New friends please  Click the blue text above “China Intelligent” to follow for free

Click the blue text above “China Intelligent” to follow for free

Article sourced from: Qianjia Zhike, copyright belongs to the original author. If there is any infringement, please leave a message for deletion.

In the past decade, 3D printing has become a buzzword. Although 3D printing in the construction industry was initially created for product development, it has evolved to become a major player in many industries, including construction.

3D printing in construction is a new technology that uses machines to build and assemble structures, replacing some traditional manual labor. It is a more cost-effective, convenient, and environmentally friendly way to create new structures. Understanding the advantages of 3D printing in construction may help assess whether this technology can accelerate operations and improve customer satisfaction.

Next, we will explore 3D printing in the construction industry through six case studies.

What is 3D Printed Architecture?

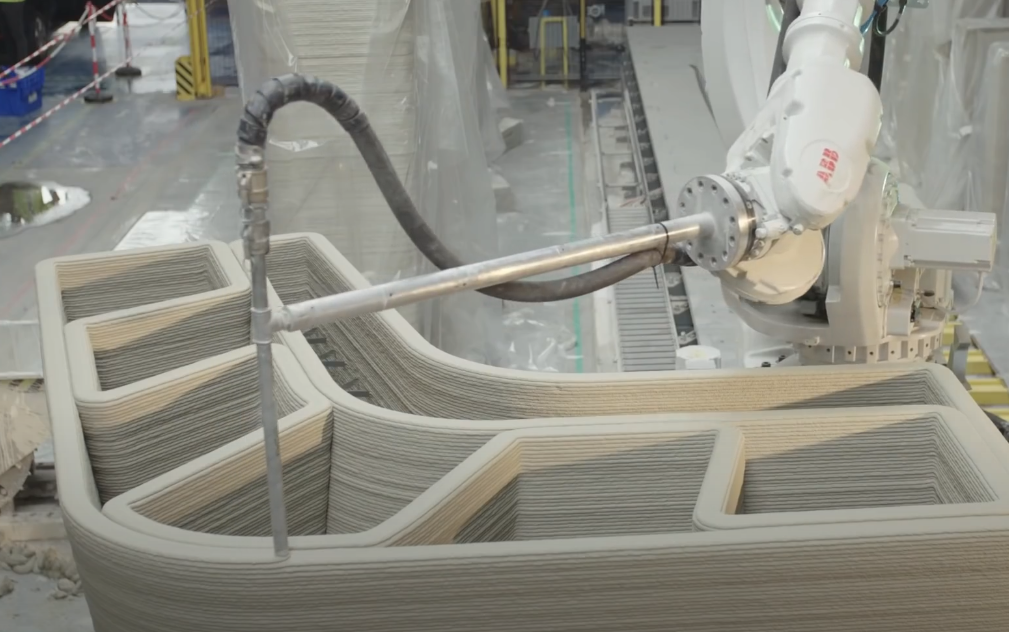

Buildings constructed using additive manufacturing processes (more specifically, 3D printing in the construction industry) are referred to as 3D printed buildings, 3D printed structures, or 3D printed architecture. To create the structural elements of the structure, materials (usually concrete or other types of construction-grade materials) are deposited layer by layer.

3D printed buildings typically use large 3D printers that can regularly extrude building materials according to pre-programmed designs. The printer constructs the building structure based on digital models or architectural designs, stacking materials layer by layer.

3D printing in construction, also known as additive manufacturing, has become a transformative technology across various industries, including construction. Here are some important reasons why 3D printing in construction is significant:

Speed and Efficiency: 3D printing in construction allows for faster and more efficient construction operations. Using 3D printing, complex structures can be built quickly, with the required time being only a fraction of what traditional construction methods would take. Therefore, construction schedules can be significantly shortened, and productivity can be improved.

Cost Reduction: 3D printing in construction can save costs through the automation of construction processes. It reduces the need for manual labor, minimizes waste, and maximizes resource utilization. Additionally, 3D printing can be used for on-site construction of structures, saving transportation costs associated with using prefabricated components.

Design Freedom: 3D printing in construction offers great design flexibility. It allows architects and engineers to create complex and customized designs that are difficult or impossible to achieve with traditional construction methods. This technology can construct complex geometries, organic shapes, and unique architectural features.

Sustainability: The use of sustainable construction methods is becoming increasingly important, and 3D printing in construction can help achieve this goal. Reducing construction waste, minimizing energy use, and using environmentally friendly materials can all be accomplished through 3D printing. Careful management of material usage also helps maximize resource efficiency.

