1. Abstract

- Research BackgroundThe mechanical properties of 3D printed carbon fiber reinforced polymer composites are crucial for engineering applications, but challenges remain in producing high-performance composites through material extrusion.

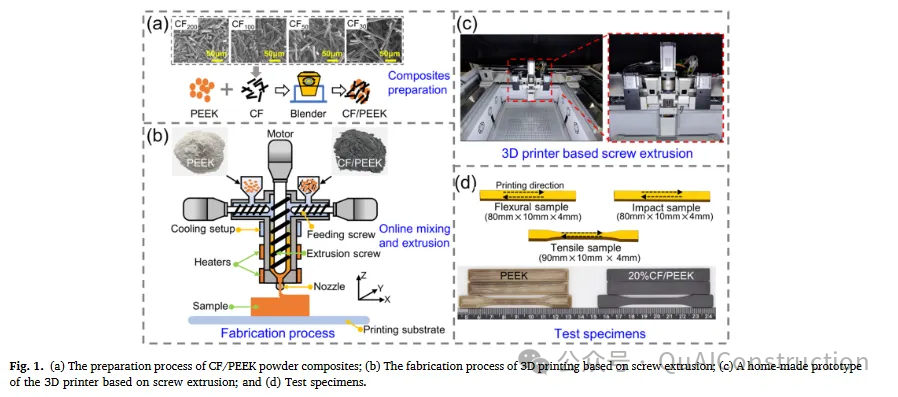

- Research MethodFour CF/PEEK composites with different fiber lengths were prepared using a self-made screw extrusion 3D printing mechanism, systematically exploring the effects of fiber length and annealing treatment on the mechanical properties of the samples.

- Research ResultsIncreasing fiber length and annealing treatment can enhance the tensile and flexural strength of components, but may reduce impact strength and ductility. Components with an average fiber retention length of 209μm after annealing exhibited excellent tensile strength (169.8MPa) and flexural strength (223.3MPa), which are increases of 143% and 88% compared to unannealed pure PEEK, respectively. Longer fiber retention lengths, higher crystallinity, and fewer internal defects contribute to improved mechanical properties of the samples.

- Research SignificanceThis provides broader prospects for the preparation and application of high-performance composites in 3D printing.

2. Introduction

- Applications of CFRP and Limitations of Traditional Manufacturing MethodsCarbon fiber reinforced polymer composites (CFRP) are widely used in aerospace, automotive, and other industries due to their excellent properties, but traditional manufacturing methods rely on molds, which are time-consuming, costly, and limited by the structural shapes of parts.

- Advantages of Additive ManufacturingAdditive manufacturing (AM) does not require traditional molds, is cost-effective, and offers high design flexibility, making it suitable for manufacturing complex components and functional parts, with widespread applications in biomedical and aerospace fields.

- Status of Material Extrusion ProcessesMaterial extrusion (such as FDM/FFF) is the primary method for preparing thermoplastic polymers and their composites, but currently, the fiber content of CF/PEEK composites is usually less than 20wt%, and the initial fiber length is typically less than 200μm, limiting their application range.

- Research ObjectiveThis study employs screw extrusion 3D printing technology to explore the relationship between fiber length and the mechanical properties of samples to further enhance the mechanical performance of components.

3. Materials and Methods

- MaterialsVictrex PEEK powder was used as the matrix material, and carbon fibers (diameter 7μm, different lengths) served as the reinforcement phase, with fiber lengths maintained below 1mm, selecting four different fiber length ranges (CF200, CF100, CF50, and CF30).

- Sample PreparationCF/PEEK powder composites with 50wt% fiber content were prepared through mechanical mixing, and test components were manufactured using a self-made screw extrusion 3D printer, with some samples undergoing annealing treatment (250°C, 2 hours).

- Characterization

- Fiber Length and Orientation CharacterizationResidual fibers were observed using SEM after high-temperature decomposition of PEEK, and fiber length distribution was measured using ImageJ software to assess fiber orientation.

- Physical Property TestingThermal properties, crystallization behavior, etc., of the composites were tested using DSC, TGA, melt flow indexer, XRD, and mechanical properties were tested using a universal testing machine and impact testing machine, with apparent density measured using a digital balance to assess porosity.

- Morphology ObservationSEM was used to analyze the fracture morphology of printed samples, and laser scanning confocal microscopy was used to evaluate surface roughness.

