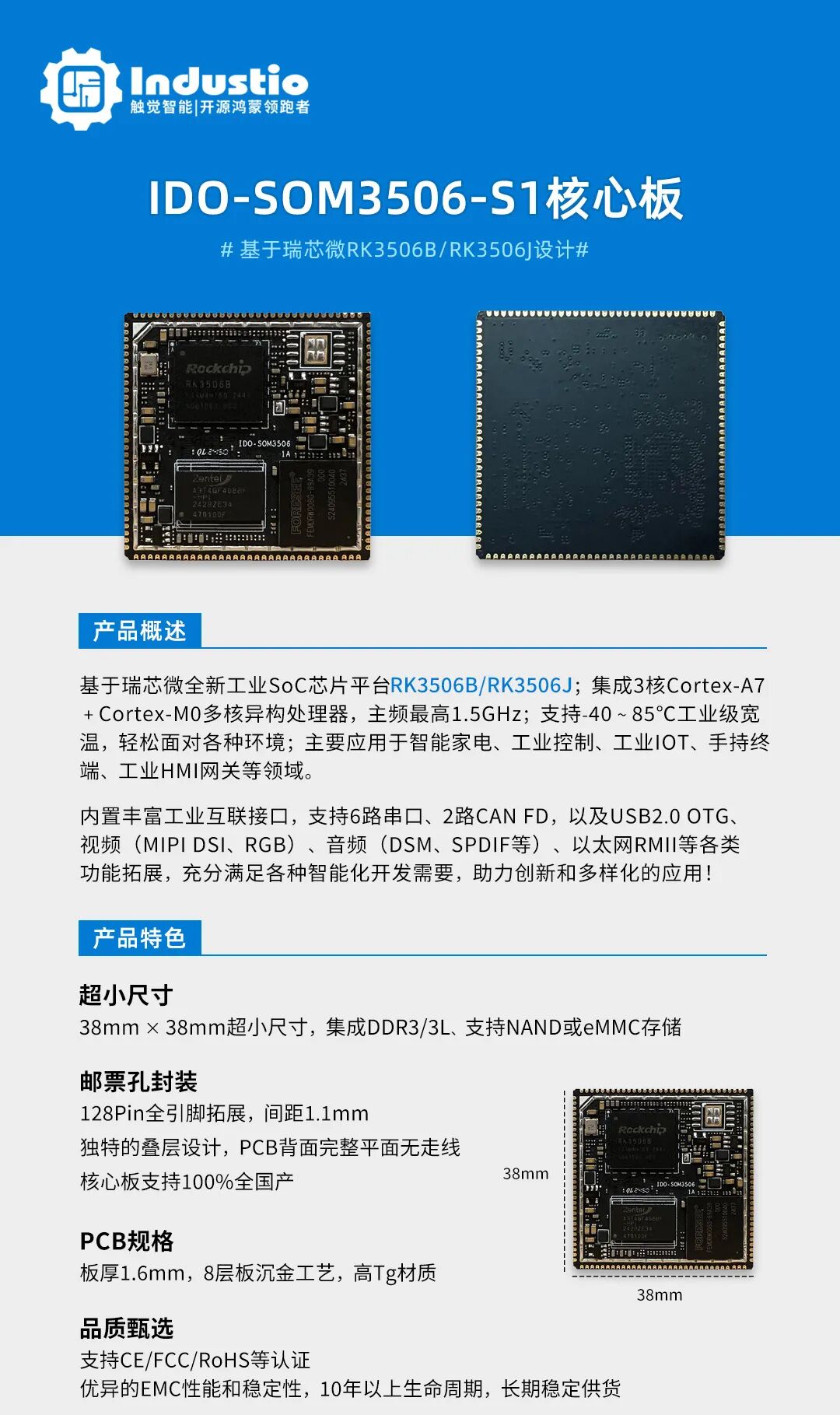

The high-precision collaborative control and real-time communication capabilities between devices have become performance indicators that cannot be ignored in the manufacturing industry. Recently, the Haptic Intelligence RK3506 core board introduced EtherCAT bus technology, combining a low cost of 59 yuan, a multi-core heterogeneous architecture, and industrial-grade reliability to provide high-performance and cost-effective solutions for the industrial automation field.

EtherCAT Bus

- What is EtherCAT?

