Youde BiologyMPI Multi-Purpose Microbial Incubator System

The MPI system includes a main unit (basic configuration includes a vacuum pump, tank, gas interface, and programming control software), along with various specifications of culture tanks, gases, and gas cylinders available for selection.

The MPI Multi-Purpose Microbial Incubator System employs the most efficient “Flushing & Gassing” gas replacement method to provide the “optimal growth environment” for various anaerobic/microaerophilic microorganisms.

Applicable to:

-

Culture of various anaerobic microorganisms

(Shigella, β-hemolytic streptococcus, Clostridium botulinum, Clostridium perfringens, Bifidobacterium, Lactobacillus, Campylobacter jejuni)

-

Pathogen risk monitoring

(Brucella, Legionella, Clostridium difficile, Helicobacter pylori, etc.)

-

Probiotic culture research

(Butyrate-producing bacteria, Lactobacillus, Bifidobacterium, etc.)

Features of the MPI Multi-Purpose Microbial Incubator System:

-

Multiple gas components, high throughput parallel operation, anaerobic or microaerophilic environment generated in minutes

-

Multi-functional: anaerobic, microaerophilic, and CO2-loving culture

-

Rapid environment generation: microaerophilic in 2 minutes, anaerobic in 5 minutes with extremely low operating costs:

-

Annual gas consumption reduced by 90% compared to anaerobic glove boxes

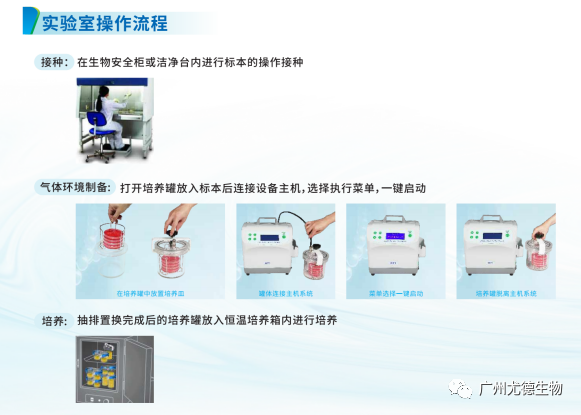

Simple operation process makes operation standard ● fast ● accurate

Components of the MPI System

-

Main unit: basic configuration includes vacuum pump, tank, gas interface, and editing control software;

-

Various specifications of culture tanks;

-

Standard mixed gases and gas cylinders.

Product Features of the MPI System

▶ Complete QA quality control, 100% reliability, 100% reproducibility

Before cultivation, the MUC microcomputer ensures complete QA quality control, guaranteeing that the culture tank is sealed without leaks, ensuring the precision of the generated gas environment quality. It can operate normally at different altitudes, balancing the pressure inside the culture tank with the local atmospheric pressure after preparing the environment.QA1 Gas input pressure testing: ensures gas input pressure is within the normal operating range of the instrumentQA2 Tank connection testing: ensures normal connection between the main unit and the tankQA3 Tank leak testing: ensures the tank is intact and leak-freeQA4 Tank lid sealing test: ensures the tank lid is sealed without leaksQA5 Catalyst activity testing: ensures the catalyst is active during anaerobic procedures▶ Multi-functional

A single instrument can meet the laboratory’s needs for anaerobic, microaerophilic, and CO2-loving bacterial cultures, with users able to select oxygen concentrations from 1% to 15% and carbon dioxide concentrations from 5% to 15%.

▶ FlexibilityVarious specifications of culture tanks available.

-

Can connect culture tanks of different capacities, with each tank able to select different culture gas environments;

-

Can increase or decrease the number of culture tanks based on specimen volume, avoiding overload and low utilization;

-

Connectable culture tanks include various specifications from 1.35L to 7.6L.

-

The tank can be equipped with various supports suitable for petri dishes, identification plates, culture plates, flasks, liquid enrichment culture bottles, homogenization bags, and other microbial culture carriers.

▶ Intelligent

-

Rapid preparation of gas environments: microaerophilic in about 2 minutes, anaerobic in about 5 minutes;

-

Extremely low operating costs: annual gas consumption reduced by 90% compared to anaerobic glove boxes.

MPI System Accessories▶ Catalyst (palladium particles) and oven

-

Used in anaerobic cultivation to remove residual oxygen from the culture tank, ensuring zero oxygen concentration inside the tank;

-

We provide reusable catalysts, along with a catalyst reduction oven.

▶ Culture tank cleaning disinfectant

-

Effectively disinfects bacteria, fungi, and viruses;

-

Excellent storage stability, non-corrosive to metals, rubber, plastics, wood, and other materials;

-

Non-adhesive to surfaces, easy to clean, and easily soluble in water.

▶ Secondary gas pressure regulator

-

We provide high-quality secondary gas pressure regulators that match the system, ensuring stable gas output from the gas source.

-

Requirements: Inlet pressure gauge 25MPA, outlet pressure gauge 0.3MPA

▶ Culture tank models and specifications

Note: