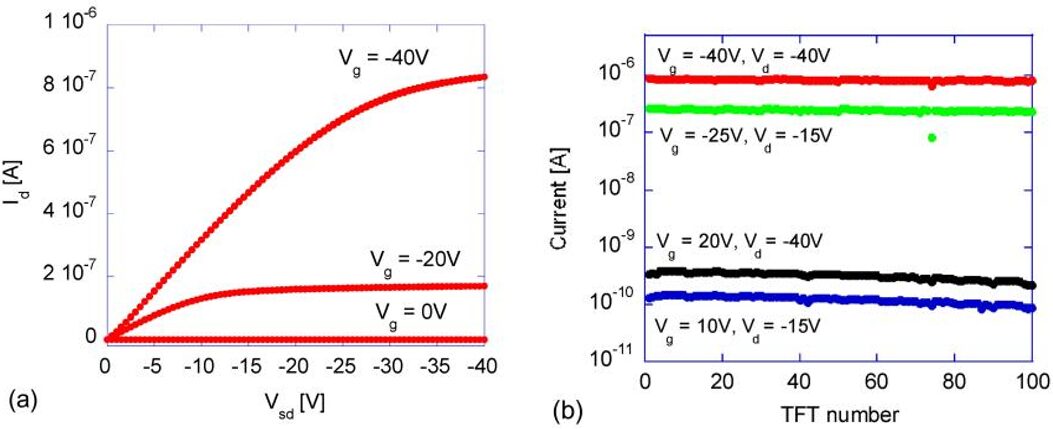

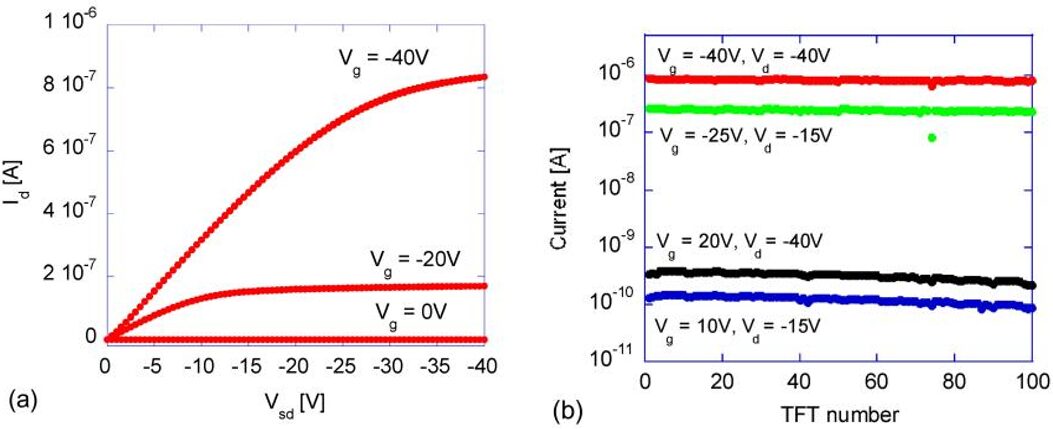

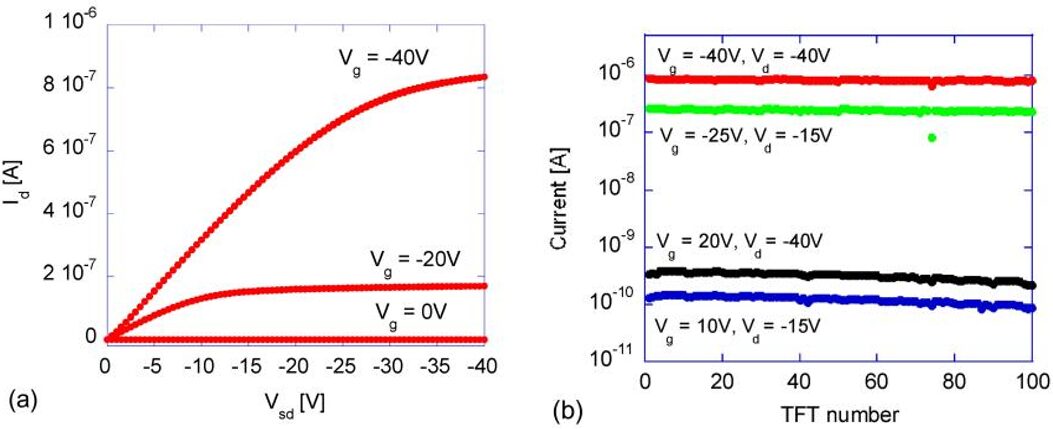

In 2006, Burns et al. fabricated an OTFT active driving backplane using polyfluorene polymer semiconductor as the active layer on a 125μm thick polyethylene terephthalate (PET) substrate, and laminated an electronic ink imaging film to create an e-paper display. The OTFT device had a mobility of 0.03 cm²·V⁻¹·s⁻¹, with a switching current ratio of 10⁵ ~10⁶, and the output characteristics are shown in Figure 1 (a). In an array containing 4800 devices, 100 TFTs were tested for variations in switching current ratio, achieving a pixel yield greater than 99%, with variations in switching current ratio less than 10%, indicating good uniformity (as shown in Figure 1 (b)).

Figure 1: TFT Performance: (a) Output characteristics of TFT on PET (L=10µm, W=240µm); (b) Uniformity of switching current of 100 TFTs in a 60×80 active matrix array.