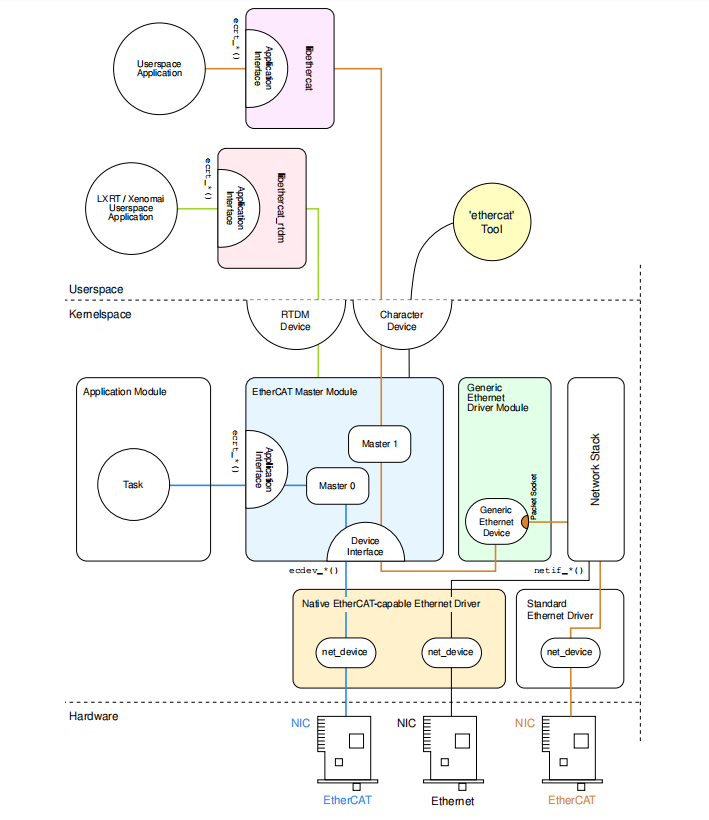

The core principle of EtherCAT: master-slave architecture and “on-the-fly processing”. The full name, Ethernet for Control Automation Technology, is a real-time industrial bus protocol based on Ethernet, with its core innovation being the “On The Fly” processing mechanism.

- Technical Features of EtherCAT

At a transmission rate of 100Mbps, 1000 I/O refresh cycles only require 30μs, and the delay for 8-axis servo synchronous control is <1ms. It also supports any topology such as linear, tree, and star, achieving redundant ring networks without the need for switches.

- Advantages of EtherCAT Protocol

Simplified protocol stack: only requires the physical layer, data link layer, and application layer, with hardware processing protocol stack latency <5μs, and CPU load reduced by 25%-30%.Strong compatibility: natively supports CODESYS, IgH master protocol, and is compatible with mainstream servo drivers such as Beckhoff and Omron.

Features of RK3506 Combined with EtherCAT

- Latency Optimization

By connecting multiple servo drivers as slaves via Ethernet, precise control of servo motors can be achieved, supporting dedicated network card drivers for stronger real-time performance!

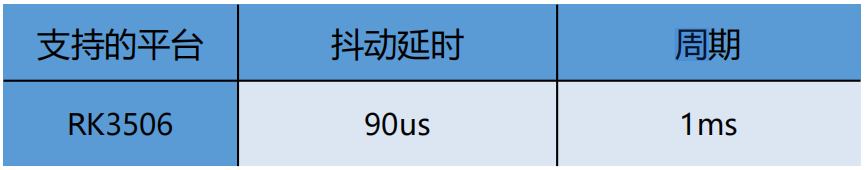

- Technical Specifications

According to the manufacturer’s data, the measured delay jitter performance reaches within 10% (control cycle of 1 millisecond).

- Industrial Reliability

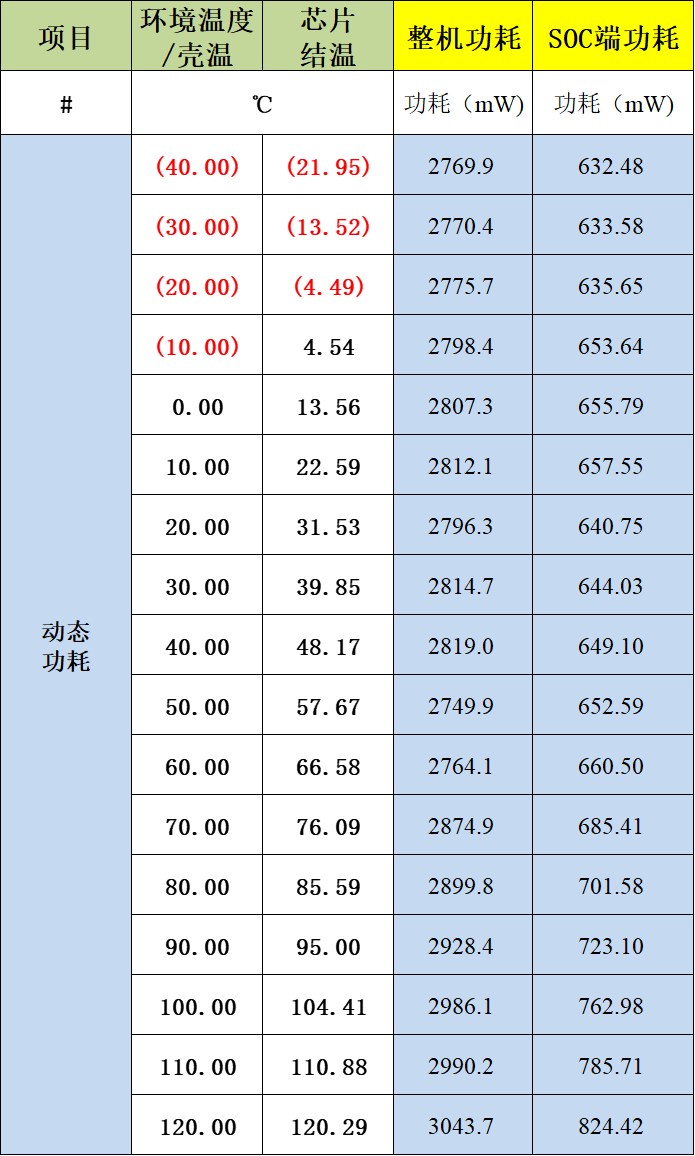

Additionally, under the Haptic Intelligence RK3506 core board’s ≤0.7W power consumption and -40~85℃ wide temperature performance, it better meets the stable operation of EtherCAT in various environments.

