Click the blue text above to follow us

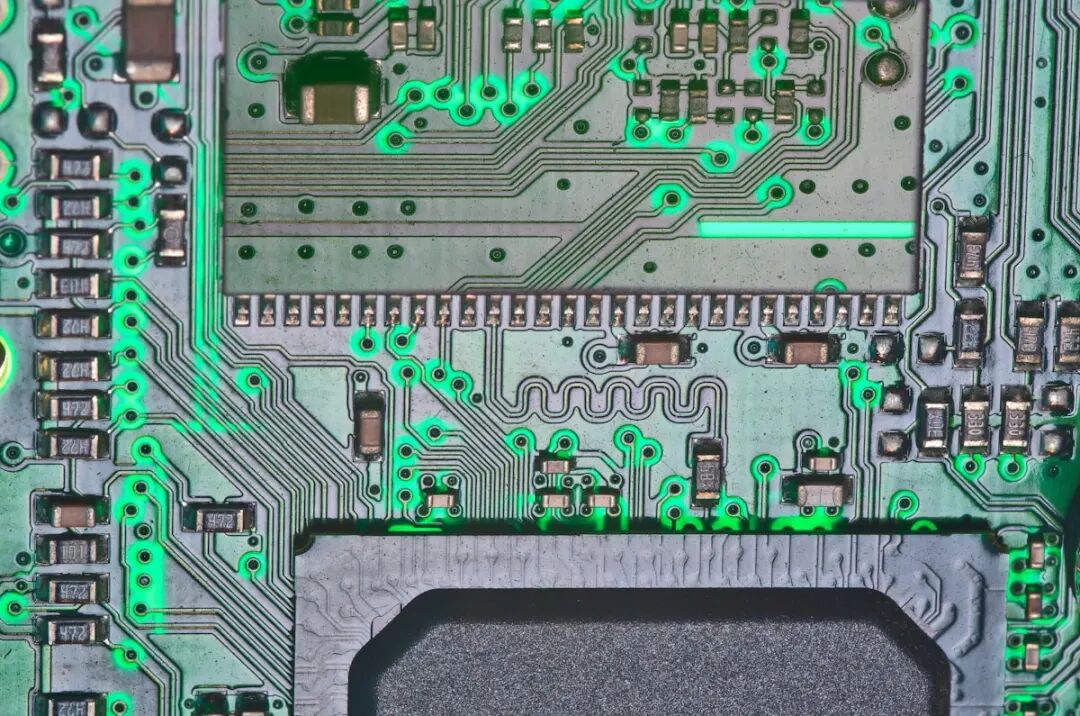

With the continuous development of the electronic manufacturing industry, the requirements for production processes are becoming increasingly refined. Visual inspection, as an important part of the inspection process, traditional manual inspection methods are not only inefficient but also prone to human error. In recent years, the topic of AI has gained popularity, and PCBA (Printed Circuit Board Assembly) visual AI inspection has emerged. So, what exactly is PCBA visual AI inspection? How does it work?

What is visual AI inspection?

