The report from Electronic Enthusiasts (by Liang Haobin) states that PMIC, or Power Management Integrated Circuit, is used to manage power distribution in electronic devices, including voltage regulation and power distribution, serving as the “power dispatch center” of electronic devices.The main feature of PMIC is its high integration, typically combining DC-DC converters, LDOs, load switches, protection, and monitoring circuits into a single chip, replacing multiple discrete components to save PCB space. At the same time, PMIC can intelligently adjust to reduce energy consumption and minimize energy waste.PMICs are widely used, from low-power wearable devices to AI accelerator cards with power ratings above 500W, and even in motor inverters rated in the hundreds of kW.The core drive motor of electric vehicles is driven by traction inverters. In traction inverters, the MCU can be seen as the brain of the system.The MCU in the inverter is responsible for executing the driver’s operational commands, determining the motor’s working state through current sensors and other signals, and using the FOC algorithm to send control pulse PWM to the gate driver, while the MCU continues to determine the motor’s position and speed based on sensor data to achieve precise control.Meanwhile, in traction inverters, in addition to the MCU, peripheral components such as high and low side drivers and current sensors are also required. The MCU and these peripheral devices need PMIC to distribute their power supply and provide stable low-voltage power, for example, the MCU and driver chips of the main drive inverter need to start or shut down in a specific sequence. PMIC ensures that the power supply sequence of each module meets design requirements through its built-in timing controller, preventing current surges or logical errors.As the demand for compactness in electric vehicle powertrains increases, the power density of the inverter section also needs to be continuously improved, including the use of third-generation semiconductor power modules like SiC to enhance power density. On the other hand, PMIC reduces the number of peripheral components and lowers PCB area and system complexity by integrating multiple power outputs, such as buck, boost, LDO, as well as protection circuits and communication interfaces, making it suitable for high-density layouts of main drive inverters, helping to increase the power density of the inverters.At the same time, PMIC also monitors the MCU and system operating conditions, serving as the last line of safety defense. Since traction motors are related to vehicle driving safety, the corresponding traction inverters often need to meet the ASIL D functional safety level. In addition to the MCU itself meeting the ASIL D functional safety level, PMIC also incorporates some fault diagnosis mechanisms, triggering shutdown or derating operations through real-time monitoring of voltage, current, and temperature to ensure system safety and further enhance safety standards.For example, the recently launched integrated multi-rail power solution OPTIREG PMIC TLF35585 from Infineon integrates DC-DC and LDO, as well as pre-regulator and post-regulator architectures, capable of providing reliable power to the AURIX series and other MCUs while achieving monitoring and control functions, meeting ASIL D functional safety and a junction temperature range of 175°C.However, in automotive applications, some manufacturers will launch SBC (System Basis Chip) based on PMIC, which has charging functions but also some differences. From a broader concept and product positioning perspective, PMIC mainly focuses on power management, providing power and timing management for processors and sensors. SBC, on the other hand, integrates more system-level functions, such as communication interfaces, system monitoring, and diagnostic protection, which can be understood as SBC being PMIC + communication interface + diagnostics + safety module, specifically aimed at automotive electronics.With the high power density requirements of traction inverters, the integration requirements of PMIC are also increasing, leading to a gradual evolution towards the concept of SBC.

Disclaimer: This article is original from Electronic Enthusiasts, please indicate the source above when reprinting. For group communication, please add WeChat elecfans999, for submission of interview requests, please send an email to [email protected].

More hot articles to read

-

AI toys are booming, chip solutions are flooding in

-

Alibaba and Goldman Sachs pessimistic about AI infrastructure, while domestic server supply chains are surprisingly thriving

-

5000 units in mass production! Optimus single machine cost drops by 70%? Tesla robots bring new shocks

-

Xiaomi releases smart audio glasses 2, welcoming three major upgrades! Its first AI glasses also have news

-

Incredible! AI PC equipped with 70B large model, computing power skyrockets, memory is off the charts

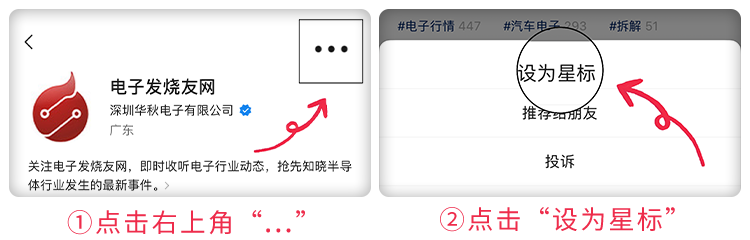

Click to follow and star us

Don’t miss any updates by marking us as a star!