New Quality Productivity

Magical

3D Printing Technology

No Molds Required, On-Site Modeling, Precise Installation

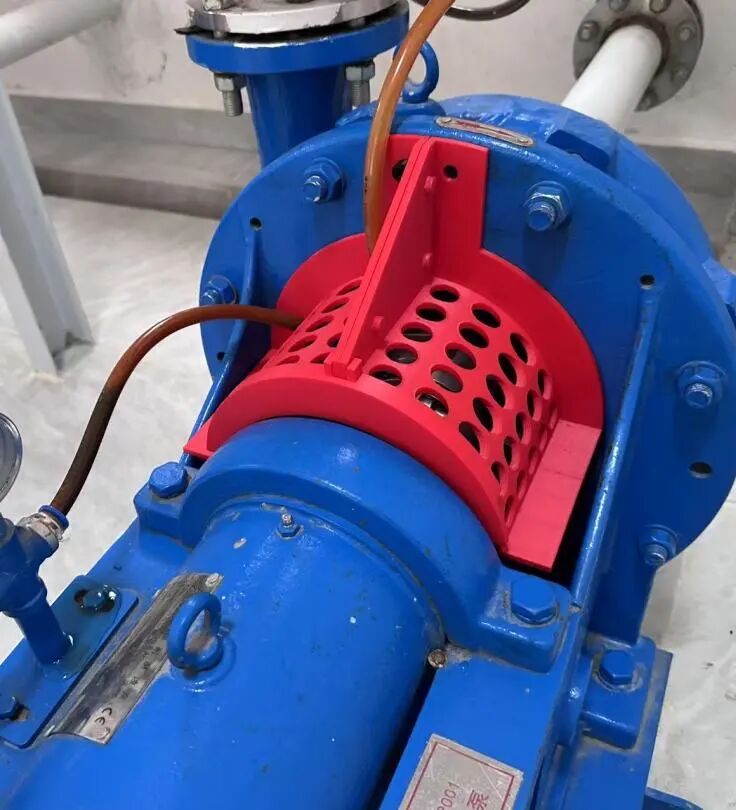

Can 3D printing be used like this? After 4 hours of the 3D printer humming, a delicate desulfurization pump mechanical seal protective cover was created.

“We utilized 3D printing technology to complete the design and installation of protective covers for the dissolving pump, flushing pump, and conveying pump mechanical seals,” said Feng Yongchao, assistant manager of the Leizhou project department of the environmental franchise company. “This technology does not require complex mold production; as long as the design is completed, it can be printed directly.”

During routine production and operation, Feng Yongchao noticed that due to the complex structure of some rotating equipment, especially the mechanical seal areas, protective devices were often not provided upon delivery. Additionally, the varying sizes of different equipment made traditional custom protective covers face challenges such as long design cycles, poor adaptability, and difficulty in standardization.

“Can we ‘print’ them ourselves?”

Based on their computer modeling capabilities, Feng Yongchao proposed to try introducing 3D printing technology to achieve customized, high-precision protective cover manufacturing.

Once the idea was proposed, he brought his modeling experience and, along with team members, immersed themselves in data measurement and drawing design work. Throughout the project, the team fully leveraged their professional advantages and utilized advanced modeling software and high-precision 3D printing platforms to successfully transform several originally “difficult to make” protective devices from blueprints into physical objects. After relentless efforts, the team successfully completed the production and installation of mechanical seal protective devices and pipeline medium flow direction markers. This innovative practice not only significantly improved production and operation efficiency but also greatly reduced maintenance costs.

As a cutting-edge technology in the manufacturing field, 3D printing is gradually becoming an important force driving industrial transformation.

Through this technology, the project department effectively addressed practical challenges such as the diversity of equipment parts models, small customization demands, and long delivery cycles, making “customization of non-standard parts” no longer difficult.

Currently, the Leizhou project department has successfully completed the application of several 3D printing results, including high-pressure motor end protective covers, equipment identification signs, and physical equipment models. Next, the project department will expand to include thermal control electrical equipment components, desulfurization demister components, bolt protective caps, desulfurization and denitrification sand table models, and standardized construction site miniature models, continuing to explore more possibilities of 3D printing and truly implementing new quality productivity into every detail of equipment and every safety protection measure. The application of technology in production sites is far more than just “printing a cover.”

– End –

Previous Recommendations

Another R&D achievement reaches international leading level

Another R&D achievement reaches international leading level

Author|Liu Zhian

Editor|Zhang Yiwen

Stock Code: 01272.HK