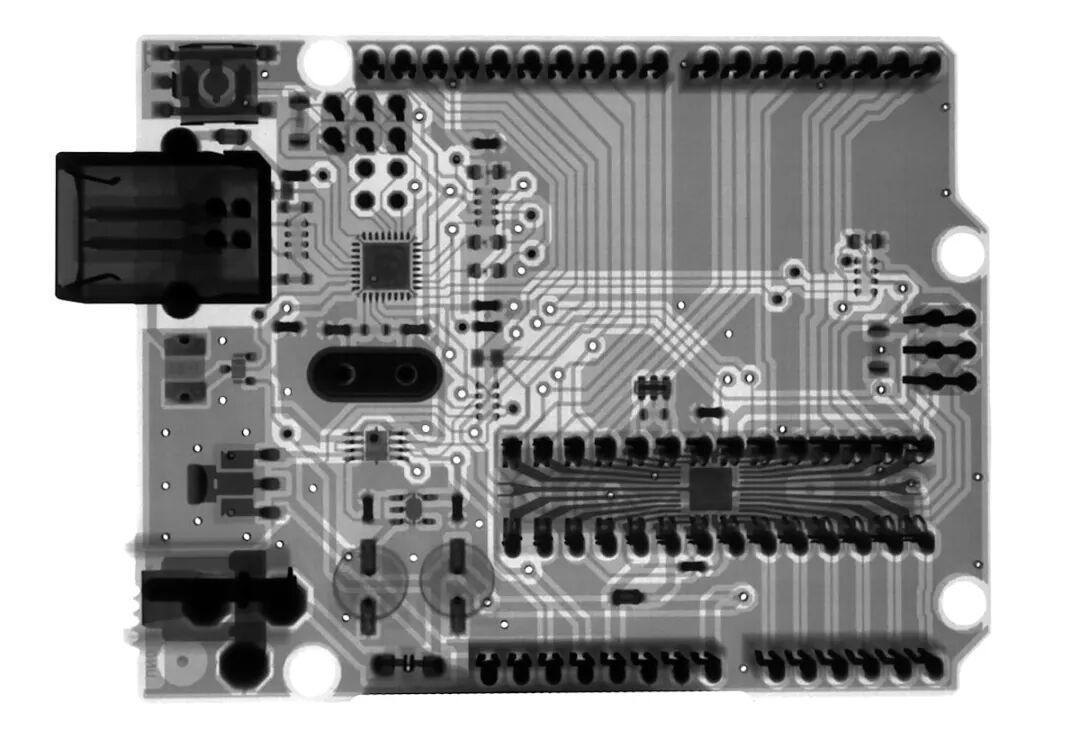

In PCBA inspection, visual AI inspection uses computer vision technology and artificial intelligence algorithms to automatically check and identify components, solder joints, and circuits on printed circuit boards. After capturing images, deep learning algorithms analyze the images, determining whether there are defects in the PCBA, whether the soldering is good, and whether the components are correctly installed. This inspection method not only improves inspection efficiency but also increases the accuracy of inspections.

Advantages of AI inspection

-

Increased inspection efficiency: PCBA visual AI inspection can quickly and accurately identify issues, saving a significant amount of time compared to manual inspection.

-

High precision and stability: AI algorithms, trained on large datasets, can make accurate judgments in various complex environments, reducing human errors and ensuring high stability.

-

Real-time feedback and traceability: Inspection results can be fed back to the production line in real-time, helping to adjust production processes promptly. Additionally, data can be saved for traceability, facilitating future quality analysis and improvements.

-

Adaptability to complex environments: In the PCBA production process, the types and layouts of components on the circuit board are very complex. The visual AI inspection system can handle complex inspection tasks and adapt to various products.

-

Cost reduction: By reducing the need for manual inspections, PCBA visual AI inspection can significantly lower labor costs, improve production efficiency, save time, and reduce rework costs caused by human errors.

Scenario Example One

Electronic product manufacturing: Widely used in the PCBA production process of electronic products such as mobile phones, computers, and home appliances to ensure product quality meets standards.

Scenario Example Two

Medical devices: For circuit boards in medical equipment, precise inspection can ensure the normal operation and safety of the devices, avoiding safety hazards caused by circuit issues.

