Author: wcc149 | Source: Electronic Circuit Development Learning

1. Introduction

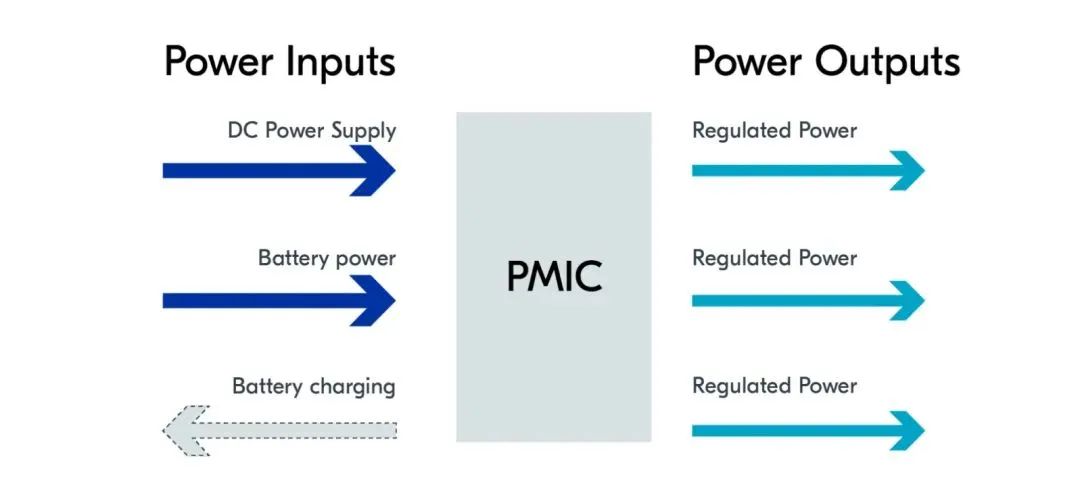

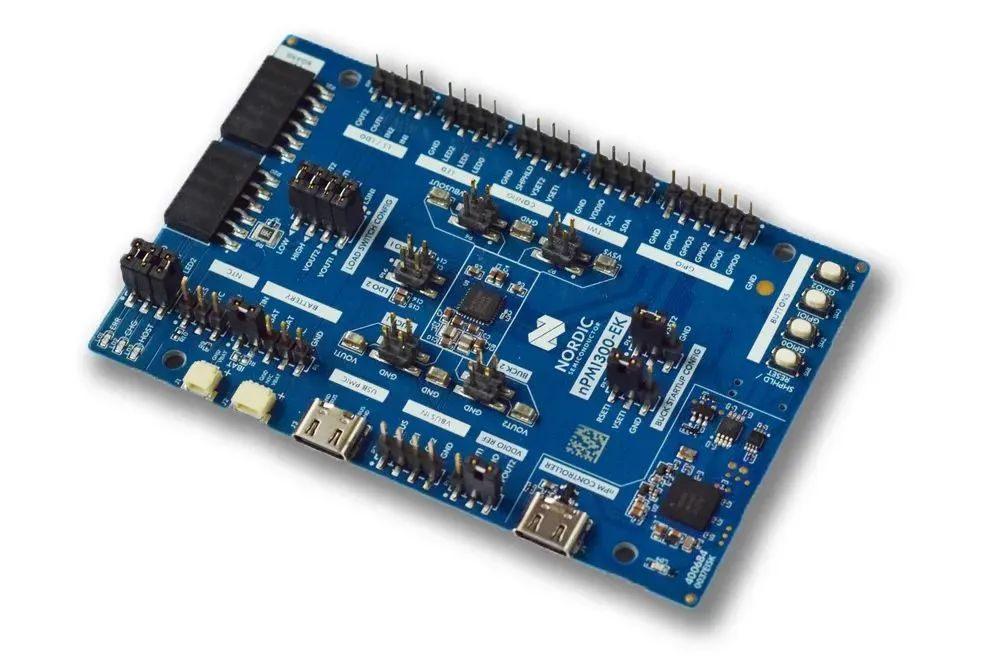

Recently, I received a board from Breadboard Community, based on Nordic’s latest nPM1300 power management chip evaluation kit. Regarding power management chips, everyone may be familiar with some discrete chips, such as buck-boost, power monitoring, POR reset, charge and discharge management, etc., but it is rare to integrate all these functions into a single chip. In this article, we will experience the world’s first power management IC (PMIC) that integrates all necessary functions—nPM1300.

2. Nordic Semiconductor

nPM1300 is a PMIC power management chip from Nordic, which was established in 1983. Friends who develop low-power Bluetooth-related products should be familiar with it. It is a pioneer in ultra-low-power wireless technology and a representative enterprise in the wireless technology field.

Nordic is headquartered in Norway and has Bluetooth, ANT+, Thread, Zigbee, WiFi, and NB-IoT technologies. Nordic’s low-power Bluetooth SoCs are widely used in the IoT field due to their high performance and ease of design, including wireless PC peripherals, gaming, sports and fitness, mobile accessories, consumer electronics, toys, healthcare, and automation products. Although many SoCs have integrated power management functions, due to limitations in power consumption, efficiency, charge and discharge management, many users still need external power management chips to meet complex functional requirements. Common power management chip architectures are usually relatively simple, generally supporting multiple adjustable voltage outputs and supporting external batteries for charge and discharge management.

With the increasing demand for product size, performance, and battery life in smart homes and wearable products, the functions of power management chips have also increased, such as:

-

Hardware reset required in abnormal situations -

Longer battery life -

Accurate battery capacity statistics -

Fast and safe charge and discharge -

Smaller size and higher efficiency

The power management IC we are evaluating in this article—nPM1300 includes all the above functions.

