On May 1, 2025, Nanjixiong learned that Xuzhou Aerospace Meilida Automatic Welding Equipment Co., Ltd., leveraging its profound welding technology accumulation and independent research and development capabilities, has officially launched the “Plasma Arc Melting Wire + Laser” hybrid additive manufacturing technology and robotic system equipment. This breakthrough overcomes the bottlenecks of traditional arc melting wire and laser additive manufacturing, filling the critical technological gap in the application of efficient hybrid additive manufacturing for complex structural components in China.

Transitioning from Welding Engineering to High-End Intelligent Manufacturing

Xuzhou Aerospace Meilida was originally a company focused on high-difficulty metal decoration projects, having undertaken iconic projects such as the main torch of the 2008 Beijing Olympics and the Global Stage of Window of the World in Shenzhen. In recent years, the company has completed a strategic transformation from engineering installation to the research and development and manufacturing of intelligent welding equipment, establishing a new technology system centered on additive manufacturing, and relocated entirely to the Xuzhou Industrial Park in 2021, forming an integrated industrial platform for research and development, manufacturing, and testing.

The company’s R&D team consists of several members from aerospace research institutes, university professors, and senior technicians, mastering core technologies across multiple disciplines such as welding, CNC, laser, and materials, successfully developing the industry-leading “Plasma Arc + Laser Hybrid Additive Robot System.”

△ Production base of Xuzhou Aerospace Meilida Automatic Welding Equipment Co., Ltd.

Hybrid Additive Technology: Merging Advantages and Breaking Bottlenecks

Traditional directed energy deposition metal 3D printing primarily relies on two paths: laser powder feeding and plasma arc melting wire. While laser powder feeding offers high forming precision, it comes with high equipment costs and metal powder material costs, as well as stringent additive process requirements, stress concentration, and susceptibility to cracking. During the additive process, if there is a halt, the additive workpiece needs to be kept warm to prevent cracking. Aluminum alloy additive processes are reflective, making them prone to defects such as cracks and pores. On the other hand, plasma arc melting wire additive processes have directional feeding, which cannot adapt to the bending or corner trajectories of the additive path, limiting the application of plasma arc melting wire in complex shape additive products.

The solution from Aerospace Meilida is to “combine the two technologies into one” to achieve synergistic optimization. The developed “Plasma Arc Melting Wire + Laser Hybrid Additive” technology has several key advantages:

1. Overcoming Directional Feeding Limitations for Complex Shape Printing

In traditional plasma arc melting wire technology, the feeding direction is fixed, making it difficult to adapt to complex trajectories. The 8-axis plasma rotating welding torch arc melting wire additive robot developed by Meilida allows the welding torch and feeding direction to rotate infinitely, solving the directional feeding issue of plasma arc additive processes. The feeding direction can change with the additive trajectory, successfully applied to the printing of complex components such as valve sealing surfaces and irregular parts. Additionally, it can continuously add multiple workpieces, achieving additive flow operations and improving production efficiency.

△ 8-axis rotating welding torch additive welding robot

2. Optimizing the Melting Pool to Reduce Defects

By using pulsed laser impact and stirring on the melting pool, the flowability within the melting pool is effectively improved, lowering the temperature gradient and reducing typical defects such as pores, cracks, and segregation, resulting in a more stable microstructure of the formed components.

3. Composite Energy Field Control of Organizational Performance

Laser and plasma arc work synergistically at the microscopic level, reducing the average grain size in the interaction zone of the laser and plasma arc by about 40%, with a more uniform element distribution. Based on the independently developed aluminum alloy plasma arc melting wire + laser hybrid additive manufacturing technology, using Al-Cu alloy as an example, the tensile strength after additive manufacturing exceeds 300MPa, and after heat treatment, it can reach the T6 state forging standard, with a post-fracture elongation rate exceeding 15%. This technology addresses the issue of high arc column temperature and large specific surface area of molten droplets during the transition process, which makes it easier to absorb hydrogen and produce a large number of gas pores, achieving the goal of synergistic control of aluminum alloy microstructure-stress-performance and defect controllability. Furthermore, this technology can also be applied to the additive manufacturing of aluminum-zinc alloys, aluminum-lithium alloys, copper alloys, and other metal components, expanding the application fields of laser additive manufacturing technology.

