From April 13 to October 13, the 2025 World Expo will be held in Osaka, Japan. This year’s Expo will showcase installations and exhibits from around the world, with the theme “Imagining a Revitalized Future Society.” Notably, visitors to the site will not only see excellent designs and architecture in various pavilions, but the rest areas are also special experiences, as each rest area is designed by a young Japanese architect.

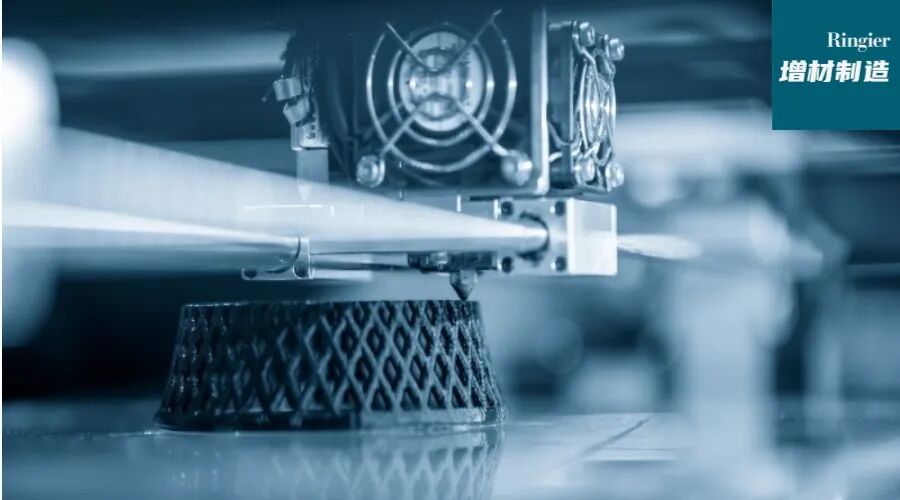

One of the rest areas has particularly attracted public attention and interest because it achieves a deep integration of 3D printing and architecture. This unique rest area was designed by Tokyo-based architectural firm Aki Hamada Architects (AHA) and incorporates a large number of large 3D printed elements, inspired by the organic forms of canyons. These structures include wall panels, flower pots, and washbasins, made from soil-based building materials and constructed using the architectural 3D printer from the Italian company WASP.

This 3D printing material draws inspiration from traditional Japanese earthen wall materials, blending various components such as soil, clay, hardeners (magnesium oxide), straw, pigments, and alginate, all sourced domestically in Japan. The purpose of developing this material is to create robust structures that can naturally decompose after the Expo concludes.

The creators of the rest area explained that while soil is heavy and fragile, and vastly different from modern industrial materials, its advantage lies in its ability to return to the earth. By utilizing it as a new building material, they aim to propose a vision for future architecture and society—where people build their habitats using local soil.

The design of the 3D printed structures in the rest area evokes nature and ecology: the architectural firm actually performed 3D scans of stones from various regions of Japan and then combined the models into composite geometries. These geometries were optimized to ensure that the 3D printed elements were strong enough to stand independently.

Interestingly, the methods of producing various 3D printed elements differ. For example, the outer wall panels of the rest area were produced off-site at a factory in Toyama. A total of 56 3D printed panels were made, each measuring 93 cm wide, 30-40 cm thick, and 120 cm high. These panels were transported to the Expo construction site and assembled onto a wooden frame. AHA noted that they embedded wooden dowels in the wall panels to secure them to the wooden frame without damaging the clay. Once assembled, the 3D printed panels formed a broad, rock-like outer wall.

The rest area also features many 3D printed flower pots, including bench flower pots and table flower pots. A WASP 3D printer with a manufacturing volume of 6.2m×1.7m was used to create four sets of bench flower pots, each with unique shapes, such as C-shaped pots or cluster pots, creating a vibrant environment for visitors. Smaller soil blocks 3D printed at the Toyama factory were also transported to the site to create stacked flower pots, reinforced with bamboo poles.

Ultimately, the AHA team designed an innovative washbasin installation for the rest area using 3D printing technology. These cylindrical structures were also inspired by natural rock textures, produced off-site, and integrated with several user-friendly design features—such as recessed knee spaces and rear access openings. These components were designed for modular installation, allowing them to slide directly into place around existing signage and counters.

The project began with a question: What forms would emerge if we were to re-explore a new rational form for architecture today? The AHA team wrote that with the advent of robotic technologies such as 3D printers—where forms are generated through additive processes, complexity is no longer a matter of cost but merely a matter of time—we envisioned a new type of habitat for contemporary people, shaped entirely by materials sourced from the surrounding environment. We believe this may represent a new form of vernacular architecture.

More Exciting Content

-

Reshaping Future Manufacturing: 3D Printing Leads a New Era in Automotive

-

Metal 3D Printing for Mass Production: Making Green Parts Processing More Economical and Reliable

-

The Advantages and Disadvantages of Additive Manufacturing

-

Integrating AI into 3D Printing for Smarter Production

Reprint/Submission/Cooperation

Metal 3D Printing

-

Alec Zhu

Email: [email protected]

Non-Metal 3D Printing

-

Erica Zhan

Email: [email protected]