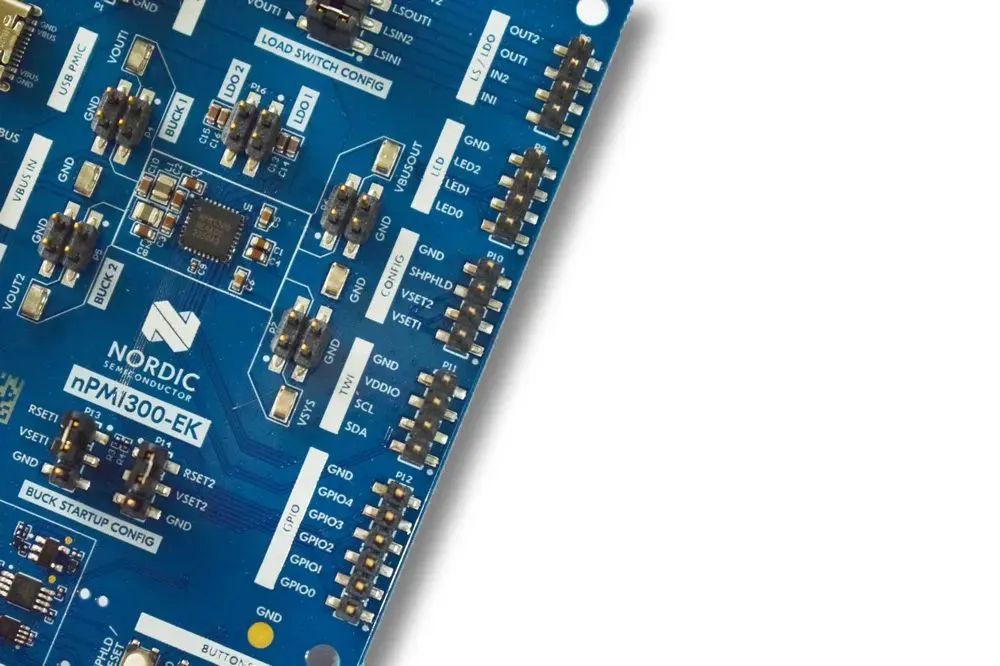

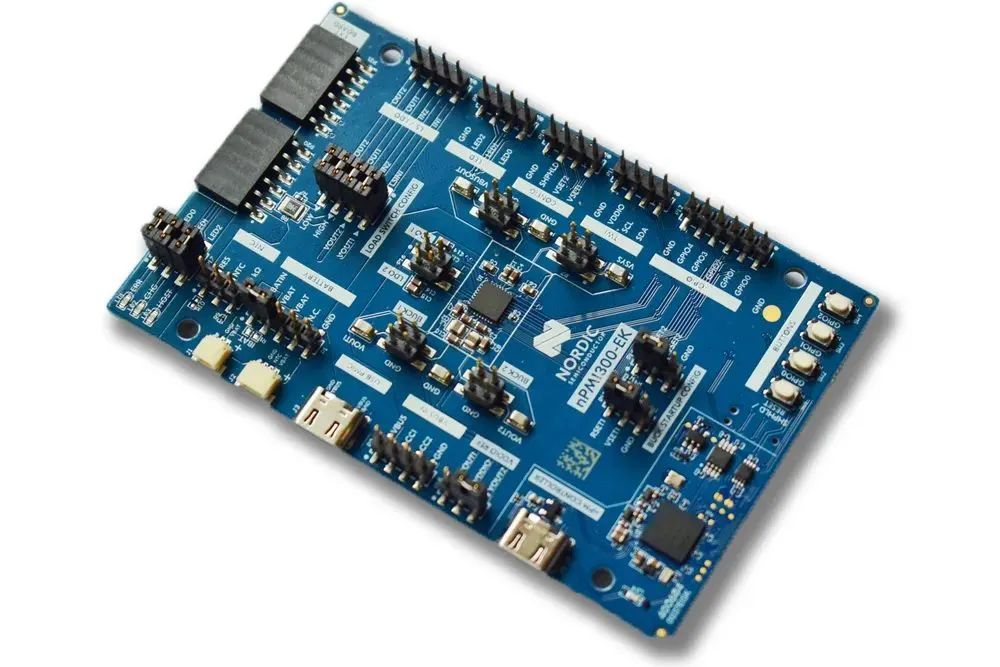

3. nPM1300 Evaluation Kit Hardware Resources

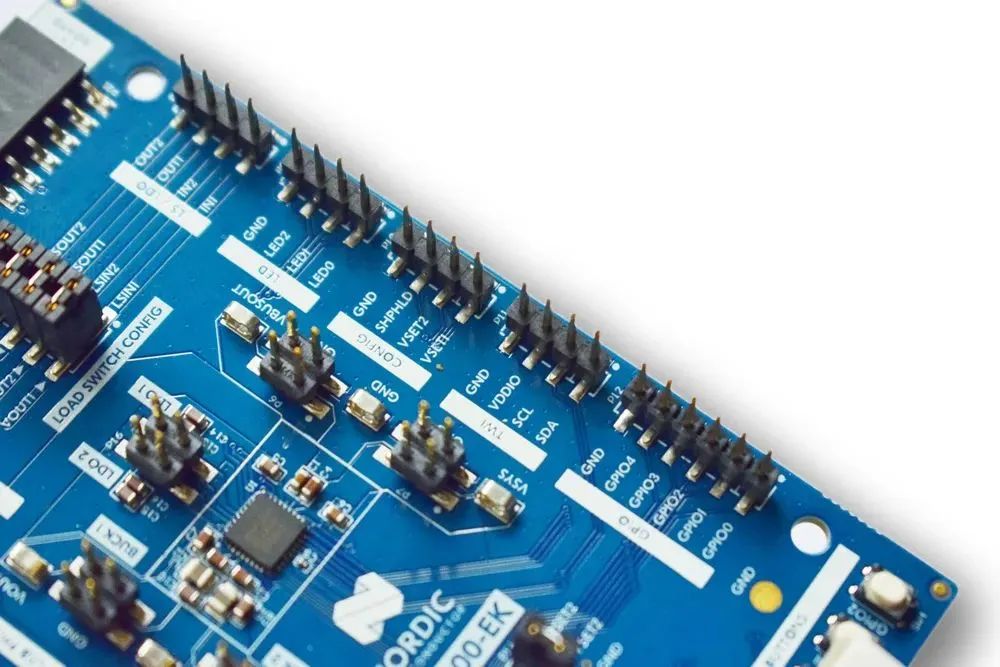

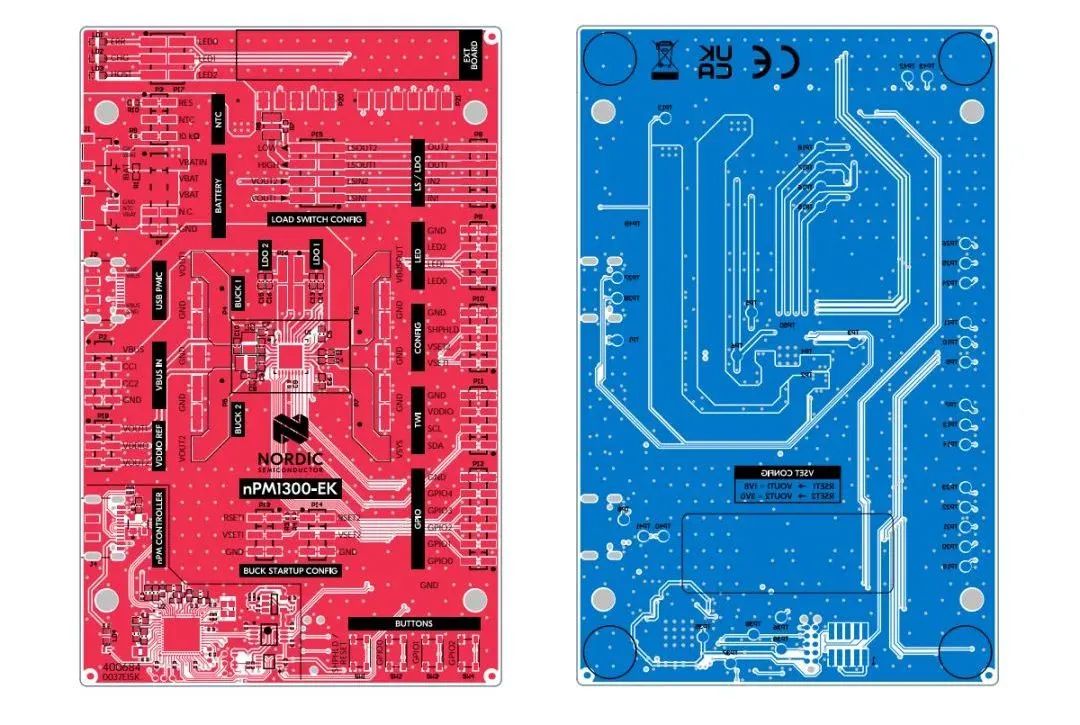

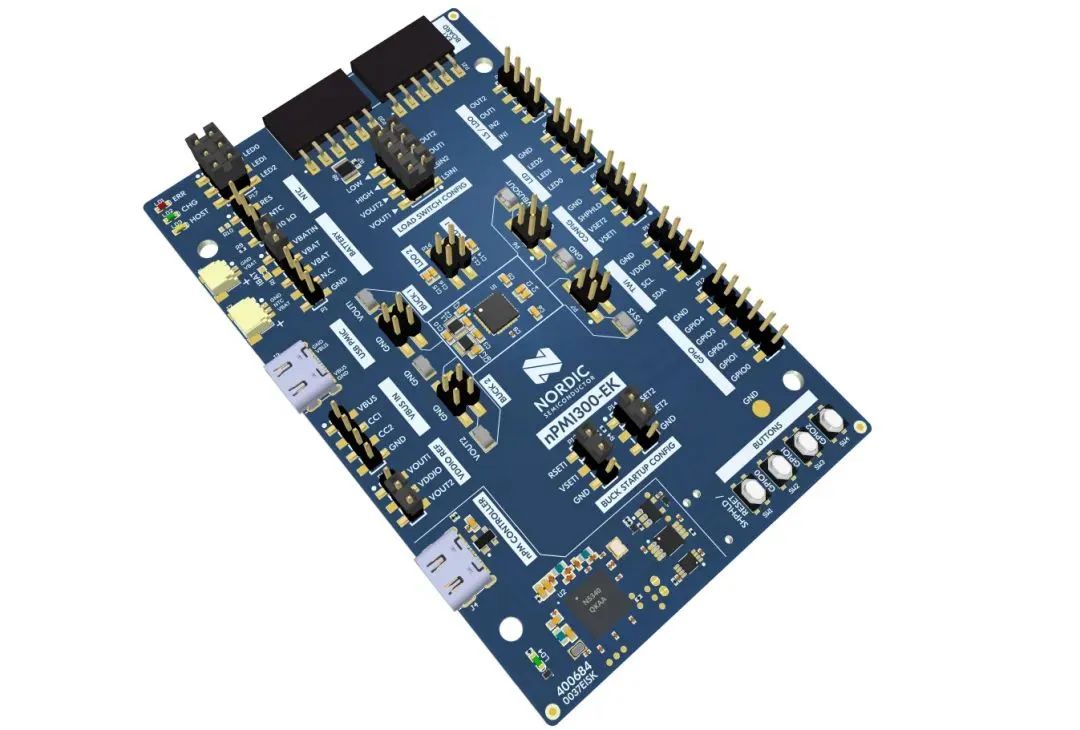

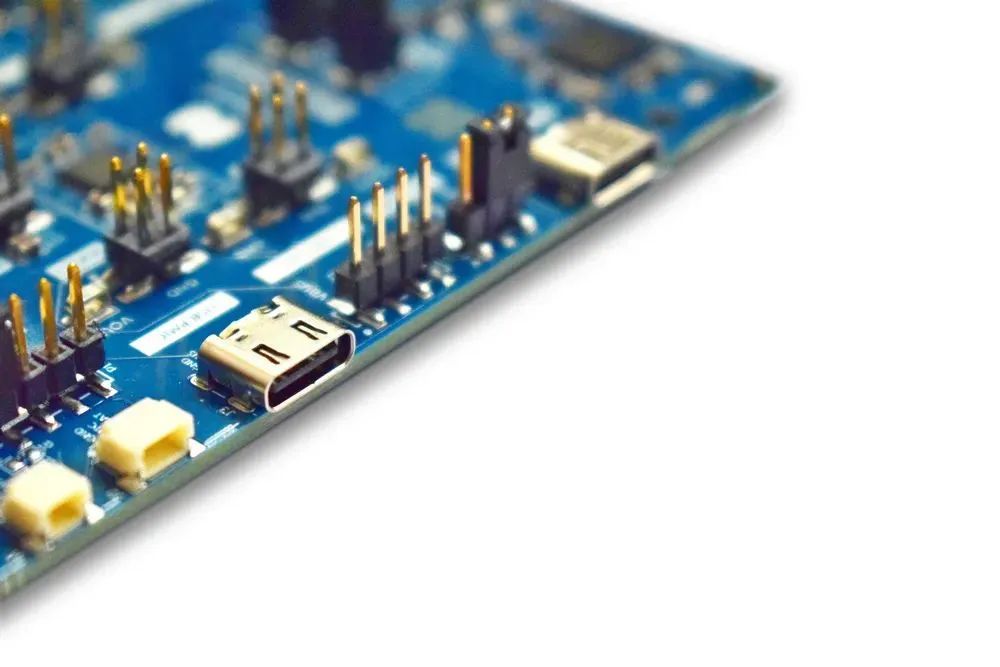

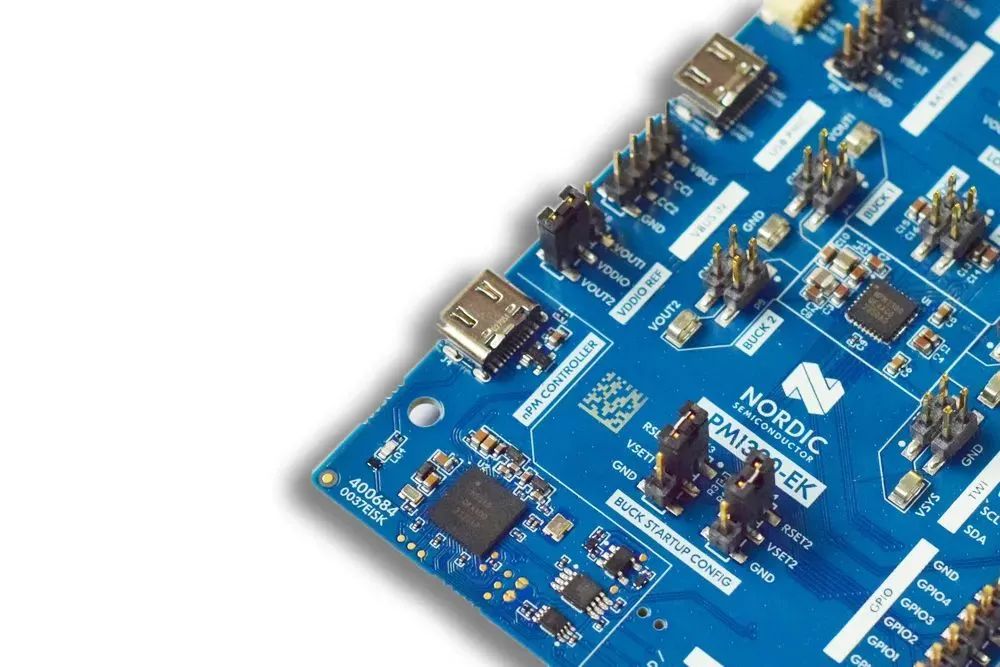

Like many of Nordic’s development boards and evaluation boards, the nPM1300 evaluation kit also adopts a cyan PCB design. The overall size of the board is 100mm long and 64mm wide, using a 4-layer PCB design, based on Altium Designer design software.

The official provides all hardware materials, such as PCB and schematics, drilling files, BOM, Gerber, and all files needed for production design and manufacturing. Now let’s take a detailed look at the hardware resources of the board:

-

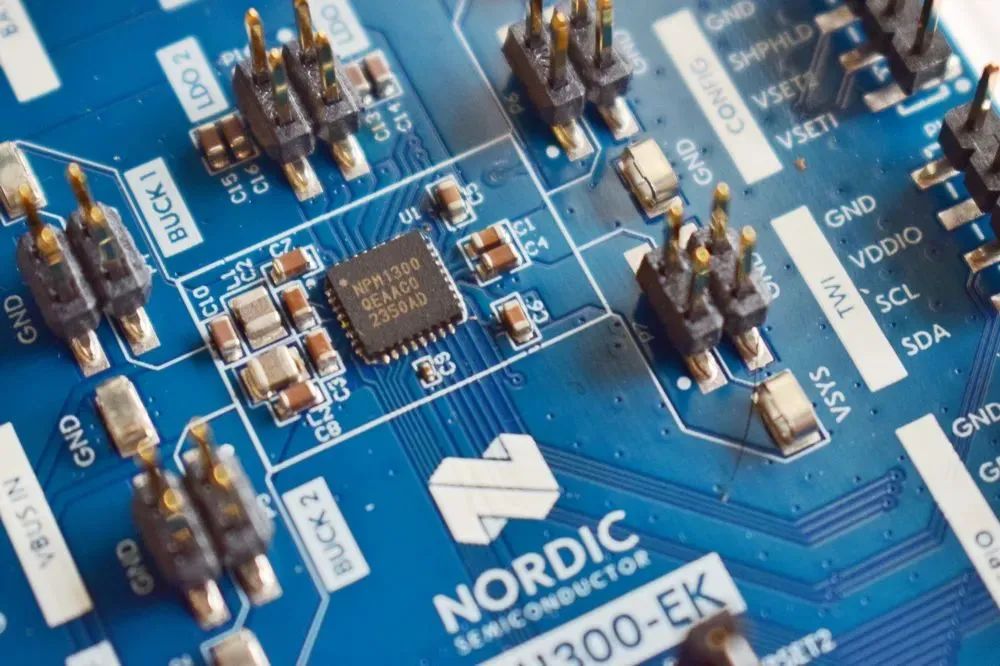

nPM1300 core chip, QFN32 package, all pins are routed through standard 2.54mm pitch headers for flexible evaluation and measurement -

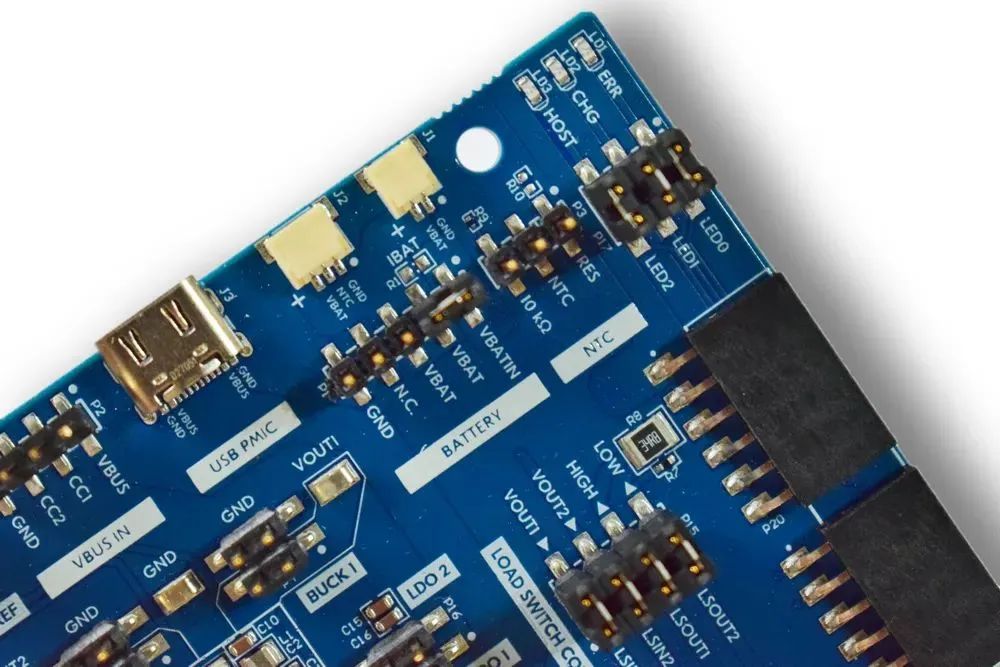

1 SHPHLD button, 3 GPIO tactile buttons, 3 LED indicators -

Supports two battery interfaces, with and without NTC -

The main control chip is nRF5340, connected to the host computer via USB serial port, and configures the nPM1300 registers through IIC communication -

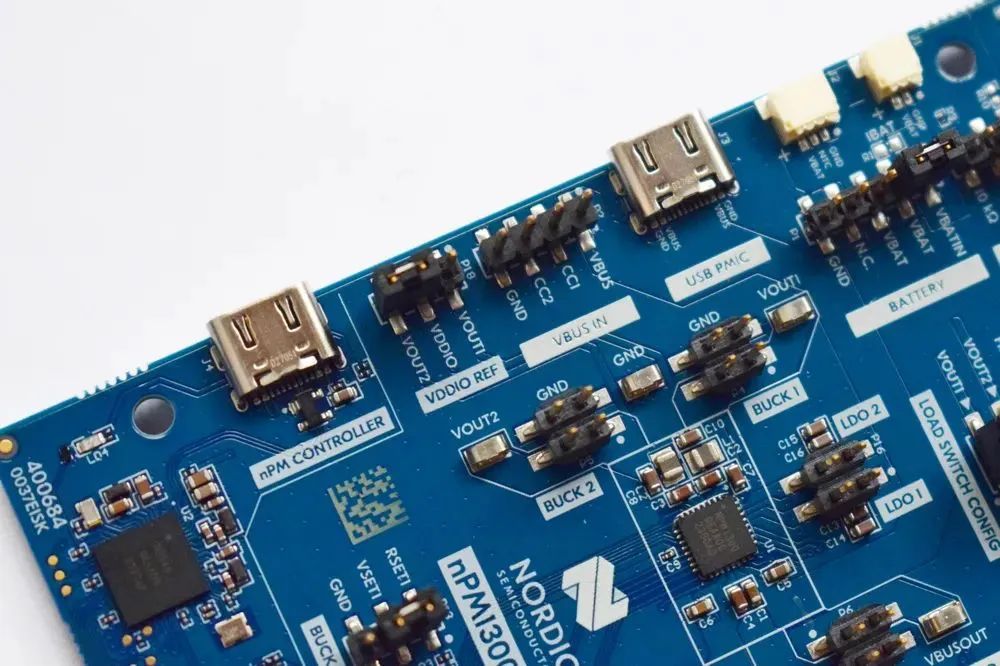

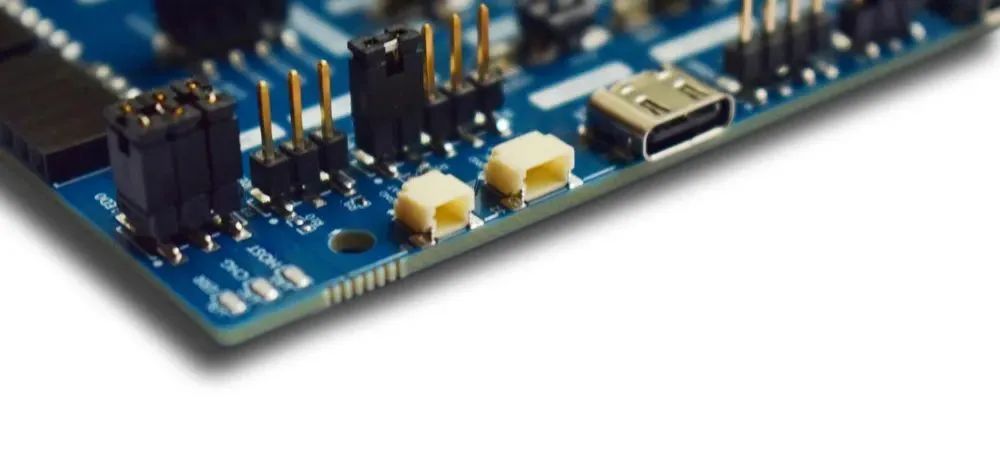

Two USB-C interfaces, one connects to nRF5340 as USB serial function, the other connects directly to nPM1300 -

