Stay Focused | Maintain Concentration | Build Expertise

|

Click Yangtze River Delta G60 Laser Alliance Follow/ Pin to Official Account

|

|

News | Technical Article | Conference Forum | Industry Investment

|

Yangtze River Delta G60 Laser Alliance Guide

Researchers from Hong Kong Polytechnic University, Hong Kong University of Science and Technology, and Central South University reported on the research titled “3D printing for ultra-precision machining: current status, opportunities, and future perspectives”. The related paper was published in Frontiers of Mechanical Engineering.

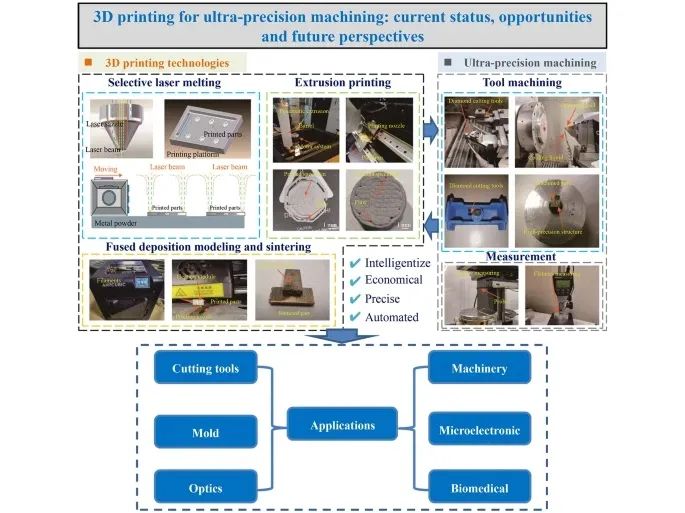

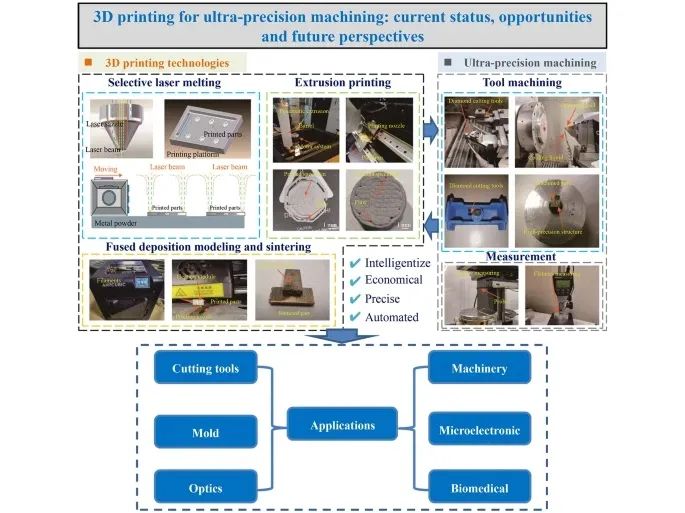

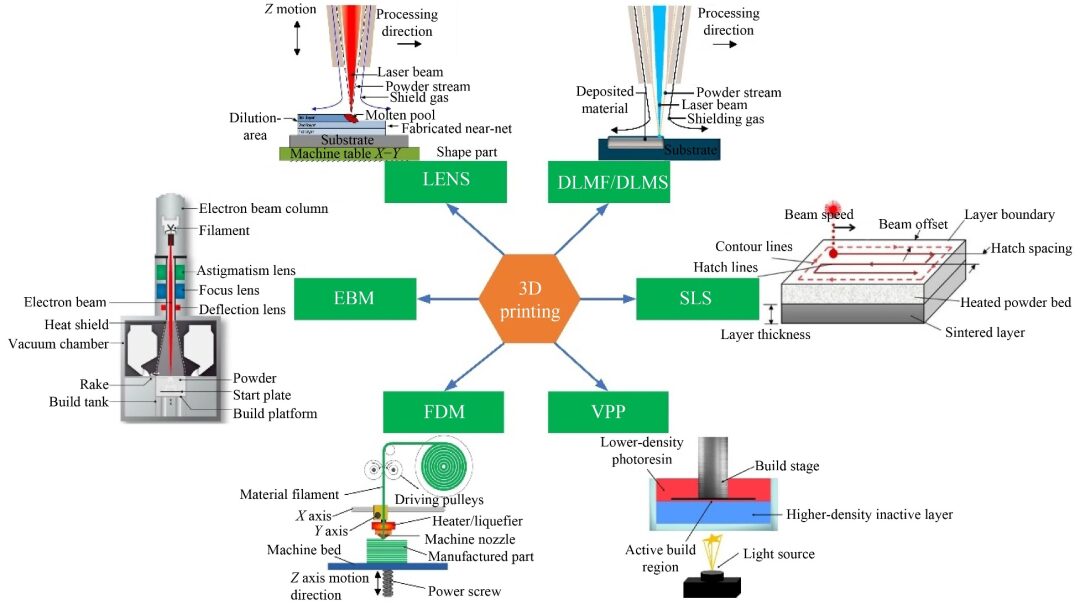

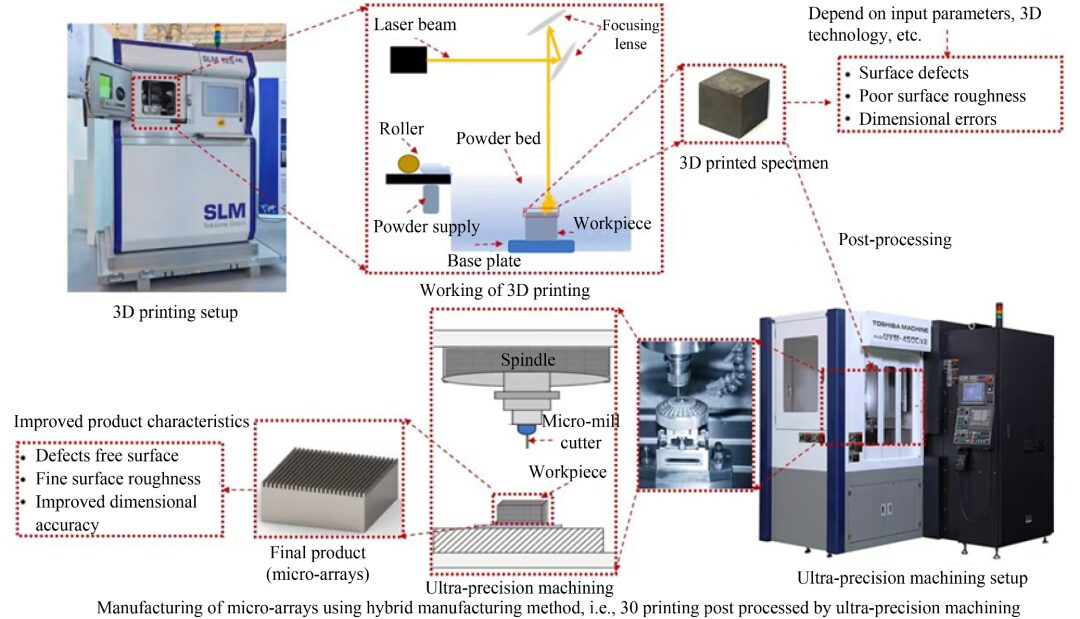

Additive manufacturing technology, commonly known as 3D printing, has revolutionized the manufacturing industry by producing complex and intricate parts at low costs and high efficiency. However, 3D printed parts often require post-processing or integration with other machining techniques to achieve the desired surface finish, accuracy, and mechanical properties. Ultra-precision machining (UPM) is a potential machining technique that