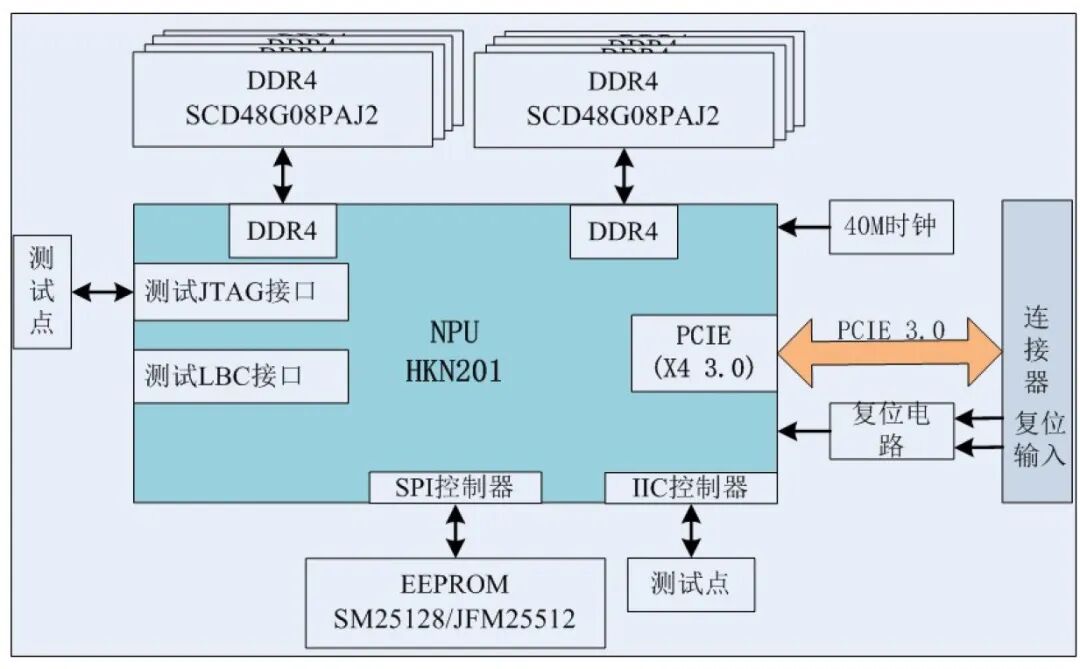

The Xiangteng NPU chip HKN201 neural network processor is a domestically produced, high-performance, multi-core processor designed for strong real-time, high-performance, and high-concurrency application scenarios by Xi’an Xiangteng Microelectronics Technology Co., Ltd.The hardware design of the HKN201 neural network processor core board requires reference documents including the hardware design guide, core board hardware schematic reference, schematic design checklist, and a summary of core board design reference materials.

1. Hardware Design Guide

The reference document “HKN201 Neural Network Processor Hardware Design Guide” introduces the key points and considerations for the hardware design of the HKN201 processor, helping users shorten the product design cycle and improve product design stability. This document covers aspects such as schematic design, PCB design, thermal design, and soldering processes.

Chapter 1: Introduction to the System Block Diagram of a Typical NPU Core Board Chapter 2: Schematic Design Recommendations

Chapter 2: Schematic Design Recommendations

- NPU Core Board Minimum System Design:Includes the core chip, peripheral resources (including DDR4 memory, EEPROM memory, PCIe bus interface), 40MHz main clock, power-on and reset design, etc. Each part’s interface design has specific requirements, such as clock input level requirements, reset signal valid time requirements, PCIe clock and interface parameter requirements, DDR4 selection requirements, etc.

- Power Supply Design:Clarifies the voltage, current range, and specification requirements for various power supplies, as well as power-on sequence requirements. Suggestions are provided for different power supply wiring, decoupling, etc.

Chapter 3: PCB Design RecommendationsProvides recommendations for PCB stacking design, power PCB design, DDR4 PCB design, etc. For high-speed routing, design principles such as controlling trace length and maintaining impedance matching are proposed.Chapter 4: Thermal Design RecommendationsProvides simulation data at an ambient temperature of 85°C, including chip junction temperature and environmental thermal resistance, and suggests adding external heat sinks and other measures to ensure thermal reliability.Chapter 5: Soldering Process RecommendationsRecommends that chips be baked in an oven at 125°C for 48 hours to remove moisture before soldering, and provides SMT curve recommendations and other soldering process requirements.

2. Core Board Hardware Schematic Reference

Reference the schematic of “HK201-CORE-D-V4_DEMO”

3. Schematic Design Checklist

Reference document “HKN201 Neural Network Processor User Schematic Self-Inspection Template” introduces the key points and considerations for hardware design, aiming to help customers shorten the product design cycle, and is used for HKN201 users to conduct schematic self-checks.

4. Summary of Core Board Design Reference Materials

Reference documents include

For detailed information, refer to Hard Ten Classroom, scan the QR code to enterhttps://www.hw100k.com/coursedetail?id=271

For detailed information, refer to Hard Ten Classroom, scan the QR code to enterhttps://www.hw100k.com/coursedetail?id=271

Chip Consultation and Procurement Contact Information