Multiple voltage test points for easy connection with oscilloscopes and multimeters -

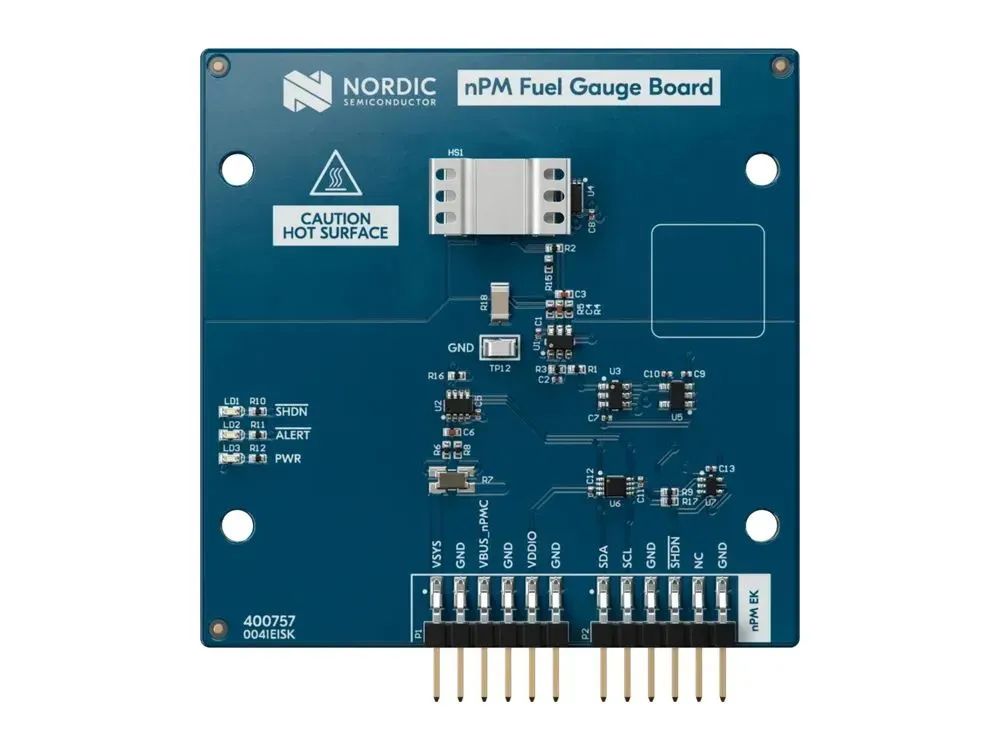

An external expansion interface can be used to connect a matching power meter expansion board

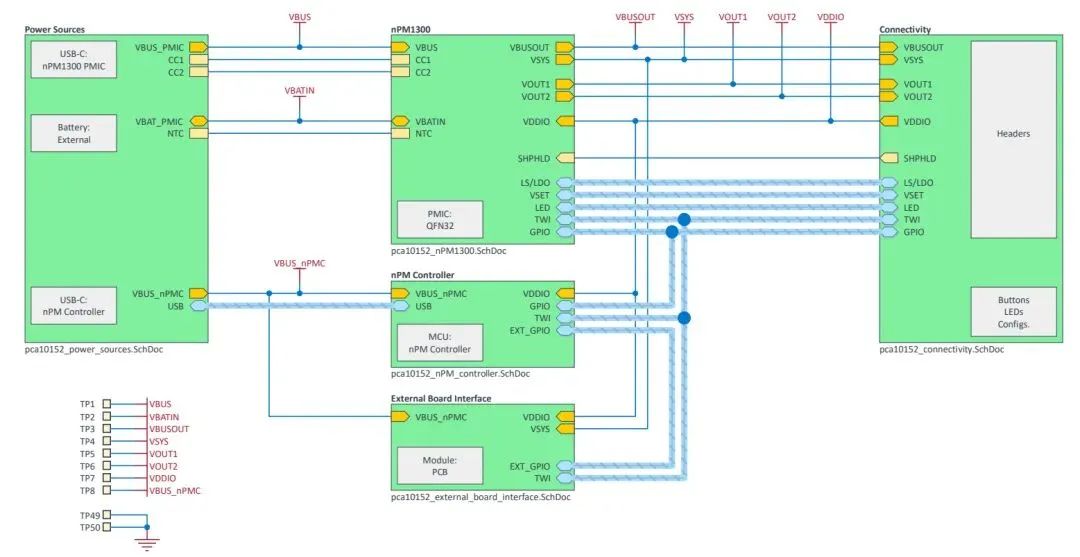

The system block diagram of the nPM1300 evaluation kit is as follows

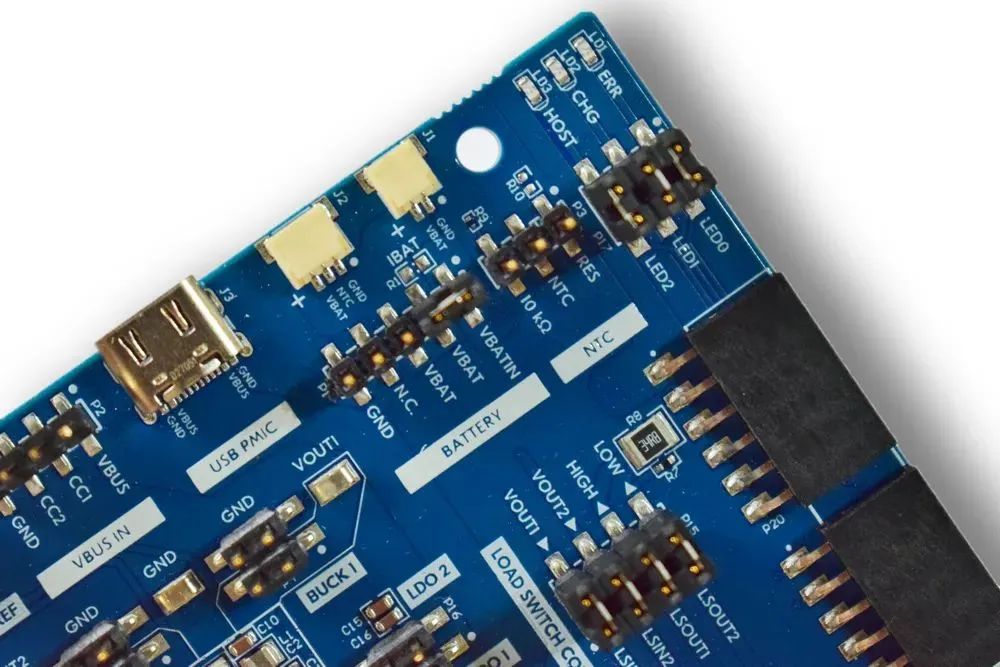

PCB top and bottom layers

PCB 3D effect:

Close-up of the nPM1300 chip

USB-C interface

On-board 3 user buttons

LED

Battery connection

Pins routed through headers

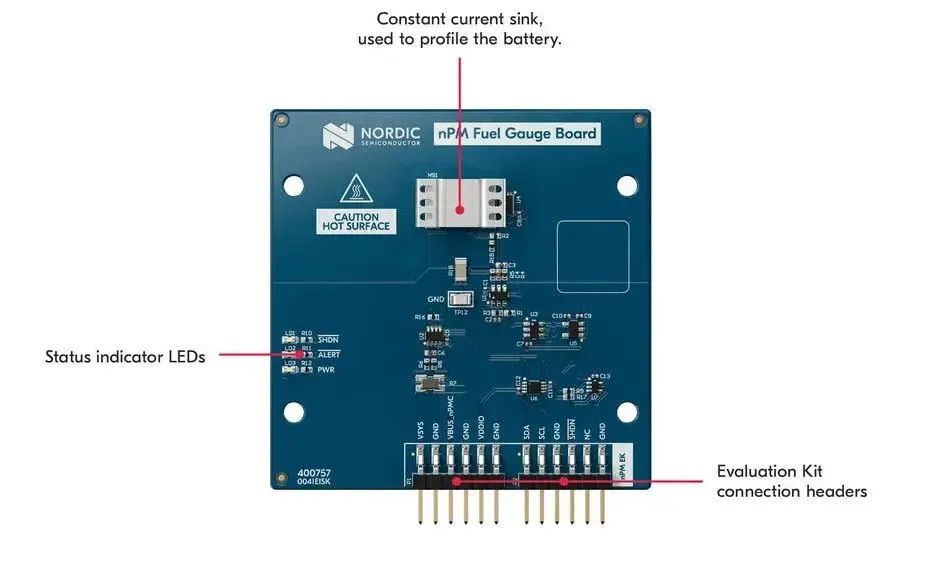

The expansion interface can connect to the power meter expansion board shown in the figure below, used to generate the charge and discharge model of the battery.

