User Question:

What are the differences between BJ technology and SLM technology?

1. Different Principles:

(1) SLM Technology: Uses a laser to directly melt metal powder, stacking layer by layer;

(2) BJ Technology: First sprays adhesive onto the metal powder, then sinters at high temperatures to solidify.

2. Part Performance:

(1) SLM Technology: Produces high-strength, high-performance metal parts, with strength close to that of forged parts;

(2) BJ Technology: Does not require support for printing, thus achieving better surface finish, and allows for faster mass printing of metal parts.

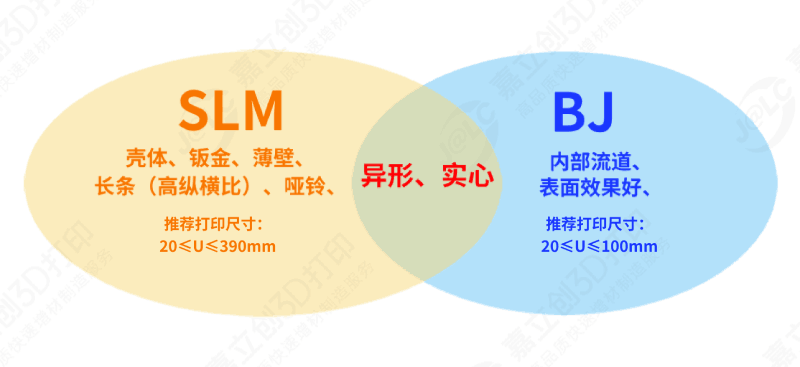

3. Applicable Scenarios:

(1) SLM Technology: Suitable for printing housings, sheet metal, and long structures that require high strength in metal parts;

(2) BJ Technology: Suitable for printing medium-sized metal parts with complex internal channels and high surface quality requirements, while avoiding printing easily deformable structures (such as sleeve parts, dumbbell shapes, and irregular shapes) and extremely small-sized structures.

Q&A | What is X Resin in 3D Printing?What materials are used?

Q&A |Why does 3D printing not support the production of models like firearms and knives?

Q&A | Why is STL file format preferred for 3D printing?

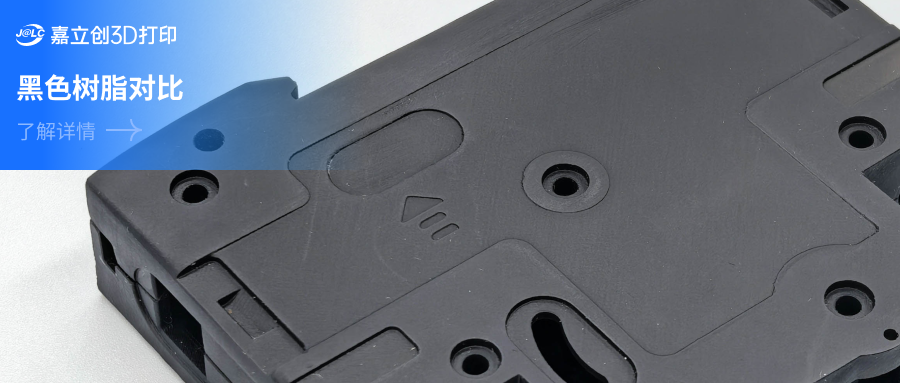

Q&A | What is the difference between black resin [JLCBlack] and [Black]?

👇 Scan to enter 👇