The price surge of Flash continues to ferment, and many manufacturers are choosing to use more cost-effective NOR Flash chips. NOR Flash has characteristics such as strong reliability and fast read speeds, making it a major product in the mid-to-low capacity flash memory chip market. However, the long programming time and low efficiency have always been a headache for manufacturers. How can we improve production efficiency?

With the development of high-tech electronic technology, the demand for storage capacity in various electronic products is increasing, from the initial 256byte capacity to the current 128Mbyte. A larger capacity means that the erase and programming times during use will also be longer.

So the question arises, what programming methods do we use when employing SPI Flash? Generally, we use programming tools (such as programmers) to write the files to the chip and then run them on the board. However, during the debugging phase, or for production lines that require a “board first, then program” process, how should programming be done? For small capacities during the debugging phase, we can write the binary code directly to Flash for debugging by programming the main control chip, or we can desolder the chip and use third-party tools to program it before running it on the board. Both methods are not very efficient.

ISP (In System Programming) allows blank devices on the circuit board to be programmed with final user code without removing the devices from the board. Devices that have already been programmed can also be erased or reprogrammed using ISP. This technology provides engineers with a way to update and debug data in Flash without desoldering the chip, saving time and process flow, and protecting the chip and circuit board. During mass production, for products that require a “board first, then program” process, users only need to leave the corresponding programming interface on the circuit board, and ISP online programming can program and update the devices after they are mounted on the board. This greatly facilitates customer production line needs and saves costs on programming fixtures.

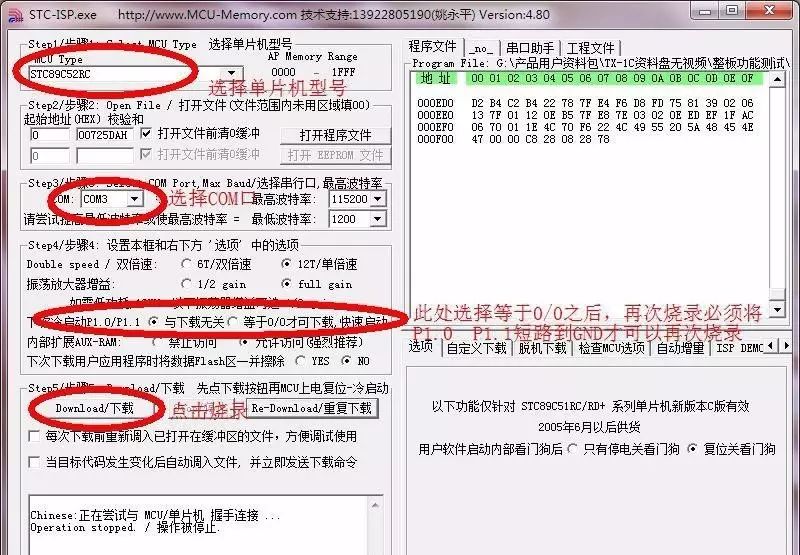

Currently, the vast majority of MCU manufacturers provide online programming tools, such as the well-known STC-ISP and J-link.

STC-ISP Programming Tool

However, there are few tools that support SPI Flash. When using SPI Flash for online programming, users must create their own programming tools, which undoubtedly adds more pressure on R&D engineers for secondary development, making it difficult to meet the strict requirements of production lines for programming tools.

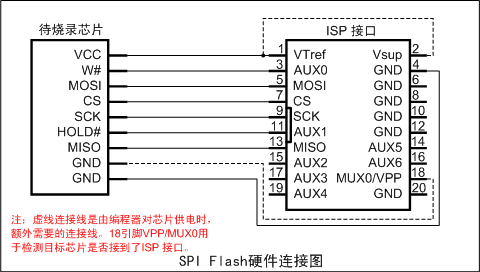

Zhiyuan Electronics’ P800isp online programmer supports various protocols for online programming, including JTAG/SWD/SPI/UART/BDM/C2, and is very familiar with programming SPI Flash using the SPI protocol. The P800isp adopts a standard 20Pin ISP interface, and the connection diagram for SPI Flash is shown below.

SPI Flash Hardware Connection Diagram

The P800isp is a 4-channel online programmer that has significant advantages in programming speed and production capacity. Below is a programming time table for a 256Mbit SPI Flash from ISSI:

256Mbit SPI Online Programming Time Table

Notes on ISP Online Programming

Online programming is still affected by many external factors compared to offline programming, which we need to pay attention to.

First, the chip is mounted on the circuit board, and the traces and surrounding components (such as pull-up and pull-down resistors, large capacitors) can all affect the programming signals. For example, the pull-down resistor on the programming interface can reduce the programming signal voltage, and in a large capacitor circuit, the power-up moment may cause overcurrent. This is particularly important for ICs with strict timing requirements.

Second, the SPI protocol is a short-distance transmission protocol, and the leads between the programming tool and the board to be programmed should not be too long (preferably within 50cm). It is best to use high-performance shielded cables, and when the cable length is longer, the SPI frequency should be appropriately lowered.

Finally, for some boards, it is possible that after powering on, the main control MCU has already taken control of the programming interface of the chip to be programmed. If the programming tool attempts to program the chip at this time, it may lead to programming failure. Therefore, during programming, it is necessary to ensure that the main MCU is in a reset state.

Conclusion

ISP programming has become a new trend in programming due to its low cost, low risk of hardware damage, immediate testing after programming, and the ability to refresh firmware at any time. SPI NOR Flash has significant advantages in usability, cost, and power consumption, making it a frequently used storage medium for users.

This article introduces the online programming method for SPI Flash. It discusses some issues in ISP programming of SPI Flash and finally provides a programming solution for SPI Flash along with some precautions.

Reply with the keyword 【Development Tools】 to see more related technical topics.

Official WeChat account introduction

Zhiyuan Electronics’ official WeChat account, a platform that gathers 500 engineers for R&D testing sharing, providing you with leading product technology and solutions in the electronics industry.。