What are the factors for selecting a power management chip? A power management chip is responsible for converting, distributing, detecting, and managing electrical energy in electronic device systems. It mainly identifies the CPU power supply amplitude, generates corresponding short pulse waves, and drives subsequent circuits for power output. Below, I will introduce how to correctly choose a power chip.

How to correctly choose a power chip?

In circuit design, the commonly used power devices are generally of two types: DC/DC and LDO.

1. LDO is a low-dropout linear regulator, or low-voltage drop device, which indicates it is generally used in situations that require voltage reduction. It has advantages such as low cost, low noise, and low quiescent current. It requires very few external components, usually just one or two bypass capacitors.

The reason why the performance of LDO linear regulators can reach this level is mainly due to the adjustment tube being a P-channel MOSFET. P-channel MOSFETs are voltage-driven and do not require current, which greatly reduces the current consumed by the device itself. Additionally, the voltage drop across the P-channel MOSFET is roughly equal to the product of the output current and the on-resistance. Since the on-resistance of MOSFETs is very small, the voltage drop across them is very low.

2. DC/DC means converting direct current to direct current (conversion of different direct current values). Any device that meets this definition can be called a DC/DC converter, including LDOs. However, generally speaking, devices that convert direct current to direct current through a switching method are referred to as DC/DC.

DC/DC includes boost, buck, buck-boost, and inverting circuits. The advantages of DC/DC converters are high efficiency, the ability to output large currents, and low quiescent current. With increased integration, many new types of DC/DC converters only require a few external inductors and filter capacitors. However, these types of power controllers tend to have larger output ripple and switching noise, and their costs are relatively high.

How to select a power chip?

If the input voltage and output voltage are very close, it is best to use an LDO regulator, which can achieve high efficiency and, most importantly, low cost. Some experts have summarized suitable applications for LDO:

▪ For products that require high power noise suppression and ripple suppression,

▪ For small PCB areas, such as mobile phones and other handheld electronic products,

▪ For circuits where inductors cannot be used, such as mobile phones,

▪ For power supplies that require instantaneous calibration and output state self-checking functions,

▪ For products that require low dropout voltage and low self-consumption of the regulator,

▪ For products that require low circuit costs and simple schemes.

If the input voltage and output voltage differ significantly or if there is a large voltage drop, then a switching-type DC/DC should be considered. This is because the input current of an LDO is generally equal to the output current; if the voltage drop is too large, too much energy is wasted in the LDO, resulting in low efficiency, making DC/DC more suitable. Although DC/DC has high efficiency and can output large currents, it also has larger output interference, a relatively larger size, and slightly higher costs.

In summary, when boosting, one must choose DC/DC, while for bucking, whether to choose DC/DC or LDO should be analyzed based on cost, efficiency, noise, and performance.

Factors in Choosing Power Management Chips

The scope of power management is quite broad, including not only standalone power conversion (mainly DC to DC, i.e., DC/DC), standalone power distribution and detection, but also systems that combine power conversion and management. Accordingly, the classification of power management chips also includes these aspects, such as linear power chips, voltage reference chips, switching power chips, LCD driver chips, LED driver chips, voltage detection chips, battery charging management chips, etc. Below is a brief introduction to the main types and applications of power management chips.

If the designed circuit requires the power supply to have high noise and ripple suppression, occupy a small PCB area (such as mobile phones and other handheld electronic products), not allow the use of inductors (such as mobile phones), require instantaneous calibration and output state self-checking functions, and require the regulator to have low dropout and low self-consumption, as well as low circuit costs and simple schemes, then linear power is the most appropriate choice. This power includes the following technologies: precision voltage reference, high-performance low-noise operational amplifiers, low-dropout regulation tubes, and low quiescent current.

In low-power supply, operational amplifier negative power supply, LCD/LED driving, etc., capacitor-based switching power chips, commonly known as charge pumps, are often used. Many chip products based on the working principle of charge pumps exist, such as AAT3113. This is a white LED driver chip composed of a low-noise, constant-frequency charge pump DC/DC converter. AAT3113 uses fractional multiplication (1.5×) conversion to improve efficiency.

