Click on the "Xiaobai Learns Vision" above, select to add "Star" or "Top"

Heavy content delivered first

Large product area and high production capacity make it impossible for manual inspection of every panel, resulting in missed detections.

Before cutting, LCD panels are usually very large. For example, a 10.5 generation line panel can have an area of 3370mm*2940mm, making manual inspection extremely difficult and prone to fatigue, thus manual inspection cannot guarantee production capacity and accuracy.

Panel defects can easily lead to product breakage.

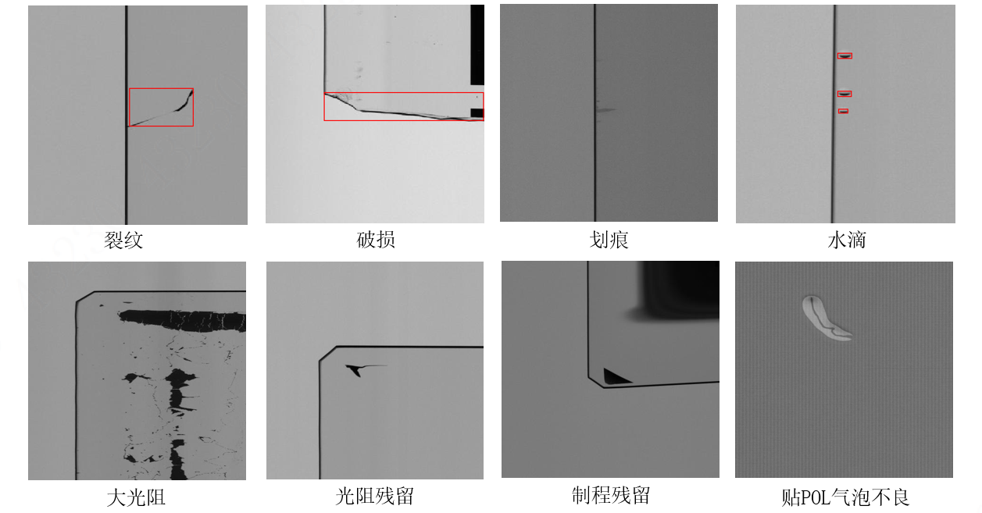

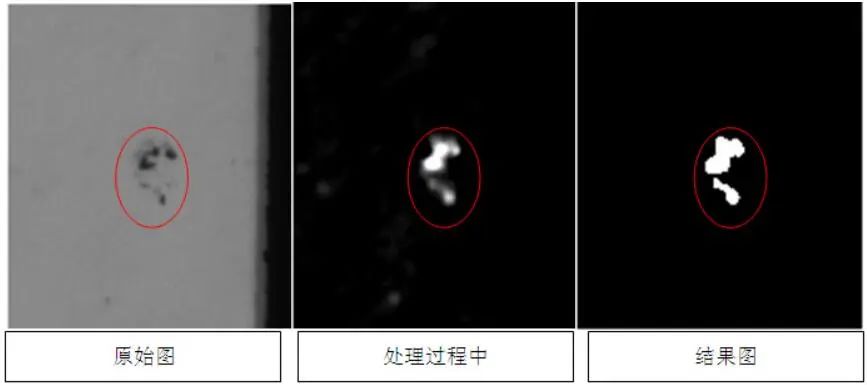

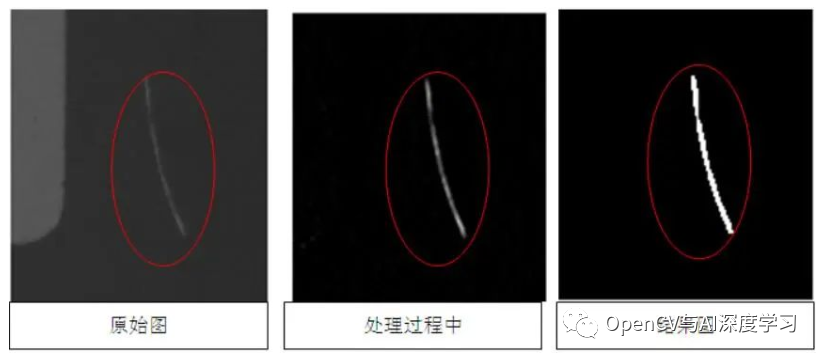

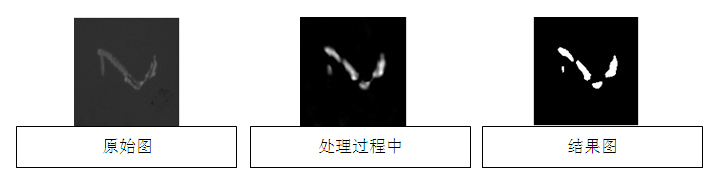

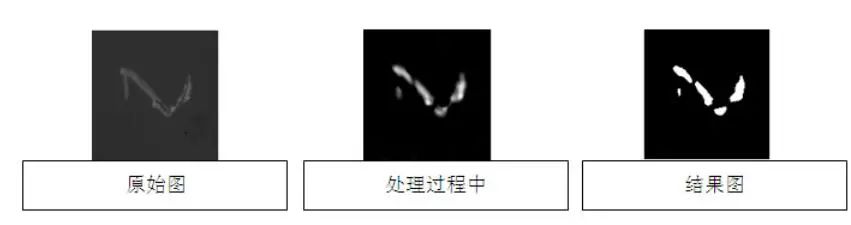

During the production of LCD panels, defects such as chipping, breakage, cracks, and scratches may occur probabilistically. If not detected and addressed in time, these issues may lead to glass breakage within the main production equipment during subsequent processes, necessitating a halt for maintenance and cleaning, resulting in economic losses due to downtime.

