Click the blue text to follow us

Magnetically driven soft microrobots have great potential in biomedical fields such as targeted drug delivery and minimally invasive surgery due to their high controllability, biocompatibility, and remote control advantages. However, traditional magnetic robots rely on high-intensity magnetic fields (usually requiring hundreds of milliteslas), which are not only costly but can also cause thermal damage to tissues and neural interference. Existing technologies struggle to balance mechanical stability and rapid response capabilities under 3–15 mT low field strengths, severely limiting their clinical practicality.

In response, Professor Cong Huaiping from Hefei University of Technology, Associate Professor Qin Haili, and Professor Yu Shuhong from the University of Science and Technology of China have developed a composite ink based on single-domain NdFeB (SD-NdFeB) nanoparticles, using magnetic field-assisted 3D printing technology to create soft microrobots capable of completing complex deformations within 1 second. The core innovations include: 1) ultra-low magnetic powder content (<2 wt.%), with a response magnetic field strength as low as 3 mT; 2) mechanical toughness increased by 10 times, with a tensile rate of up to 1600%; 3) support for multimodal movement (turning, rolling, climbing, etc.) and execution of tasks in biological environments.

On June 23, 2025, the related work titled “Robust and Fast-Transforming Soft Microrobots Driven by Low Magnetic Field” was published in Advanced Materials.

On June 23, 2025, the related work titled “Robust and Fast-Transforming Soft Microrobots Driven by Low Magnetic Field” was published in Advanced Materials.

Figure and text introduction

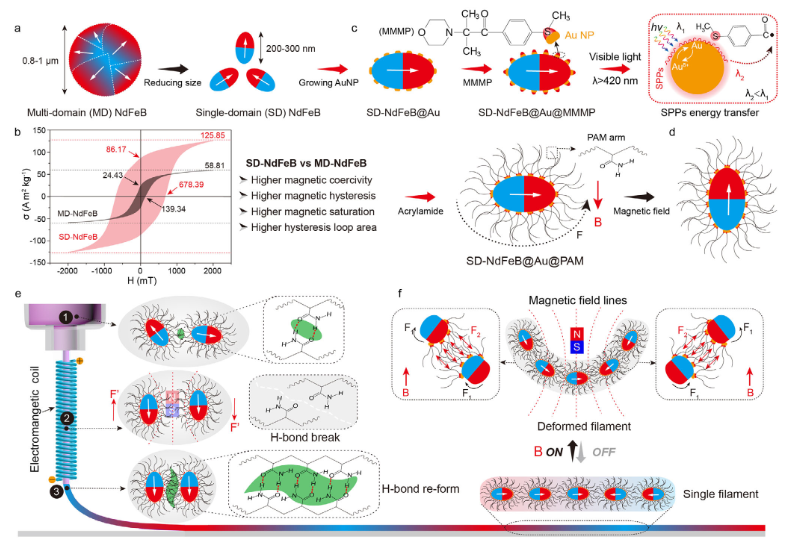

Innovation in Magnetic Domain Design

The team replaced traditional multi-domain materials with single-domain NdFeB particles (200–300 nm), whose high coercivity (678 mT) and saturation magnetization (125 A·m²/kg) ensure a strong magnetic response under weak fields. After modifying the surface with gold nanoparticles, polyacrylamide (PAM) chains were grafted to form a core-shell structure, where the synergy between magnetic force (F₁) and polymer crosslinking force (F₂) achieved efficient deformation drive.

Figure 1. Design of SD-NdFeB@Au@PAM magnetic colloid for magnetically driven microrobots.