can address these challenges by achieving high surface quality, accuracy, and repeatability for 3D printed parts. This study outlines the current status of UPM for 3D printing, including the current stages of UPM and 3D printing, as well as the applications of UPM in 3D printing.

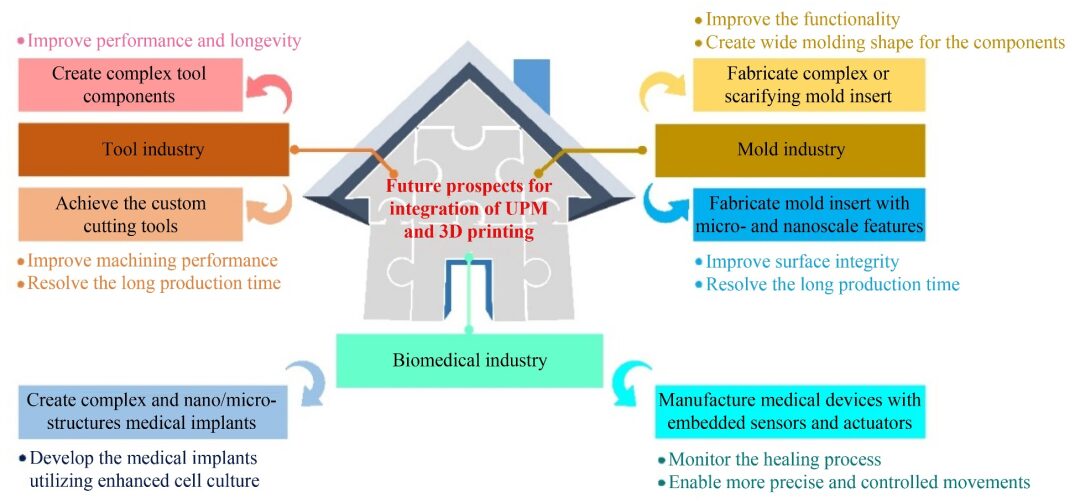

This study discusses in detail the benefits of combining UPM with 3D printing, as well as the opportunities for using UPM for 3D printing or mutual support. In particular, future opportunities are primarily focused on manufacturing cutting tools for UPM through 3D printing, UPM for practical applications of 3D printed parts, and the post-processing of 3D printed parts. Finally, the future prospects of integrating these two advanced manufacturing technologies into potential industries are discussed. The conclusion of this study is that UPM is a promising technology for 3D printed parts, with the potential to enhance the functionality and performance of 3D printed products across various applications. This study also discusses how UPM and 3D printing complement each other.

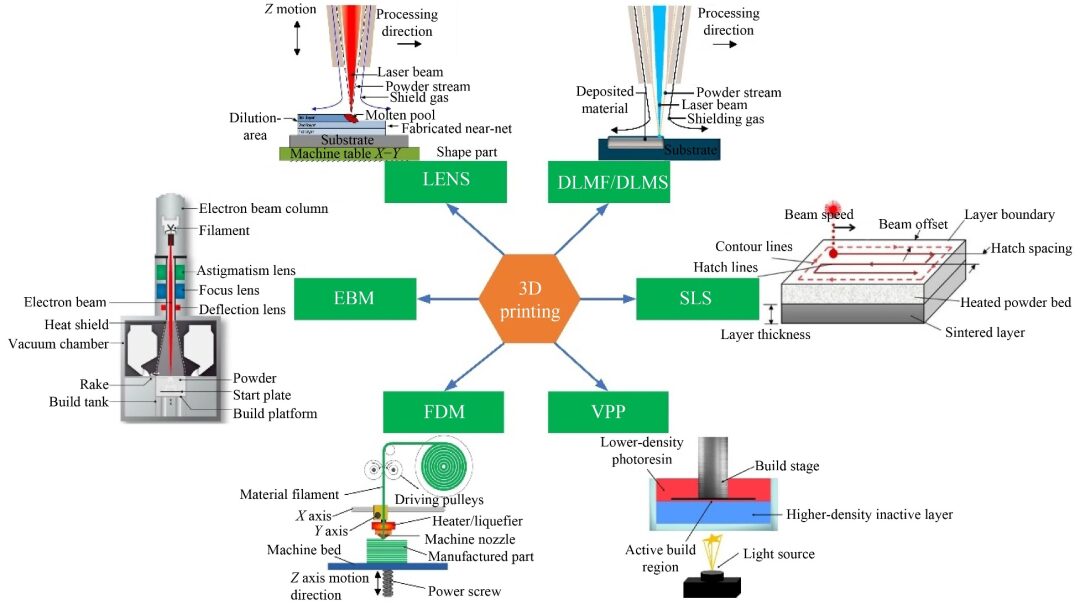

Figure 1 Current mainstream 3D printing technologies.