Customization and Adaptability: With 3D printing in construction, it is now easier to modify structures to meet specific needs. This level of adaptability is particularly beneficial when building in remote or challenging areas or in regions prone to natural disasters. 3D printing in construction enables rapid prototyping and iterative design processes, simplifying necessary modifications and improvements.

In summary, 3D printing in construction has the potential to revolutionize the construction industry, providing cost-effective, sustainable, and personalized building solutions while introducing new technologies and streamlining processes. As technology advances, its impact on the construction industry may become even more profound.

Key Steps in 3D Printing in Construction

3D printing in construction creates structures by layering materials, fundamentally changing traditional construction methods.

The following are key steps for successfully implementing 3D printing in construction projects:

-

Design Phase: First, conduct comprehensive design considering structural integrity, material requirements, and project specifications. Collaborate with architects and engineers to create 3D models compatible with construction-grade materials.

-

Material Selection: Choose materials suitable for 3D printing, focusing on durability, cost-effectiveness, and compatibility with the selected printing technology. Common materials include concrete mixtures, polymers, and composites specifically designed for construction purposes.

-

Printing Technology: Select the appropriate 3D printing technology based on project scale and requirements. Options range from robotic arms and gantry systems to large 3D printers. Consider factors such as printing speed, accuracy, and build volume.

-

Site Preparation: Set up 3D printing equipment and ensure a controlled environment, preparing the construction site. Calibrate the printing system, considering environmental conditions such as temperature and humidity.

-

Printing Process: Initiate the printing process according to the programmed design. Monitor the printing process in real-time, addressing any issues that may arise. Adjust parameters as needed to ensure accurate material layering.

-

Post-Processing: After printing is complete, perform necessary post-processing tasks. This may include removing support structures, surface finishing, and ensuring the structure meets quality standards.

-

Quality Assurance: Implement strict quality assurance processes to verify structural integrity and compliance with design specifications. Conduct inspections, material testing, and structural evaluations to ensure the safety and longevity of the printed structure.

-

Regulatory Compliance: Ensure compliance with local building codes and regulations governing 3D printed structures. Collaborate with regulatory bodies to obtain the necessary approvals and certifications for construction projects.

-

Maintenance and Monitoring: Develop maintenance plans and implement monitoring systems to track the long-term performance of 3D printed structures. Regular assessments can identify potential issues and ensure ongoing safety and functionality of the structure.

By following these steps, construction professionals can efficiently complete the 3D printing process to create innovative structures that shorten construction time and reduce costs. Staying informed about advancements in technology and materials will continuously improve the efficiency of 3D printing in the construction field.

Case Studies of 3D Printing in Construction

The innovations in 3D printing are reshaping the landscape of the construction industry, offering unprecedented possibilities in design, efficiency, and cost-effectiveness. Next, we will showcase six notable cases of buildings constructed using 3D printing (from residential homes to complex bridges), demonstrating the transformative potential of this technology in the construction industry.

