Opinion / Champion

This is the68th original content from the Watt Product Design public account.

▪ Potting WaterproofingCurrently, the most common method for potting waterproofing is the use of epoxy resin potting glue, which is used for potting electronic product modules, allowing the entire PCB to be encapsulated, thus providing waterproof, moisture-proof, salt spray-proof, mold-proof, shock-resistant, and impact-resistant properties.Epoxy resin is a saturated resin, and the potting glue made from it has high intrinsic strength, strong adhesion, good weather resistance, low shrinkage, high insulation strength, and is non-toxic and environmentally friendly. After potting, it can maintain stable mechanical and electrical performance between -45 to 120°C. It provides comprehensive protection for the circuit board, greatly extending its lifespan. However, there are also some critical issues, such as the significant impact on the PCB’s heat dissipation, and the most troublesome aspect is that the product is almost impossible to repair, or the repair cost is prohibitively high.▪ Surface Coating Waterproofing: Conformal CoatingConformal coatings, also known as circuit board protective oils, coating oils, waterproof glues, insulation paints, and moisture-proof paints, are generally quite thick, with a coating thickness reaching 50 microns, which hinders heat dissipation and has high viscosity. The yield per kilogram is relatively low, and the drying time is slow, often taking one to two hours to dry.Conformal coatings are applied to the PCB of electronic products to create a cured film that protects against moisture, corrosion, and salt spray. However, this film can only protect against moisture and a small amount of water; if the electronic product is completely submerged in water, it will fail.

Due to the inherent process limitations of conformal coatings, they are not impact-resistant or vibration-resistant, and are prone to peeling under external force, providing very limited protection for the PCB. It is difficult to visually inspect whether the coating is uniform. Many conformal coatings still use volatile solvents, which can be harmful to human health and the environment, making them unsuitable for manufacturing enterprises that need to meet environmental standards for exports to Europe and the United States.

▪ Surface Coating Waterproofing: Nano Coating

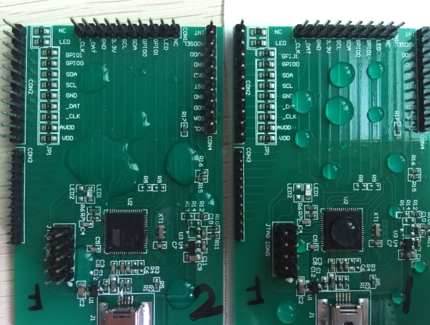

The nano waterproof coating for circuit boards is a new nano material, also known as a nano coating. It is currently the most ideal substitute for conformal coatings, with a thickness of only 2-4 microns, invisible to the naked eye, forming an extremely thin mesh on the PCB surface that effectively reduces the surface energy of the PCB, creating a lotus leaf effect. It has good heat dissipation properties and does not affect the normal conductivity of connectors. The waterproof rating can reach IPx5, which basically meets the standard for everyday waterproofing, and it can also resist corrosion and acids, bases, and salts.

Currently, high-end sports headphones use this coating technology for sweat resistance, and electronic cigarettes use it to protect circuit boards from e-liquid corrosion, as e-liquid leakage onto the mainboard can corrode the components on the board. The nano coating is very easy to apply; simply immerse the circuit board in the nano waterproof solution for a few seconds, remove it, and let it air dry for 10 minutes, without the need to wait 24 hours or bake the board, making repairs convenient.

Observe the droplet phenomenon on the surfaces of the two PCBs in the image above, where the right PCB has a nano waterproof coating.

In Conclusion

If you find this article helpful, please give it alike and a look.You can alsoshare it with your friends and invite them to take a look!Recommended reading: Introduction to Automotive Wiring HarnessesPrevious article: Design References for Waterproof Structures in Consumer Electronics

END