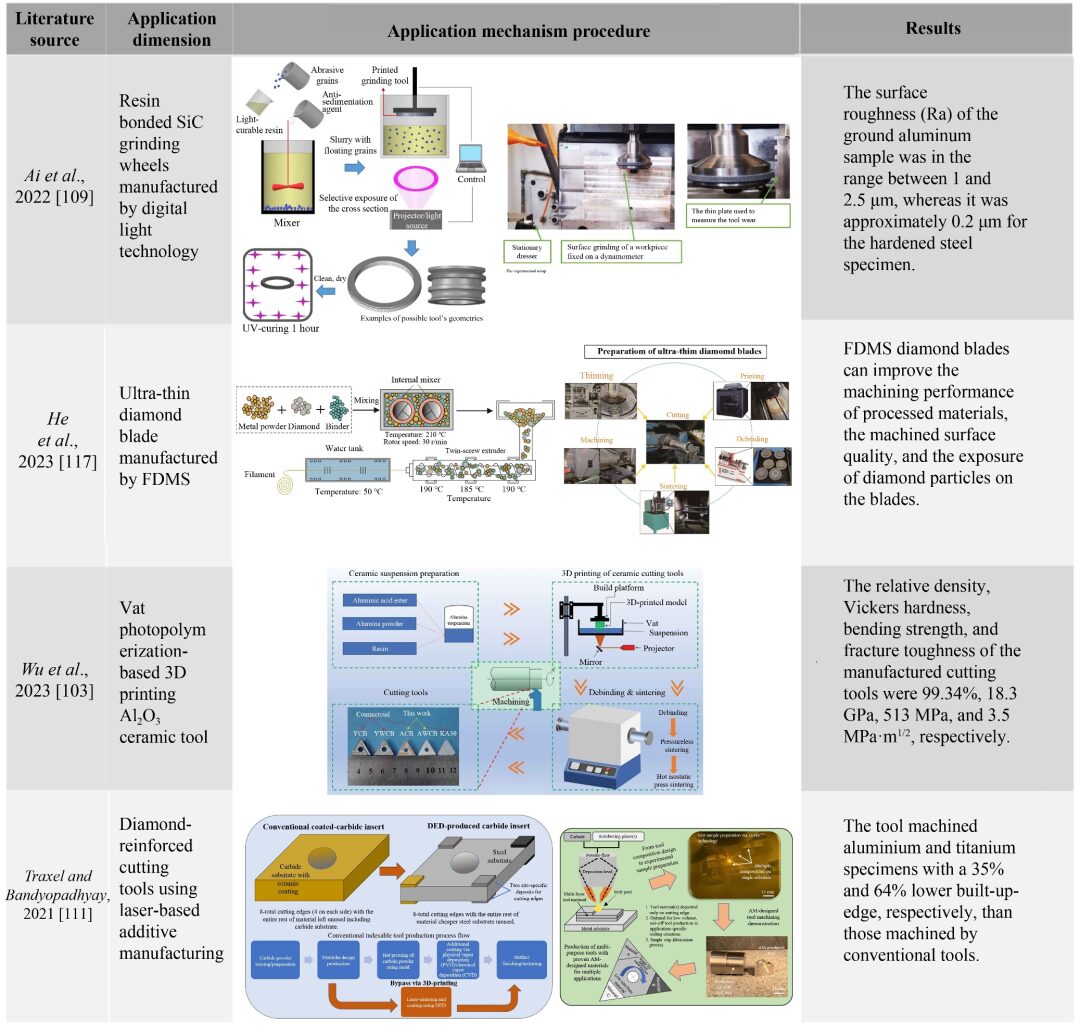

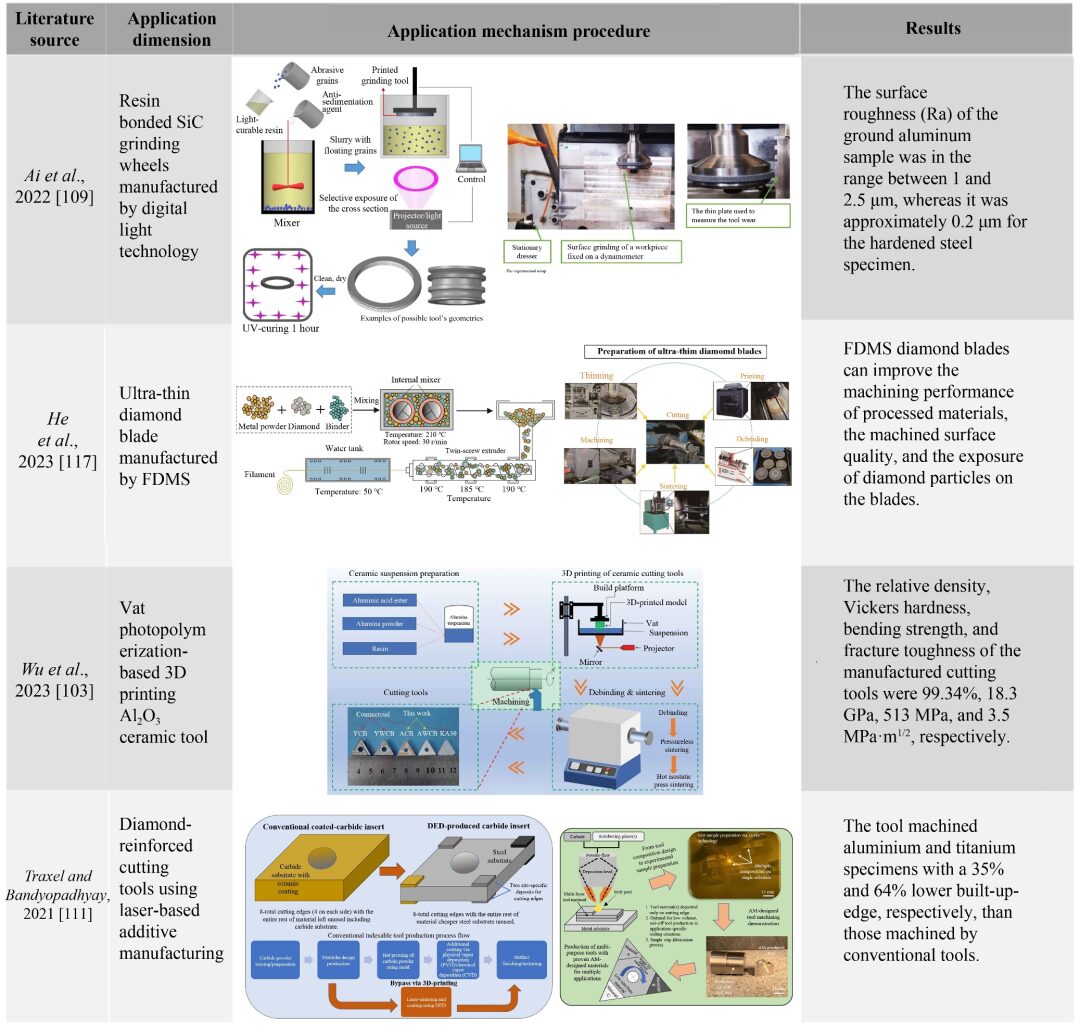

Figure 2 Integration of UPM and 3D printing in cutting tools.