4. Introduction to nPM1300 Chip Characteristics

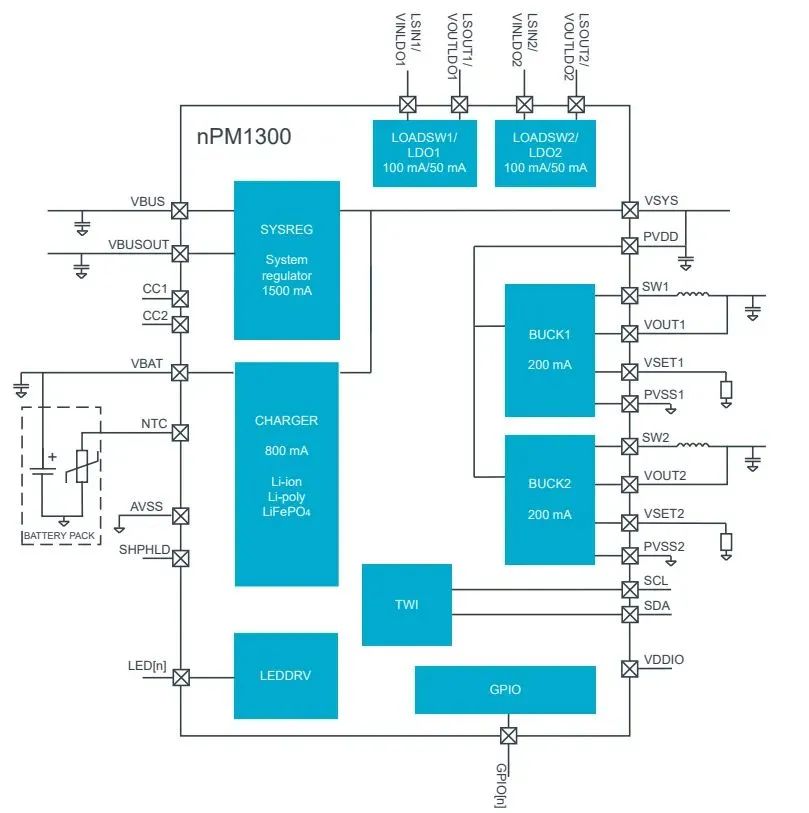

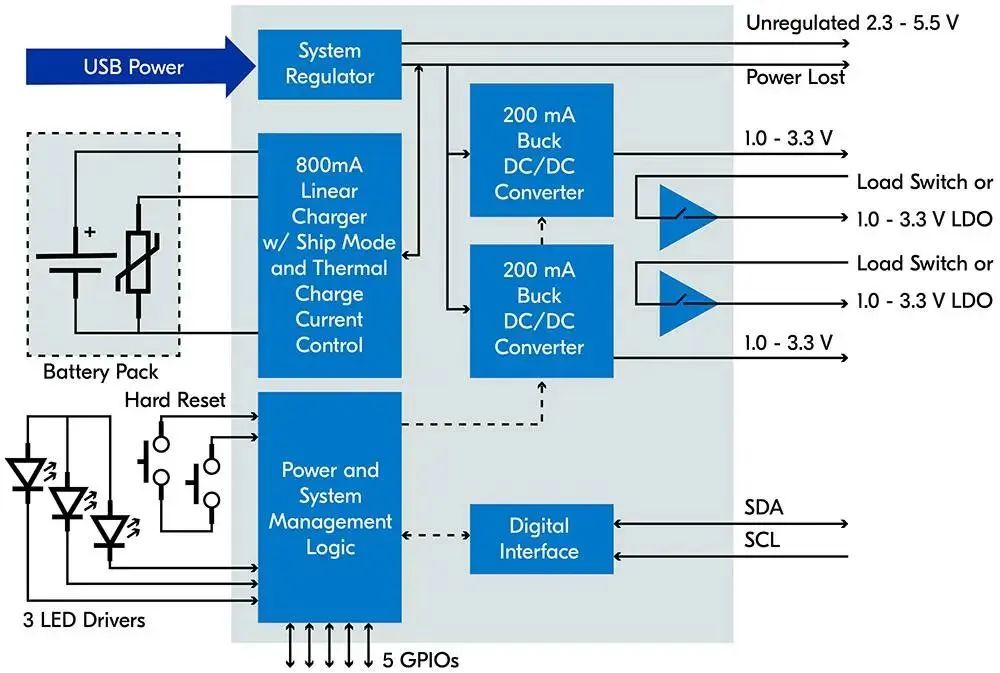

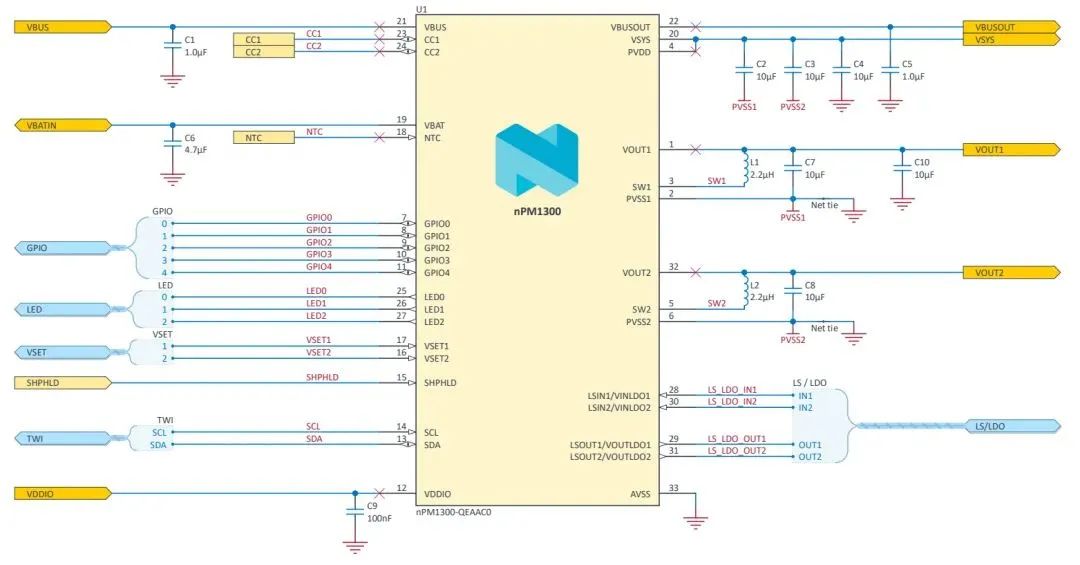

After understanding the hardware resources of the evaluation board, let’s focus on the core of this board—nPM1300 chip. From the official data manual, we can see the internal structure of the chip:

Mainly includes the following parts:

-

DC-DC BUCK converter -

Battery charge and discharge management section -

GPIO and LED driving section -

Digital interface bus section -

Load switch section

The detailed electrical characteristics of nPM1300 are as follows:

-

Two ultra-efficient DC-DC buck outputs, adjustable from 1.0-3.3v, maximum 200mA output -

32-800mA adjustable charging current, step size 2mA, supports NTC input, output voltage from 3.5v to 4.45v -

No limit on battery capacity, supports lithium-ion, lithium polymer, and lithium iron phosphate batteries -

Two 100mA load switches or 50mA LDO, supporting voltage from 1.0-3.3v -

Supports USB Type-C interface, CC pins can be directly connected to chip pins, with built-in 5.1k pull-down resistor, no external configuration needed -

Input voltage 4.0-5.5v, maximum 1.5A, 22v overvoltage protection -

5 configurable GPIOs, 3 configurable LED outputs -

Fully compatible I2C TWI digital bus interface, supporting speeds up to 400KHz -

Manufactured with 180nm technology, operating temperature range -40℃ to 85℃, PN junction temperature less than 125℃ -

Two hardware resets, watchdog timer, wake-up timer, general-purpose timer -

10-bit precision ADC to measure input voltage, battery voltage, current, and chip temperature -

Supports power statistics function, sampling battery voltage, current, and temperature values through internal ADC, and can accurately perform power statistics through the official algorithm -

Overvoltage, undervoltage, overcurrent protection, temperature protection -

Ultra-small package size: 3.1×2.4 mm WLCSP and 5.0×5.0 mm QFN -

Requires only 5 passive components for use -

Supports ultra-low power transport mode, with a static current of 370nA in factory mode -

Graphical interface configuration, one-click export of configuration to the user’s MCU application

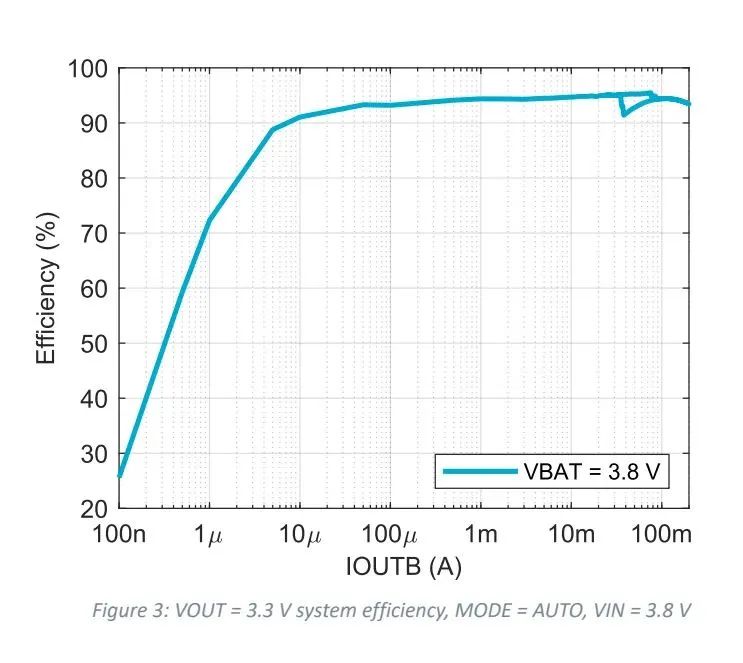

The conversion efficiency at different output currents can reach up to about 95%, which is still very efficient!

