1. Industry Background of Escalator Monitoring Systems

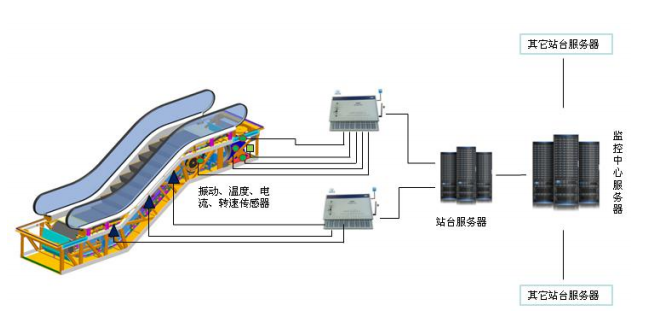

In recent years, the rapid development of urban rail transit in China has also led to several major accidents caused by mechanical failures of escalators, resulting in significant casualties. To prevent such major accidents, it is necessary to establish a fault monitoring system for escalators to detect equipment failures in a timely manner. This proposal establishes a health monitoring system for escalators, monitoring vibration, speed, temperature, and current of components such as motors, reducers, drive wheels, and handrails. By jointly analyzing relevant indicators and establishing a database, changes in these indicators can be monitored before equipment failures occur, allowing for timely detection of alarms and issuing warnings to prevent major accidents. The system consists of several parts, including a front-end sensor system, high-precision data acquisition instruments, online monitoring software, and a network transmission system.

2. Monitoring Objectives of the Escalator Monitoring System

Excessive vibration during escalator operation caused by wear of bearings, guide rails, etc., can lead to serious accidents such as loosening or breaking of fixed bolts, resulting in displacement of the drive unit. The damage to mechanical equipment often develops gradually and may not be visible in the early stages of failure. When the damage reaches a certain level, it may suddenly result in catastrophic accidents. However, early failures of equipment, such as bearing or gear wear, are already reflected in the vibration signals, and appropriate data processing can detect them in advance. Therefore, sensors can be arranged at key components to monitor different types of failures.

3. Role of Sensors in the Escalator Monitoring System

(1) Monitoring Objects and Sensors

Vibration acceleration sensors: Vibration acceleration sensors monitor the vibration signals of various mechanical components. When bearings, gears, or tracks wear or when anchor bolts loosen, the vibration signals will change. By extracting characteristic indicators such as peak-to-peak values, kurtosis, effective values, main frequency amplitudes, and low or high-frequency amplitudes, and combining analysis methods such as cepstrum and envelope spectrum, early characteristics of faults can be effectively captured.

(2) Dynamic Data Acquisition Instruments

This proposal uses a mainstream international 24-bit AD high-precision, high-dynamic range data acquisition instrument to perform analog-to-digital conversion and preprocessing of the sensor signals. This monitoring-type acquisition instrument is designed to be windproof, dustproof, moisture-proof, and highly resistant to electromagnetic interference, making it suitable for relatively harsh field environments. Multiple escalators at rail transit platforms can be equipped with distributed acquisition instruments for data collection.

4. Sensor Products from Sensor Technology

310AT Temperature and Vibration Integrated Sensor:

The 310AT series is an industrial IEPE acceleration sensor for synchronous measurement of temperature and vibration. It features a ceramic crystal in a ring shear mode as the sensitive element, which maintains stable output over time. The internal circuit of this acceleration sensor provides constant current excitation and transmits low-impedance voltage output signals on a two-wire IEPE system. An integrated temperature sensor transmits temperature signals as voltage signals, with signal ground internally shielded and isolated from the housing. The signal amplification circuit design considers polarity reverse protection. The housing is manufactured using laser welding technology to ensure product sealing; the output connector uses a standard MIL-C-5015 glass-insulated connector to ensure stability of output in different environments. The 310AT series acceleration sensors provide a 1/4-28 threaded hole for secure installation in addition to adhesive mounting. With wide frequency response and shock resistance, the 310AT is an ideal acceleration sensor for industrial vibration monitoring and measurement in harsh environments. Additionally, Sensor Technology offers cables compatible with the standard MIL-C-5015 connector, model 20A-L available.

IN-SDG Data Acquisition Device:

The IN-SDG intelligent vibration transmitter is developed against the backdrop of the transition from equipment manufacturers to operators, the concept of full equipment lifecycle, big data, artificial intelligence, smart factories, and changes in communication methods, along with the emergence of 5G applications. The IN-SDG intelligent vibration transmitter is mainly used for detecting large sliding bearing equipment, such as steam turbine generators, large axial flow fans, and large air compressor units, as well as rolling bearing equipment with gearboxes, such as wind turbines, rolling mills, and various pumps and blowers.

After long-term monitoring of equipment, operational status data for each period will be continuously accumulated. Based on this historical data, fitting methods can be used to obtain a fitting curve that reflects the trend of data changes, indicating the trend of equipment operational status changes. Typically, as the equipment usage time increases, the condition of the equipment deteriorates due to wear and tear, leading to increased vibration data. The trend curve can provide insights into the rate of equipment deterioration and predict whether it will reach or exceed dangerous thresholds within a certain future timeframe. Trend prediction can allow for timely maintenance actions before equipment failure occurs, achieving predictive maintenance.