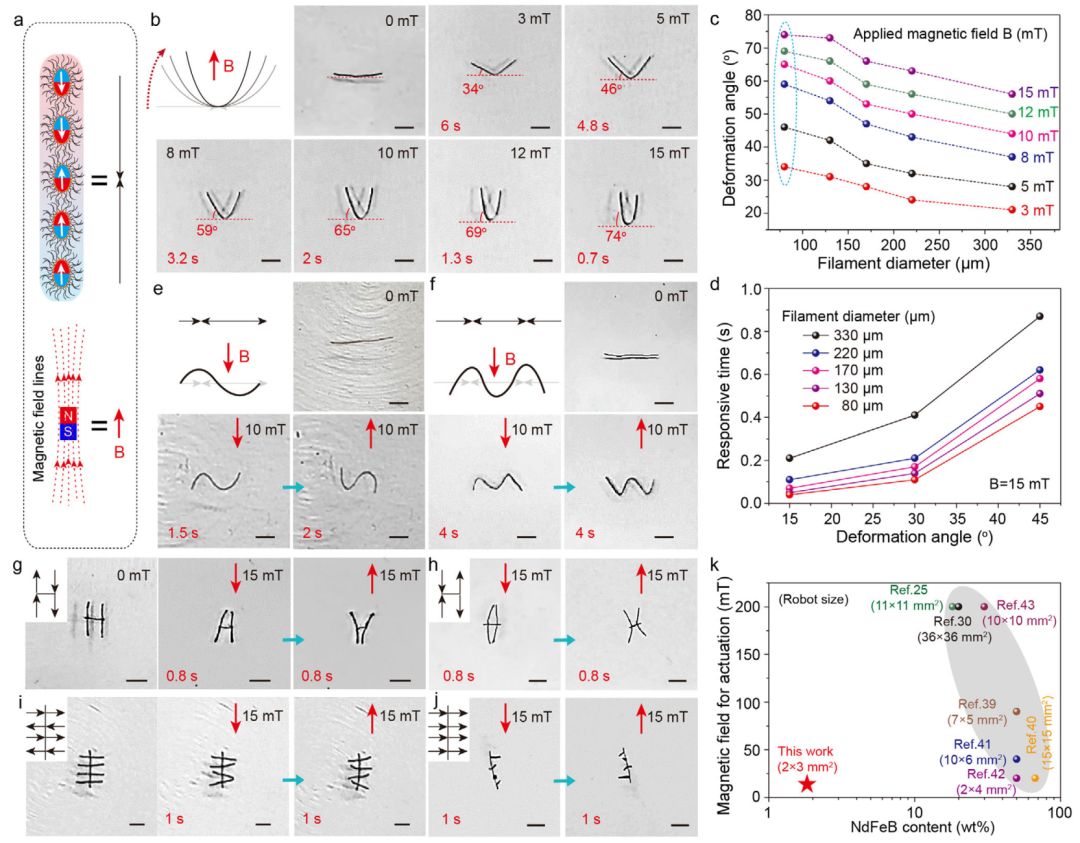

Ink Performance and Printing Optimization

The gel ink based on reversible hydrogen bonding (Figure 2a) exhibits shear-thinning properties, supporting the printing of ultra-fine filaments of 80 μm (Figure 2d). The magnetic moment density reaches 220 kA·m⁻¹ at 10 mT, with magnetic dipole interactions contributing 90% of the toughness (28.33 MJ·m⁻³), allowing the filaments to lift weights of 100 grams (Figure 2e-g).

Figure 2. Characterization and printing of SD-NdFeB@Au@PAM.

Programmable Motion Control

By programming the magnetic field direction, 80 μm filaments bend 15° within 0.04 seconds under 15 mT and complete U-shaped deformations (Figure 3b-d). H-shaped and multi-legged robots achieve precise turning, rolling, and vertical movement (Figure 3g-j), with their magnetic powder content only 1/10–1/30 of the literature values (Figure 3k).

Figure 3. Ultra-fine filaments with fast and programmable behaviors.

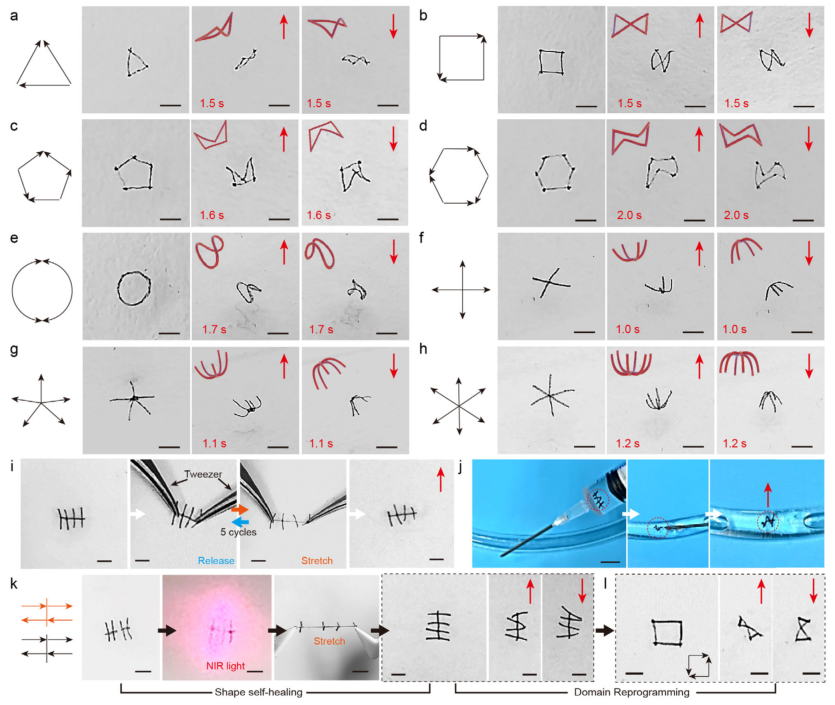

Complex 3D Deformation and Self-Healing Ability

Structures such as triangular and six-armed grippers fold within 1 second under a field strength of 15 mT (Figure 4a-h). The robots withstand subcutaneous injection compression (Figure 4j) and achieve near-infrared light damage repair within 1 minute through the photothermal effect of gold nanoparticles (Figure 4k), while the magnetic domain reconstruction function supports material reuse (Figure 4l).

