How to Build a High-Performance Mini Desktop Scroll Saw

DIY a High-Performance Mini Desktop Scroll Saw

Product Features Overview

Compact Structure, Portable & Easy to Use

Infinitely Adjustable Speed

PWM Speed Control Module: Current 10A, Voltage 12-40V

Suitable for Precision Cutting of Thin Sheet Materials

Blade Specifications: 18T, Length 133mm, Width 3mm

DC Motor Driven

Motor Model: 775 Motor, Voltage 12-24V, Speed 2500-20000rpm

Multiple Power Supply Options

Compatible with Battery Packs or DC Power Adapters (demonstration uses 18V 5A power supply)

Compact Dimensions

Height approximately 32cm, Worktable size approximately 18cm x 24cm

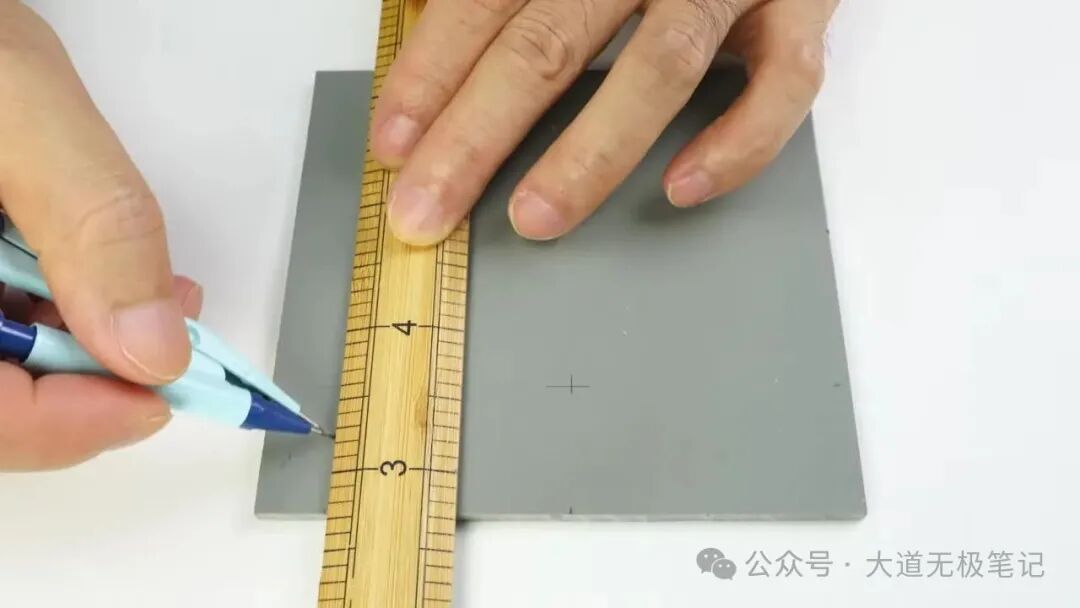

Step 1: Prepare Base Plates for Drive Mechanism

Mark cutting lines on plastic sheets. Cut pieces to required size.

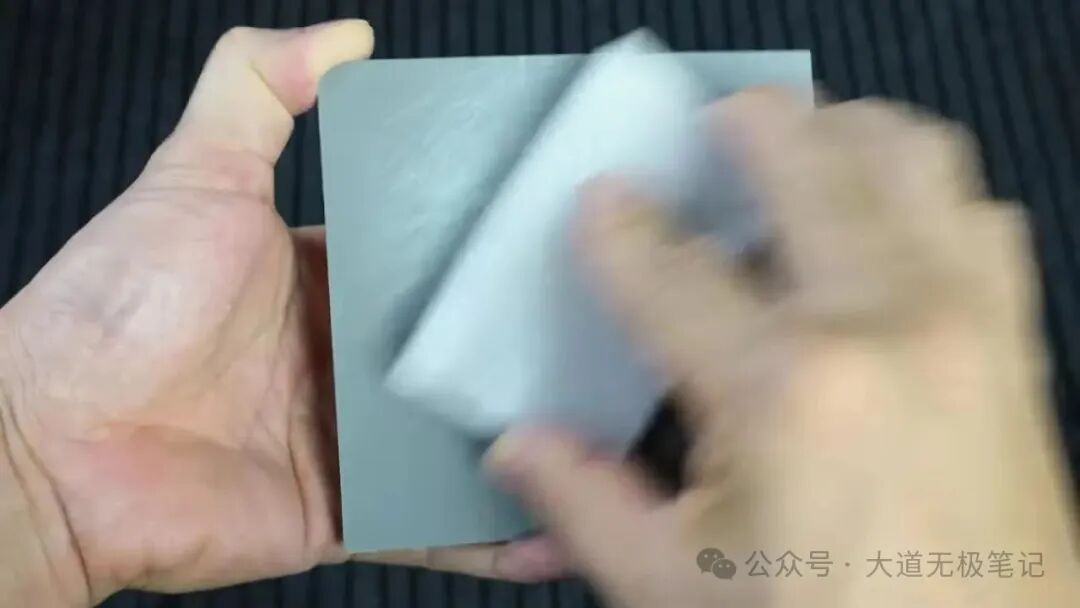

Bond multiple layers for thickness and sand the surface.