4. Results

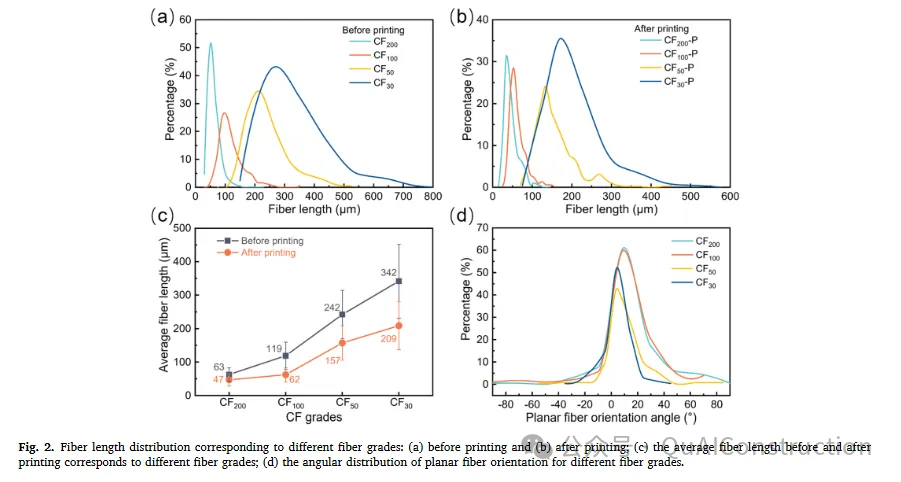

- Fiber Length and Orientation DistributionAll grades of fiber length were further shortened after printing, with only CF30 having an average fiber length exceeding 200μm; longer fibers exhibited better orientation, primarily concentrated around 5°.

The fiber length distribution before and after printing for different carbon fiber grades is shown in Figure 2 (a) and (b). The average fiber lengths before and after printing for different fiber grades are shown in Figure 2 (c). Figure 2 (d) illustrates the planar fiber orientation for various fiber lengths.

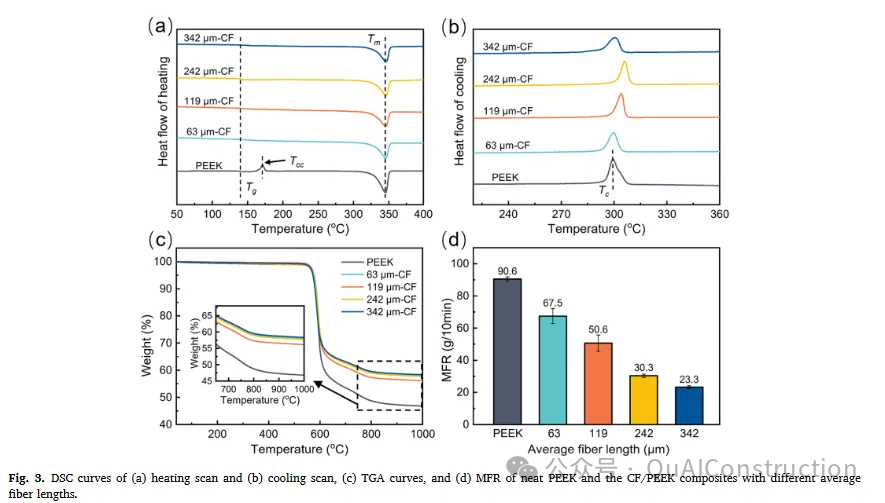

- Thermal and Flow PropertiesThe addition of CF and changes in fiber length have little effect on Tm, but will increase Tg and Tc, enhancing crystallinity and thermal stability; the flowability of the composites decreases with increasing fiber length.

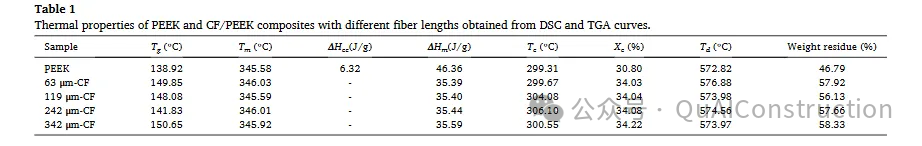

The heating and cooling DSC curves of CF/PEEK composite extruded filaments are shown in Figures 3 (a) and (b). Figure 3 (c) illustrates the thermal stability of the composites with different fiber lengths, with corresponding thermal decomposition temperatures (Td) and residual mass recorded in Table 1. The flowability of CF/PEEK composites is shown in Figure 3 (d). Crystallization BehaviorAs fiber length increases, the crystallinity of the components first increases and then decreases, with crystallinity further increasing after annealing.

