Source: TechSugar

One of the primary indicators for new car buyers when judging a car’s technological content and innovation level is the size and number of in-car displays. The size of in-car displays is gradually becoming a new driving force in purchase decisions. Whether it’s a gasoline car, electric vehicle, or hybrid, the size of the in-car display often affects people’s perception of the car’s performance.

Automakers are well aware that first impressions are hard to change, so they are increasingly focusing on the design of human-machine interface (HMI) displays, striving for not just size but perfection. Organic Light Emitting Diode (OLED) display technology not only leaves consumers with the best first impression but also provides cabin designers with more room for creativity, allowing users to experience tangible benefits.

According to a recent report from the Korean Display Industry Association (KDIA), the global automotive display market is expected to grow at an annual rate of 7.8%, increasing from $8.86 billion in 2022 to around $12.63 billion by 2027[1]. The incorporation of OLED displays in vehicles is considered one of the driving forces behind this growth. In 2022, OLED only accounted for 2.8% of the market share, but this figure is expected to rise to 17.2% by 2027.

Let’s take a look at the factors driving the growth of automotive OLED display technology.

OLED Technology in Automotive Displays

Until recently, Liquid Crystal Display (LCD) technology was the mainstream technology for automotive displays. This mature and well-established display technology originated from the consumer electronics sector and was later adapted for automotive applications.

From smartphones to computer monitors and televisions, the modern consumer electronics industry has begun transitioning to OLED display technology, as this technology combines high-quality visual effects with a slim profile, and the automotive industry has similar demands. Moreover, certain characteristics of OLED technology are particularly attractive for automotive display applications.

Pure Black and High Contrast

Since OLED is an emissive display technology, it does not emit any light when pixels are off, resulting in a “pure black” appearance. In contrast, LCD technology presents black by blocking light from the backlight unit, resulting in a deep gray instead of “pure black.”

LCD manufacturers have attempted to overcome this drawback by using mini-LED arrays for local dimming and turning off backlight areas of black pixels. Although this method can improve contrast, it lacks pixel granularity and may lead to undesirable display effects like haloing.

Furthermore, the added layer of mini-LED arrays and their electronic control components increases the system’s thickness, weight, and cost. As screen sizes increase, these disadvantages can become even more pronounced.

What benefits can OLED display technology bring to automotive users?

-

Most automotive graphical user interfaces (GUIs) use a black background to avoid distracting the driver and passengers while driving at night. Thanks to the pure black characteristics of OLED, user comfort has greatly improved.

-

High contrast enhances the readability of the display, contributing to overall vehicle safety.

-

Wide viewing angles ensure that the display can be clearly seen from different positions in the vehicle.

-

Unlike other display technologies, OLED displays maintain fast response times even in low-temperature environments. Even on cold winter mornings, OLED displays can clearly present critical real-time information without delay, helping you start your day right.

-

OLED is eye-friendly as it does not require backlight switching, reducing fatigue from prolonged viewing.

Integrated Cabin Design with Lower Power Consumption

OLED technology helps automakers solve multiple challenges. As display sizes increase, the advantages of OLED technology over LCD technology become even more apparent. OLED has fewer layers and a thinner structure, allowing automotive OEMs more room to enhance the quality of cabin design, such as:

-

Lighter and thinner stacked structures help reduce the weight of larger screens.

-

Curved display designs can have smaller radii, aiding in the creation of innovative cabin designs that showcase brand identity.

-

Thanks to pure black technology, the edges of the display can blend seamlessly with a black frame, presenting a unique appearance for HMI modules.

-

Low power consumption, especially when background images are darker.

-

Environmentally friendly, using less plastic than comparable LCD products.

Low power consumption and lighter, thinner large-size displays are particularly advantageous for electric vehicle manufacturers, as they can provide longer range with the same battery capacity.

OLED Technology Adapted for Automotive Requirements

Automakers and suppliers should be well aware of the drawbacks of older OLED displays. For example, issues like burn-in caused by many static (often unused) icons in automotive GUIs and poor readability due to low screen brightness in sunlight have been resolved with advancements in OLED technology.

With dual-layer OLED technology or series-connected OLED structures, display manufacturers have significantly increased display brightness. In addition to brighter screens, the organic layers added in the OLED structure also disperse energy to improve stability and extend lifespan. Tier-1 automotive manufacturers have recognized these improvements and are increasingly adopting OLED displays in their high-end vehicles.

Touch Interfaces

Regardless of the display technology used, touch interfaces are key to delivering an exceptional user experience. Moreover, the requirements for touchscreen in vehicles are much higher than for consumer devices, including:

-

Reliable operation under a wider range of environmental changes.

-

Support for glove operation.

-

Electromagnetic compatibility in terms of immunity and RF emissions.

-

Meeting functional safety standards ISO26262 ASIL-B level, as safety-critical mechanical buttons are gradually being replaced by virtual buttons on touch screens.