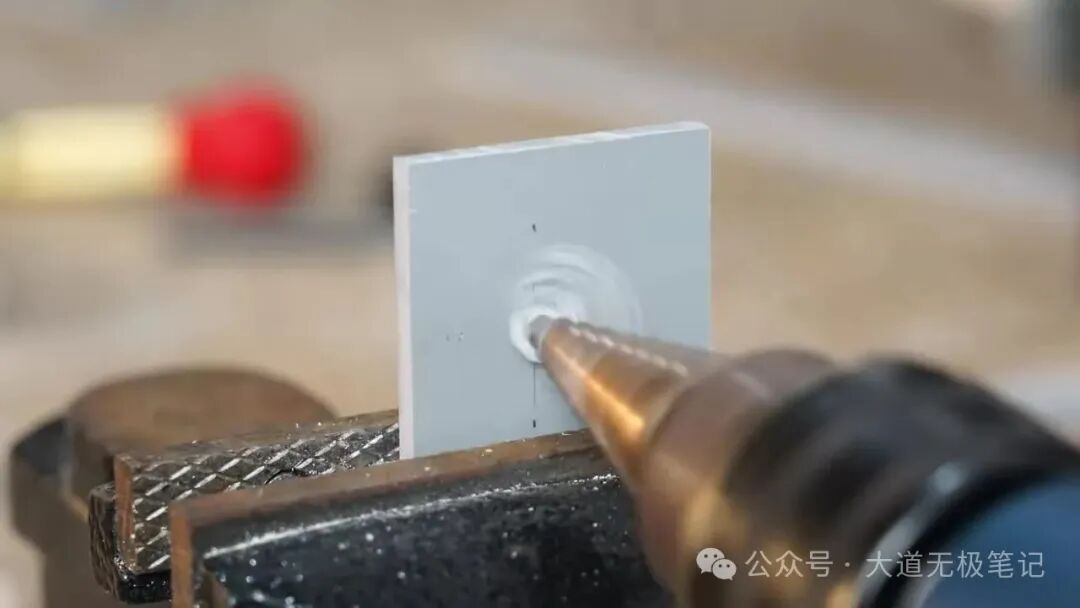

Step 2: Fabricate Motor Mount and Install Bearing

Mark and drill holes on the bonded piece for motor and bearing installation. Install an axle bearing (Inner diameter: 5mm, Outer diameter: 10mm).

Step 3: Fabricate and Install Large Pulley Bearing Block

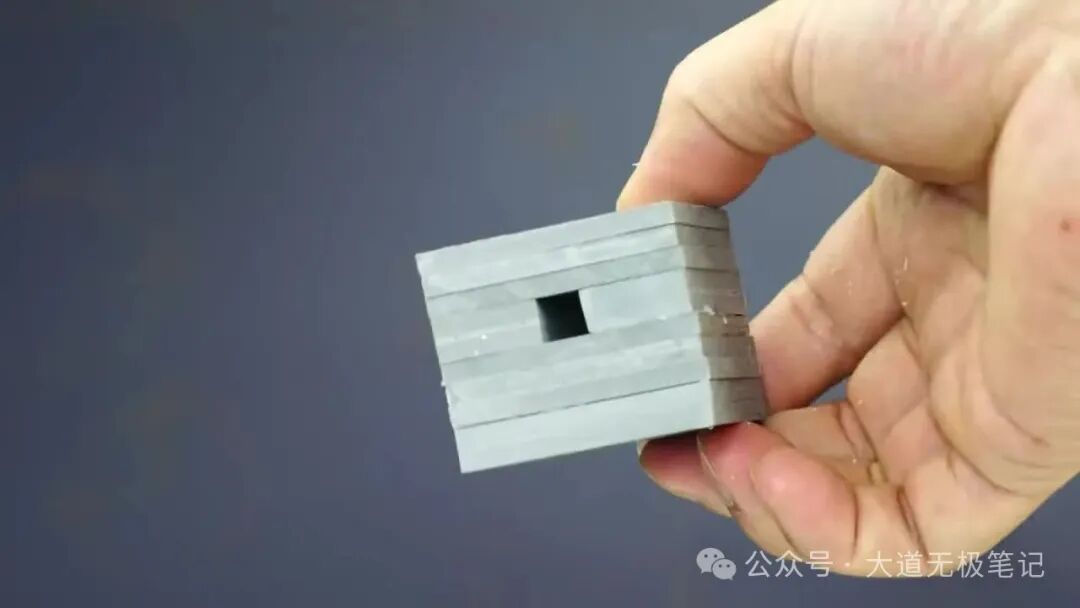

Bond multiple layers to make a square bearing block, drill a hole and install a linear bearing (Inner diameter: 10mm, Outer diameter: 19mm).

