Introduction by Antarctic Bear: Many people think of FDM 3D printers as those machines that print ordinary plastics on a desktop, but in reality, FDM extrusion technology can create many groundbreaking devices.

Today, let’s explore a “open-source granular material extrusion technology that combines additive and traditional subtractive manufacturing” marvel.

Introducing the new Titan 3D printer series from the international giant 3D Systems! First, check out the video to feel it out.

Three Major “Hardcore” Features

Redefining 3D Printing

❶ Speed: 10 Times Efficiency Disrupting Tradition

Tired of waiting three days and nights to print a mold? Titan directly adopts exclusive extrusion technology, achieving a printing speed that is 10 times faster than traditional methods. Large parts that used to take weeks can now be completed quickly! With dual modes of “additive + subtractive” for automatic surface milling after printing, precision is maximized, easily handling aerospace-grade precision components.

❷ Compatible with Hundreds of Materials, Creating Thousands of Products

Printer choosing materials? Titan says: “I want them all!”

-

Supports hundreds of granular/filament materials: from everyday plastics like PLA, PETG, ASA, polycarbonate, to high-performance polymers for aerospace and healthcare like ABS, PEEK, Radel®, and polyphenylene sulfide. It also offers elastomers and carbon or glass-filled materials.

-

Super large printing size: A “behemoth” space of 1.8 meters high × 1.27 meters wide can print car molds, large sculptures, and even entire furniture frames, from gears to thermoforming equipment, all in one machine! It can print most large parts without needing to bond them together.

❸ Industry “Versatile Handyman”: From Hardcore Manufacturing to Artistic Creation

Whether it’s making airplanes, cars, or engaging in cultural creativity and design, Titan can be your “best partner”:

1. Aerospace: Print lightweight, high-strength parts, reducing weight by 30% while withstanding extreme temperature differences.

2. Automotive Manufacturing: Rapidly customize molds, halving the new car development cycle.

3. Consumer Product Design: Print flexible materials for wearable devices, even creating “moving” midsoles for sports shoes.

4. Art and Intangible Cultural Heritage: High-precision replication of cultural relics and 3D printed furniture, allowing tradition and technology to collide and spark new ideas.

Real Cases: See How Various Industries Use Titan to “Level Up”

01

Case 1: Pioneers of Thermoforming Technology — Duo Form

Unlike traditional CNC machining techniques for manufacturing ceramic or metal molds, Duo Form currently uses polymer granules to print thermoforming molds on the Titan 3D printer. Large-format granular extrusion additive manufacturing employs thermoplastic granules commonly found in injection molding and other extrusion manufacturing processes, offering high economic benefits, with costs nearly 10 times lower than traditional FDM filaments. Titan also supports high-throughput printing, achieving speeds over 10 times faster than traditional filaments. 3D Systems and Duo Form have jointly developed a glass-filled polycarbonate granule that is not only economical and readily available but also withstands the rigors of thermoforming processes, making it an ideal material for printing thermoforming molds.

02

Case 2: Racing Team’s “Speed Partner” — Airtech & Brumos Racing

Brumos Racing Porsche GT 2 RS Clubsport car front end (bumper removed to show 3D printed intake manifold)

Racing parts pursue “light as a feather, strong as a rock”; Titan directly prints aerodynamic components from carbon fiber reinforced PA. The Brumos Racing Porsche GT 2 RS Clubsport car won the championship and set a record in the 2023 Peak International Hill Climb (PPIHC) with 3D printed radiator intake manifolds produced by 3D Systems’ EXT 1070 Titan Pellet printer.

03

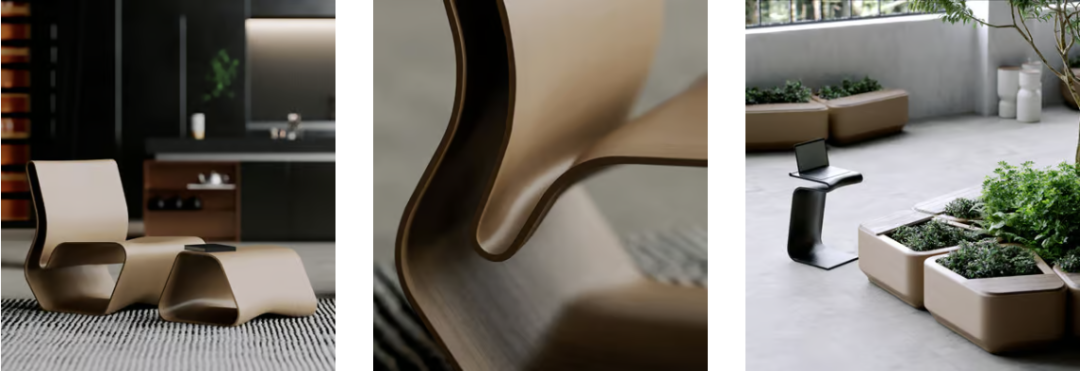

Case 3: The “Eco Pioneer” in Furniture — Model No.

While others rely on cutting down trees for furniture, they rely on “printing trees”! Model No. Furniture is reshaping the furniture industry with its sustainable high-tech approach, utilizing 3D Systems’ EXT Titan™ pellet extrusion printer to create high-end furniture. From recycling sawdust and other plant waste into 3D printing materials to implementing on-demand manufacturing processes, Model No. merges computational design, material science, and manufacturing technology to pursue zero environmental impact. The shapes can be freely contoured (curved surfaces and hollow designs are all achievable), significantly reducing material waste. Custom production ensures that each piece is a “unique eco-artwork”.

04

Case 4: Leading Polyolefin Manufacturer Braskem Enters the 3D Printing Materials Market

Braskem relies on Titan’s ability to produce large-scale, high-resolution parts with excellent surface quality and end-use functionality, using the Titan large 3D printer with extrusion technology to test its materials and manufacture parts for display.

Jeep Wrangler equipped with 3D printed fenders

The Braskem team collaborated with 3D design studio Dive Design to create large display pieces for trade shows, conferences, and Braskem’s additive manufacturing lab. The team created a fully waterproof paddleboard made up of three modular printed components, requiring no post-processing, along with a set of custom off-road SUV door panels and fenders, complete with custom 3D printed accessories such as shovel holders, tent hooks, and cup holders, perfect for outdoor adventurers.

05

Case 5: Astech: A Foundry Transformed by Additive Manufacturing

Astech once relied on a traditional model shop, typically waiting 4-6 weeks for model delivery. By bringing model production in-house with AM, they have reduced this time to just 3-10 days.

An Astech employee pouring molten steel into a sand mold made from a 3D printed model

An Astech employee cutting the sprue from a cast pump housing

Today, Astech 3D prints about 90% of its models. “In-house additive manufacturing has become our ‘secret weapon’. It gives us an edge over competitors in terms of tooling costs, precision, production speed, and the ability to modify existing work with lightning-fast turnaround times,” said Helwer. In fact, the speed and cost advantages of additive manufacturing have allowed Astech to grow, improve profitability, and continue to provide high-quality casting products to customers.

For a guide on large-format 3D printers, please visit “Read the original article”