Source: Liquid Crystal and Display, 2022, 37(8): 948-958. Fig.2

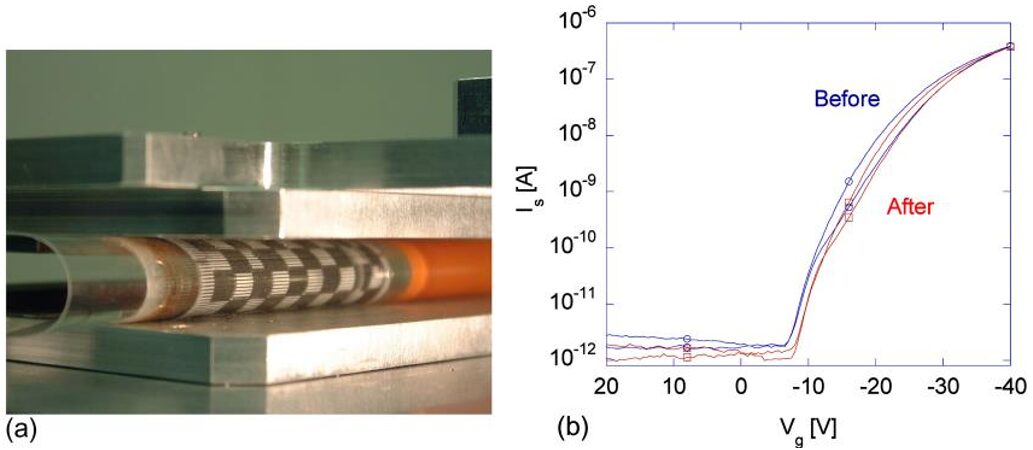

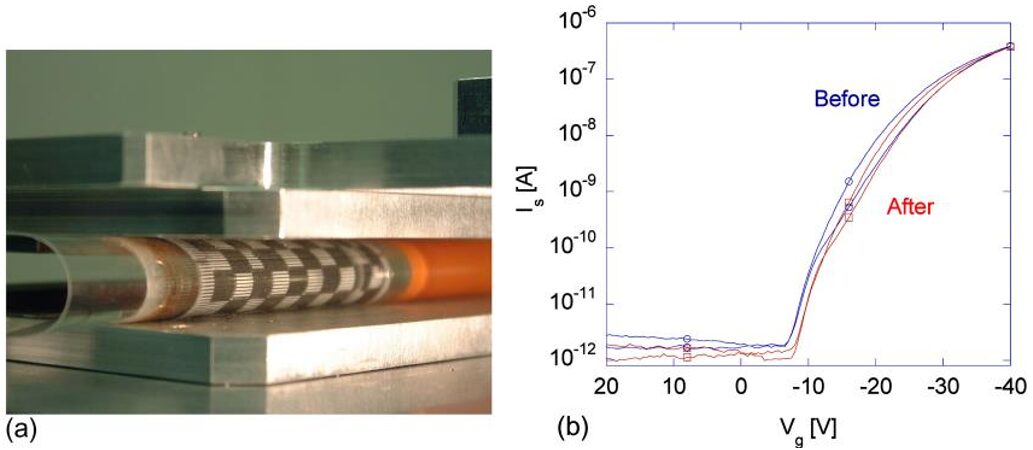

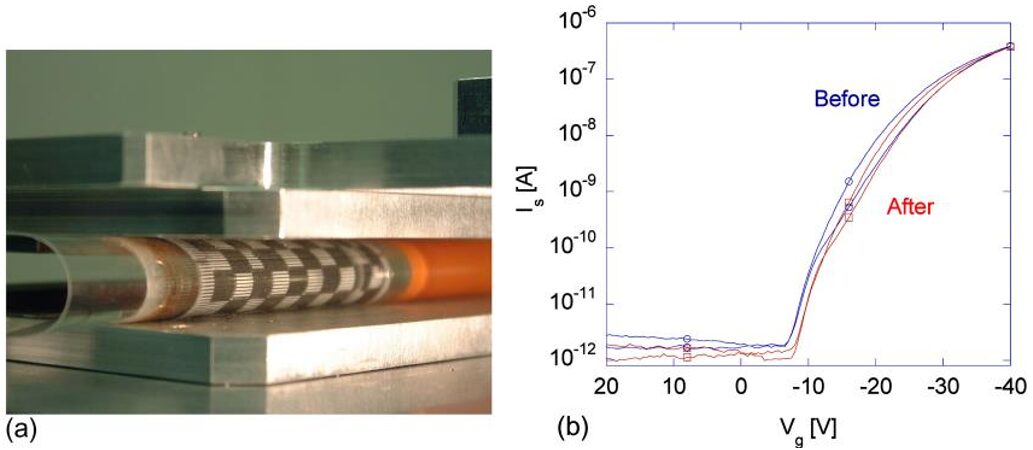

Flexible e-paper displays can be bent to a curvature radius of 5 mm (as shown in Figure 2) without significantly degrading device performance, and after 30 million pulse tests (equivalent to 500,000 refreshes in a 600-row e-paper display), the devices still showed no significant performance degradation.

Figure 2: (a) Photo of the flexible display operating when bent to a curvature radius of 5 mm; (b) Performance of the TFT before and after bending to a curvature radius of 5 mm.