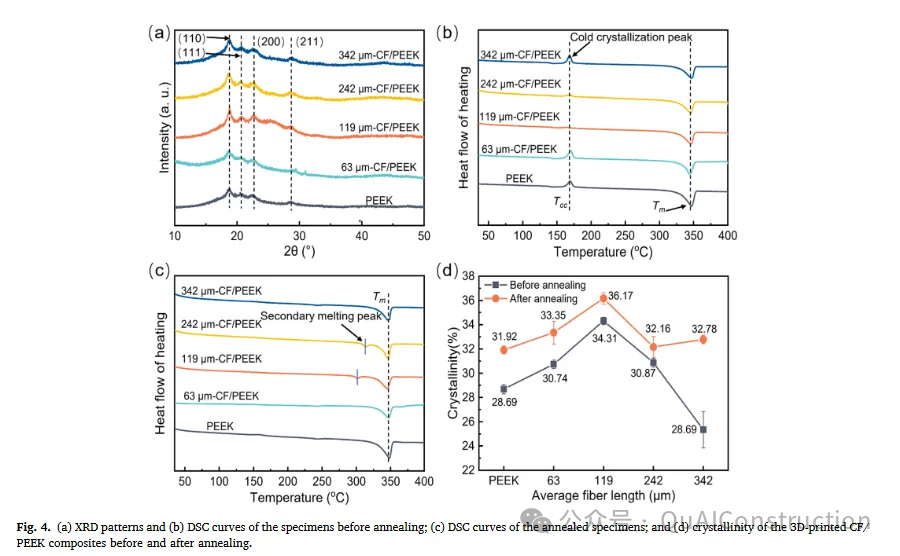

Crystallization BehaviorAs fiber length increases, the crystallinity of the components first increases and then decreases, with crystallinity further increasing after annealing.

The XRD diffraction patterns of unannealed pure PEEK and CF/PEEK composites are shown in Figure 4 (a). The DSC curves of parts without and with annealing are shown in Figures 4 (b) and (c). Figure 4 (d) illustrates the crystallinity of components before and after the annealing process.

