As a product development engineer, the selection of tape in the design and manufacturing process of touch display modules directly affects the product’s reliability, performance, and production costs.This article systematically organizes the core rules for tape selection in touch display modules, providing comprehensive technical guidance from material properties to application scenarios, from functional requirements to process compatibility. The content covers substrate selection criteria, optical performance requirements, environmental adaptability considerations, process compatibility assessments, and cost optimization strategies. Specific selection recommendations are provided for different module parts (such as bonding the module to the casing, fixing the LCD, connecting FPC, EMI shielding, etc.), helping engineers avoid common selection pitfalls and improve product yield and market competitiveness. The advantages and disadvantages of tape must also be given equal attention, as aging failure issues cannot be overlooked. Therefore, in environments with vibration and sustained stress, product design must consider mechanical fixation solutions.

The advantages and disadvantages of tape must also be given equal attention, as aging failure issues cannot be overlooked. Therefore, in environments with vibration and sustained stress, product design must consider mechanical fixation solutions.

Substrate Type and Property Analysis

The substrate, as the supporting framework of the tape, determines the mechanical properties and basic functions of the tape. Common substrate types in touch display modules include:

- Polyester Film(PET): This is the most widely used substrate material, with excellent mechanical strength, dimensional stability, and temperature resistance(-40℃~150℃).PET substrate thickness typically ranges from9μm to250μm, with ultra-thin types suitable for compact designs with space constraints.PET substrates have high light transmittance(>90%), making them suitable for applications requiring optical transparency.

- Polyurethane Foam:The typical substrate used in the 3M VHB series, it has excellent cushioning and impact resistance, and can replace traditional mechanical fixation methods(such as screws and rivets). Its porous structure effectively absorbs stress, preventing micro-cracks in modules under vibration, making it particularly suitable for automotive display applications.

- Conductive Fabric/Metal Foil: Tape substrates used for electromagnetic shielding applications, such as 3M or TESA, have conductive metal foil double-sided tape that combines conductivity and thermal conductivity, addressing bothEMC and heat dissipation issues. Copper foil substrates can have surface resistances as low as0.01Ω/sq, making them ideal for high-frequency signal processing.

- Polyimide(PI): Outstanding high-temperature resistance, with a long-term working temperature of up to260℃ and short-term resistance to350℃ high temperatures, suitable for modules requiring reflow soldering processes. However, its cost is relatively high, typically used only in special high-temperature environments.

5. PVC Film: Lower cost, good flexibility, but relatively poor temperature resistance and dimensional stability, mostly used for temporary fixation or low-end products. Some high-temperature resistantPVC tapes can withstand125℃.Comparison of Common Tape Substrate Properties for Touch Display Modules

| Substrate Type | Typical Thickness(um) | Temperature Resistance Range(℃) | Main Characteristics | Typical Applications |

| PET | 9~250 | -40~150 | High transparency, dimensional stability | Optical bonding,FPC fixation |

| Polyurethane Foam | 200~1000 | -40~120 | High elasticity, good cushioning | Structural fixation, shock absorption |

| Conductive Fabric/Metal Foil | 25~100 | -40~150 | Conductive/ good thermal conductivity | EMI shielding, grounding |

| PI | 12~125 | -260~350 | High temperature resistance, chemical stability | High-temperature process areas |

| PVC | 50~200 | -20~105 | Low cost, soft | Temporary fixation, labeling |

Light Blocking and Reflective Properties

In certain specific areas, the tape needs to have precisely controlled light blocking or reflective functions to meet the optical design requirements of the display module:

- Black and White Double-Sided Tape Applications: The white side has a reflectance of up to89.5%, used to enhance the reflective film effect on the light guide plate; the black side has a transmittance of0.0%, perfectly achieving light blocking functionality. This tape is widely used inLCD backlight modules, fixing the LCD, reflective film, and diffusion film while optimizing optical performance.

- Local Light Blocking Design: The edges of the display module often need to prevent light leakage, using black matrix tape(such as Teraoka 6372#25, with a transmittance of<0.1%) to precisely control the light propagation path. This type of tape usually requires halogen-free characteristics and UL-certified temperature resistance(such as 130℃).

- Colored Identification Tape: Different colored tapes (blue, green, gray, etc.) can be used for local wrapping in areas such as the four-door harness, providing intuitive visual differentiation at the assembly site. Although this does not directly affect optical performance, it improves production efficiency and maintenance convenience.

Environmental Adaptability and Reliability Standards

Touch display modules face diverse environmental challenges in practical applications, from extreme temperature fluctuations to continuous mechanical vibrations, from chemical corrosion to long-term aging. As a key connecting material in the module, the tape must possess excellent environmental adaptability to ensure product reliability throughout its lifecycle. Engineers must comprehensively assess the tape’s performance under various stress conditions and establish a scientific environmental adaptability assessment system.

Temperature Resistance Performance

Temperature performance is a core consideration in tape selection, with different application scenarios having significantly different requirements for temperature resistance:

- Wide Temperature Stability: Automotive display modules have the most stringent temperature requirements, needing to withstand a working temperature range of-40℃ to85℃ and even105℃. OrdinaryPVC tapes tend to soften and fail at high temperatures, while high-temperature resistantPVC tapes (125℃) or polyester fabric-based tapes are more reliable choices.3M VHB series foam tapes can maintain stable performance for over25 years in harsh environments, suitable for aerospace applications.24.

- Thermal Cycling Resistance: Rapid temperature changes can cause mismatches in thermal expansion coefficients between materials, leading to stress. The tape needs to have sufficient flexibility to absorb this stress, preventing delamination or cracking. Although silicone adhesives have lower bonding strength(about0.1MPa), their low elastic modulus allows them to better adapt to thermal cycling stress.8.