1. Tecla House

Architect: MCA Architects

City: Ravenna, Italy

Project Year: 2021

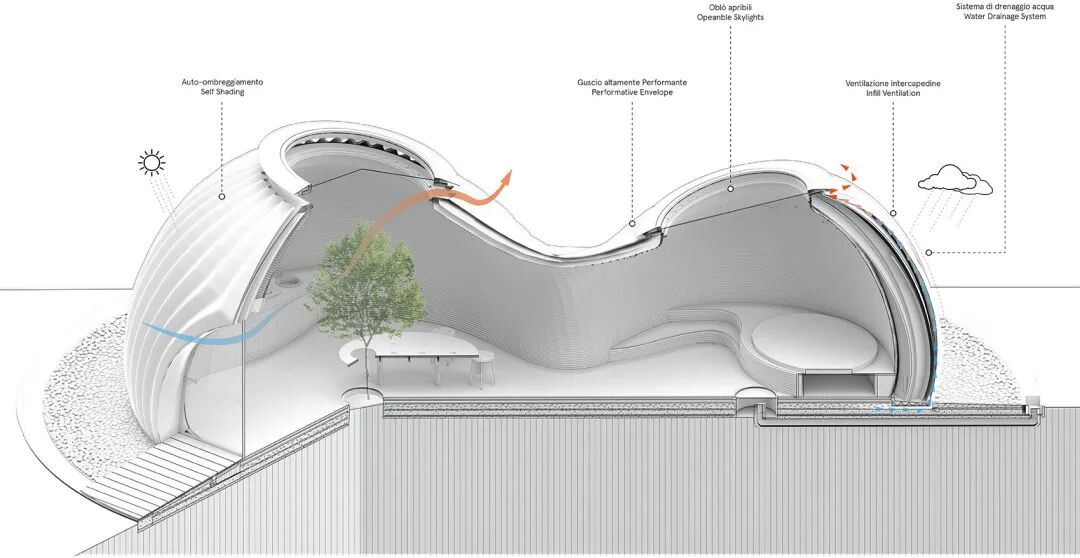

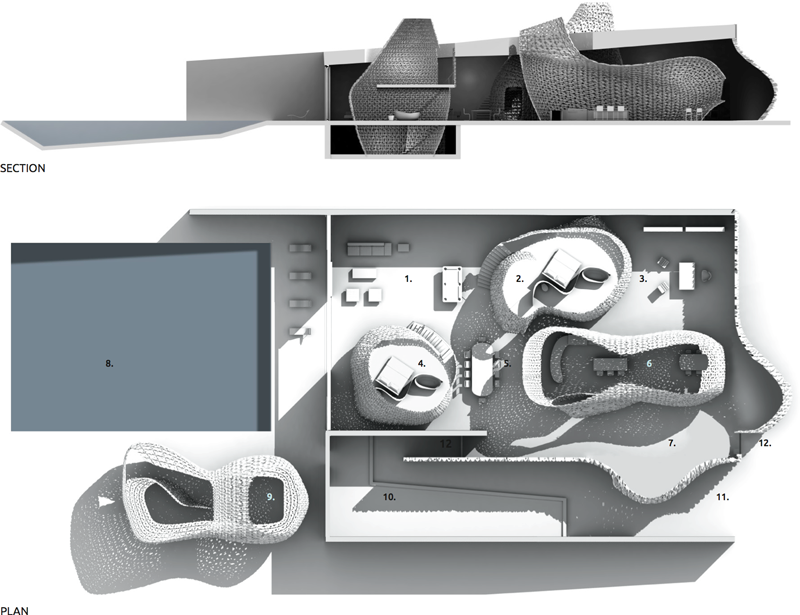

Tecla House, printed in Massarenti, Italy, is a combination of the words technology and clay, inspired by Italy’s historical cities, aiming to establish a connection between past and present technologies. This residence was designed by Mario Cucinella Architects and built by Wasp using clay sourced from nearby riverbeds.

The building consists of two interconnected dome-shaped structures, with ribbed outer walls made up of 350 layers of 3D printed clay stacked together. The clay layers are arranged in a wavy pattern, providing structural stability and insulation.

The prototype was constructed using a multi-layer modular 3D printing mechanism, equipped with two synchronized arms, each with a printing surface of 50 square meters, capable of producing components simultaneously.

According to the construction team, using this technology, it takes only 200 hours to produce the housing module while consuming an average of 6 kilowatts of energy, almost completely eliminating typical construction waste.

Tecla consists of two continuous parts that combine to form two circular skylights, emitting “zenith light” through the use of a winding continuous sine curve.

Tecla’s unique shape, including its complex geometries and external ridges, demonstrates that 3D printing can balance complex design with structural stability.

Inside Tecla, there is a living room and kitchen, as well as a sleeping area with amenities, covering an area of approximately 60 square meters. Some furniture is 3D printed from local soil, recyclable or reusable, complementing the earthen architecture and aligning with the core values of this circular house model.

Tecla is part of a study on ecological sustainability, focusing on bioclimatic principles and indigenous architecture and construction to build low-carbon residences, demonstrating that beautiful, healthy, and sustainable homes can be built by machines while providing essential information for local materials.

2. House Zero

Architect: Lake Flato Architects

Builder: ICON

City: Austin, Texas

Project Year: 2022

The concept of “House Zero” was proposed by Lake | Flato Architects in Texas and built by the construction technology company ICON. This is the first project in ICON’s “Exploration Series,” aimed at “changing the paradigm of residential construction” by emphasizing the possibilities of additive manufacturing and creating a new design language. The material honesty of this house merges the expressiveness of robotic construction methods with the texture of natural wood, creating a timeless design.

The residence is located in a single-family neighborhood in East Austin, constructed using ICON’s Vulcan building system.

This technology utilizes 3D printing to mechanically distribute material layers according to a computer program, constructing the walls of a 2,000 square foot (186 square meter) house. Printing the 3D printed wall components takes ten days.