Source: Liquid Crystal and Display, 2022, 37(8): 948-958. Fig.3

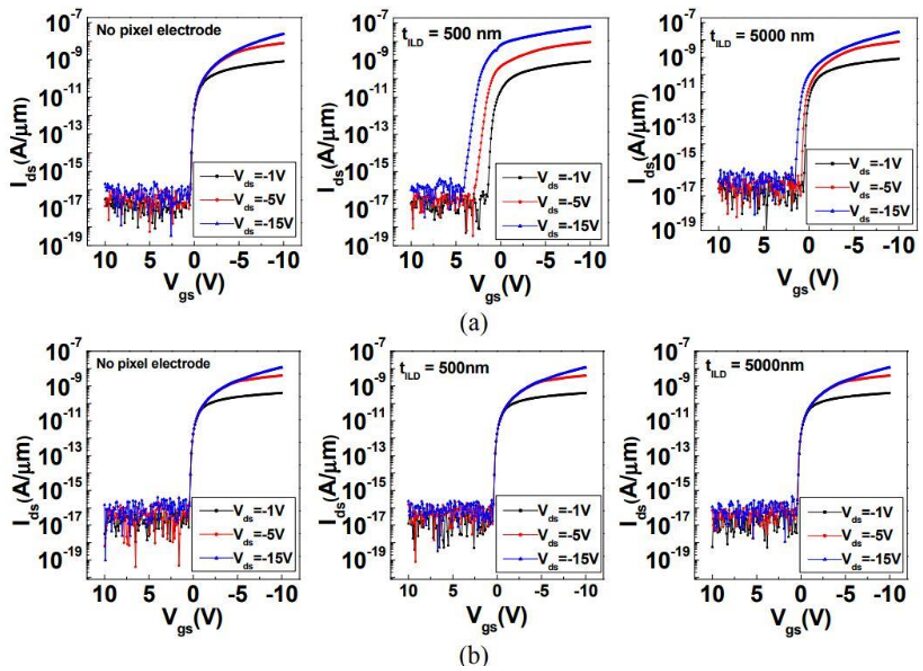

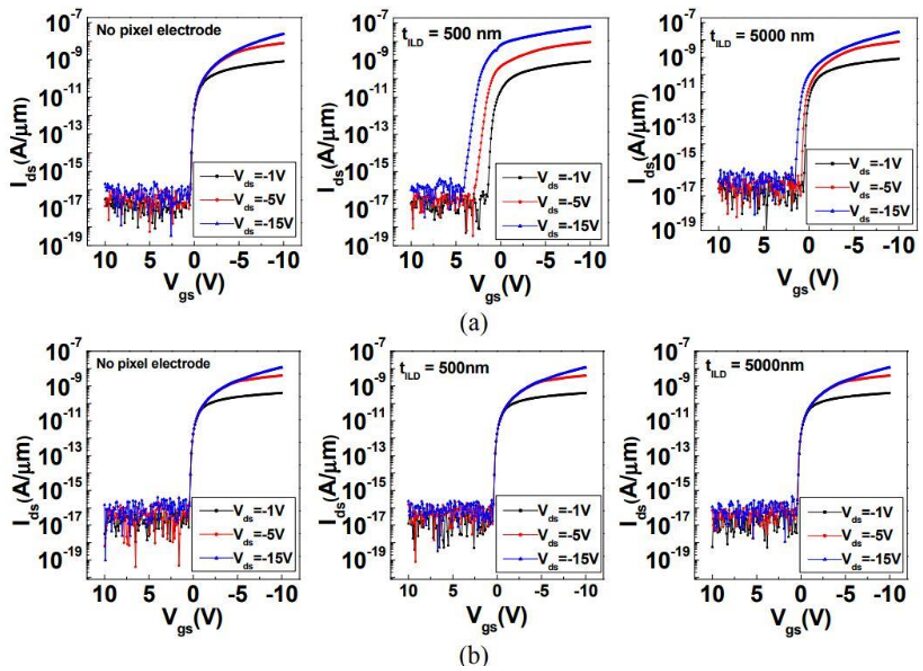

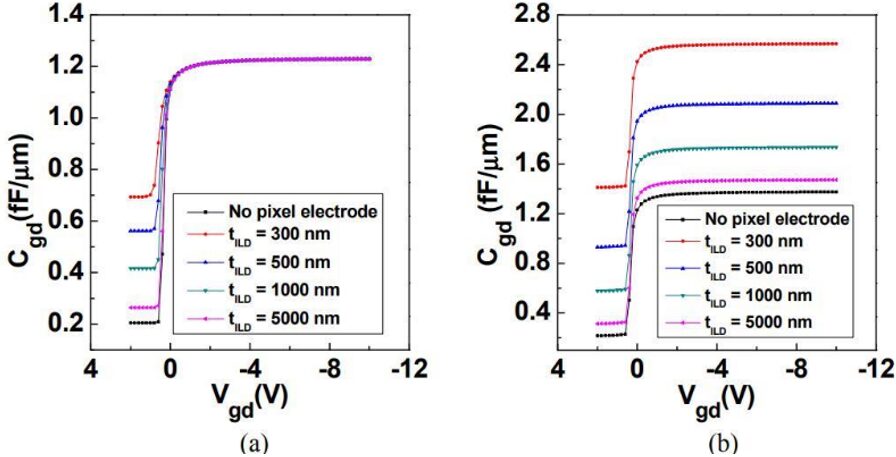

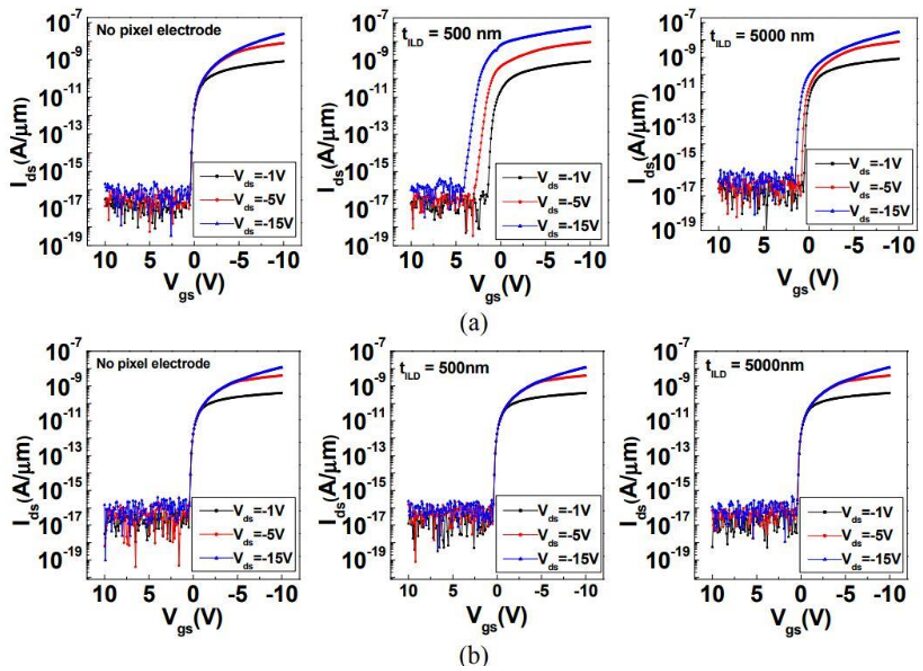

In 2011, Feng et al. compared the performance of two structures of OTFT: Bottom-contact top-gate (BCTG) and Bottom-contact bottom-gate (BCBG). By varying the thickness of the interlayer dielectric (ILD) between the pixel electrode and OTFT, they plotted the simulated transfer characteristics of the two structures (as shown in Figure 3). It can be seen that the presence of the pixel electrode in BCBG OTFT causes the transfer characteristic curve to shift positively with increasing drain bias, and the extent of the shift decreases with increasing thickness of ILD; while the transfer characteristics of BCTG OTFT are unaffected by the pixel electrode, thanks to the top-gate structure’s electric shielding effect on the channel.