- High-Temperature Aging Performance: Areas near engines or LED backlight sources need to withstand high temperatures for extended periods, requiring both the substrate and adhesive of the tape to have excellent thermal stability. Polyimide-based tapes can withstand long-term temperatures of up to260℃, and short-term temperatures of350℃, making them ideal for high-temperature areas.

- Low-Temperature Brittleness Resistance: In cold regions, tapes must not lose adhesion or flexibility due to brittleness at low temperatures. Acrylic adhesives typically perform better than rubber-based adhesives at low temperatures, with some specialty acrylic tapes maintaining stable performance at-60℃..

Long-Term Reliability Assessment Methods

To ensure the long-term reliability of tapes in practical applications, a scientific assessment system must be established:

- Accelerated Aging Tests: Including high-temperature storage(such as 85℃/1000h), temperature cycling(such as -40℃~85℃, 500 times), and damp heat aging(85℃/85%RH, 1000h), simulating long-term usage environments.

- Mechanical Stress Testing: Vibration testing(such as random vibration20-2000Hz,3 axes for 24h), mechanical shock(such as 50G, 11ms,3 axes for 3 times), drop testing, etc., to verify mechanical reliability.

- Chemical Resistance Testing: Immersing the tape in typical chemical agents(such as isopropanol, artificial sweat, etc.) to assess performance changes.

- Optical Stability Testing: IncludingUV exposure(such as 500kWh/m²), and changes in optical performance after thermal shock, etc.

Chemical and Weather Resistance

Touch display modules may come into contact with various chemicals and environmental factors, and the tape must possess corresponding resistance capabilities:

- Solvent Resistance: During module cleaning and maintenance, solvents such as isopropanol and ethanol may come into contact, and the tape should not swell or dissolve. Cross-linked acrylic adhesives and silicone adhesives typically have good solvent resistance.

- Grease Resistance: Automotive dashboards or industrial equipment display modules may come into contact with lubricants and greases, and the tape must remain stable. Tapes with polyurethane foam substrates typically have good oil resistance3..

- UV Aging Resistance: Display modules used outdoors are exposed to sunlight for extended periods, and the tape needs to addUV stabilizers to prevent degradation.PET substrates have goodUV stability, whilePVC substrates require additional stabilization treatment.

- Moisture and Corrosion Resistance: High humidity environments may lead to hydrolysis of the tape or corrosion of metal components. Tapes with a water-blocking layer, such as certain flexible tape designs, can effectively block moisture penetration7.. In high-corrosion environments such as coastal or industrial areas, the tape should also have salt spray resistance.

Mechanical Stress Adaptability

Touch display modules will endure various mechanical stresses during use, and the tape needs to possess corresponding mechanical properties:

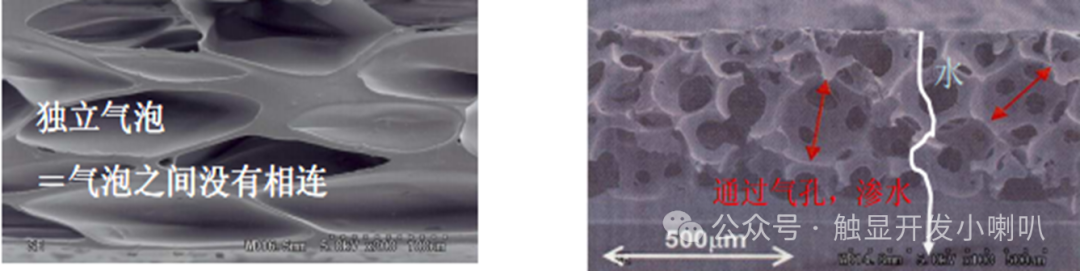

- Vibration and Impact Resistance: Automotive display modules face continuous vibration environments, and the tape must have good energy absorption capabilities. Foam-based tapes have excellent shock absorption performance due to their hollow structure3. In conductive strip designs, foamTYPE requires a higherH value(about 0.1mm) to ensure reliable contact in vibration environments..

- Shear and Peel Resistance: Large display modules may generate shear stress due to thermal expansion or mechanical deformation, and the tape needs to have sufficient shear strength.VHB series tapes can achieve shear strengths of1MPa or more, capable of replacing mechanical fasteners..

- Creep Resistance: Under long-term static loads, the tape should not exhibit significant creep deformation. Adhesives with high cross-link density(such as some acrylic adhesives) have better creep resistance.

- Flexibility and Bending Life: Tapes for foldable display modules must withstand repeated bending without cracking. Ultra-thin polyester films(such as 9μm) substrates paired with flexible adhesives are common solutions.。

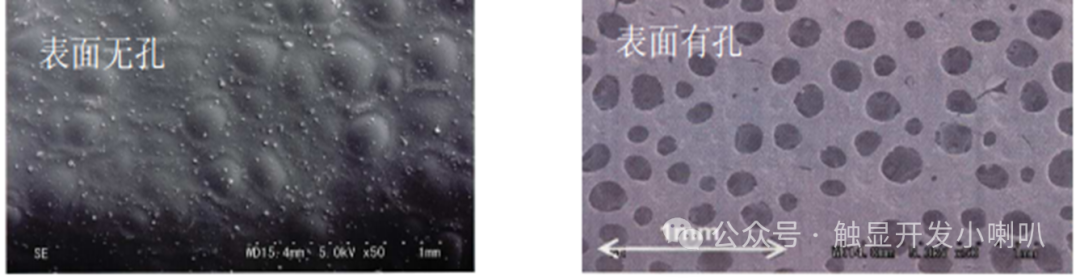

* If the tape has waterproof and dustproof requirements, be sure to choose closed-cell foam tape. As seen in the comparison images, closed-cell foam will not absorb moisture and dust particles.