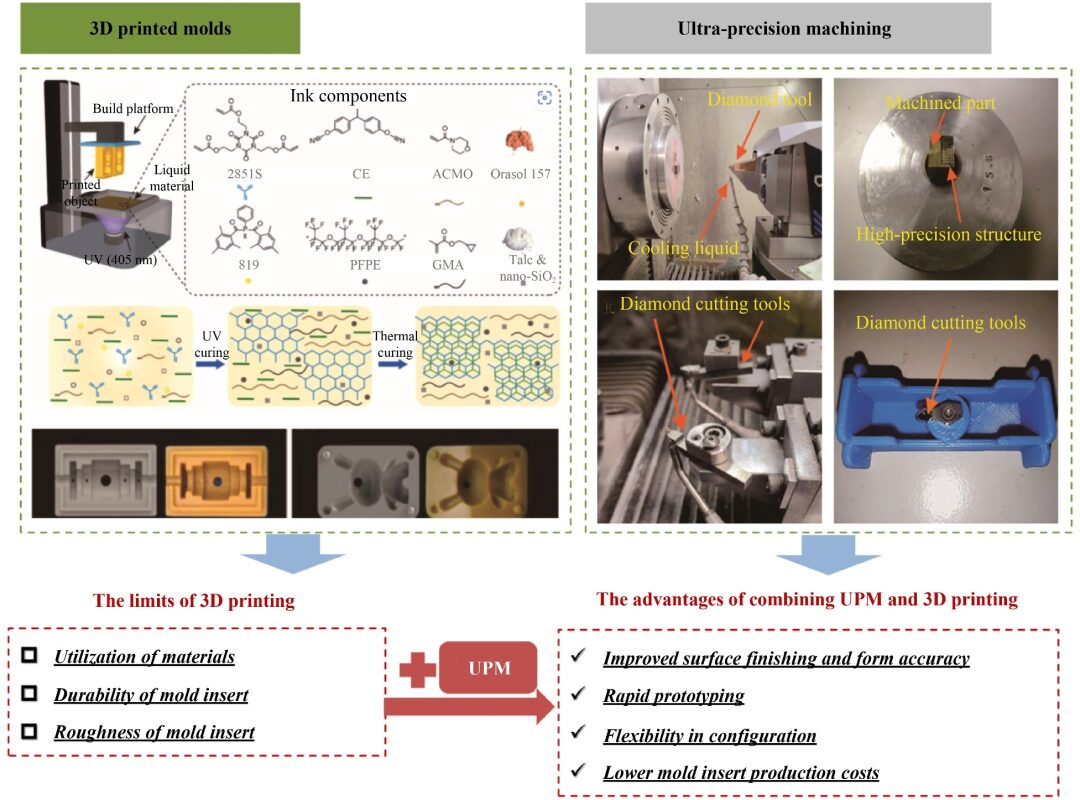

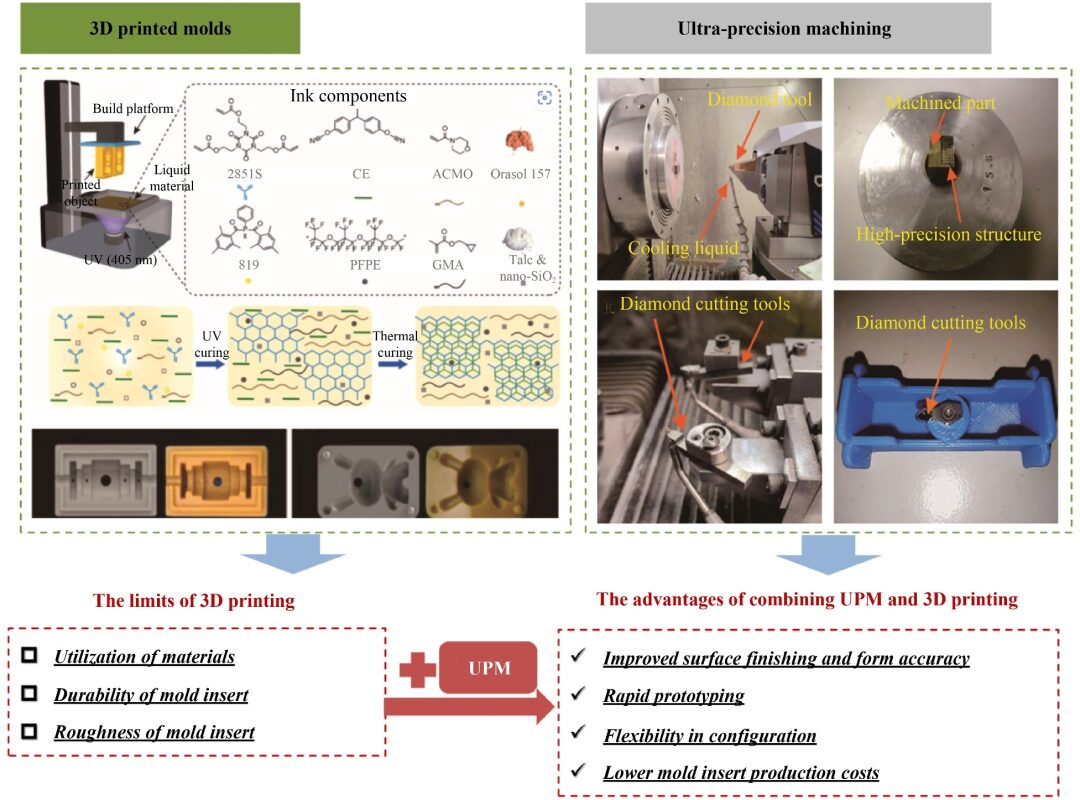

Figure 3 Combining UPM and 3D printing technologies for mold insert manufacturing.