Step 4: Fabricate Connecting Rod

Cut and sand aluminum square tube.

Drill holes at both ends of the connecting rod, install a bushing at one end.

Bushing Inner diameter: 5mm, Outer diameter: 10mm

Step 5: Install Synchronous Pulleys and Connecting Rod

Drill a hole on the large synchronous belt pulley (60 teeth) for a screw. Fix the small synchronous belt pulley (20 teeth) onto the motor shaft. Fix the connecting rod to the large synchronous belt pulley with a screw.

Step 6: Fabricate Vertical Shaft Holder Tube

Cut and sand metal tube. Make a slot on the tube and drill a hole for a pin.

Step 7: Fabricate Upper Saw Blade Clamp

Fabricate a metal clamp part to hold the upper end of the saw blade.

Step 8: Fabricate Main Body Frame

Cut and bond multiple layers of plastic sheets to form the “C”-shaped frame.

Step 9: Fix Drive Mechanism to Base and Frame

Fix the motor/drive mechanism base onto the main frame base. Secure connections with screws.

Step 10: Fabricate and Install Work Table

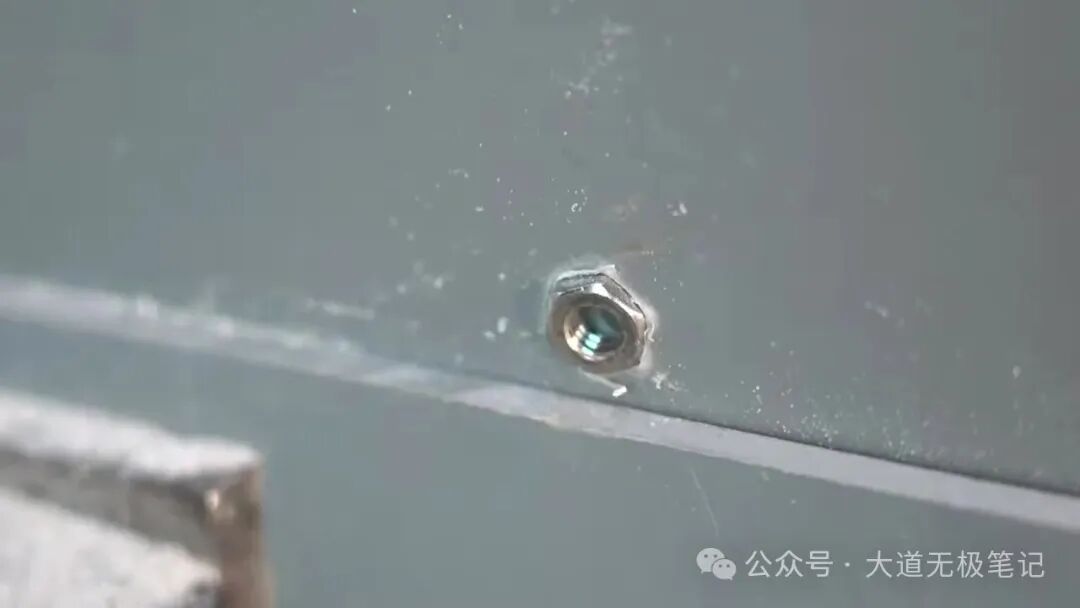

Bond multiple layers for the work table, trim and sand edges. Drill a hole in the center for the saw blade and install a bushing/insert.

Step 11: Fix Work Table to Base

Drill holes on the base, install bushings, then fix the work table to the base with screws. Install rubber feet.

Step 12: Install Vertical Shaft and Saw Blade Mechanism

Insert the vertical shaft through the upper and lower bearing blocks, connect the connecting rod. Install the upper saw blade clamp and spring, adjust the blade tension.

Step 13: Fabricate and Install Control Box

Fabricate the control box enclosure, install and wire the PWM Speed Regulation Switch (Current: 10A, Voltage: 12-40V), voltage display, switches, and terminals.

Step 14: Final Assembly and Power Connection

Fix the control box to the machine body, connect motor wires and power connectors. Can be powered by a battery pack or 18V 5A DC power adapter.

Step 15: Cutting Demonstration

Turn on power, adjust speed, and perform precise cutting operations.

Thank you for watching!

Thank you for watching!