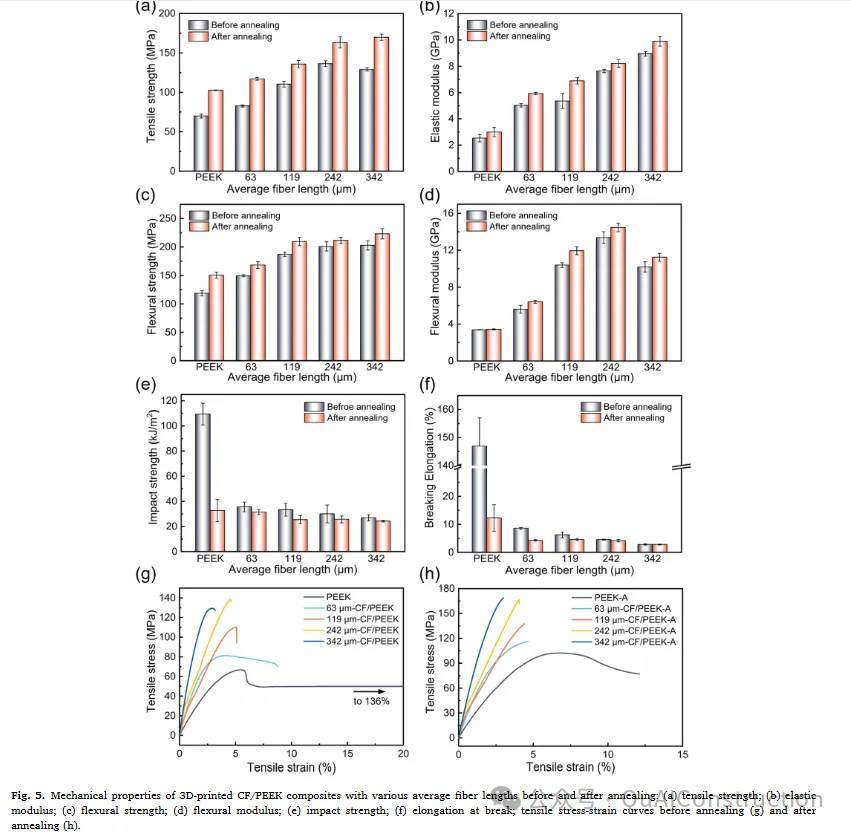

- Mechanical PropertiesIncreasing fiber length and annealing treatment can enhance the strength and stiffness of components, but reduce impact strength and ductility; samples with an average fiber retention length of 209μm after annealing exhibited the highest tensile and flexural strength.

Figure 5 (a) illustrates the tensile strength of pure PEEK and CF/PEEK composites with different fiber lengths before and after annealing. The elastic modulus of pure PEEK and CF/PEEK samples with different fiber lengths before and after annealing is shown in Figure 5 (b). Figure 5 (c) shows the flexural strength of pure PEEK and CF/PEEK composites with different fiber lengths before and after annealing. In contrast, the flexural modulus peaks at an average fiber length of 242 μm, reaching 13.38 GPa and 14.49 GPa before and after annealing, respectively [Figure 5 (d)]. The impact strength of pure PEEK and CF/PEEK composites before and after annealing is shown in Figure 5 (e). The addition of fibers and annealing helps reduce the ductility of the samples [Figure 5 (f)]. Figures 5 (g) and (h) describe the tensile stress and strain curves of composites with different fiber lengths before and after annealing.

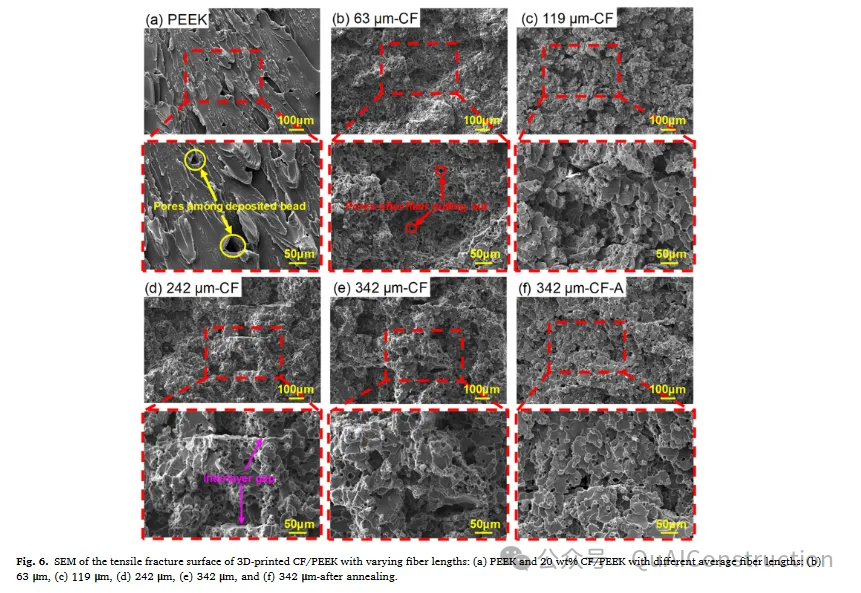

- Microstructure and PorosityPure PEEK and composite tensile fracture surfaces exhibited triangular pores and interlayer gaps, with reduced porosity after annealing.

Figure 6 shows the 3D-printed specimens. Triangular pores were observed in the deposited beads of pure PEEK and composite tensile fractures. Additionally, significant interlayer gaps were visible in the tensile cross-section, especially at average fiber lengths of 242 μm and 342 μm.