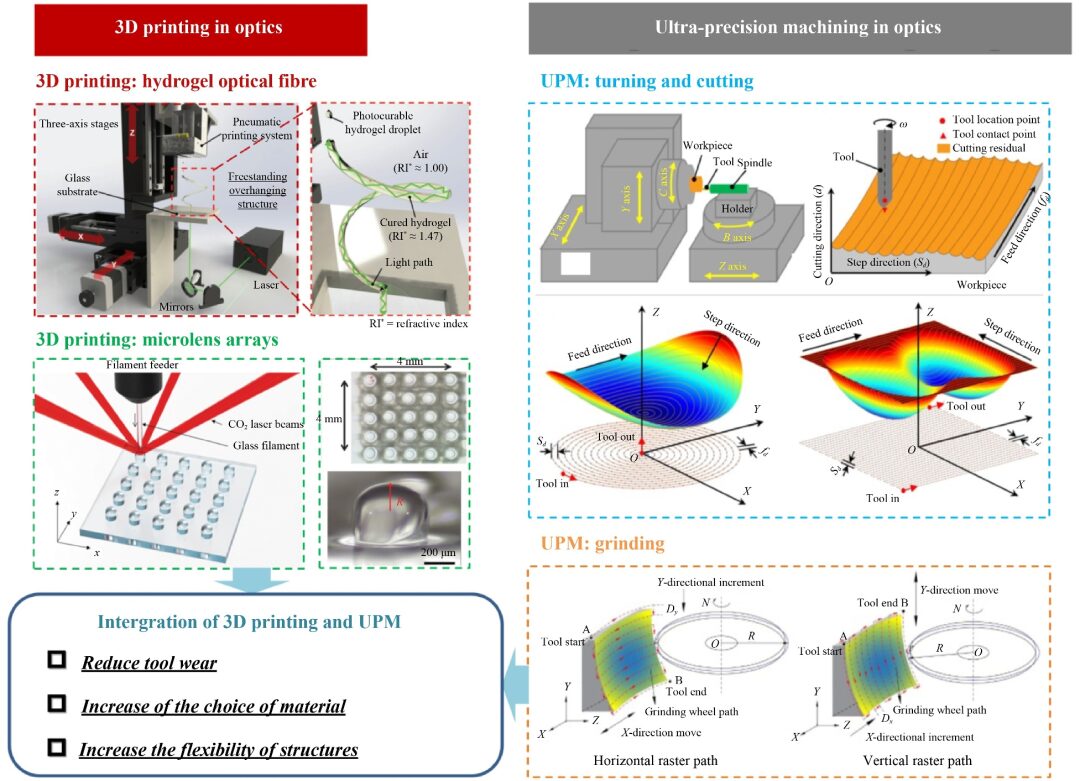

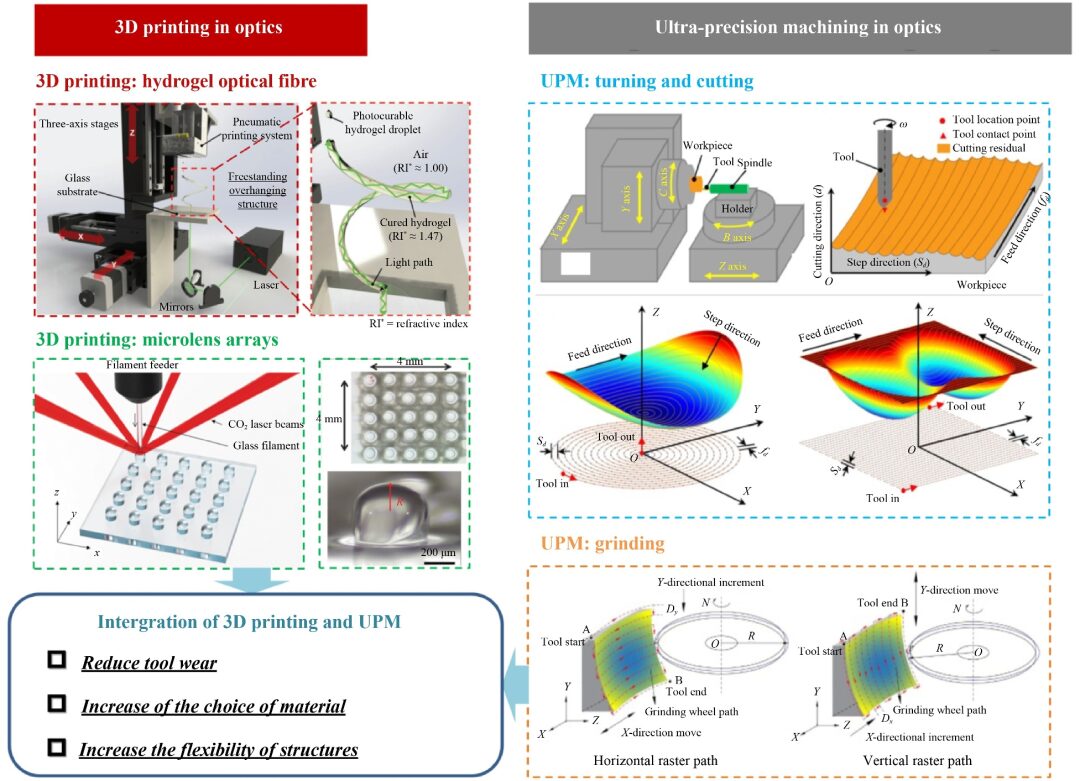

Figure 4 Application of UPM and 3D printing technologies in the optical field.