Working principle of visual AI inspection

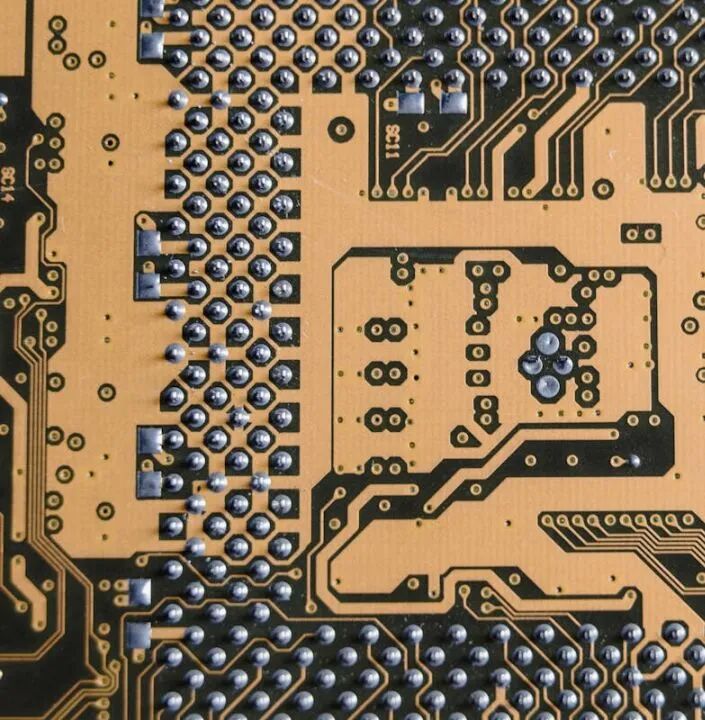

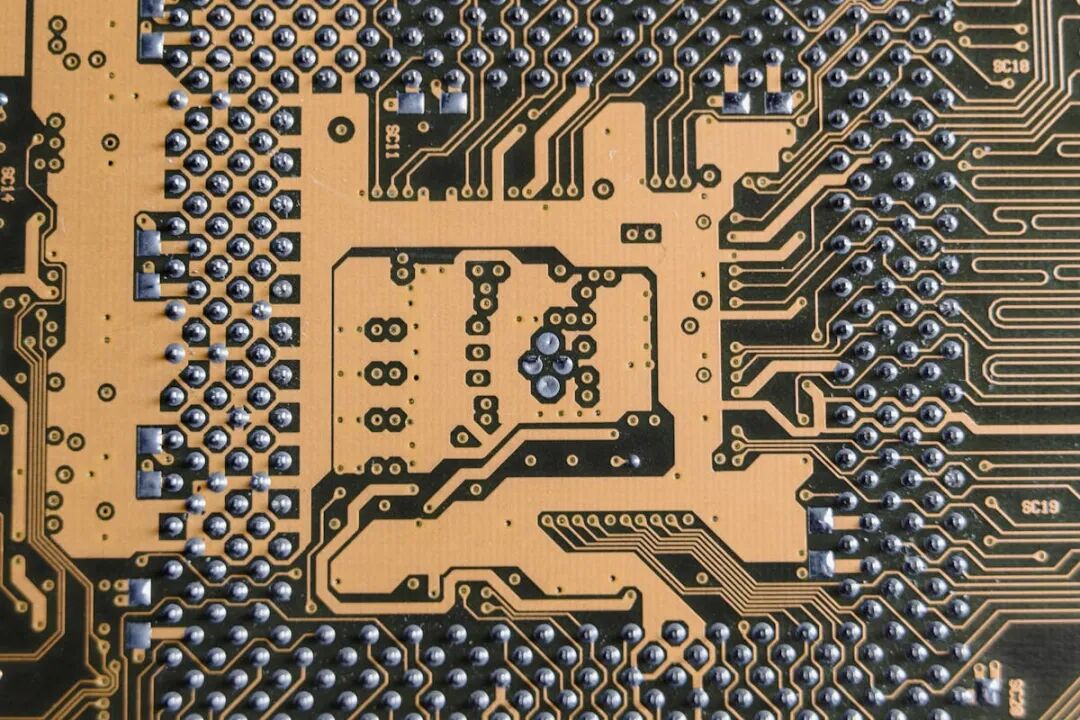

1. Image Acquisition

High-definition cameras or specialized cameras capture images of the PCBA board. These images contain details of components, solder joints, and circuits on the board.