The device drives four LED channels in parallel. The input voltage range is 2.7V to 5.5V, providing approximately 20mA of current for each output channel. The device also features thermal management characteristics to protect against short circuits at any output pin. Its embedded soft-start circuit prevents current overshoot during startup. AAT3113 utilizes a simple serial control interface for chip enabling, disabling, and 32-level logarithmic brightness control.

On the other hand, inductive DC/DC chips have the widest application range, including PDAs, cameras, backup batteries, portable instruments, miniature telephones, motor speed control, display bias, and color adjustment. The main technologies include: BOOST structure current mode loop stability analysis, BUCK structure voltage mode loop stability analysis, BUCK structure current mode loop stability analysis, overcurrent, overtemperature, overvoltage, and soft start protection functions, synchronous rectification technology analysis, and reference voltage technology analysis.

In addition to basic power conversion chips, power management chips also include power control chips aimed at rational utilization of power. Such as intelligent fast charging chips for NiH batteries, lithium-ion battery charging and discharging management chips, overvoltage, overcurrent, overtemperature, short-circuit protection chips for lithium-ion batteries; chips for switching management between line power supply and backup batteries, USB power management chips; charge pumps, multi-channel LDO power supplies, power-on timing control, various protections, and complex power chips for battery charging and discharging management.

What specific steps should be taken for DC-DC power solutions?

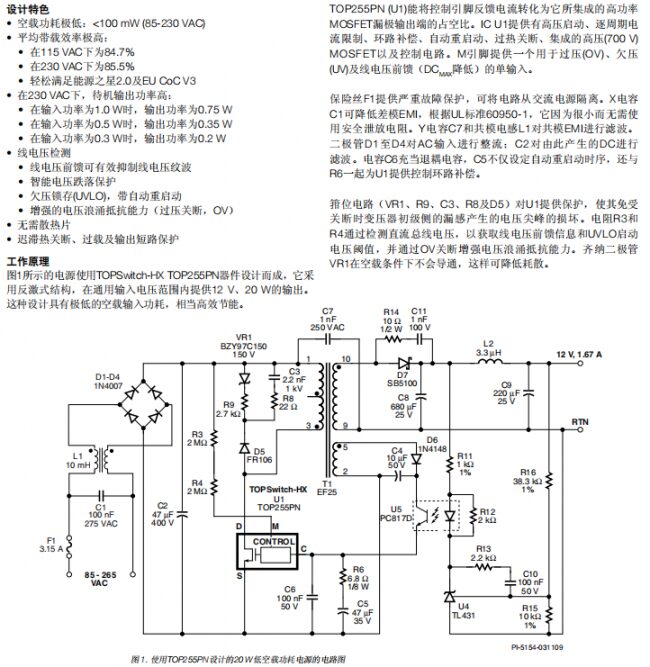

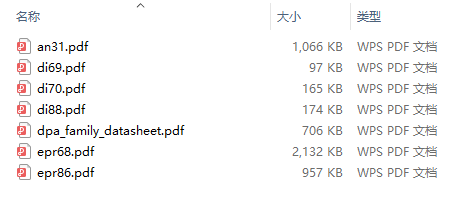

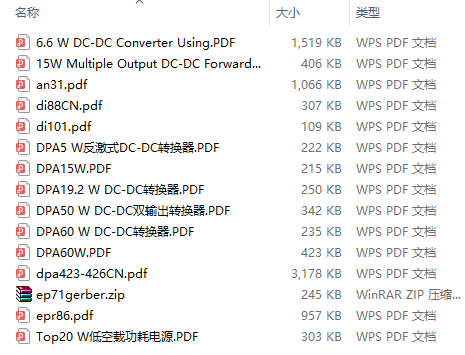

After introducing the specific selection of chips, we then need to provide power design solutions. Here, the editor has compiled nearly 100 power management integrated circuits, covering various power circuit boost and buck, DC/DC, AC/DC, LDO, surely there is one that you want.

How to obtain the above power management (PMIC) design solution materials?

Long press the following QR code, scan to join the group to receive for free!