4. Dual Advantages of Cost and Efficiency

-

The cost of arc power supply is only 1/10 of that of lasers and 1/30 of electron beam systems;

-

Using wire material instead of powder, the cost is only 1/3 of the latter;

-

The forming efficiency can reach 350cm³/h, with some materials achieving additive efficiency of up to 3kg/h, comparable to or even surpassing that of high-power laser systems.

Diverse Application Scenarios: From Aerospace to Civil Industries

The hybrid additive manufacturing technology of Aerospace Meilida has been validated in multiple practical engineering projects, demonstrating broad industrialization prospects.

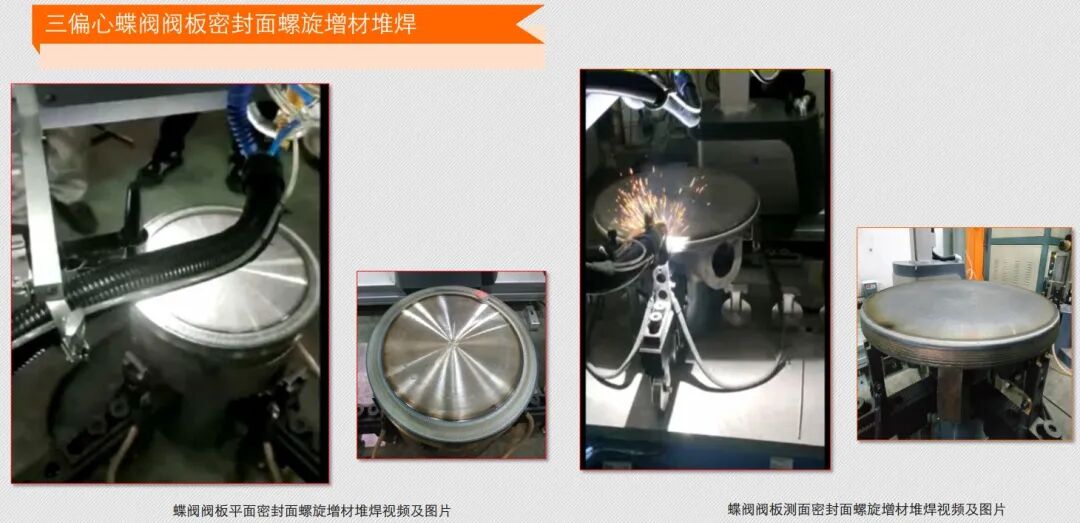

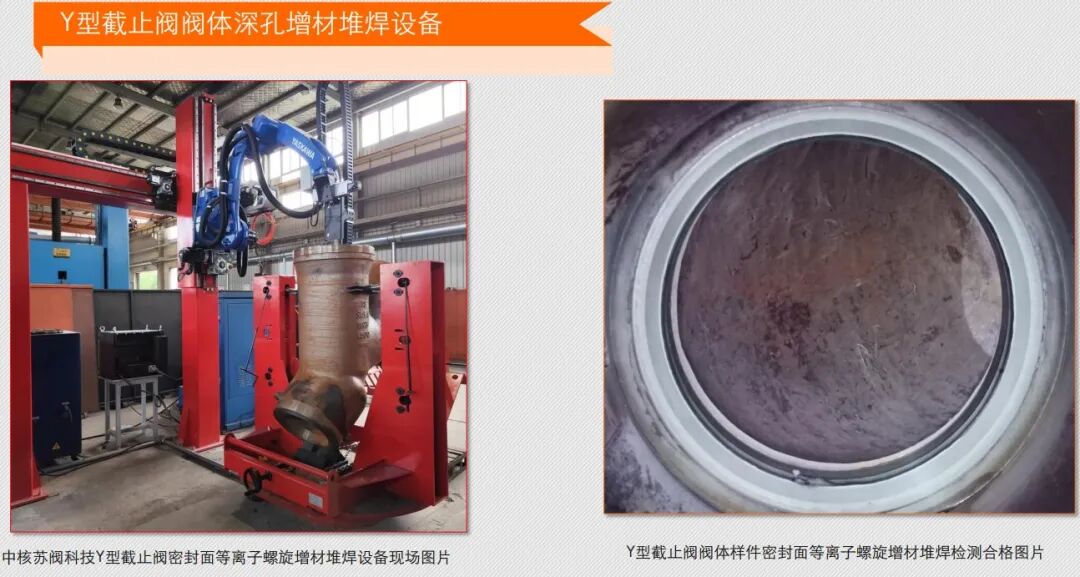

1. Manufacturing of Valve Sealing Components

In the cooperation project with China Nuclear Su Valve Technology, the hybrid additive robot was successfully used for the cladding of sealing surfaces of deep-hole Y-type stop valves and triple eccentric butterfly valves. Through precision machining and testing, all met the qualification standards, showcasing excellent sealing performance and corrosion resistance.

△ Video and images of spiral additive cladding on the sealing surface of the butterfly valve plate

2. Aerospace Structural Components

The hybrid additive technology has been used for the printing of aerospace structures made from titanium alloys, aluminum-lithium alloys, and high-temperature alloys, such as engine casings and connectors, meeting the stringent requirements for lightweight and high strength.

3. Additive Manufacturing of Complete Special Vehicles

The modular combination gantry robot system developed by the company can achieve 3D printing of structural components for complete special vehicles, suitable for rapid deployment manufacturing needs in military, emergency, and rail transportation industries.

4. Microstructure Precision Control of Complex Parts

By adjusting the laser pulse parameters and plasma energy distribution, the technical team has achieved regional control of the microstructure, laying the foundation for the next step in the manufacturing of functionally graded materials and multi-scale composite components.

In addition to its advanced process capabilities, Aerospace Meilida also possesses a complete independent research and development and manufacturing system, having achieved localization of all core components such as power supplies, welding torches, and high-intensity cameras. To date, Aerospace Meilida has obtained three invention patents, six design patents, and twenty-four utility model patents, and has received honors in innovation and entrepreneurship from “Maker China” and “Science and Technology Innovation Jiangsu.” The Ministry of Education’s technology novelty report clearly states that its eight-axis rotating welding torch + high-intensity monitoring system’s assembly line butterfly valve additive solution is a domestic first, with no similar reports found in the novelty literature.