The walls are reinforced with steel and covered with a special material called Lavacrete, which is similar to cement and enhances insulation while sealing.

Jason Ballard, co-founder and CEO of ICON, stated: “House Zero is the starting point for a new design language and architectural style that will utilize robotic construction to meet our housing needs: comfort, beauty, dignity, sustainability, feasibility, and hope.”

ICON claims that the house is built using biophilic design principles, and the “natural circulation path of the entire house” is created by the smooth curves of the 3D printed supporting walls. In addition to being able to build houses faster, this technology also means that such houses can be built at a lower cost.

3. 3D Printed Two-Story House

Creator: Kamp C

Builder: COBOD

City: Estremadura, Belgium

Project Year: 2022

Belgian company Kamp C utilized the largest 3D printer in Europe to print an entire two-story house. This house covers an area of 90 square meters and is the first of its kind in the world, using a fixed printer for integrated printing.

Kamp C project manager Emiel Ascione stated: “The uniqueness of this house lies in the fact that we printed it with a fixed 3D concrete printer.”

This two-story 3D printed house is three times more durable than houses built with lightweight blocks. Kamp C project manager Marijke Aerts stated: “The compressive strength of this material is three times higher than that of traditional quick blocks.” The first house is an experimental building that will test its sturdiness over time.

In addition to the fibers already present in the concrete, minimal shrinkage reinforcement is required. Due to the use of printing technology, concrete molds are no longer necessary. It is reported that this saves 60% of time, money, and materials. For example, a future house may only take two days to print. If all printing days are added up, Kamp C’s house will be printed in less than three weeks.

The European C3PO project aims to accelerate the application of 3D printing in the construction industry in Flanders, Belgium, making the construction of current houses possible.

According to the company, 3D printing in construction can help architects avoid mistakes.

Aerts stated that using the printing process requires leveraging BIM technology.

In a sense, you are pre-building the house during the design phase. She continued, this can avoid many potential mistakes.

“Many potential costs can be avoided. Once you have a good design, adjusting some parameters is relatively simple.”

4. Milestone

Architect: Houben & Van Mierlo Architects

City: Eindhoven, Netherlands

Project Year: 2021

On April 30, 2021, the first 3D printed building in the Netherlands was delivered to residents. The Eindhoven residence is the first of five houses built under the “Milestone project,” fully compliant with all applicable building regulations.

This single-story building has a floor area of 94 square meters, including a living room and two bedrooms. Its shape mimics a large stone, blending into the surrounding environment, reflecting the design flexibility offered by 3D concrete printing. Due to the use of ultra-thick insulation materials and connection to a heating network, this house is very comfortable and energy-efficient, with an energy performance coefficient of 0.25.

The design of this residence, inspired by the shape of rocks, was completed by Dutch architects Houben & Van Mierlo.

It was constructed by printing multiple layers of stacked concrete, consisting of 24 different components, with its outer walls being curved and inclined.

These components were produced at a nearby printing facility and then transported to the construction site, where they were assembled, fixed to the foundation, and fitted with a roof, windows, and doors.

Bas Huysmans, CEO of Weber Benelux, stated: “We have taken an important step in this project towards further developing 3D concrete printing in construction,” by printing three-dimensional curved insulation and self-supporting wall components.

The “Milestone project,” conducted in collaboration with Eindhoven University of Technology and several architectural experts, aims to learn from it to advance the manufacturing of 3D printed houses and reduce the cost of building houses through the use of 3D printing in construction.

5. Urban Cabin

Architect: DUS Architects

City: Amsterdam, Netherlands

Project Year: 2016

In Amsterdam, the Dutch architectural firm DUS Architects 3D printed a small eight-square-meter cabin with a bathroom, now inviting guests to stay overnight.

The 3D printed “Urban Cabin” transforms a former industrial area in Amsterdam into a cozy urban retreat, featuring a small park and outdoor bathtub. This building is a study of small, eco-friendly housing options in urban environments. Since it is entirely made of bioplastics, it can be fully recycled and reprinted in the coming years.

The building cleverly utilizes the relationship between indoor and outdoor areas to create luxury with minimal footprint. It is entirely 3D printed from dark biobased materials, showcasing various facade decorations, form optimization methods, and resource-efficient insulation techniques.

The Urban Cabin is part of DUS Architects’ 3D printing living laboratory. Utilizing internal 3D printing technology, it takes a step towards creating sustainable, adaptable, and on-demand housing options for the rapidly expanding global urban population.