Figure 3: (a) Simulated transfer characteristics of OTFT in BCBG structure and (b) BCTG structure.

Source: Liquid Crystal and Display, 2022, 37(8): 948-958. Fig.6

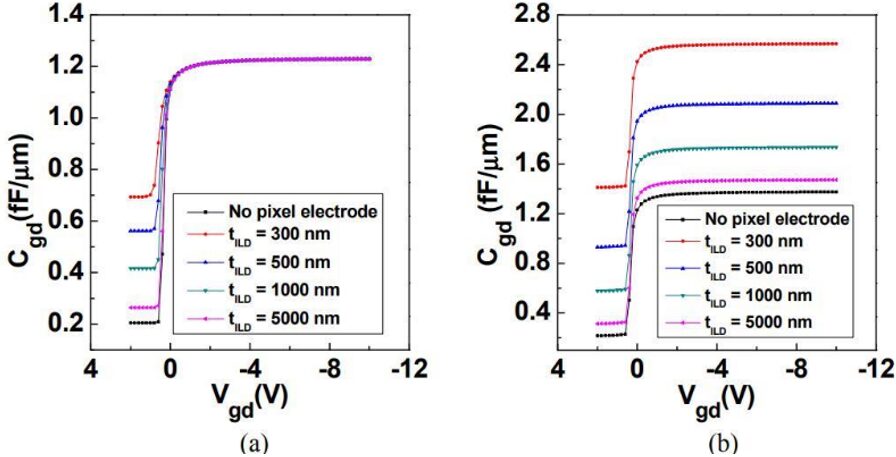

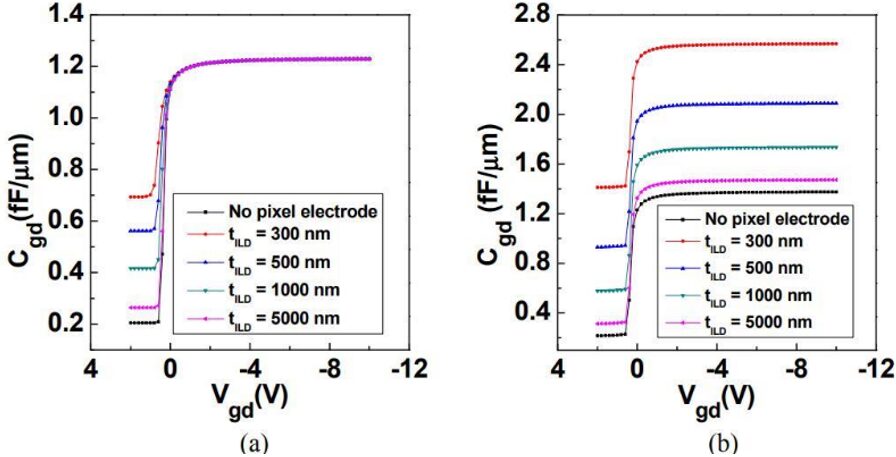

The parasitic capacitance Cgd in the BCBG structure is overall smaller than that in the BCTG structure due to the additional capacitance formed between the pixel electrode and gate electrode in the latter, which can be reduced by increasing the thickness of ILD, as shown in Figure 4.

Figure 4: Simulated gate-drain parasitic capacitance (Cgd) as a function of Vgd: (a) BCBG structure; (b) BCTG structure.

Source: Liquid Crystal and Display, 2022, 37(8): 948-958. Fig.7

Therefore, when using OTFT as the switch for e-paper displays, it is necessary to implement responsive improvements for different structures: BCTG OTFT should design a thicker ILD layer to alleviate the larger parasitic capacitance Cgd, without considering the interference of the pixel electrode; while for BCBG OTFT, Cgd is much smaller, but a wider gate voltage swing is needed in the design to compensate for the shift in transfer characteristics. Organic semiconductors, with their inherent flexibility and lower deposition temperatures, provide a pathway for the manufacturing of flexible active driving backplanes.