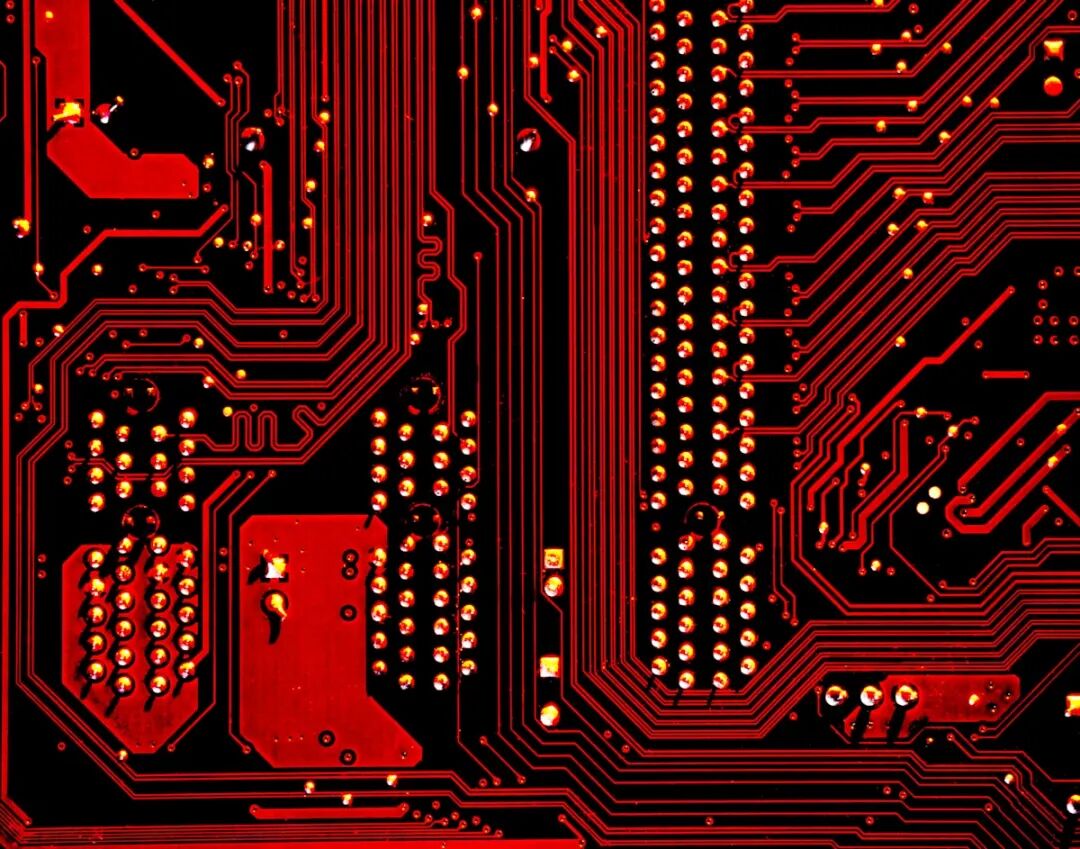

2. Image Preprocessing

Preprocessing operations such as denoising, contrast enhancement, and edge detection are performed on the captured images to prepare for subsequent analysis.