Common application scenarios include:

-

Wearable devices -

Handheld entertainment devices -

Portable medical equipment -

Rechargeable smart home sensors -

Mouse, keyboard, touchpad -

Body sensing games and other interactive entertainment devices -

Low-power sensors and other IoT devices

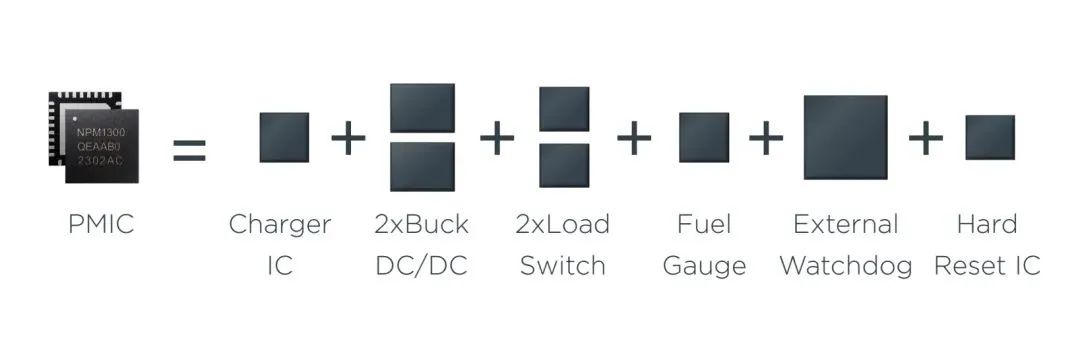

5. nPM1300 One is Better Than Eight

nPM1300 can make users’ work easier, hardware engineers do not need to write code, and software engineers do not need to read data manuals, it is ready to use right out of the box, just set it up in the intuitive graphical interface and export the overlay file, then add it to your SDK project to use. Compared to multiple independent power management chips, nPM1300 integrates almost all the functions of power management chips. It combines the functions of the following 8 chips, including:

-

1 charging management chip -

2 BUCK buck chips -

2 load switch chips -

1 power meter chip -

1 watchdog chip -

1 hardware reset chip

Conventional discrete chip designs require many passive components, leading to complex schematics, large PCB areas, and high BOM costs. The peripheral circuits required for nPM1300 are very simple, needing only 5 passive components for use.

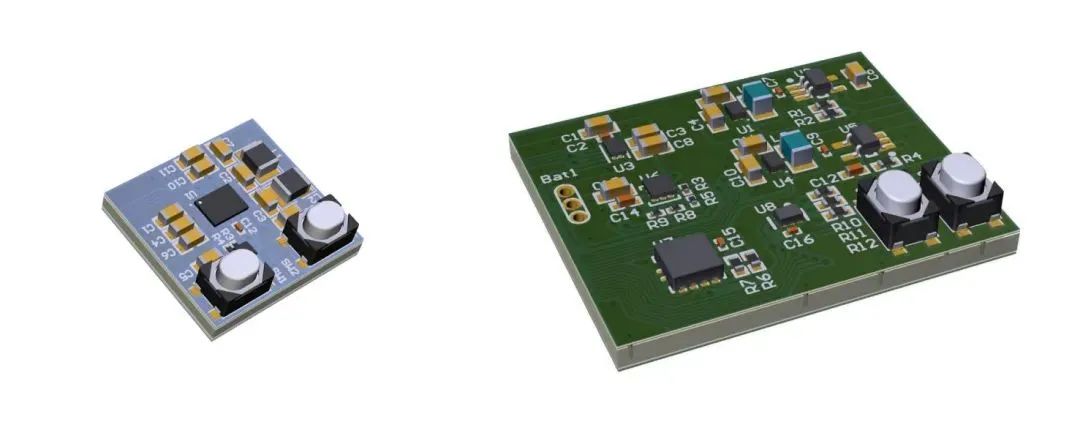

The official provides two recommended layout schemes for the two packages: https://nsscprodmedia.blob.core.windows.net/prod/software-and-other-downloads/reference-layouts/npm1300/qfn/npm1300-qeaa-reference-layout-1_1.ziphttps://nsscprodmedia.blob.core.windows.net/prod/software-and-other-downloads/reference-layouts/npm1300/wlcsp/npm1300-caaa-reference-layout-1_0.zip

Comparison of conventional discrete chips and nPM1300 schematic design:

PCB size comparison design:

It can be said that nPM1300 is truly one is better than eight!

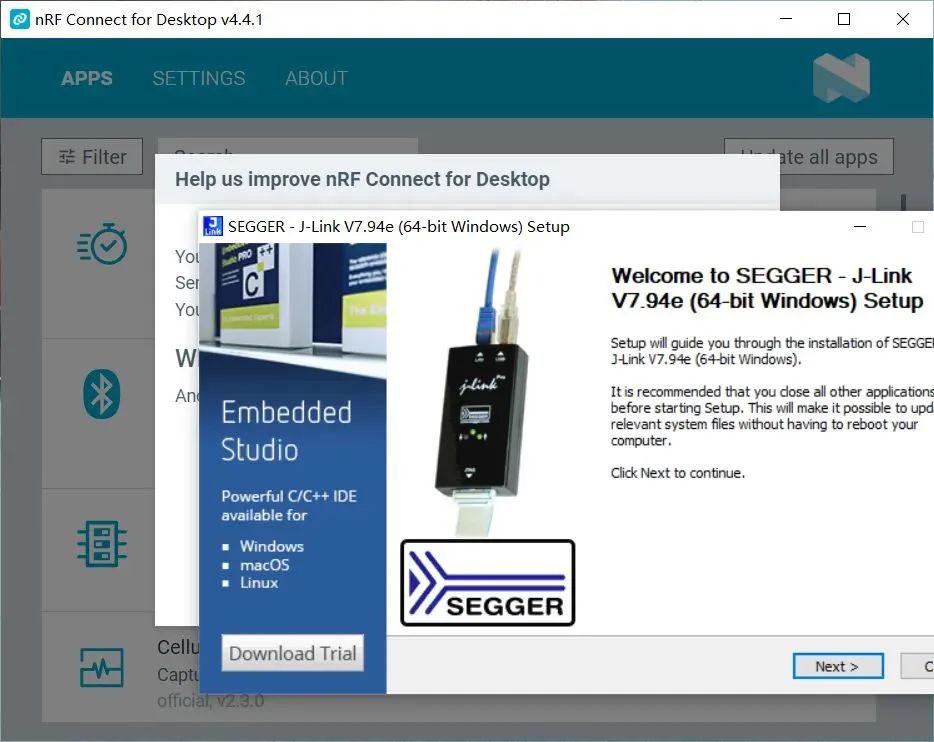

6. nPM1300 Evaluation Kit Hands-On Experience

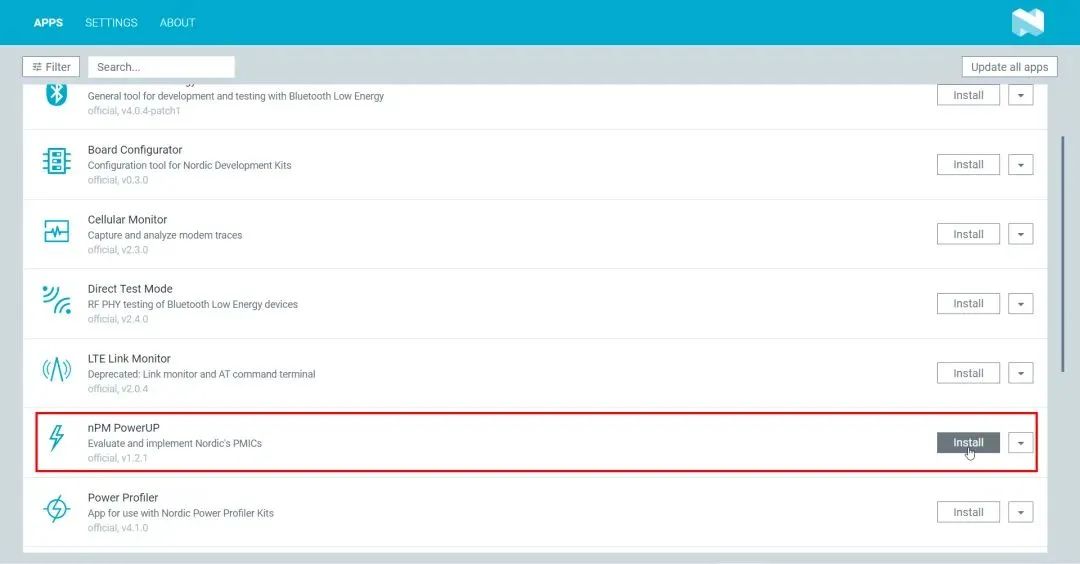

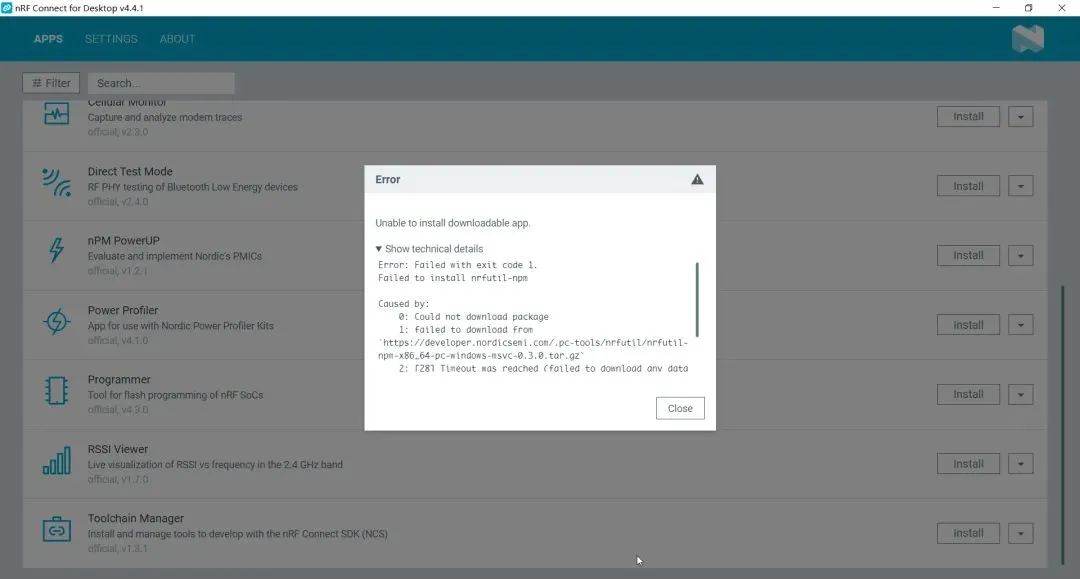

After installation, open the software, and you can see that this tool is a collection of commonly used host software for Nordic chips. We are evaluating the PMIC, so we also need to install nPM PowerUP,

If installation fails, you can try a few more times or restart your computer.

