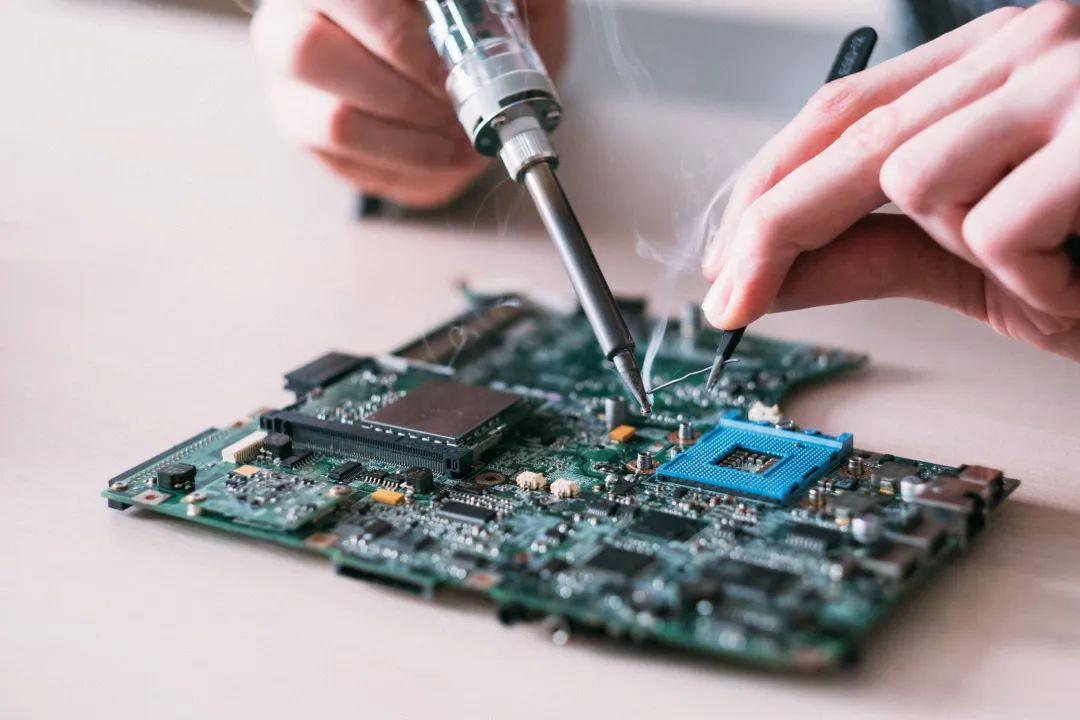

When performing PCB soldering, we need to strictly control the entire soldering process to ensure the quality of the soldering. Below are the key considerations for PCB soldering.

1. After receiving the bare PCB, first conduct a visual inspection to check for issues such as short circuits or open circuits. Then familiarize yourself with the schematic diagram of the development board and compare it with the PCB silkscreen layer to avoid discrepancies between the schematic and the PCB.

2. Once all materials required for PCB soldering are prepared, classify the components. You can categorize all components by size to facilitate subsequent soldering. A complete material list should be printed. During the soldering process, mark off each item on the list as it is completed to assist with subsequent soldering operations.

3. Before soldering, take anti-static measures such as wearing an anti-static wrist strap to prevent static electricity from damaging the components. Ensure that all necessary soldering equipment is ready and that the soldering iron tip is clean and tidy. For initial soldering, it is recommended to use a flat-tipped soldering iron, as it can better contact the pads when soldering components like 0603 package components.

4. When selecting components for soldering, solder them in order from the lowest to the highest and from the smallest to the largest. This prevents larger components from obstructing the soldering of smaller components. Prioritize soldering integrated circuit chips.

5. Before soldering an integrated circuit chip, ensure that the orientation of the chip is correct. For the chip silkscreen layer, the rectangular pad generally indicates the starting pin. When soldering, first secure one pin of the chip, then adjust the position of the component before securing the diagonal pin of the chip, ensuring that the component is accurately connected before soldering.

6. For surface-mounted ceramic capacitors and voltage regulator diodes, there is no positive or negative polarity. However, for light-emitting diodes, tantalum capacitors, and electrolytic capacitors, the polarity must be distinguished. Generally, the end with a significant marking should be the negative side. In the packaging of surface-mounted LEDs, the direction of the light indicates the positive-negative direction. For components with a silkscreen marking in the diode circuit diagram, the end with a vertical line should be placed as the negative terminal of the diode.

7. For crystal oscillators, passive crystal oscillators generally have only two pins and have no polarity. Active crystal oscillators typically have four pins, and it is important to pay attention to the definition of each pin to avoid soldering errors.

8. For through-hole components such as power module-related components, the component pins can be modified before soldering. After placing and securing the components, generally, the solder is melted from the back with a soldering iron and flows into the front pad. Do not use too much solder, but ensure that the component is stable first.

9. During the soldering process, promptly record any PCB design issues discovered, such as installation interference, incorrect pad size design, or incorrect component packaging, for future improvements.

10. After soldering, use a magnifying glass to inspect the solder joints for any cold soldering or short circuits.

11. After completing the PCB soldering work, clean the surface of the PCB with alcohol or other cleaning agents to prevent metal shavings from causing short circuits and to make the PCB cleaner and more aesthetically pleasing.

Some screenshots from electronic books

【Complete Set of Hardware Learning Materials Collection】