2.2 a-Si TFT Applications in E-Paper Displays

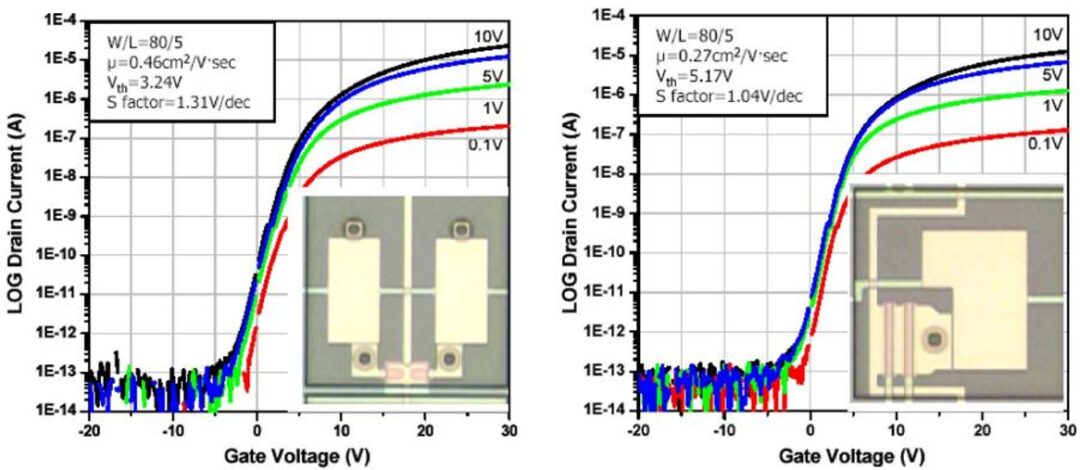

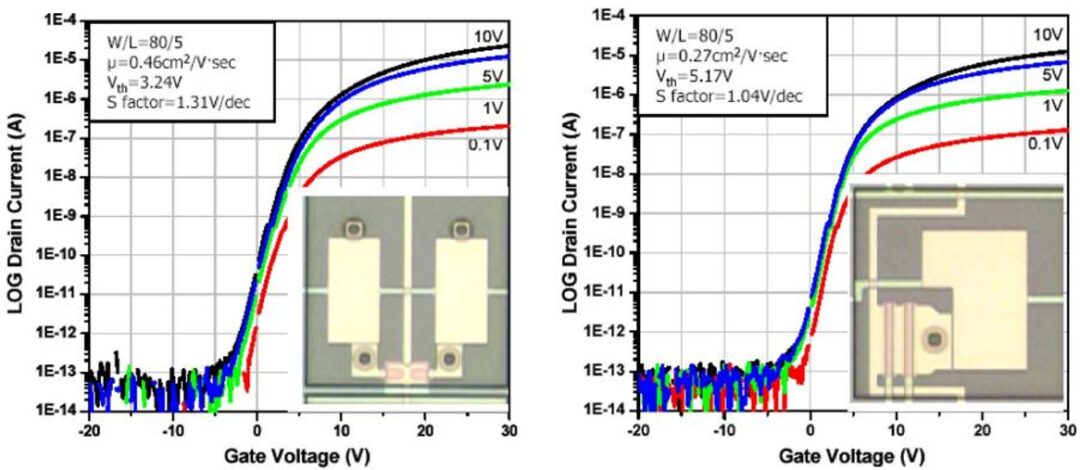

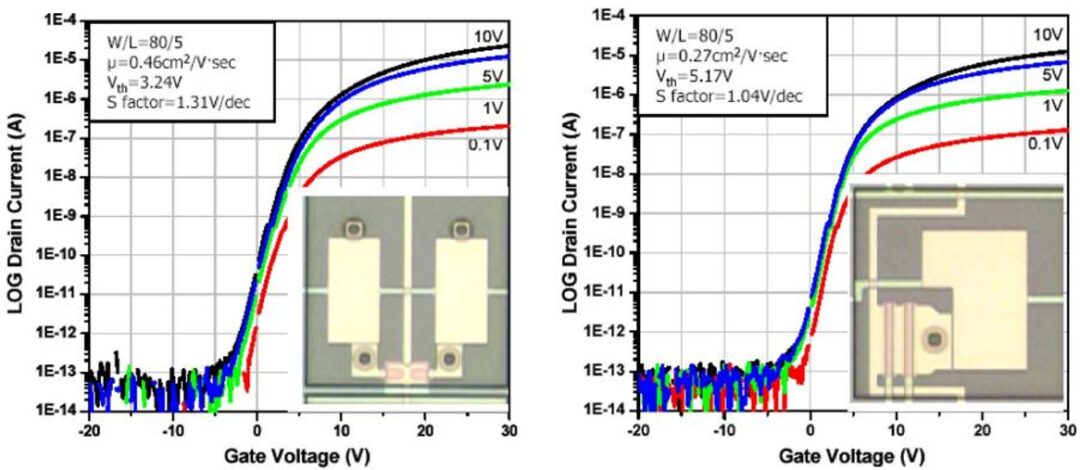

The research group led by Kim has made significant contributions to the study of a-Si TFT e-paper displays. In 2007, they developed a 14-inch flexible color e-paper using a-Si TFT, achieving a true paper-like appearance, excellent flexibility, wide viewing angles, and high contrast. Three years later, based on previous research, they compared the performance of two novel structures of TFT: U-type double TFT and double gate TFT, with results shown in Figure 5. The U-type double TFT exhibited higher mobility and current switching ratios, while the double gate TFT performed better in sub-threshold swing (s-factor) and off-state current characteristics. The asymmetric structure of the U-type double TFT reduced the parasitic capacitance between the TFT gate and source, enhancing device charging rates and voltage retention. They developed a-Si:H TFT backplanes with this structure at low processing temperatures below 150℃, producing flexible color e-paper displays that are as thin as paper and extremely low power consumption, extending the panel size to 14.3 inches.

Figure 5: Transfer curves of U-type double TFT (left) and double gate TFT (right) on metal foil.