The overall area of the house is 8 square meters by 25 square meters. It features a mini porch and a room with a sofa that can be used as a double bed. The Urban Cabin is suitable for short-term stays, providing a cozy refuge along the canals.

This idea also represents a significant step forward in building micro-temporary housing in space-constrained and disaster-prone areas. This material can be destroyed after use and then reprinted with different patterns.

6. House 1.0

Architect: SAGA Space Architects

Builder: COBOD

City:: Holstebro, Denmark

Project Year: 2022

The Danish 3D printing company 3DCP Group launched the first 3D printed concrete small house in Europe, “House 1.0.”

This concrete apartment is located in Holstebro, Denmark, built in collaboration with Saga Space Architects and modular 3D construction printing company COBOD.

The building installs all necessary facilities within just 37 square meters, aiming to minimize costs as much as possible. The overall goal is to build better, faster, and more environmentally friendly while reducing heavy labor during the construction process.

This house consists of triangular sections arranged in a circular pattern, connected by an open core. The compact residence includes a bathroom, an open kitchen, a living room, and a bedroom. The bedroom is located in a loft above the bathroom to save space. To achieve this, the roof has been raised.

Using COBOD’s large construction 3D printer, the entire building (including the roof and foundation) is made of solid concrete at a reasonable cost. To reflect Nordic architectural customs, the interior is finished with warm wood.

3DCP claims that 3D printing in construction is the next major advancement in the construction industry. You may be familiar with traditional plastic 3D printers used in hobby rooms at home. The idea is the same; however, our printers are much larger.

The Danish company explains, “We use printers to layer concrete, minimizing waste and overall material consumption while integrating various processes and workflows, all of which contribute to advancing construction quickly and efficiently.”

The Future and Impact of 3D Printing in the Construction Industry

The future potential of 3D printing in construction is immense, and it is expected to have a significant impact on the industry. 3D printing in construction, also known as additive manufacturing, involves creating three-dimensional objects by depositing materials layer by layer. When applied to the construction industry, this technology has the potential to fundamentally change the design and construction of buildings and structures. Key aspects of the future and impact of 3D printing in construction include faster, more cost-effective construction, design freedom and customization, sustainability, and reduced environmental impact, as well as the use of eco-friendly and recyclable materials. 3D printing in construction has the potential to improve structural performance, reduce transportation and carbon emissions, and integrate functional elements into printed components.

It can be used for both on-site and off-site construction projects, particularly in challenging environments. However, there are still some challenges to overcome before 3D printing becomes mainstream in the construction industry, such as regulatory barriers, scalability of technology, material development, and the need for standardized processes. However, with ongoing research and development, the future of 3D printing in construction is expected to continue evolving and have a transformative impact on the industry.

Advantages of 3D Printing in the Construction Industry

3D printing in construction offers numerous advantages, changing traditional construction methods. This revolutionary technology provides several key benefits that help improve efficiency, cost-effectiveness, and sustainability in the construction industry.

One major advantage of 3D printing is its unparalleled design flexibility. This technology enables architects and engineers to create complex and intricate structures that were previously difficult or impossible to achieve using traditional construction methods. The layer-by-layer additive manufacturing process allows for unique geometries, resulting in innovative and aesthetically pleasing designs.

Additionally, 3D printing significantly shortens construction time. By eliminating the need for time-consuming molds and enabling rapid layering of materials, projects that previously took months to complete can now be finished in a short time. This accelerated construction speed not only shortens project timelines but also minimizes labor costs, thereby enhancing overall cost-effectiveness.

Cost-effectiveness is not limited to labor savings. 3D printing in construction often utilizes local and sustainable materials, reducing transportation costs and minimizing the environmental impact of traditional construction practices. Furthermore, the precision of 3D printing minimizes material waste, optimizing resource utilization and further enhancing economic and environmental sustainability.

Another significant advantage is the potential for improved structural integrity. The layering process allows for precise control over material distribution, enhancing the strength and durability of structures. This can create resilient buildings that better withstand environmental challenges, extending the lifespan of building assets.

The customization capabilities of 3D printing are also advantageous, especially in the affordable housing sector. Companies like ICON have demonstrated the ability to customize 3D printed homes according to specific design requirements and local needs, providing cost-effective solutions to housing challenges.

In summary, the advantages of 3D printing in construction include design flexibility, accelerated construction time, cost-effectiveness, sustainability, enhanced structural integrity, and customized solutions. As technology continues to advance, these advantages position 3D printing as a transformative force in the construction industry, offering new possibilities for innovation and efficiency.