More importantly, the hybrid additive system has achieved engineering breakthroughs in cost control and operational stability, providing feasible metal 3D printing solutions for many small and medium-sized manufacturing enterprises.

Conclusion: Aerospace Welding Spirit Ignites the Engine of Domestic High-End Additive Manufacturing

Additive manufacturing is transitioning from “substituting processing” to “structural innovation.” The “Plasma Arc + Laser Hybrid Additive Robot Technology” from Xuzhou Aerospace Meilida not only resolves the conflict between cost and efficiency but also breaks through the technical bottlenecks of complex structures and microstructure control, establishing the “second curve” of metal additive manufacturing.

“Achieving customer dreams, welding the pillars of the nation” is the corporate philosophy upheld by Aerospace Meilida. The hybrid additive technology not only serves the high-end aerospace industry but also promotes the widespread application of 3D printing in energy, automotive, shipping, and medical fields. This technology represents an engineering application-oriented metal 3D printing solution and a groundbreaking attempt of “Made in China” in the welding manufacturing field. Nanjixiong predicts that in the future, this technology is expected to deeply integrate with AI design, digital twins, intelligent control, and move towards a truly intelligent additive manufacturing new stage.

Directory of Chinese 3D Printing Manufacturers: https://www.nanjixiong.com/forum-244-1.html

Recent Hot Articles from Nanjixiong:

“AI-Driven Progress in 3D Printing, Tencent Cloud Collaborates with Nanjixiong for an Exchange Event”

“I Dreamed of Raising 20 Billion Yuan to Acquire All Foreign 3D Printing Listed Companies and Achieve 290 Billion in A-Share”

“China’s 100-Meter Metal 3D Printer to be Built in Tianjin, Developed by Beijing Institute of Technology, with Ultra-Large Specification Metal Lattice Structure Multi-Arc Parallel 3D Printing Technology and Equipment”

“CCTV Report: Under Tariff Bullying, Delayed US 3D Printing Toy Orders are Gradually Returning”

Notice for 3D Printing Professionals:

△Scan to open the Nanjixiong website, set WeChat to Star Mark☆, or open it in a mobile browser and set it to the phone desktop