Application Scenarios of EtherCAT

- Intelligent Production Line Control

The Haptic Intelligence RK3506 core board can be paired with NearLink wireless technology, combined with EtherCAT master to drive 8-axis servos, achieving a network of thousands of devices with a delay only 1/30 of traditional solutions.

- Industrial Robotic Arms

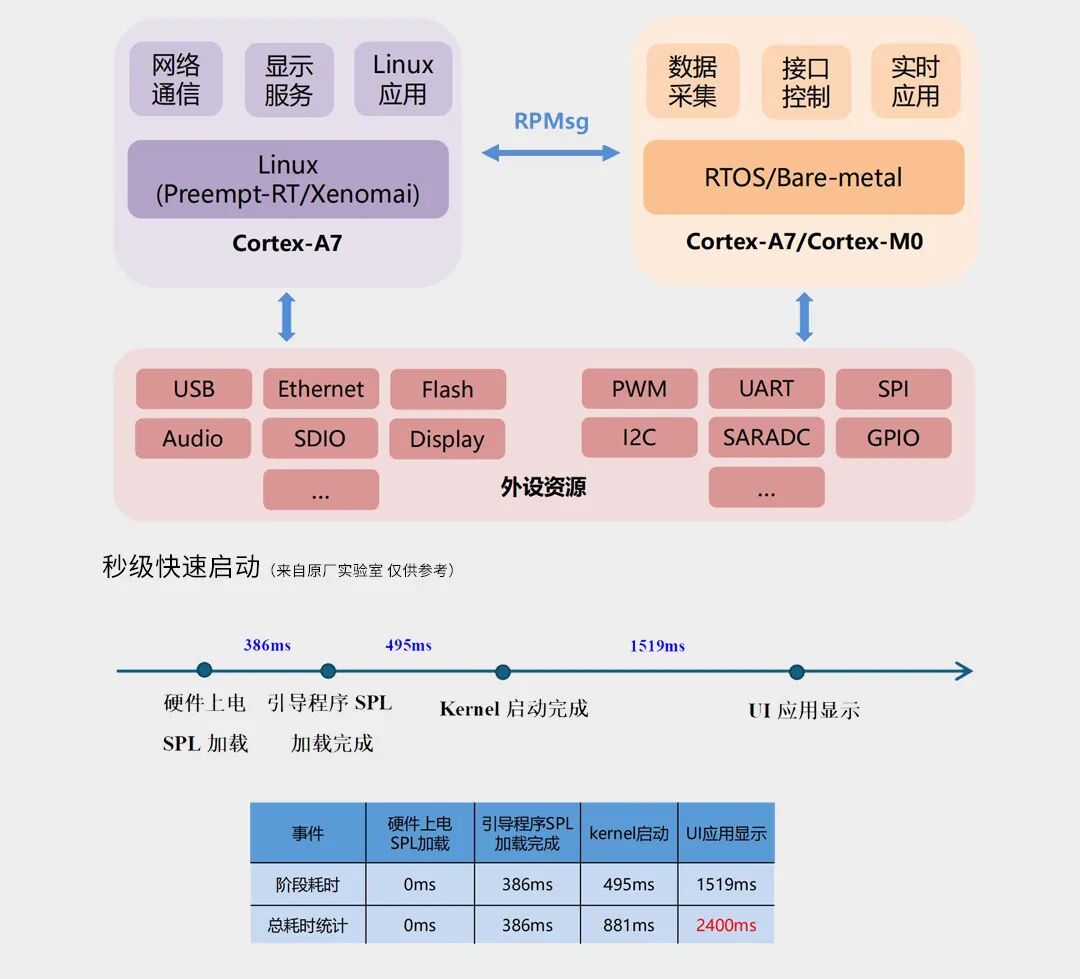

The Haptic Intelligence RK3506 core board, under the APM multi-core heterogeneous system, can process joint control through the RTOS system, run vision on the Linux system, and support ring topology to simplify wiring.

- High-Precision Detection Equipment

EtherCAT synchronously triggers 100MSPS high-speed ADC, directly transmitting data to the MES system, paired with the LVGL interface to achieve μs-level waveform display!

- Distributed Energy Systems

EtherCAT combined with NearLink technology solutions ensures that redundant ring topology guarantees uninterrupted power grid communication, making it more suitable for energy and power scenarios.

Haptic Intelligence RK3506 Core Board

Video:Image:

END

END