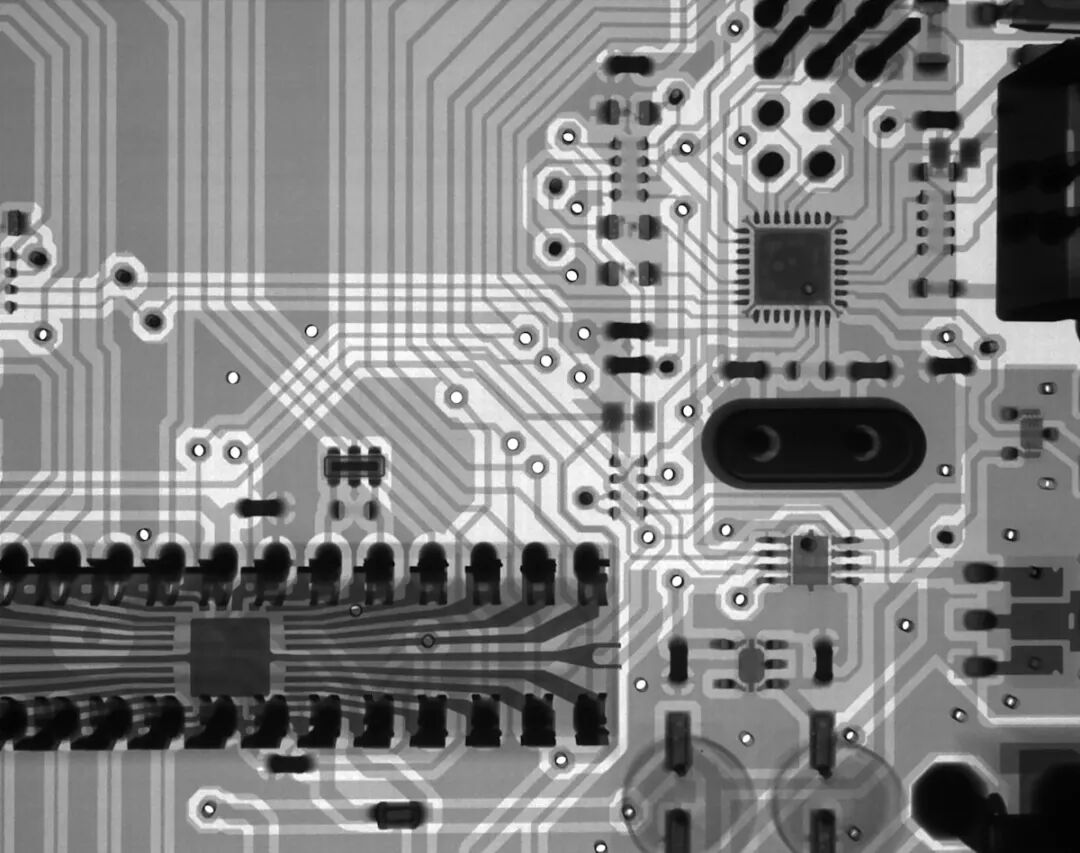

3. Deep Learning Analysis

Using deep learning algorithms such as Deep Neural Networks (DNN) or Convolutional Neural Networks (CNN), the processed images are analyzed. The system automatically identifies features such as the position, shape, and color of components using a trained model and compares them to determine if they meet standards.

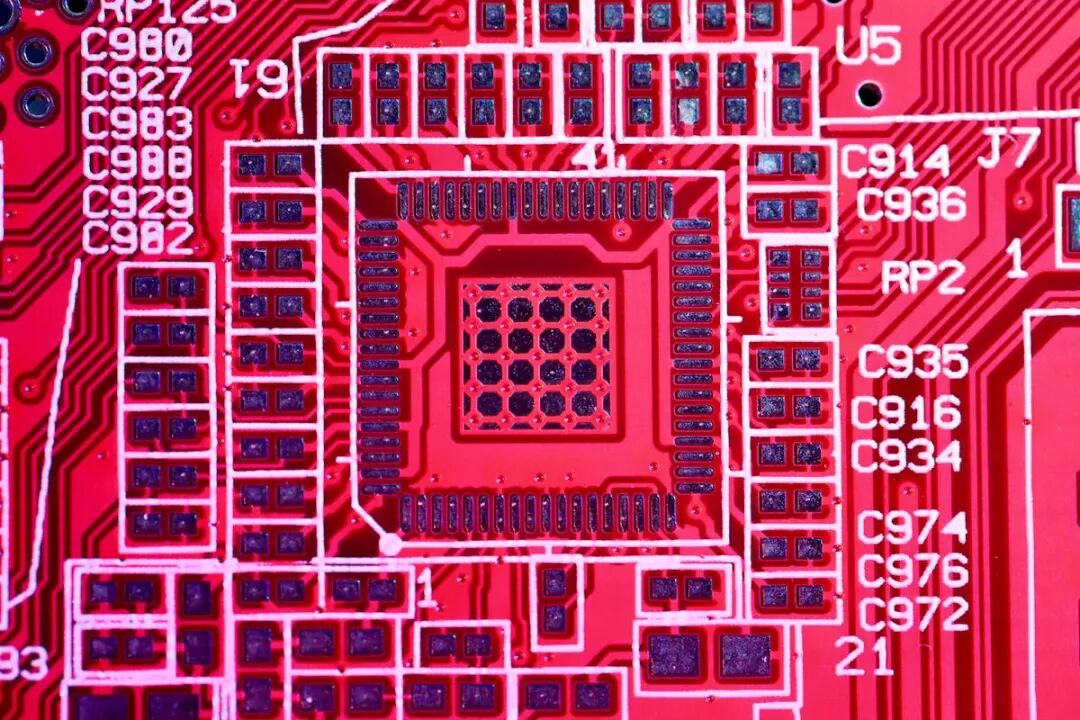

4. Defect Identification and Localization

The system can automatically detect various defects on the PCB, such as missing components, poor solder joints, short circuits, open circuits, and cold soldering, and accurately locate them.

5. Automatic Reporting and Feedback

When the system detects a defect, it generates a detailed inspection report and feeds the issues back to the production line operator or system for timely handling and repair.

With the continuous advancement of AI technology and the integration of 5G, the Internet of Things, and artificial intelligence, future PCBA visual AI inspection will be even more efficient, capable of handling more complex circuit board designs and high-density components. At the same time, the continuous optimization of deep learning models will further improve the accuracy and recognition capabilities of inspections, bringing greater transformation to the electronic manufacturing industry.

END

If you click “share,” it will give me a boost~