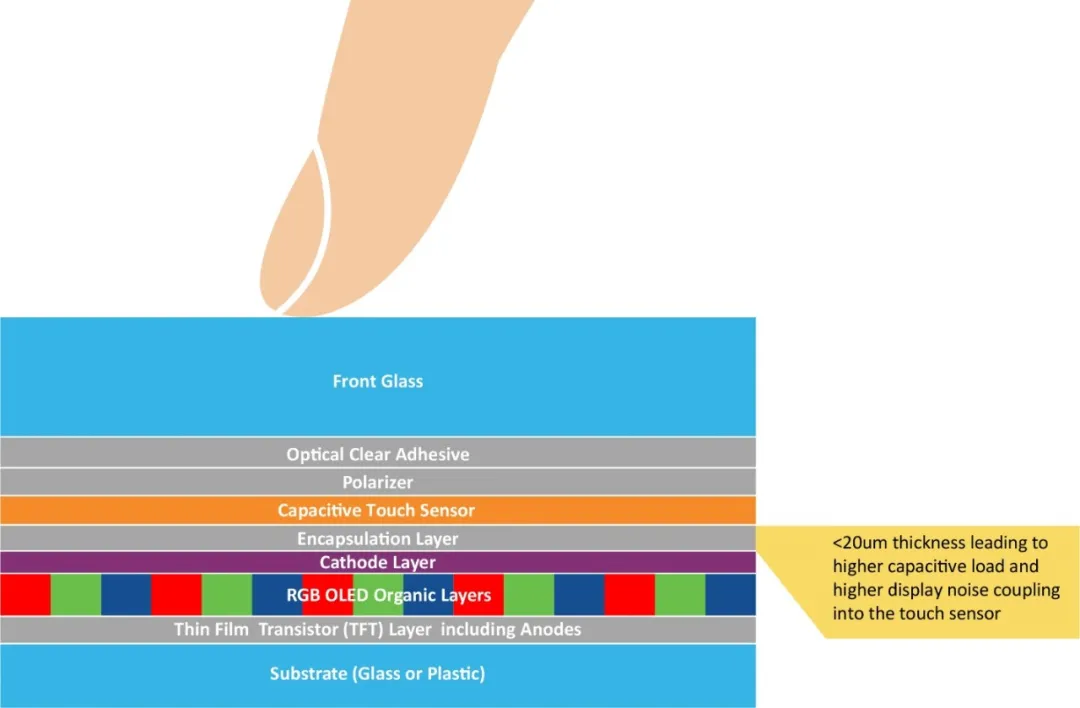

In recent years, most LCD display manufacturers have utilized On-cell or In-cell technology to integrate multi-touch functionality into their display products. Since OLED technology uses a full low-impedance cathode layer above the pixels, it has adopted only the On-cell structure. Currently, all major OLED automotive manufacturers have either developed or are in the process of developing this design, as it allows for thinner, lighter, and more flexible touch OLED displays.

Figure 1: Automotive On-cell Touch OLED Stacking Structure

Although using On-cell technology can make OLED displays thinner, it also presents new challenges for touch screen controllers. This is because the touch electrodes become closer to the cathode layer and display pixels (see Figure 1: Automotive On-cell Touch OLED Stacking Structure). After adopting the On-cell design, the capacitive load to ground for the touch electrodes has now become higher. While the capacitive size of the finger touch has not changed, the sensitivity of the finger touch has decreased.

To illustrate this challenge, consider the following example: For the previous display technology, detecting the capacitive touch of a finger was like measuring the water level after pouring a cup of water into a small bucket. After adopting the thin On-cell OLED structure, detecting the capacitive touch of a finger is now akin to measuring the water level in a full bathtub!

Touch Controller

The electromagnetic noise generated by pixel switching and its stronger coupling with the touch electrodes increases the risk of touch misdetection or missed detection.

Therefore, when selecting touch screen controller technology, attention must be paid to the signal-to-noise ratio (SNR) detection capability. The touch screen controller must achieve the following functions:

-

Adaptation to the high load characteristics of On-cell OLED touch sensors for driving and detection solutions.

-

Powerful display noise elimination technology.

-

Fast and efficient signal processing to improve touch reporting rates and reduce first touch latency.

Futuristic Appearance

OLED can provide high-quality visual effects, pure black backgrounds, higher energy efficiency, and lightweight curved panels, helping end products attract modern buyers and actively facilitate purchase decisions.

Although thin automotive On-cell OLED technology presents numerous technical challenges, it is crucial to ensure that the user touch experience is flawless.Microchip’s maXTouch® touch screen controller not only features proven technology for rapid, precise, and waterproof multi-touch detection (even operable with gloves) but also offers extensive flexibility to adapt to the screen aspect ratios used in automotive designs. The latest M1 generation maXTouch touch screen controller introduces new driving and detection mechanisms, coupled with advanced signal processing technology to ensure fast, reliable, and safe touch operations on new automotive OLED displays.

References:

[1] https://displaydaily.com/automotive-display-market-set-for-robust-growth-with-oleds-taking-center-stage/