In the wave of modern industrial automation, Industrial Control Systems (ICS) play a crucial role. They not only enhance production efficiency but also improve the safety and reliability of processes. Among the many ICS, SCADA, DCS, and PLC are three frequently mentioned but often confused terms. This article will delve into the differences between these three and explore their applications in industrial automation.

SCADA: Wide Area Applications of Data Acquisition and Monitoring Systems

The SCADA system, or Supervisory Control and Data Acquisition system, is at the core of industrial control. It integrates data acquisition, data transmission, and Human-Machine Interface (HMI) software, providing operators with a centralized platform for monitoring and controlling. The design intent of SCADA systems is to collect field information, transmit this information to computer systems, and display it in graphical or textual form. This allows operators to monitor and control the entire system in real-time from a centralized location, automatically executing related operations or tasks.

The main application areas of SCADA systems include water treatment, oil and gas pipelines, power transmission and distribution systems, railways, and other distributed systems. These systems often need to span vast geographical areas, and SCADA systems provide an effective solution for remote monitoring and control.

DCS: Process Control of Distributed Control Systems

DCS, or Distributed Control System, is primarily used for controlling production processes in the same geographical environment. DCS systems coordinate local controllers to execute the entire production process through centralized monitoring, reducing the impact of a single failure on the entire system. This type of system is very common in industrial control fields such as refineries, wastewater treatment plants, power plants, chemical plants, and pharmaceutical factories.

Typically, interfaces are set up between DCS systems and enterprise systems to reflect the production process within the overall business operations. This integration makes DCS systems particularly important in modern factories, as it not only improves production efficiency but also enhances flexibility and scalability in production.

PLC: Field Control with Programmable Logic Controllers

PLC, or Programmable Logic Controller, is a new type of industrial control device that incorporates microelectronics, computer technology, automatic control technology, and communication technology based on traditional sequential controllers. The purpose of PLCs is to replace relays, execute logic, timing, counting, and other sequential control functions, establishing a flexible program-controlled system.

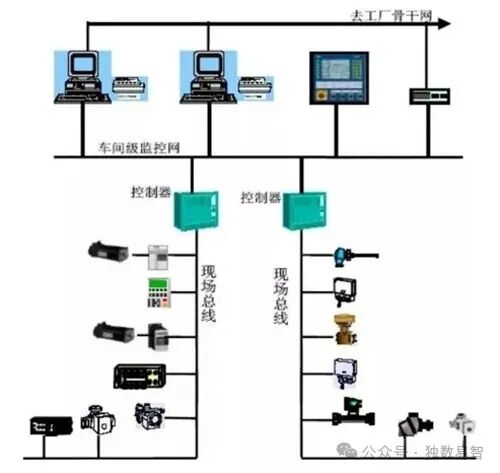

In the network architecture of industrial automation and control systems, PLCs serve as important control components, typically applied in SCADA and DCS systems to implement specific operations and process control of industrial equipment. PLCs have user-programmable memory to store instructions for specific functions, such as I/O control, logic, timing, counting, PID control, communication, arithmetic, data, and file processing.

Differences and Connections Among the Three

SCADA, DCS, and PLC each have their characteristics and application scenarios in industrial control systems. SCADA and DCS are more often viewed as system concepts, while PLC is a specific product. DCS is primarily used for process automation, PLC is mainly used for factory automation (production lines), and SCADA addresses wide-area needs.

From the perspective of computers and networks, they are unified, with differences mainly in application requirements. SCADA can be seen as the scheduling management layer, DCS as the plant management layer, and PLC as the field device layer. These systems collaborate in the process of achieving industrial automation, ensuring high efficiency and safety in industrial production.

SCADA is the scheduling management layer,DCS is the plant management layer,PLC is the field device layer.

DCS is a “Distributed Control System,” while PLC (Programmable Logic Controller) is merely a type of control “device”; the distinction lies between “system” and “device.” A system can realize the functions and coordination of any device, while a PLC device only implements the functions inherent to its unit.

As technology advances, the boundaries between SCADA, DCS, and PLC are becoming increasingly blurred, and their integration and collaborative operation are becoming more important. Understanding the differences and connections among these systems is crucial for designing and implementing effective industrial automation solutions. With the advancement of Industry 4.0, these systems will continue to evolve to meet the growing demands of industrial automation.