Limitations, Challenges and Solutions

While 3D printing holds great promise in the construction industry, it also faces several limitations and challenges that need to be addressed for widespread adoption and success in the industry.

-

Scale Limitations:

-

Current construction-grade 3D printers often have size limitations, hindering their applicability in large projects such as commercial buildings or infrastructure development.

Ongoing research aims to develop larger and more complex 3D printing systems capable of handling large structures.

-

Material Limitations:

-

The supply of construction-grade materials suitable for 3D printing remains a challenge.

The industry needs to explore a broader range of materials that possess both structural integrity and durability.

-

Regulatory Barriers:

-

Strict building codes and regulations were not initially designed with 3D printing in mind, leading to uncertainty and delays in obtaining approvals.

Proactively collaborating with regulatory bodies is crucial for establishing standardized guidelines and ensuring compliance.

-

Lack of Standardization:

-

The lack of standardized processes and best practices hinders the seamless integration of 3D printing into the construction industry.

Collaboration across the industry is needed to develop standardized procedures and guidelines for various 3D printing technologies.

Addressing Challenges:

-

Interdisciplinary Collaboration:

Researchers, engineers, architects, and policymakers must collaborate to address scale limitations and develop scalable 3D printing systems.

-

Through joint efforts, new materials can be explored, ensuring they meet safety standards and are suitable for construction applications.

-

Regulatory Engagement:

-

Proactively collaborating with regulatory bodies is essential for developing clear guidelines and standards for construction 3D printing.

This collaboration can facilitate the establishment of regulatory frameworks that adapt to the unique aspects of 3D printing technology.

-

Material Innovation:

-

Collaborative efforts between materials scientists and construction engineers can promote the development of a broader range of construction-grade materials for 3D printing.

Research programs should focus on materials that not only meet structural requirements but also comply with industry safety standards.

-

Standardization Initiatives:

-

Industry stakeholders, including researchers and practitioners, should work together to establish standards and best practices for 3D printing in construction.

Standardization efforts will enhance interoperability, streamline processes, and contribute to the broader adoption of 3D printing technology.

As these initiatives progress, the limitations and challenges of 3D printing in construction will gradually be addressed, establishing a more robust and widely accepted framework for this transformative technology.

Environmental Impact

As 3D printing explores innovative technologies in the construction industry, its environmental impact is an important aspect to consider. While 3D printing offers significant sustainability advantages, it also presents environmental challenges that need careful consideration.

Advantages:

-

Reduction of Material Waste:

-

Traditional construction often results in significant material waste due to the need for precise measurements and cutting. 3D printing, as an additive manufacturing process, minimizes waste by using only the materials necessary for the structure.

-

Localized Production:

-

3D printing enables on-site construction, reducing the need for long-distance transportation of heavy building materials. This localized production helps lower carbon emissions associated with transportation.

-

Optimized Material Usage:

-

The layer-by-layer construction process of 3D printing allows for precise control over material distribution, optimizing resource utilization. This efficiency contributes to reducing the overall environmental footprint and achieving sustainability.

-

Energy Efficiency:

-

Some 3D printing technologies inherently have energy-saving effects compared to traditional construction methods. For example, the energy required for using robotic arms or gantry systems in 3D printing is less than that used by heavy machinery in traditional construction.

Challenges:

-

Material Considerations:

-

The environmental impact depends on the materials used in 3D printing. While there is a growing trend towards using sustainable and eco-friendly materials, some printing materials may still have environmental impacts. Ongoing research aims to develop more environmentally friendly alternatives.

-

Energy Consumption:

-

The energy consumption of 3D printers (especially large construction printers) is a concern. Optimizing the energy efficiency of these systems and exploring renewable energy sources to power the printers is an area of ongoing research.

-

Disposal Considerations:

-

Understanding the disposal considerations of 3D printed structures is crucial. The handling and recycling of 3D printing materials require extra caution, especially those enhanced with fibers or other additives to prevent environmental harm.

-

Regulatory Compliance:

-

Ensuring that 3D printed structures comply with environmental regulations is an ongoing challenge. Regulatory frameworks may need to be adjusted to address the unique aspects of 3D printing in construction and its environmental impact.

In summary, while 3D printing in construction offers significant opportunities to reduce environmental impact through waste reduction, localized production, and optimized material usage, addressing challenges related to material considerations, energy consumption, disposal considerations, and regulatory compliance is crucial for fostering a truly sustainable and eco-friendly construction ecosystem. Ongoing research and interdisciplinary collaboration are essential to maximize the positive environmental impact of 3D printing in construction.