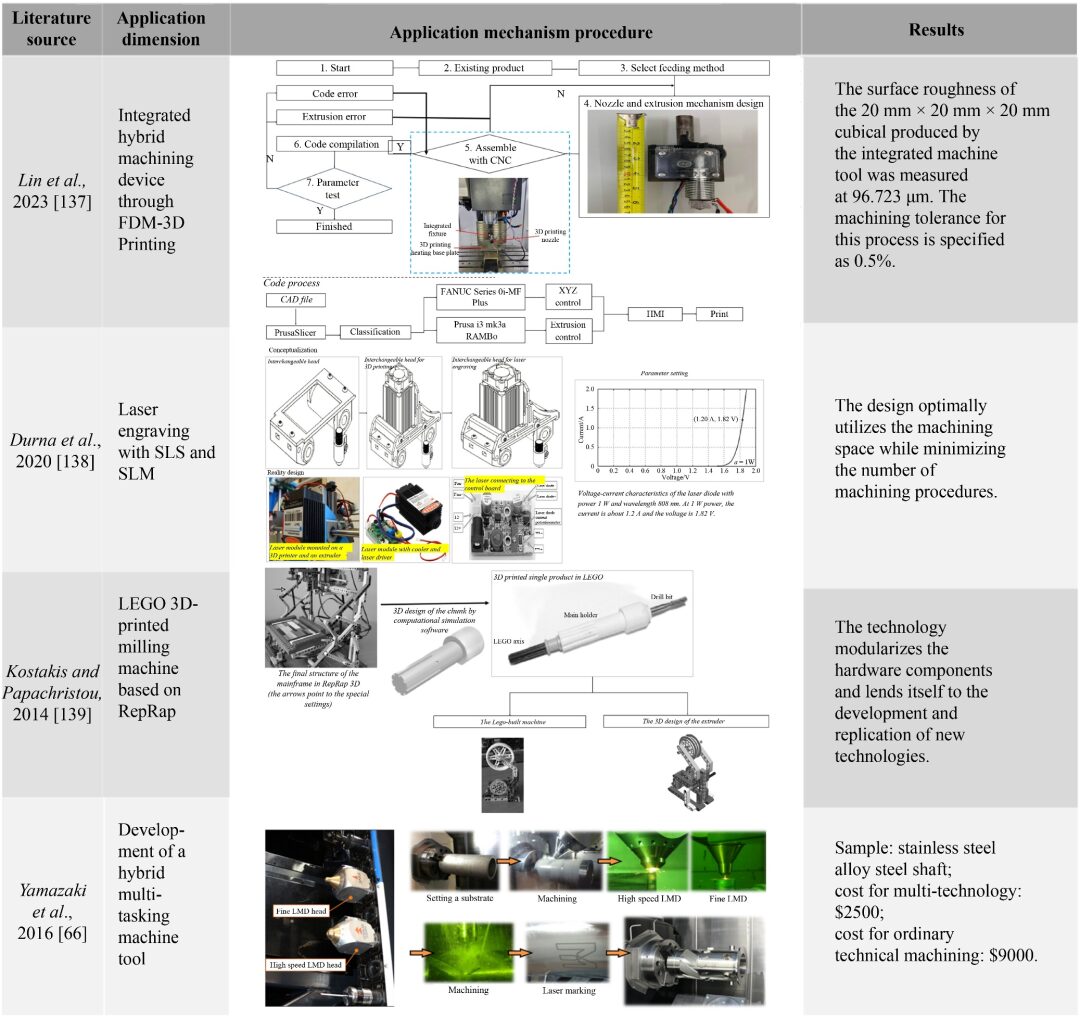

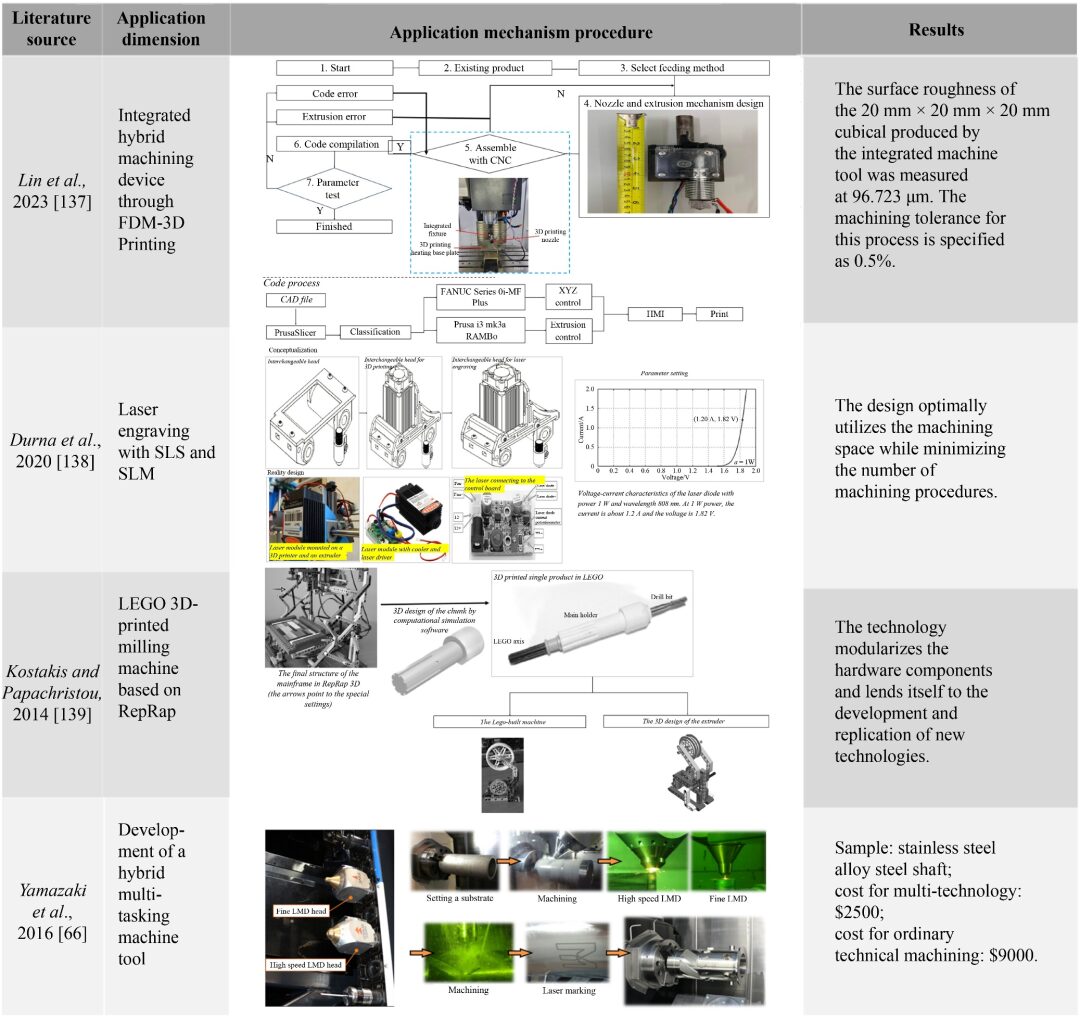

Figure 5 Integration of UPM and 3D printing in the mechanical field.