Source: Liquid Crystal and Display, 2022, 37(8): 948-958. Fig.8

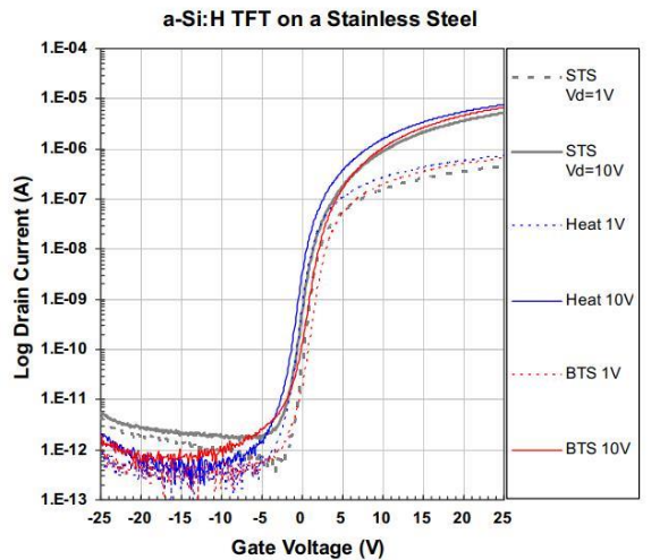

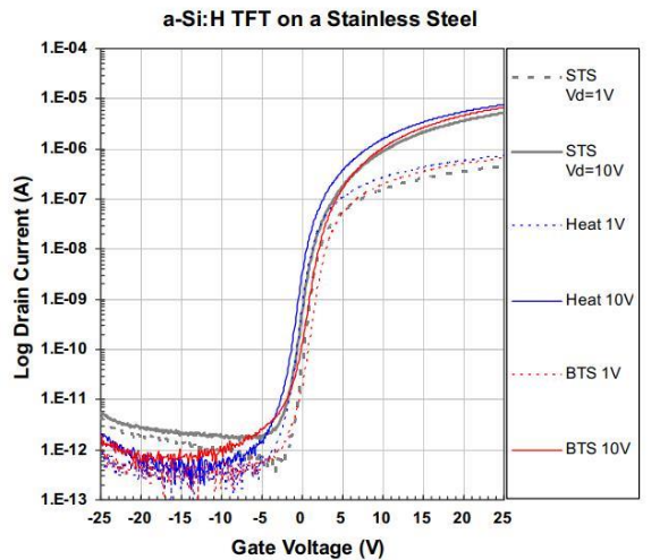

They also continued using the U-type double TFT structure to successfully manufacture larger size (approximately 19 inches) a-Si TFT flexible e-paper displays on stainless steel substrates using a “single board process,” employing GIP (Gate in Panel) technology during manufacturing to reduce the number of driver chips required for the TFT while enhancing the flexibility of the display module. The resulting device had a mobility of 0.35 cm²·V⁻¹·s⁻¹, with a sub-threshold swing of 0.69 V/dec, and the transfer characteristics are shown in Figure 6. However, due to the poor stability of a-Si TFT manufactured below 200℃ under bias temperature stress, the processing temperature had to be increased to 250℃ to achieve reliable TFT backplanes.

Figure 5: Transfer curves of U-type double TFT (left) and double gate TFT (right) on metal foil.

Source: Liquid Crystal and Display, 2022, 37(8): 948-958. Fig.8

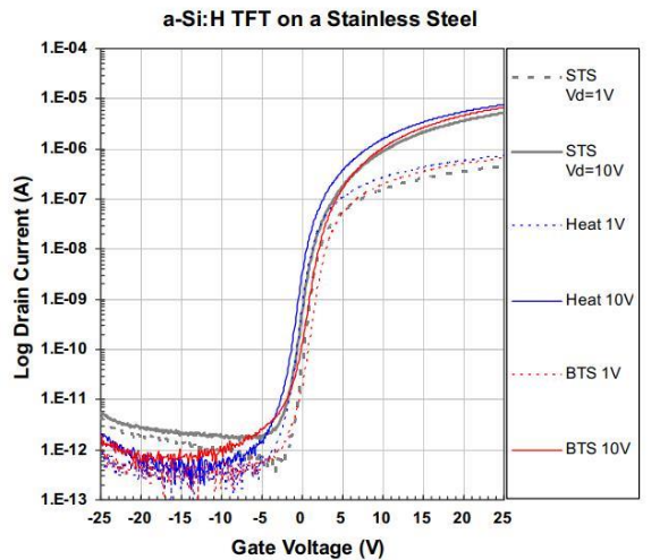

They also continued using the U-type double TFT structure to successfully manufacture larger size (approximately 19 inches) a-Si TFT flexible e-paper displays on stainless steel substrates using a “single board process,” employing GIP (Gate in Panel) technology during manufacturing to reduce the number of driver chips required for the TFT while enhancing the flexibility of the display module. The resulting device had a mobility of 0.35 cm²·V⁻¹·s⁻¹, with a sub-threshold swing of 0.69 V/dec, and the transfer characteristics are shown in Figure 6. However, due to the poor stability of a-Si TFT manufactured below 200℃ under bias temperature stress, the processing temperature had to be increased to 250℃ to achieve reliable TFT backplanes.

Figure 6: Initial (gray curve), thermal treatment (blue curve), and bias-temperature stress (red curve) characteristics of a-Si:H TFT prepared on a stainless steel substrate at 250℃.

Source: Liquid Crystal and Display, 2022, 37(8): 948-958. Fig.9

The application of a-Si TFT in e-paper remains limited by low mobility and processing temperatures.

2.3 MOTFT Applications in E-Paper Displays

Compared to traditional a-Si TFTs, MOTFTs generally have an order of magnitude higher mobility, significantly smaller sub-threshold voltage swings, and better stability under electrical bias. For flexible plastic substrates, satisfactory performance can be achieved even when manufacturing MOTFTs at room temperature, while a-Si often requires elevated processing temperatures to improve device performance metrics. Amorphous oxide semiconductors possess unique transparency, allowing MOTFTs to effectively reduce light blocking and mirror reflection, ensuring the reflectivity of e-paper displays.