Training and Skills Development

The integration of 3D printing with the construction industry requires a skilled workforce equipped with the expertise and knowledge to navigate this transformative technology. Training and skills development programs play a critical role in ensuring that construction professionals can fully leverage the potential of 3D printing.

Training Programs: Formal training programs are essential for introducing construction professionals (including architects, engineers, and construction workers) to the principles and practices of 3D printing. These programs should cover the fundamentals of 3D printing technology, including the operation of 3D printers, understanding construction-grade materials, and the complexities of structural design suitable for additive manufacturing.

Educational Partnerships: Collaboration between educational institutions and industry participants is crucial for developing curricula that meet the evolving needs of the construction industry. Integrating 3D printing modules into existing architecture and engineering courses can help students gain practical experience with this cutting-edge technology, preparing them for future construction project demands.

Certification Programs: Establishing industry-recognized certification programs can ensure that professionals can validate their expertise in construction 3D printing. These certifications cover various aspects, from operating specialized 3D printers to implementing 3D printing technology in construction projects. Certification not only enhances individual skills but also provides standardized benchmarks for employers seeking qualified professionals.

Continuing Professional Development: Given the rapid advancements in 3D printing technology, ongoing professional development is essential. Workshops, seminars, and online courses can help construction professionals stay informed about the latest developments, emerging materials, and best practices in the field. Industry associations and organizations can play a key role in organizing such events.

Hands-On Training: Practical training is essential for developing hands-on skills. Training centers equipped with 3D printers and construction-grade materials provide professionals with simulated environments to familiarize themselves with the equipment, troubleshoot common issues, and refine their printing techniques.

Apprenticeships and On-Site Learning: On-site apprenticeships allow construction professionals to gain practical experience under the guidance of experienced practitioners. This experiential learning approach ensures individuals can apply theoretical knowledge to real-world scenarios, addressing specific challenges related to construction 3D printing.

In summary, a robust training and skills development framework is crucial for unlocking the potential of 3D printing in construction. By investing in educational programs, certification initiatives, and ongoing learning opportunities, the construction industry can cultivate a skilled workforce capable of driving innovation and successfully implementing 3D printing technology in construction projects.

Economic Impact

The application of 3D printing in construction has significant economic implications, affecting various aspects of the construction industry and the broader economy. These impacts include cost savings, labor market dynamics, construction affordability, and economic growth.

-

Cost Savings:

3D printing is expected to significantly reduce construction costs. The efficiency of additive manufacturing minimizes material waste, while the reduced need for traditional construction methods like molds lowers labor costs. Additionally, the ability to use local materials may further contribute to cost savings.

-

Labor Market and Skills Demand:

The introduction of 3D printing in construction has created a demand for skilled professionals who can operate and maintain 3D printers, design structures compatible with additive manufacturing, and oversee 3D printing construction projects. While some shifts may occur in traditional construction jobs, the overall impact on the labor market is likely to be positive, as new skill sets are required.

-

Construction Costs and Affordability:

The efficiency and cost-effectiveness of 3D printing contribute to providing more affordable housing solutions. Companies like ICON and New Story have explored using 3D printing to build affordable homes, addressing housing challenges and enabling more people to access housing.

-

Economic Growth and Innovation:

The integration of 3D printing with the construction industry fosters innovation and drives economic growth. Investments in research and development, technological advancements, and the creation of new businesses around 3D printing contribute to a vibrant and forward-looking construction sector.

-

Market Competition:

The adoption of 3D printing technology introduces new competitive dimensions to the construction industry. Companies that adopt and invest in 3D printing may gain competitive advantages in efficiency, project timelines, and cost-effectiveness, influencing market dynamics and business strategies.

-

Infrastructure Development:

The economic impact extends to infrastructure development, where 3D printing can streamline and accelerate construction projects. The efficiency of building infrastructure such as bridges and overpasses promotes economic development by shortening project timelines and associated costs.

While the economic impact of 3D printing in construction holds great promise, careful consideration must be given to address challenges related to regulatory frameworks, material costs, and initial technology investments. As the technology matures and becomes more widely adopted, its positive economic impact is expected to continue growing, influencing construction practices and economic outcomes globally.

Interactive Tools and Simulations

The integration of interactive tools and simulations in construction 3D printing represents a significant advancement, providing enhanced visualization, planning, and decision-making capabilities. These tools leverage virtual reality (VR) and augmented reality (AR) to transform construction processes, offering a range of benefits.