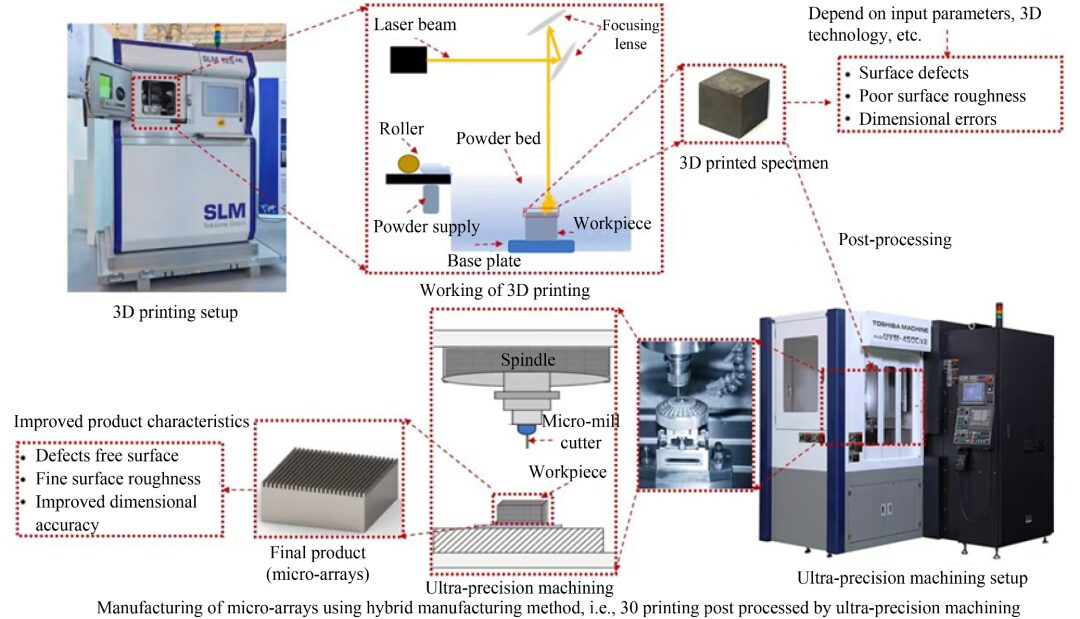

Figure 6 Mixed schemes of UPM and 3D printing for microstructure manufacturing.

