High-Frequency Quenching Equipment: The Key Force Driving Upgrades in Wheel Production Processes

In the wheel manufacturing industry, product quality directly impacts traffic safety and corporate reputation. As a professional wheel manufacturing factory, we are committed to enhancing product performance and optimizing production processes. Drive wheels and guide wheels, as critical components of vehicles, must withstand heavy loads and frequent friction during operation, which requires their surfaces to possess high hardness and wear resistance, while the core maintains a certain level of toughness and plasticity to ensure overall performance and service life. Through long-term exploration and practice, we have found that high-frequency quenching technology and supporting equipment provide a practical solution to meet these stringent requirements.

1. High-Frequency Quenching Technology Adapted to Wheel Production Needs

High-frequency quenching technology forms a hard and wear-resistant martensitic structure on the surface of the wheel through surface hardening, while the core retains its original structure, perfectly meeting the different requirements for surface and core performance of drive wheels and guide wheels, ensuring stable operation under complex working conditions.

2. Advantages of High-Frequency Quenching Equipment in Wheel Production

Custom Induction Coils Tailored to Production Needs

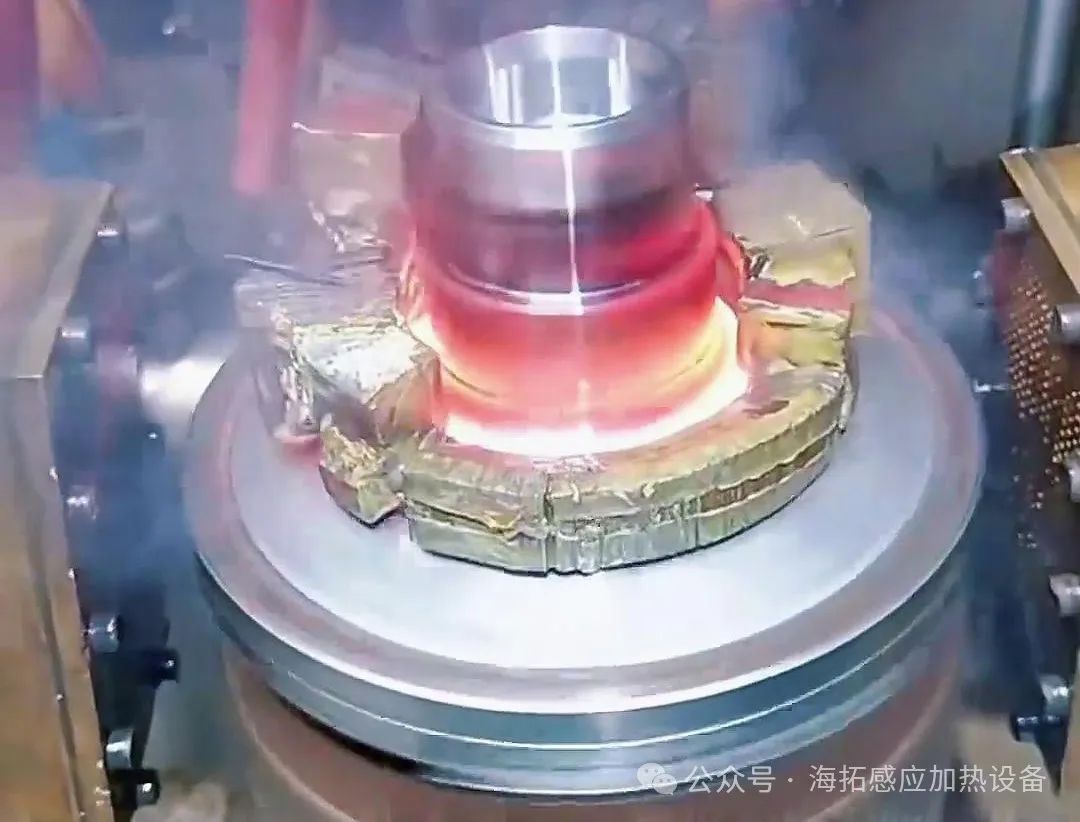

We collaborate with equipment suppliers to customize specialized contour quenching induction coils based on the size, shape, and quenching requirements of drive wheels and guide wheels. These coils can closely fit the surface of the workpiece, achieving uniform heating and concentrated heat, laying the foundation for high-quality quenching results. In actual production, wheels of different specifications can achieve precise quenching treatment with the help of custom coils.