-

Enhanced Visualization:

Interactive tools and simulations enable stakeholders (including architects, engineers, and clients) to visualize construction projects in a highly immersive manner. Virtual models created with these tools can present the final structure in detailed and realistic ways, aiding better decision-making during the design and planning phases.

-

Design Iteration and Collaboration:

Virtual simulations allow for rapid design iterations and collaborative decision-making. Stakeholders can explore different design options in a virtual environment before actual construction begins, identifying potential challenges and making informed decisions. This iterative process enhances collaboration and reduces the likelihood of costly modifications during later construction stages.

-

Project Planning and Coordination:

Interactive tools assist in project planning and coordination by providing detailed overviews of construction sites and project components. This helps optimize construction workflows, efficiently schedule tasks, and minimize conflicts. Stakeholders can identify potential issues early on, facilitating smoother project execution.

-

Worker Training and Safety:

VR and AR simulations are valuable tools for training construction workers in a safe and controlled environment. Workers can familiarize themselves with the operation of 3D printers, construction processes, and safety protocols. This immersive training helps improve on-site performance and enhances safety.

-

On-Site Construction Assistance:

Augmented reality can be used on construction sites to provide real-time assistance to workers. AR overlays digital information onto the actual construction site, guiding the precise placement of components and ensuring accuracy in the 3D printing process.

-

Client Engagement:

Interactive simulations allow clients to experience projects in virtual spaces, enhancing client engagement. Clients can explore designs, understand project details, and provide valuable feedback before construction begins. This can improve communication and ensure that the final product meets client expectations.

-

Quality Control and Monitoring:

These tools assist in real-time monitoring and quality control during construction. Stakeholders can track progress, identify design deviations, and implement corrective measures promptly. This helps improve overall efficiency and quality of construction projects.

In summary, the integration of interactive tools and simulations in construction 3D printing transforms traditional practices by providing dynamic and immersive project visualization, collaborative design iterations, improved project planning and coordination, enhanced worker training and safety, on-site construction assistance, increased client engagement, and real-time quality control and monitoring. As these tools continue to evolve, they are expected to play a key role in optimizing construction processes and further advancing the application of 3D printing in the industry.

Conclusion

With the introduction of 3D printing technology, the construction industry is undergoing a profound transformation. The advantages of this technology, including design flexibility, shortened construction time, cost-effectiveness, sustainability, enhanced structural integrity, and customized solutions, position 3D printing as a revolutionary force in the industry. The ability to construct complex structures with unprecedented efficiency and reduced environmental impact marks a paradigm shift in construction methods.

The environmental impact of 3D printing in construction presents a dual nature, with advantages such as waste reduction and optimized material usage, but also challenges related to material considerations, energy consumption, disposal considerations, and regulatory compliance. Ongoing research and collaboration are needed to improve materials, enhance energy efficiency, and establish clear guidelines for eco-friendly 3D printing practices.

The integration of interactive tools and simulations adds another layer of complexity to 3D printing in construction, providing enhanced visualization, collaborative design iterations, improved project planning and coordination, advanced worker training and safety, on-site construction assistance, increased client engagement, and real-time quality control and monitoring. As these tools continue to evolve, they are expected to play a key role in optimizing construction processes and accelerating the adoption of 3D printing technology.

Looking ahead, the future potential of 3D printing in the construction industry is immense. Ongoing innovation, research, and collaborative efforts will pave the way for overcoming current limitations and challenges. The economic, environmental, and transformative benefits of 3D printing indicate that this technology will become an integral part of the construction industry, reshaping how we conceive, design, and build structures for a more sustainable and efficient future.

[Further Reading]

Case Study: Digital Agriculture – Smart Grape Industry Park IntroductionCase Study: BIM Technology-Based 3D Visualization R&D Center Operation and Maintenance Management PlatformCase Study: Smart City – Comprehensive Smart Community Service Management PlatformCase Study: Smart City Comprehensive Parking + Charging MapCopyright Notice: This public account is dedicated to original and selected articles on smart buildings, smart cities, government and enterprise information technology, digital economy, and related policy recommendations. Some articles may have been pushed without timely contact with the original authors. If there are any copyright issues, please contact us promptly.Contact: Leave a message directly in the background, or WeChat: ysqwhzj001 (formerly zbzn002), phone: 13967532005. Original authors are welcome to submit articles or claim manuscript fees.

The End

Click below “Read the original” to learn more