3D Printing Aids in Solving the Challenges of Large-Scale Production of Perovskite Solar Cells (PSCs)

The market potential for perovskite solar cells (PSCs) is enormous, and 3D printing may represent another significant technological application direction.

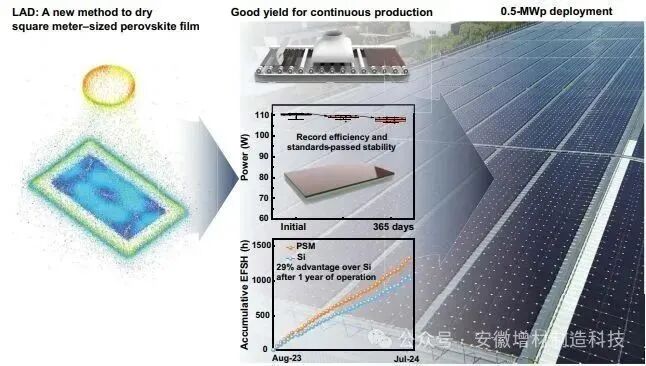

Researchers from Hangzhou Weidao Nano Technology Co., Ltd., the School of Civil Engineering and Architecture at Zhejiang University of Science and Technology, and the School of Optoelectronic Science and Engineering at Zhejiang University published a groundbreaking study inScience titled 3D laminar flow–assisted crystallization of perovskites for square meter–sized solar modules, demonstrating an innovative method for optimizing the large-scale manufacturing process of perovskite solar cells (PSCs) using 3D printing technology.The researchers successfully addressed the challenge of uniform crystallization of large-area perovskite films by designing and 3D printing a novel laminar air dryer (LAD), promoting the commercial production of efficient and stable square meter-sized perovskite solar modules.

Research Background

Perovskite solar cells are widely regarded as a promising new generation of photovoltaic technology due to their excellent photoelectric conversion efficiency, low raw material costs, and relatively simple manufacturing processes. Laboratory-level small-area perovskite solar cells have achieved efficiencies exceeding 26%, with stability continuously improving.However, translating laboratory results into large-scale industrial production faces numerous challenges, one of the core issues being how to rapidly and uniformly prepare high-quality perovskite films on large-area substrates?

Perovskite solar cells are widely regarded as a promising new generation of photovoltaic technology due to their excellent photoelectric conversion efficiency, low raw material costs, and relatively simple manufacturing processes. Laboratory-level small-area perovskite solar cells have achieved efficiencies exceeding 26%, with stability continuously improving.However, translating laboratory results into large-scale industrial production faces numerous challenges, one of the core issues being how to rapidly and uniformly prepare high-quality perovskite films on large-area substrates?

Research Content: Innovative Design and Application of 3D Printed Laminar Air Dryer (LAD)