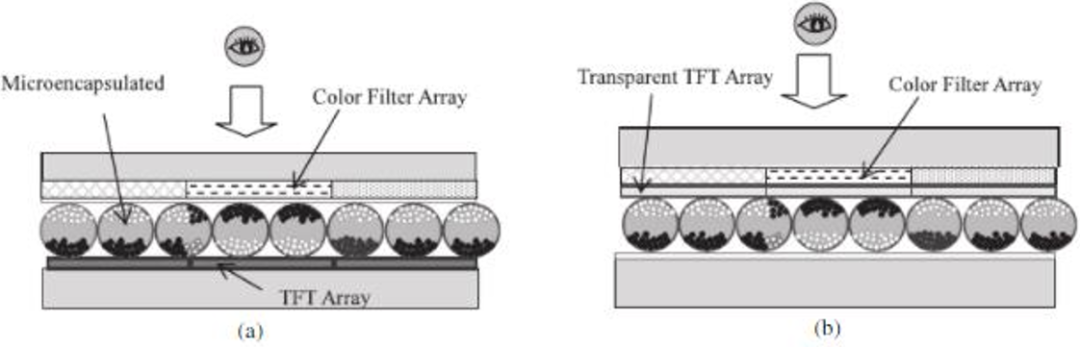

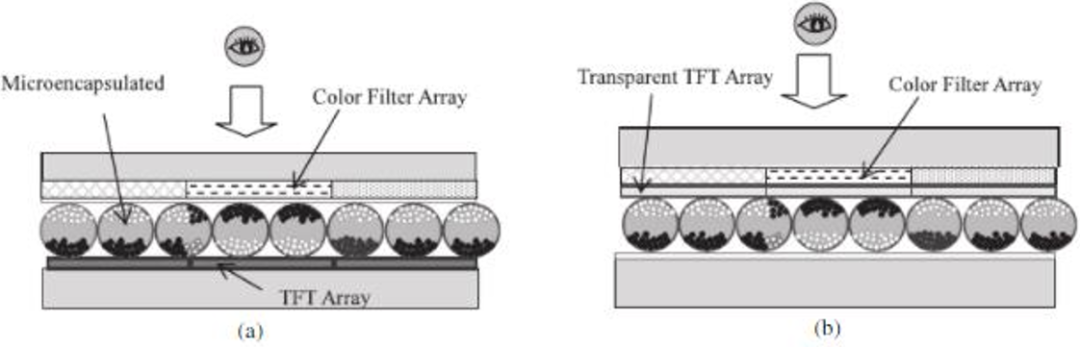

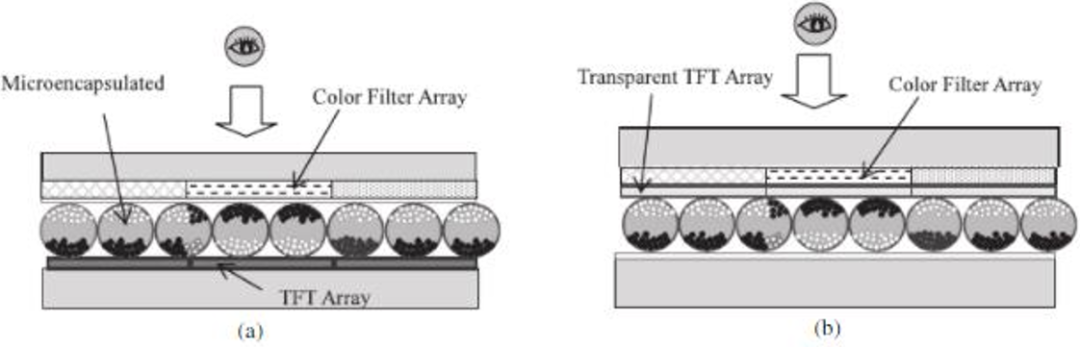

In 2006, Toppan Printing developed a full-color e-paper using a novel “front-driven” structure (as shown in Figure 7), where the filter array and TFT array were integrated in the front plane using the high transparency of a-IGZO TFT, greatly facilitating the alignment of the filter and TFT.

Figure 7: (a) Structure of traditional color e-paper, (b) novel “front-driven” structure.