Fast Heating Speeds Enhance Production Efficiency

High-frequency quenching equipment has an extremely fast heating speed, capable of heating the surface of the workpiece to quenching temperature in a short time. This not only significantly shortens the production cycle but also reduces the time the workpiece spends in high-temperature environments, effectively avoiding grain growth and oxidation decarburization, ensuring the material properties and surface quality of the wheels.

Excellent Quenching Results Ensure Product Quality

By precisely controlling the heating temperature and cooling speed, high-frequency quenching equipment enables the wheel surface to form an ideal quenching structure, significantly improving hardness and wear resistance. At the same time, the quenching layer depth is uniform, and the transition layer is smooth, comprehensively ensuring the overall performance of the parts, reducing the defect rate, and enhancing product reliability and durability.

Automated Operation Increases Production Stability

The modern high-frequency quenching equipment we have introduced is equipped with CNC quenching machine tools and automated loading and unloading devices, achieving automated operation of the quenching process. This not only reduces manual intervention and labor intensity but also improves production efficiency and the stability of product quality, meeting the demands of large-scale production.

3. Standard Operating Procedures for High-Frequency Quenching Equipment

Preparation Phase

During the material preparation stage, we strictly select suitable metal materials and perform forging, normalizing, and other pretreatment processes to provide a good material foundation for subsequent processing. At the same time, we customize specialized contour quenching induction coils based on the size and shape of the workpiece to ensure perfect compatibility between the equipment and the wheels.

Quenching Operation

The workpiece is clamped on the CNC quenching machine tool, ensuring close contact between the workpiece and the induction coil. Based on the material and quenching requirements of the workpiece, appropriate process parameters such as heating temperature, heating time, and cooling speed are set. After starting the high-frequency quenching equipment, the device automatically performs heating, holding, and cooling operations according to the preset program.

Quality Inspection and Treatment

After quenching, we conduct hardness testing and metallographic analysis of the workpiece to strictly control product quality. If necessary, low-temperature tempering treatment is performed to eliminate quenching stress and further enhance product performance.

4. Key Points for Using High-Frequency Quenching Equipment

Selecting Suitable Quenching Media

Based on the wheel materials and quenching requirements, we carefully select appropriate quenching media, such as water, water-soluble quenching liquids, or oils. We ensure that the cooling speed of the quenching media is moderate to achieve ideal quenching results.

Precise Control of Heating Parameters

Heating speed and temperature significantly affect the quenching results. We use high-precision temperature sensors and control systems to accurately control heating temperature and speed, avoiding product quality issues caused by improper parameters.

Preventing Overheating and Overburning

Overheating can lead to grain growth and reduced hardness, while overburning can cause grain boundary melting and structural defects. Therefore, we regularly check and replace aging induction coils to ensure uniform heating and prevent overheating and overburning.

Strictly Adhering to Safety Operating Procedures

High-frequency quenching equipment is classified as high-pressure and high-frequency equipment, and we require operators to strictly follow safety operating procedures and implement protective measures to ensure personal and equipment safety.

With significant technical advantages, standardized process flows, and strict operating regulations, high-frequency quenching equipment has become our ideal choice for the quenching treatment of drive wheels and guide wheels. By customizing specialized induction coils, precisely controlling process parameters, and implementing automated operations, we have achieved efficient and high-quality quenching treatment, enhancing the performance and service life of the wheels. In the future, we will continue to optimize high-frequency quenching processes to provide customers with higher quality wheel products.