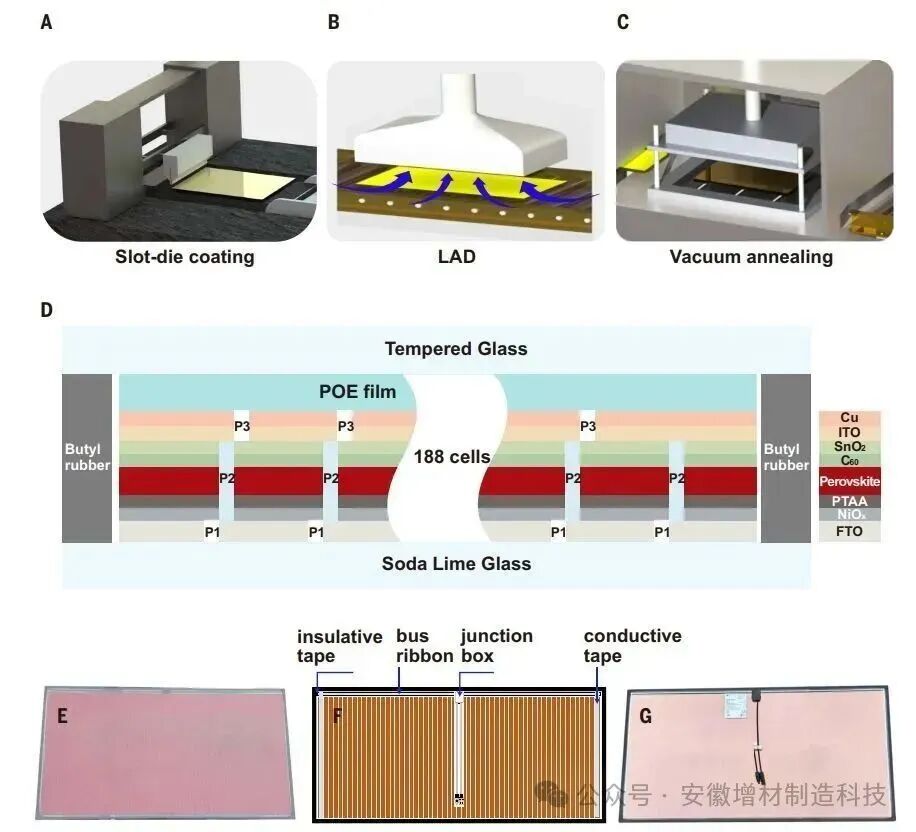

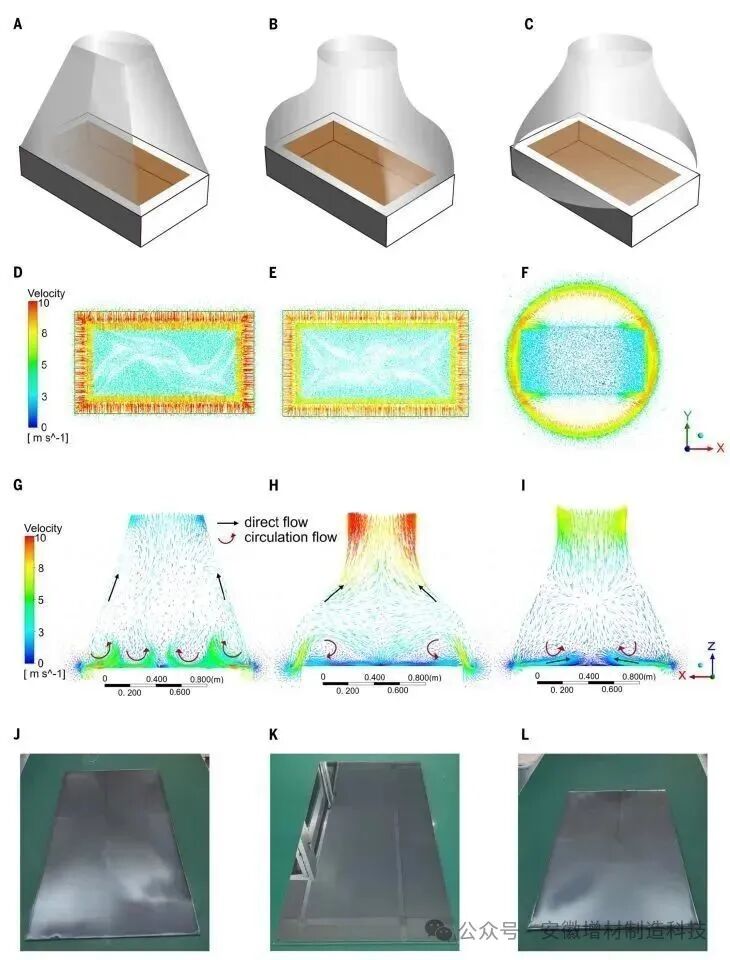

To overcome the aforementioned challenges, the research team innovatively proposed and utilized 3D printing technology to manufacture a “laminar air dryer” (LAD), aiming to simulate a uniform convective drying environment during the spin-coating process. By generating highly uniform laminar flow, it promotes the rapid and uniform evaporation of solvents in the perovskite precursor solution across the entire film surface, thereby achieving the formation of high-quality perovskite crystals.

To overcome the aforementioned challenges, the research team innovatively proposed and utilized 3D printing technology to manufacture a “laminar air dryer” (LAD), aiming to simulate a uniform convective drying environment during the spin-coating process. By generating highly uniform laminar flow, it promotes the rapid and uniform evaporation of solvents in the perovskite precursor solution across the entire film surface, thereby achieving the formation of high-quality perovskite crystals.

Research Results: Significant Advantages of LAD Technology in the Manufacturing of Perovskite Solar Modules

