In the field environment of Profibus, we use a variety of systems, and the devices we face interference from are diverse, so the sources of interference are also varied. Many failures caused by interference are more difficult to troubleshoot than other faults. Before troubleshooting interference failures, we need to understand the types of interference.

In summary, the types of interference are as follows:

Power Interference

Often, failures of PLC control systems, even downtime, are caused by interference introduced by power sources. The control system is generally powered directly by the power grid. Due to the wide coverage of the power grid and the large number of devices within it, especially when the operating environment and load of the grid change, such as large switch operations, frequent starts and stops of large equipment, and harmonics caused by AC and DC drive devices, all these can directly affect the power grid and transmit through the grid to the incoming power of enterprise electrical equipment, leading to a significant decline in power quality. In severe cases, this can even damage electrical equipment. Therefore, isolation or purification devices are generally installed at the incoming power supply of automated equipment in enterprises, but the effectiveness varies greatly due to the performance of the devices.

Signal Interference

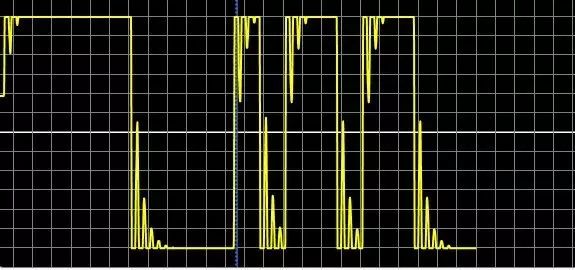

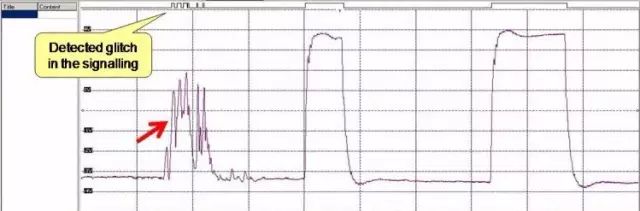

In the wiring construction process of the metallurgical industry, high-voltage, high-current lines are often located very close to signal and communication lines, and large electrical equipment frequently starts and stops. This situation easily causes rapid changes in the magnetic field around the signal and communication lines, thus interfering with the transmission of line signals. The interference introduced into the system can cause instability in analog signals, abnormal operation of digital signals, and interruptions in communication data. In severe cases, instability in various signals can lead to communication interruptions, loss of stations, or even system paralysis, and may even cause irreparable damage to system hardware.

Load Interference

In control systems, there are often many loads with energy storage characteristics. If signal isolation devices or surge absorbers are not installed, when control contacts switch, they can generate back electromotive forces that exceed the power supply voltage by several times or even tens of times, which can have a significant impact on related equipment in the system.

Grounding Interference

There exists a potential difference between the PLC control cabinet and the ground. A standardized and well-functioning grounding system can reduce interference currents caused by this potential difference. Interference mixed into signal and communication lines can be introduced to the ground through grounding wires, thereby reducing the impact of interference. Poor grounding and non-standard grounding methods are often significant causes of grounding interference.

On engineering project sites, various types of interference should be comprehensively addressed based on actual conditions. Firstly, good cable routing and shielding work must be done. Control cables and various types of signal lines must be properly shielded, and control cables should be placed separately. Profibus-DP twisted pairs should avoid being placed in the same conduit as other signal lines, control cables, and high-voltage power cables to avoid cross-talk and minimize interference sources. When wiring, the shielding layer should be properly connected, leaving a suitable length of the shielding layer to avoid contact with the internal wires.

Secondly, good grounding is an important measure to prevent interference in field buses. The ground is generally selected as a reference point at zero potential, and grounding is establishing a pathway between two contact nodes, connecting electrical equipment to the ground. The main purpose of grounding is to protect people and equipment and to reduce electromagnetic interference. Attention to the fixation of communication interfaces is also very important. In addition to grounding, the influence of other equipment power supplies and cables on communication signals is significant. Under favorable conditions, devices and power supplies with good isolation performance should be selected, and wiring should be isolated as much as possible. In addition, to combat interference, a large number of analog signal isolators (also known as signal transmitters) should be used to resist interference. Signal isolators provide three-way isolation and signal conditioning for various analog signals, significantly reducing signal interference. Due to their strong anti-interference capabilities, adding signal isolators has become a common method in automated control systems, with widespread application in the field.

Cold rolled electrical control, focusing on core technologies such as AGC and ATC, is committed to improving the automation level of China’s cold rolling equipment.