After installation, prepare two Type-C USB data cables, and connect the two USB interfaces of the board to the computer. You can see that the LD4 indicator light is breathing. If the USB PMIC interface is not connected, the LD4 indicator light is in a fast flashing state.

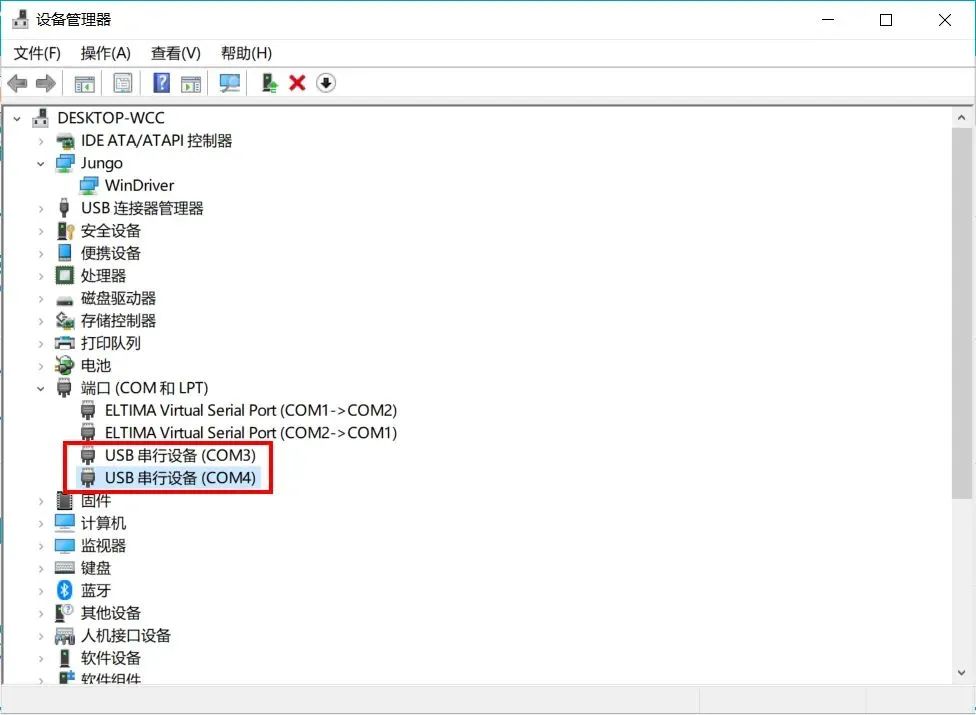

After connecting to the computer, the device manager will show two additional serial numbers:

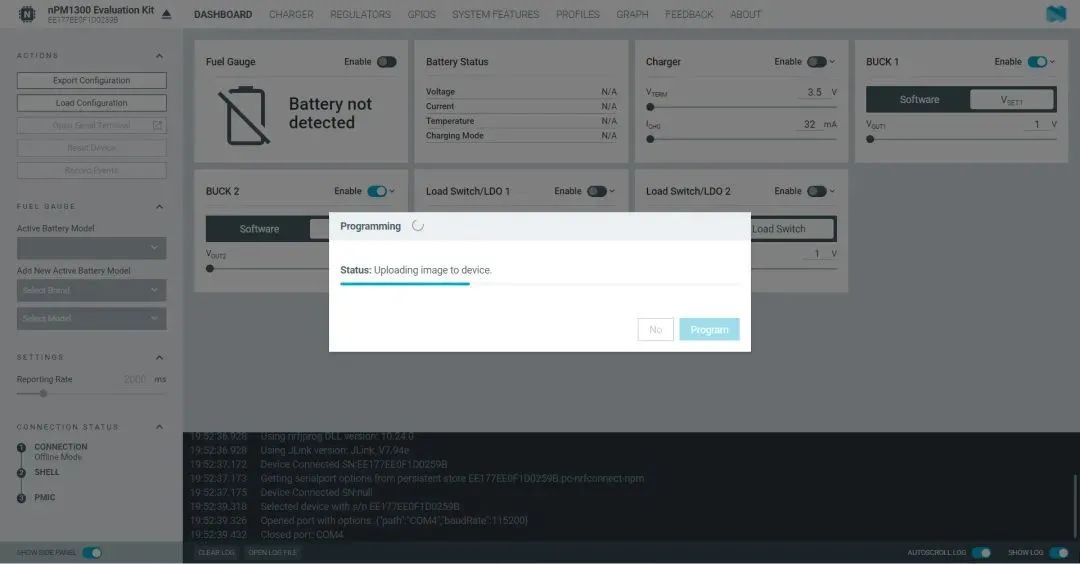

The first time using this software, you need to update the firmware of the SoC on the board:

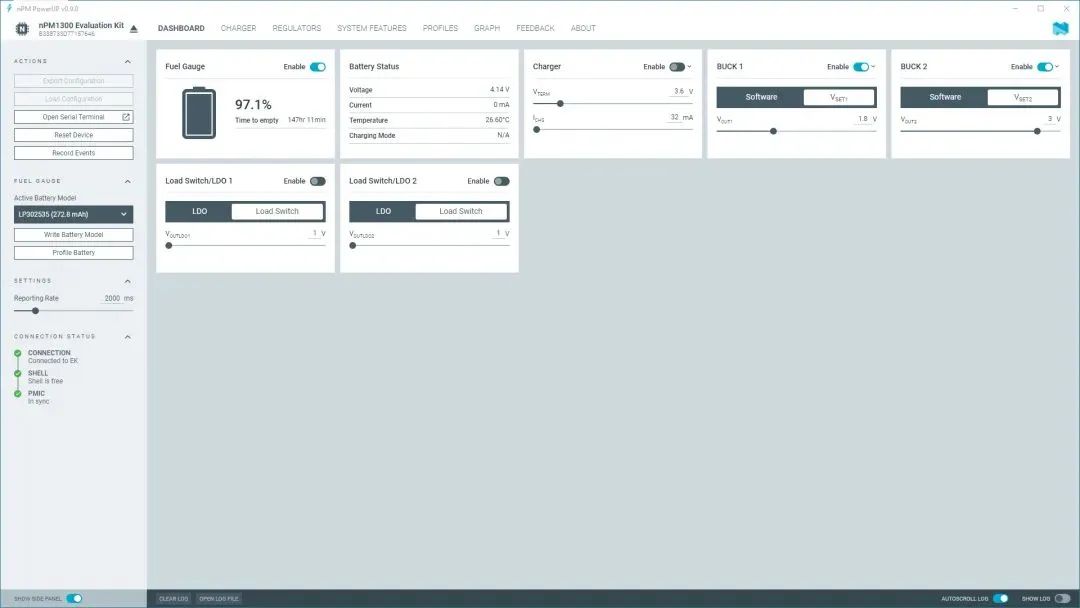

Open the nPM PowerUP software to connect the board, and you can see the logs in the bottom console:

14:52:40.188 Device Connected SN:EE177EE0F1D0259B14:52:40.189 Getting serialport options from persistent store EE177EE0F1D0259B.pc-nrfconnect-npm14:52:40.190 Device Connected SN:null14:53:45.467 Selected device with s/n EE177EE0F1D0259B14:53:45.478 Opened port with options: {"path":"COM4","baudRate":115200}14:53:45.575 Closed port: COM414:53:45.575 Device setup ready for device with s/n EE177EE0F1D0259B14:53:45.581 Opened port with options: {"path":"COM4","baudRate":115200}14:53:47.831 Reset cause: SWRESETThe graphical interface is as shown in the figure below:

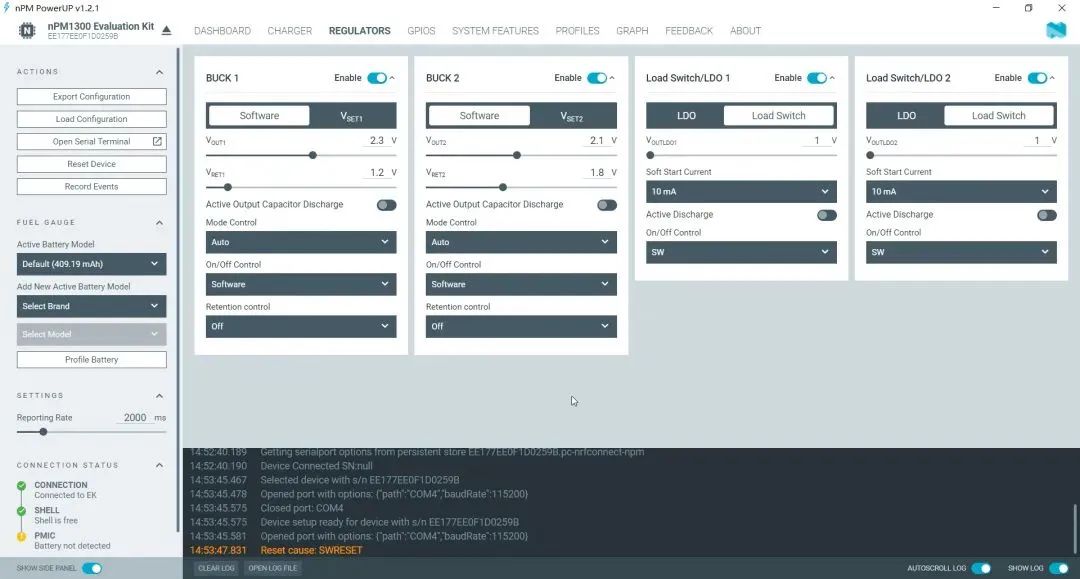

The basic functions of each window are:

-

DASHBOARD: Overall configuration of nPM1300 chip -

CHARGER: Battery charging current and voltage configuration -

REGULATORS: DC-DC converter and load switch configuration -

GPIOS: Configuration of 5 GPIOs and 3 GPIOs -

SYSTEM FEATURES: Configuration of system reset, timer, POR, input current, etc. -

PROFILES: Battery model creation and loading -

GRAPH: Real-time curves of battery voltage, current, and temperature

You can adjust the output voltage value arbitrarily by sliding the slider or manually entering numbers. Using a multimeter or oscilloscope to measure the voltage values of VOUT1 and VOUT2 will change with the set values. Since I do not have a usable lithium battery on hand, this evaluation did not assess the charging, discharging, and power statistics functions.

Interested friends can connect a battery for testing and see real-time information such as battery voltage, current, and temperature in the software.

The official also provides a power meter expansion board that matches this evaluation kit—nPM Fuel Gauge Board, to generate battery charge and discharge model data. According to official information, within 12 hours under temperature changes from -20°C to +60°C, the software algorithm power meter accuracy error is within 3%.

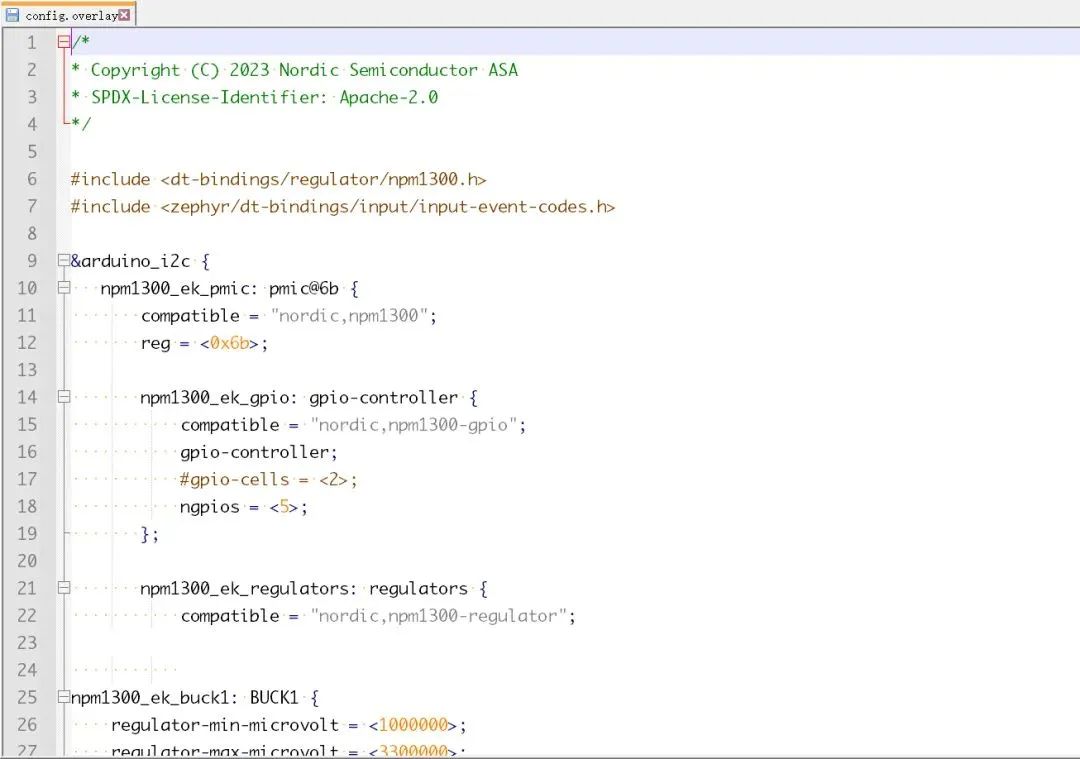

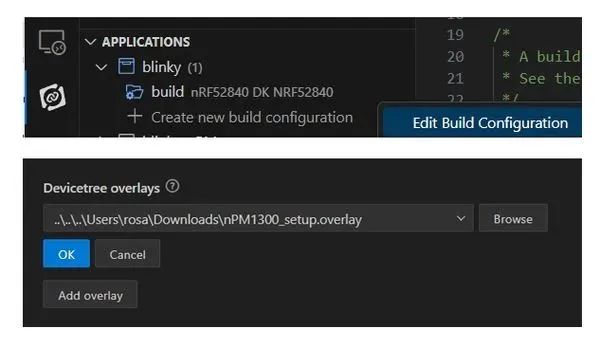

After configuring the chip, click on the left Export Configuration to export the current configuration, with optional overlay and json file formats. The overlay file can be used in our MCU applications. After adding this file to the project, it will be called in the Zephyr TWI driver.

To execute the device tree overlay file, please click “edit build configuration” in the nRF Connect for VS Code extension, and then use the “Add overlay” button under “Devicetree overlay” to add the overlay file.

Make sure that prj.conf includes these configurations:

CONFIG_GPIO=yCONFIG_SHELL=yCONFIG_LOG=yCONFIG_REGULATOR=yCONFIG_SENSOR=yCONFIG_LED=yIf your application does not enable the IIC bus, you also need to add the following lines of code at the end of the file:

&i2c0_default { group2 { psels = <NRF_PSEL(TWIM_SCL, 0, 27)>, <NRF_PSEL(TWIM_SDA, 0, 26)>; bias-pull-up; }; };/delete-node/ &{/pin-controller/i2c0_default/group1/};This will enable the internal pull-up for the I2C line, where 27 and 26 values specify the SDA and SCL pin numbers used by the SoC.

7. nPM1300 Evaluation Kit Supporting Materials

The supporting materials for the evaluation kit are very comprehensive, making it almost ready to use for developers, mainly including:

-

Board hardware material package, including schematics, PCB, BOM, Gerber filesnsscprodmedia.blob.core.windows.net/prod/software-and-other-downloads/dev-kits/npm1300-ek/npm1300-evaluation-kit—hardware-files-1_1_0.zip

-

Chip data manualinfocenter.nordicsemi.com/pdf/nPM1300_PS_v1.0.pdf -

nPM1300 EK evaluation kit introductionwww.nordicsemi.com/-/media/Software-and-other-downloads/Product-Briefs/Translated-versions/nPM1300EK.pdf -

nPM1300 chip product introductionwww.nordicsemi.com/-/media/Software-and-other-downloads/Product-Briefs/Translated-versions/nPM1300-PMIC_PB_SC.pdf -

Visual graphical configuration softwarewww.nordicsemi.com/Products/Development-tools/nrf-connect-for-desktop

8. References

-

nPM1300 official homepagewww.nordicsemi.cn/products/npm1300/ -

nPM1300 EK official homepagewww.nordicsemi.cn/tools/npm1300ek -

nPM1300 hardware design guide https://infocenter.nordicsemi.com/topic/nwp_050/WP/nwp_050/intro.html?cp=7_1_4_1 -

In-depth analysis of Nordic’s new generation PMIC in low-power wireless IoT devices (Part 1)www.eeyxs.com/livebroadcast/index/playback.html?tid=842&cid=6471 -

In-depth analysis of Nordic’s new generation PMIC in low-power wireless IoT devices (Part 2)www.eeyxs.com/livebroadcast/index/playback.html?tid=842&cid=6472 -

nPM1300 and nRF54 series solutionswww.eeyxs.com/livebroadcast/index/playback.html?tid=842&cid=6473 -

Webinar on July 5, 2023, Nordic’s power management product director Geir Kjosavikwww.youtube.com/watch?v=aN5umN5zV0E

9. Summary

This article introduces the characteristics of the nPM1300 power management chip and briefly experiences the basic functions of the evaluation kit and the basic use of the graphical configuration interface. During the use process, it can be found that this chip is very simple and easy to use, almost without the need to read the data manual or write code to apply it in the project. It should be noted that the nPM1300 cannot be used independently and requires an MCU host for configuration and control through the I2C interface. The recommended typical application is to use it with nRF52 and nRF53 series SoCs, but it can also be used on other non-Nordic chips.

Overall, the high integration of nPM1300 greatly reduces the user’s workload. Its ultra-low power consumption and ultra-high efficiency are the advantages of this chip, making it very suitable for low-power IoT devices that do not require high current.

【Contact Us】

Chinese official website: www.nordicsemi.cn

English official website: www.nordicsemi.com

WeChat public account: nordicsemi

【Nordic Developer Forum】

https://devzone.nordicsemi.com

【Sales Contact】

Beijing Branch: +86 010 8438 2767

Shanghai Branch: +86 21 6330 0620

Shenzhen Branch: +86 755 8322 0147