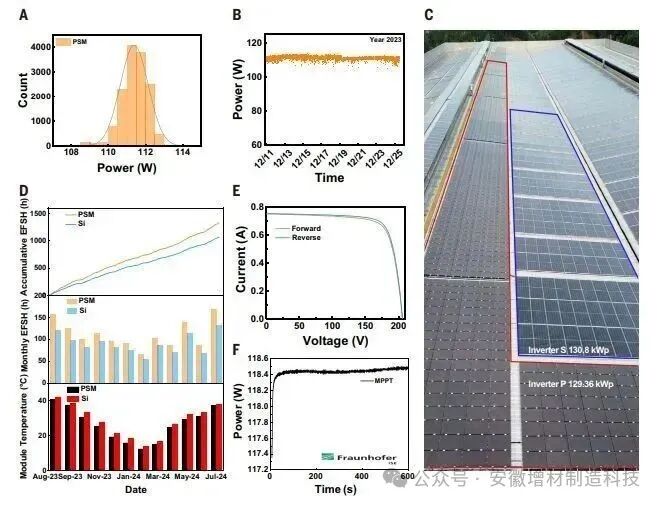

●Improved film quality and device stabilityFourier-transform infrared spectroscopy (FTIR)analysis indicates that compared to vacuum flash evaporation, the residual solvent (such as DMF and DMSO) content in perovskite films treated with LAD is significantly reduced, and the film defect density is lower. In ultraviolet aging tests, the solar modules treated with LAD maintained 98.2% of their initial power after aging for 1000 hours, far exceeding the 70.7% of the vacuum flash-evaporated modules.Electroluminescence imagingalso shows fewer dark spots in the LAD-treated modules, indicating superior long-term operational stability.●Enhanced process compatibility and flexibilityThe airflow intensity and drying time of LAD are adjustable, effectively handling perovskite precursor solutions containing high-boiling-point solvents or complex additives, demonstrating a good process window and compatibility with different perovskite formulations.●Achieving efficient and stable production of square meter-sized modulesThe research team successfully combined LAD technology with slot-die coating technology to achieve continuous and large-scale production of square meter-sized perovskite solar modules (PSMs). During a 15-day pilot production, a total of 14,527 perovskite solar modules were manufactured, with an average power output of 111.4 watts (corresponding to an efficiency of 14.1%), and 98.5% of the modules’ power fluctuations were controlled within ±2.5% of the average value, demonstrating excellent production consistency. Among them, the largest module reached 7906 square centimeters, with a certified efficiency of 15.0% (power of 118 watts), and successfully passed three key reliability tests in the IEC 61215 standard: thermal cycling, damp freeze, and damp heat, proving its commercial potential.

●Improved film quality and device stabilityFourier-transform infrared spectroscopy (FTIR)analysis indicates that compared to vacuum flash evaporation, the residual solvent (such as DMF and DMSO) content in perovskite films treated with LAD is significantly reduced, and the film defect density is lower. In ultraviolet aging tests, the solar modules treated with LAD maintained 98.2% of their initial power after aging for 1000 hours, far exceeding the 70.7% of the vacuum flash-evaporated modules.Electroluminescence imagingalso shows fewer dark spots in the LAD-treated modules, indicating superior long-term operational stability.●Enhanced process compatibility and flexibilityThe airflow intensity and drying time of LAD are adjustable, effectively handling perovskite precursor solutions containing high-boiling-point solvents or complex additives, demonstrating a good process window and compatibility with different perovskite formulations.●Achieving efficient and stable production of square meter-sized modulesThe research team successfully combined LAD technology with slot-die coating technology to achieve continuous and large-scale production of square meter-sized perovskite solar modules (PSMs). During a 15-day pilot production, a total of 14,527 perovskite solar modules were manufactured, with an average power output of 111.4 watts (corresponding to an efficiency of 14.1%), and 98.5% of the modules’ power fluctuations were controlled within ±2.5% of the average value, demonstrating excellent production consistency. Among them, the largest module reached 7906 square centimeters, with a certified efficiency of 15.0% (power of 118 watts), and successfully passed three key reliability tests in the IEC 61215 standard: thermal cycling, damp freeze, and damp heat, proving its commercial potential. △Power output data of the perovskite solar modules (PSM) used in this project under standard test conditions (STC), energy output of the rooftop photovoltaic (PV) system measured in equivalent full sun hours (EFSH), and an overview of module performance●Excellent actual power generation performance

△Power output data of the perovskite solar modules (PSM) used in this project under standard test conditions (STC), energy output of the rooftop photovoltaic (PV) system measured in equivalent full sun hours (EFSH), and an overview of module performance●Excellent actual power generation performance

Research Outlook and Significance

By using 3D printing technology to manufacture key process components, the research successfully addressed the core technical bottlenecks in the large-scale production of perovskite solar cells, providing a feasible solution for the commercial production of efficient and stable square meter-sized perovskite solar modules.The introduction of LAD technology not only significantly improved the quality of perovskite films and the stability of devices but also demonstrated its superior power generation potential in practical applications compared to traditional silicon-based solar cells.3D printing has played an important role in promoting the development of emerging photovoltaic technologies, injecting strong momentum into the industrialization process of perovskite solar technology. As the technology matures further and costs continue to optimize, innovative manufacturing methods represented by LAD are expected to accelerate the widespread application of perovskite solar cells in the global clean energy sector, contributing significantly to achieving carbon neutrality goals.

By using 3D printing technology to manufacture key process components, the research successfully addressed the core technical bottlenecks in the large-scale production of perovskite solar cells, providing a feasible solution for the commercial production of efficient and stable square meter-sized perovskite solar modules.The introduction of LAD technology not only significantly improved the quality of perovskite films and the stability of devices but also demonstrated its superior power generation potential in practical applications compared to traditional silicon-based solar cells.3D printing has played an important role in promoting the development of emerging photovoltaic technologies, injecting strong momentum into the industrialization process of perovskite solar technology. As the technology matures further and costs continue to optimize, innovative manufacturing methods represented by LAD are expected to accelerate the widespread application of perovskite solar cells in the global clean energy sector, contributing significantly to achieving carbon neutrality goals.