The Q.Big 3D’s Queen 1 system completed the full cockpit assembly of a full flight simulator in just over a month, achieving rapid construction, high surface quality, and dimensional accuracy.

The 3D printed cockpit components are made from Q.mid GF25 glass fiber. The cockpit components are 3D printed using Q.mid GF25 glass fiber.

Reiser Simulation and Training GmbH (Berg, Germany) recently commissioned Murtfeldt Additive Solutions GmbH (Kusterdingen, Germany) to produce a modular cockpit for a full flight helicopter simulator. The cockpit was successfully manufactured using Murtfeldt’s Queen 1 additive manufacturing (AM) system from Q.Big 3D (Aalen, Germany), which utilizes a variable fused granulate fabrication (VFGF) process to produce large parts through 3D extrusion printing.

The project aims to overcome the limitations of traditional manufacturing strategies; conventional mold-based processes, especially for large volume components, often incur high processing costs and long delivery times. According to the relevant companies, such projects typically take 3-6 months to complete. Additionally, traditional fused deposition modeling (FDM) printers often cannot produce large-volume 3D components, have uneconomical build rates, and use filament materials that are typically seven times more expensive per kilogram compared to granulate 3D printers.

By using a 3D extrusion printer for production, tooling costs are eliminated, allowing for new building strategies (such as new component geometries) to be realized within a short amortization period, and compared to FDM printers, standard granulate materials without filaments can be used in 3D printing.

The resulting modular cockpit components were 3D printed with dimensions of 2.260×1.780×1.705 mm. The cockpit frame is made from aromatic polyamide with a glass fiber content of 25% (Q.mid GF25), offering high dimensional stability, temperature stability up to 200°C, high rigidity, and optimized paintability, with the cockpit weighing only 200 kg. All components were manufactured in just over a month; however, Murtfeldt AS expects that by optimizing the process chain, subsequent project construction times will be shorter; a network of printers consisting of several Queen 1 machines can also reduce delivery times for time-critical requests, as the longest single build job takes nearly 100 hours.

Michael Ortmann from Reiser Simulation and Training, responsible for the design and development, stated that 3D extrusion printing offers many previously seemingly impossible potential benefits. He listed several aspects: “Short time to market, fast build speed, lightweight structures, biomimicry, functional integration, and cost-effective manufacturing without molds, as well as the advantages of using granulates.”

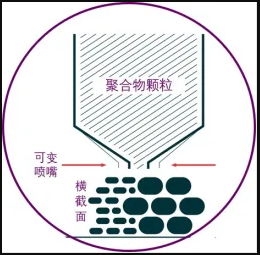

The VFGF extrusion print head with a variable nozzle diameter enables highly specific component structures.

In addition, it is possible to control the deformation of large complex parts, maintain small tolerance gaps, and achieve high surface quality. The reassembly of detachable modules at the user’s location has also been optimized, and conversion kits can economically and efficiently simulate two helicopter models (Airbus Helicopters H135 and H145).

According to partners, the Queen 1 3D extrusion printer provides several features that make all of this possible:

• High surface quality, even with strong overhangs in the geometry.

• High assembly precision (dimensional accuracy, small gaps) of components due to active temperature control in the external chamber and the printer’s build space.

• Constant system temperature regardless of temperature fluctuations in the production hall.

• Variable nozzle control system enables fast build rates, adapting to the specific characteristics of each geometry. The mode changes automatically as needed. In summary, partners pointed out that the investment risk with the Queen 1 system is very low, eliminating post-processing costs and offering advantages over competitors’ AM strategies like SLS or FDM printing.

Johannes Matheis, Managing Director of Murtfeldt AS, stated: “With Q.Big 3D’s VFGF system technology, we can specifically delve into further application areas of the VFGF manufacturing strategy. If you master the entire process chain, it is possible to achieve complex large 3D parts with high repeatability and part quality.”

Note: The original article can be found in ‘Large-volume VFGF extrusion printer facilitates modular composite cockpit.’

Source: Composite Materials Experience Center, Yang Chaofan

Disclaimer: Articles published on the WeChat account of the China Composite Materials Society are intended solely for the exchange and sharing of professional knowledge and market information in composite materials, and not for any commercial purposes. If any individual or organization has doubts about the copyright or the authenticity and accuracy of the content of the article, please contact us immediately. We will address it promptly.