Figure 4. Elastic microrobots with complex 3D shape changes and sustainable behaviors. Schematic diagrams and optical images show various skeletal structures printed from SD-NdFeB@Au@PAM and the corresponding experimental results of deformation under alternating magnetic directions.

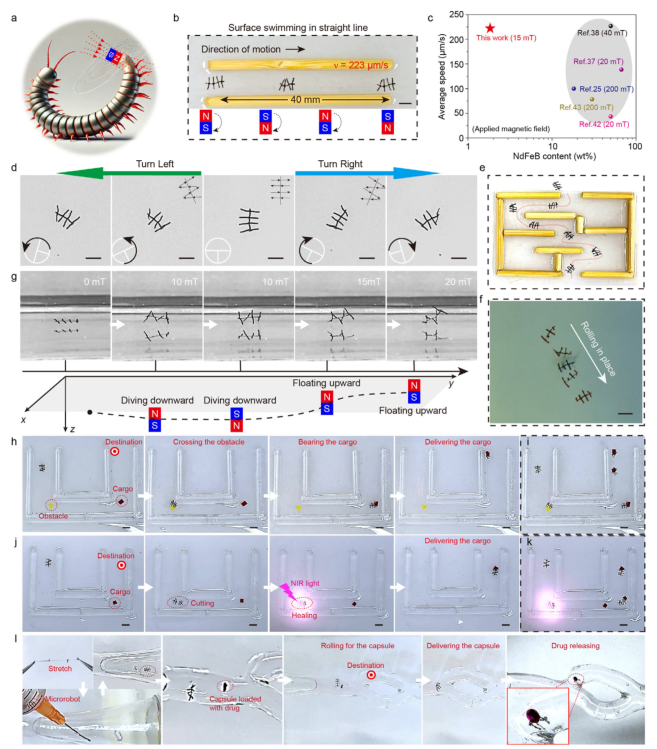

Multi-Scenario Task Execution

The multi-legged robot moves at a speed of 223 μm/s (Figure 5b-c), demonstrating excellent performance in maze navigation, obstacle crossing, and drug delivery (Figure 5e,h,l), with a magnetic torque/gravity torque ratio of 184:51 (15 mT), ensuring reliable drive under weak fields (Figure 5a).

Figure 5. Multi-modal movement and strong task handling capabilities.

Future Outlook: Promoting Precision Medicine and Green Manufacturing

This technology addresses the challenge of “mechanical stability and magnetic responsiveness being mutually exclusive” in soft robots through the single-domain magnetic domain assembly strategy. Future breakthroughs are expected in minimally invasive surgery and targeted drug delivery, while its self-healing and reconfigurable characteristics provide a new paradigm for sustainable robot manufacturing.

Original Link

https://doi.org/10.1002/adma.202505193

Related Progress

Professor Yu Shuhong, Professor Cong Huaiping, et al. Adv. Mater.: Preparation of ultra-tough single-network hydrogels

Academician Yu Shuhong, Professor Cong Huaiping Nat. Commun.: High-strength and tough biomimetic oriented structure heterogeneous hydrogels

The team of Professor Cong Huaiping from Hefei University of Technology and Professor Yu Shuhong from the University of Science and Technology of China Nat. Synth.: Successfully developed highly environmentally resistant elastic conductors

The research groups of Professor Cong Huaiping from Hefei University of Technology and Professor Yu Shuhong from the University of Science and Technology of China in “Nat. Commun.”: New hydrogel actuators can achieve directional deformation and automatic healing

The research groups of Professor Cong Huaiping from Hefei University of Technology and Professor Yu Shuhong from the University of Science and Technology of China in “Adv. Mater.”: Significant progress in the construction of real-time repairable stretchable supercapacitors

Disclaimer: Some materials may originate from the internet, and the purpose of reprinting is to convey more information and share, which does not imply endorsement of their views or verification of their authenticity, nor does it constitute other advice. It only provides a communication platform and is not responsible for its copyright. If there is any infringement, please contact us for timely modification or deletion. Original articles are welcome for personal forwarding and sharing; for publications or media, please contact us for reprinting. Contact email: [email protected]

Scan the QR code | Follow us

WeChat ID: Chem-MSE

We sincerely invite submissions

Experts and scholars are welcome to provide manuscripts related to chemistry, chemical engineering, materials science and engineering, and biomedical engineering to [email protected], and please indicate detailed contact information. The Chemical and Materials Science Society will promptly select and push.