Source: Liquid Crystal and Display, 2022, 37(8): 948-958. Fig.11

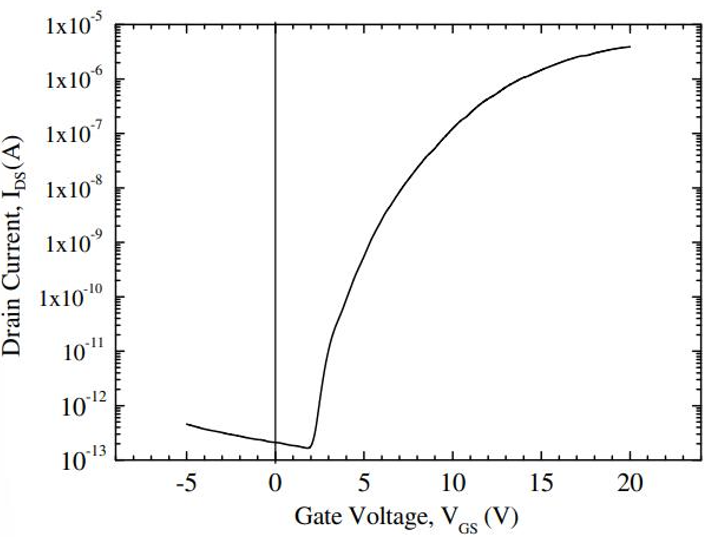

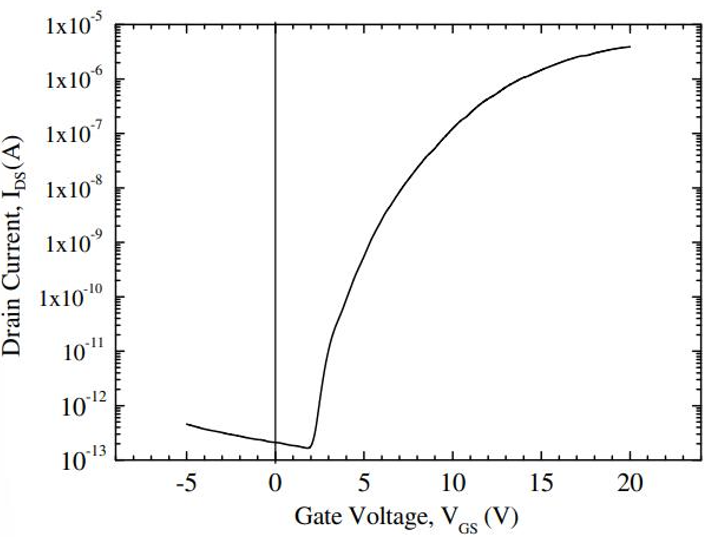

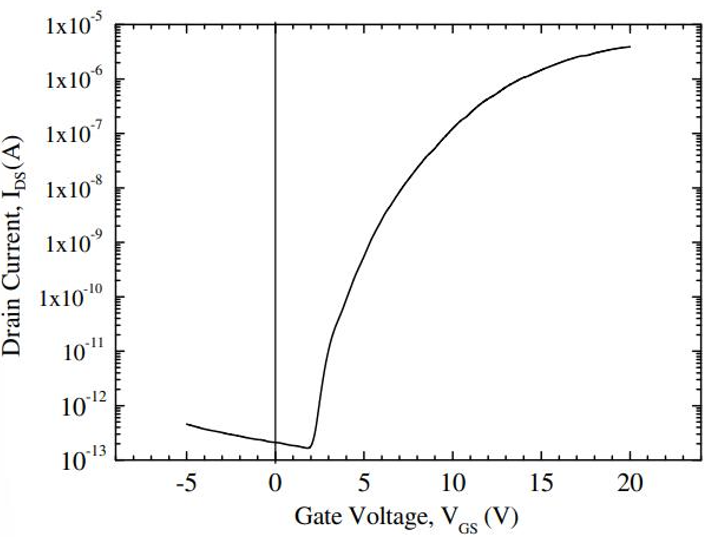

In 2008, they continued with the front-driven structure to explore the feasibility of using amorphous oxide TFTs to create higher resolution e-paper displays, increasing the resolution from the original 120×160 to 640×480. The annealing temperature for a-IGZO TFT was slightly reduced from the original 200℃ to 180℃, and all layers were fabricated at room temperature, achieving a high switching ratio exceeding 10⁷ and a field effect mobility of 2.8 cm²·V⁻¹·s⁻¹ (as shown in Figure 8).

Figure 8: Transfer characteristics of a-IGZO TFT.

Source: Liquid Crystal and Display, 2022, 37(8): 948-958. Fig.13

In 2011, Kaftanoglu et al. developed an indium zinc oxide (IZO) TFT driver backplane for e-paper applications at low temperatures (200℃). The device had a saturation mobility of 14.2 cm²·V⁻¹·s⁻¹, with a sub-threshold swing of 0.22 V/dec and a switching ratio greater than 10⁹. After 10,000 seconds of DC stress, the threshold voltage change was within 2.5V, and the saturation current change was about 19%; while for a-Si:H TFT, the changes were as high as 10V, with saturation current changes of 71%. These results indicate that IZO TFT devices have better voltage stress stability. In 2015, Fukada et al. successfully fabricated a fully screen-printed IZO TFT backplane for low-cost large-area production of oxide TFT driver backplanes.

Considering the low-cost manufacturing of e-paper, ZnO is also a good choice for e-paper display backplanes. In 2010, Lee et al. demonstrated a color ZnO-TFT e-paper display with a backplane transmittance of about 80%, device mobility of 4.6 cm²·V⁻¹·s⁻¹, a sub-threshold swing of 0.23 V/dec, an off-state current of less than 10⁻¹³A, and a switching current ratio of about 10⁸.

3. Outlook

Despite the excellent flexibility of organic thin film transistors, mass production has not yet been achieved, making it difficult to apply them in flexible e-paper displays; a-Si thin film transistors are cost-effective, but their low mobility limits their application in high-performance flexible e-paper; in contrast, metal oxide thin film transistors have advantages such as transparency, high mobility, and mass production, meeting the requirements for the development of high-performance flexible e-paper displays.

For organic TFTs and a-Si TFTs to have further applications in future e-paper displays, efforts should focus on improving the device field effect rate and switching ratios to meet the demands for higher refresh rates and resolutions in e-paper displays. Meanwhile, the performance of metal oxide TFTs is easily affected by environmental factors such as water and oxygen, and future efforts should focus on developing methods to enhance device stability. The presence of oxygen vacancies tends to make oxide semiconductors n-type donor defect doped, making it challenging to achieve p-type conductive characteristics. The development of p-type oxide TFTs will promote complementary technology between n-type and p-type devices, which is significant for realizing low-power driving circuits for e-paper.

We believe that as more and more researchers invest in in-depth studies of thin film transistors for flexible e-paper displays, both the preparation methods and device performance will see further improvements in the near future. We also believe that high-performance metal oxide thin film transistors have the potential to become the best choice for the fabrication of large-area, low-cost, low-power e-paper display driver backplanes.

Paper Information

Gao Zhiwen, Xu Wei, Yao Rihui, Wei Xiaoqin, Zhong Jinyao, Yang Yuexin, Fu Xiao, Liu Taijiang, Ning Honglong, Peng Junbiao. Research Progress on Flexible Thin Film Transistors for E-Paper [J]. Liquid Crystal and Display, 2022, 37(8): 948-958.

https://cjlcd.lightpublishing.cn/thesisDetails#10.37188/CJLCD.2022-0102

Corresponding Author Profile

Ning Honglong, Ph.D., Professor, graduated with a bachelor’s and master’s degree from Central South University in 1993 and 1999, respectively, and obtained a doctorate from Tsinghua University in 2004. He has long been engaged in research on active information new display thin film transistor array materials and structures. He has served as the chief scientist at Samsung Display in South Korea, a member of the patent review expert group for Samsung Display, and a certified green belt mentor for Samsung’s Six Sigma system; he returned to China in 2013 to join the State Key Laboratory of Light Materials and Devices at South China University of Technology, focusing on the development of new display materials, TFT unit and array structure design, preparation of flexible display devices, printing display devices, and optimization of information display device performance; he has won the first prize of Guangdong Province Science and Technology Invention Award in 2017 and the second prize of Guangdong Province Science and Technology Progress Award in 2021. He has led multiple national and provincial projects, including the National Key R&D Program, the National Natural Science Foundation projects, and major scientific research projects in Guangdong Province. He has published over 200 papers and applied for over 200 patents, of which more than 100 have been granted; he serves as a reviewer for academic journals such as ACS Appl. Mat. Interfaces, J. Mater. Chem. C, Ceram Int., IEEE Electr Device L, IEEE T Electron Dev, Soc. Inf. Display, Journal of Luminescence, and Materials Reports, and is an editorial member of Liquid Crystal and Display and Digital Printing.

Welcome to submit promotional articles to the research group

Please scan the QR code to contact the duty editor

Click here 👇 to follow me