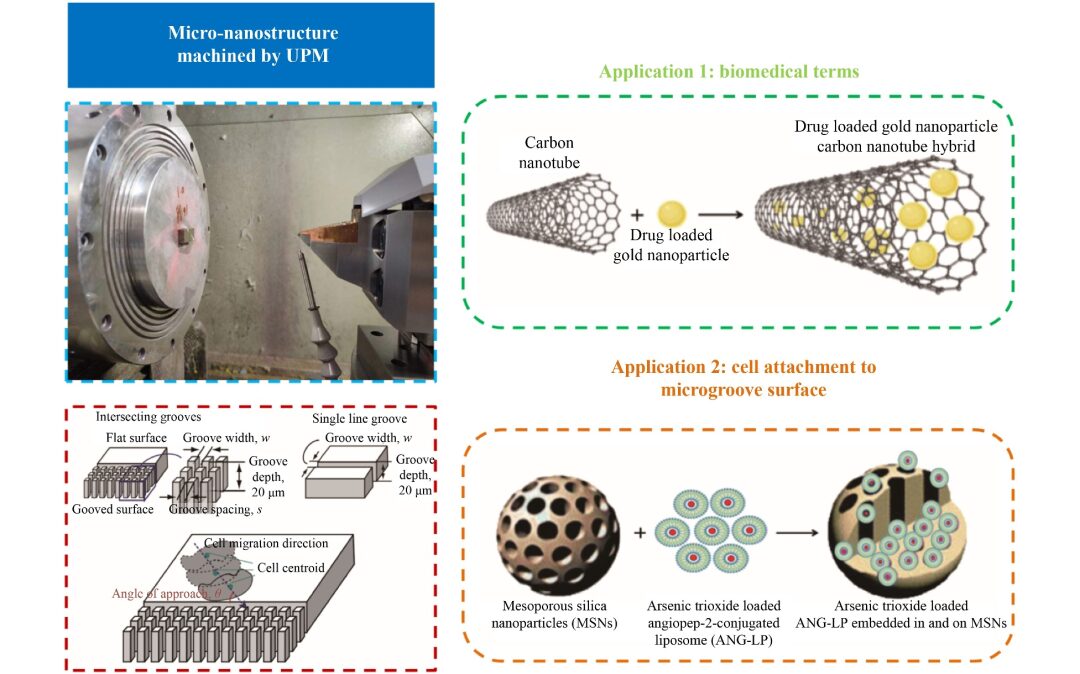

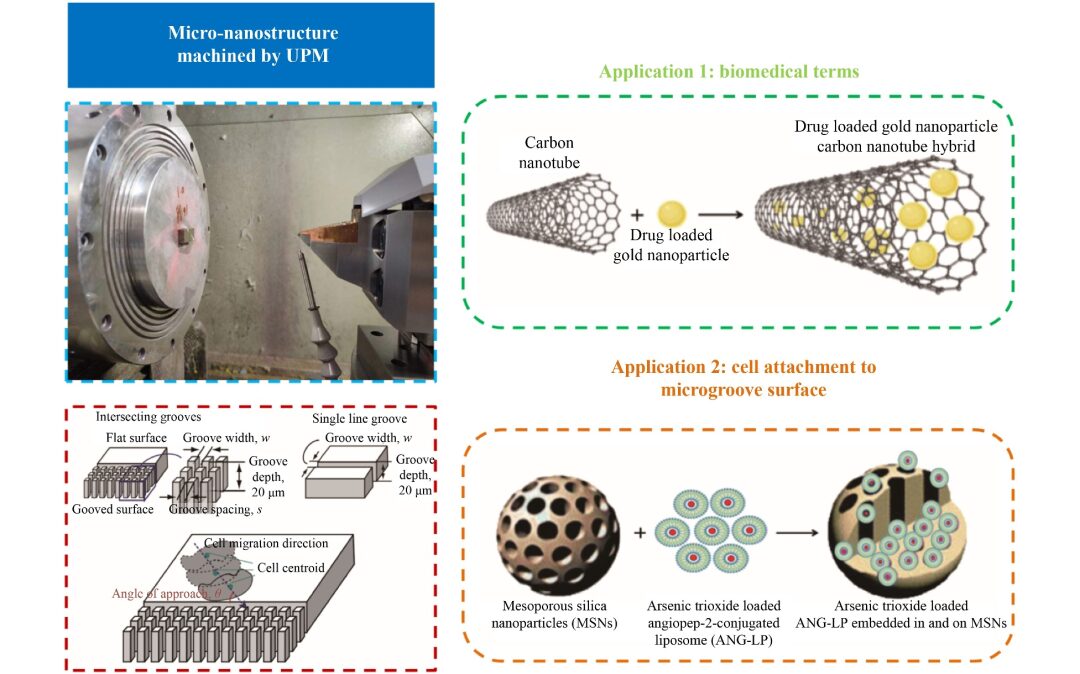

Figure 7 Potential micro-nano structures in biomedical applications.

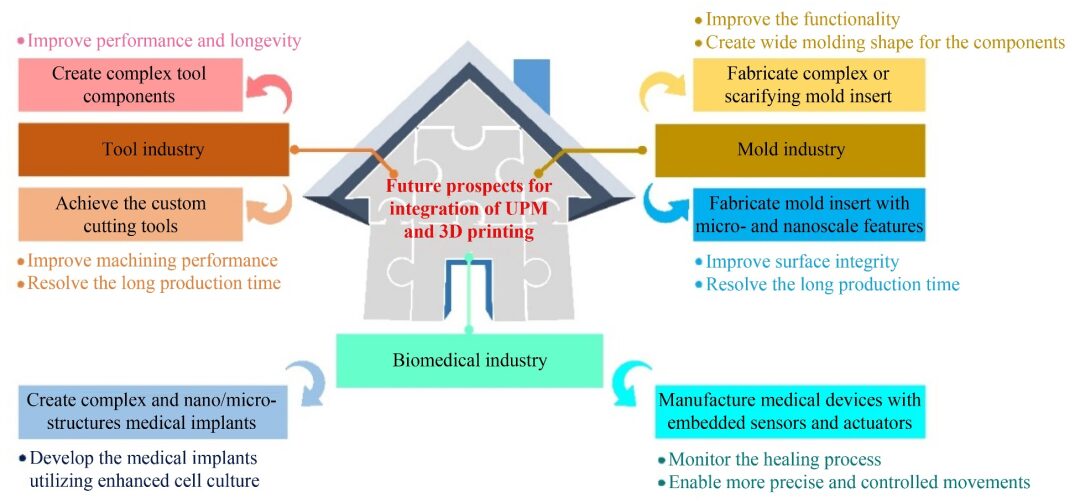

Figure 8 Future prospects of mixed manufacturing of 3D printing and UPM.

Additive Manufacturing (AM), especially 3D printing, has facilitated the low-cost and efficient production of complex and precise components, bringing revolutionary changes to the manufacturing industry. To achieve the desired surface quality, accuracy, and mechanical properties, 3D printed parts often need to be combined with another machining technique. UPM is a forward-looking technology capable of achieving nanoscale surface generation, which has the potential to eliminate the disadvantages of 3D printed parts. This study explores the current status, opportunities, and future perspectives of 3D printing and UPM from a fresh perspective. The highlights of this study are as follows:

1. Introduces the advantages of combining UPM with 3D printing, as well as the opportunities for using UPM for 3D printing or mutual support.

2. Provides detailed demonstrations of manufacturing cutting tools for UPM through 3D printing, UPM for practical applications of 3D printed parts, and the post-processing of 3D printed parts through examples and discussions of advantages.

3. Discusses potential industries that will benefit from integrating these two advanced manufacturing technologies from a future perspective, including tools, molds, and industries.

Paper link:

He, T., Yip, W.S., Yan, E.H.et al. 3D printing for ultra-precision machining: current status, opportunities, and future perspectives. Front. Mech. Eng. 19, 23 (2024). https://doi.org/10.1007/s11465-024-0792-4

Get the original text can click the bottom to read the original text, log in to the Jiangsu Alliance website to register and download, or contact us through WeChat.

Get the original text can click the bottom to read the original text, log in to the Jiangsu Alliance website to register and download, or contact us through WeChat.

Contact: 18914010962, 18913557664, 19901479960 (same as WeChat)

Website: www.laserjs.cn

Email: [email protected] [email protected] [email protected]

WeChat ID:Yangtze River Delta G60 Laser Alliance

English ID: laserjs

Get the original text can click the bottom to read the original text, log in to the Jiangsu Alliance website to register and download, or contact us through WeChat.

Get the original text can click the bottom to read the original text, log in to the Jiangsu Alliance website to register and download, or contact us through WeChat.