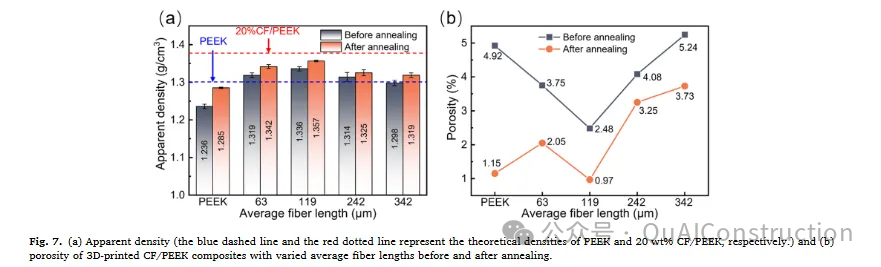

The apparent density of parts before and after annealing is shown in Figure 7 (a). It can be seen that the relative density of the samples (apparent density to theoretical density ratio) is above 94%, with corresponding porosity below 6%. Specifically, before annealing, the porosity of the components initially decreased and then increased with increasing fiber length [Figure 7 (b)].

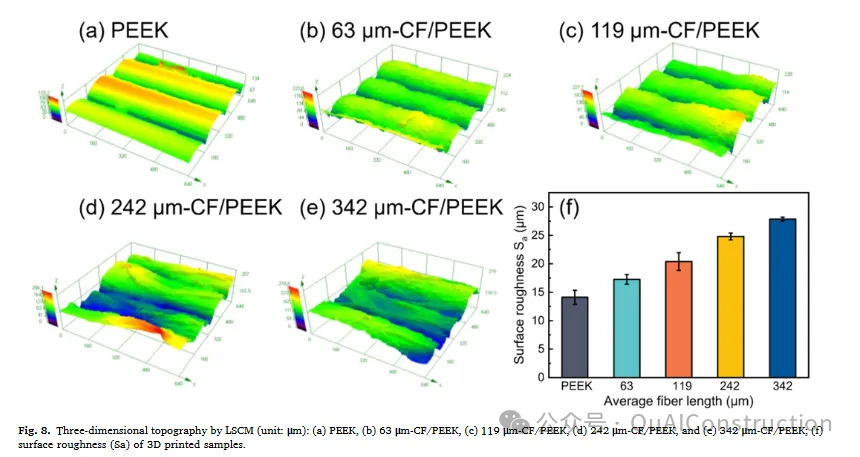

- Surface MorphologyAs fiber length increases, the surface roughness of the components gradually increases.

The surface morphology of the 3D printed CF/PEEK components is shown in Figure 8. As shown in Figures 8 (a) to (e), the incorporation of fibers and the increase in fiber length resulted in rougher surfaces compared to pure PEEK. Notably, the surface roughness (Sa) of the components gradually increased with fiber length, reaching a maximum of 27.85 μm at an average fiber length of 342 μm, while the minimum roughness of pure PEEK was 14.12 μm, as shown in Figure 8 (f).

5. Discussion

- Impact of Fiber LengthFiber length is crucial for component performance; in this study, the degree of fiber breakage after printing varied, with a maximum fiber loss rate of less than 50%, and longer fibers exhibited better orientation, which is beneficial for enhancing mechanical performance.

- Thermal Properties and Crystallization BehaviorThe addition of CF improved the Tg, Tc, and crystallinity of the composites, enhancing thermal stability; annealing treatment can eliminate the cold crystallization peak and improve crystallinity.

- Factors Affecting Mechanical PropertiesFiber length, crystallinity, and internal porosity jointly affect the mechanical properties of components; longer fibers and annealing treatment can enhance strength and stiffness, but increasing fiber length may lead to increased internal defects and reduced crystallinity, limiting the enhancement of mechanical properties.

- Comparison with Other StudiesThe tensile strength of the CF/PEEK composites prepared in this study exceeds that of most similar materials produced by 3D printing and injection molding, attributed to longer fiber retention lengths and lower porosity.

6. Conclusion

- Successfully manufactured CF/PEEK composites with different fiber lengths using a self-made screw extrusion 3D printer, with the maximum processable fiber length limited to below 1mm during the inline mixing extrusion process, and fiber loss rates below 50%, with longer fibers exhibiting better orientation.

- The addition of fibers improved the Tg, Tc, crystallinity, and thermal stability of the composites, while increasing fiber length led to increased surface roughness of the components.

- Increasing fiber length and annealing treatment can enhance the strength and stiffness of components, but reduce impact strength and ductility; samples with an average fiber retention length of 209μm after annealing exhibited the best mechanical performance.

- The mechanical performance of components is non-linearly related to fiber length, influenced by fiber length, crystallinity, and internal porosity, with annealing improving mechanical performance by enhancing crystallinity, reducing porosity defects, and improving interfacial bonding.