The location and type of defects cannot be statistically analyzed or summarized, making digitization impossible.

Manual inspection lacks image documentation, resulting in poor consistency in inspection standards and making product traceability impossible.

High difficulty in recruitment and high labor costs.

As wage levels continue to rise, labor costs also increase year by year, and recruitment difficulties and high personnel turnover are significant issues. Additionally, manual inspection poses considerable strain on the eyes, leading to high turnover rates and recruitment challenges.

Increase Efficiency

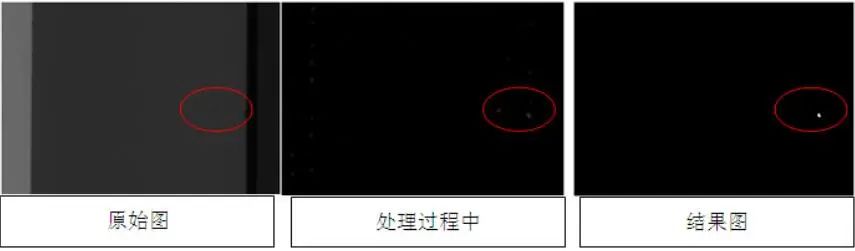

Deep learning algorithms can more accurately identify production hazards such as chipping, eliminating downtime caused by glass fragments, and preventing false alarms due to misidentification, thereby improving production efficiency.

Reduce Costs

Avoid equipment damage caused by glass breakage, reduce costs associated with downtime, and lower maintenance costs.

Improve Quality

Reduce product quality issues caused by surface scratches and stains affecting circuit production and liquid crystal imaging.

Enhance Processes

By digitizing quality inspection, we enhance data traceability and analysis capabilities, providing strong support for improving production processes.

LCD Screen Appearance Defect Detection Scheme

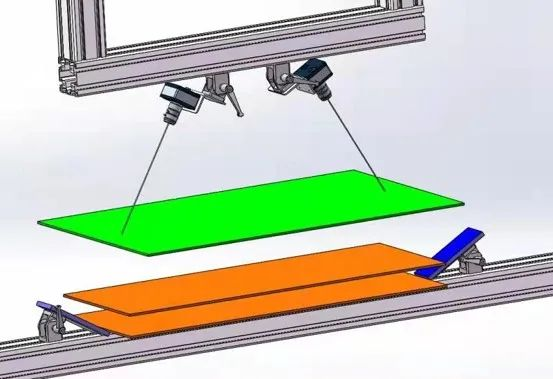

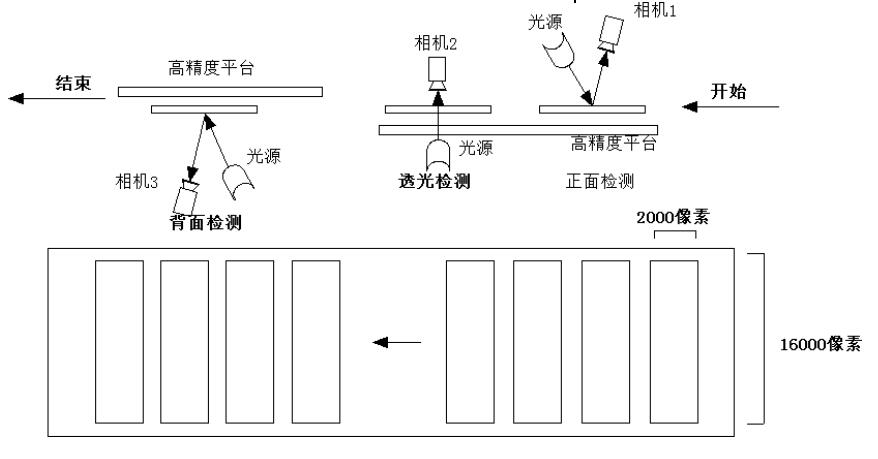

1. Open the product to 180°, placing the LCD screen horizontally on the stage; 2. Start detection: the stage moves, and the camera begins to capture images; 3. After image acquisition is complete, the stage resets; 4. Detection software analyzes the quality of the LCD screen; 5. Based on the analysis results, an OK or NG judgment is given; 6. Operator: performs sorting and re-inspection based on the results;

Download 1: OpenCV-Contrib Extension Module Chinese Version Tutorial

Reply "Extension Module Chinese Tutorial" in the background of "Xiaobai Learns Vision" public account to download the first OpenCV extension module tutorial in Chinese available online, covering installation of extension modules, SFM algorithms, stereo vision, target tracking, biological vision, super-resolution processing, and more than twenty chapters of content.

Download 2: 52 Lectures on Python Vision Practical Projects

Reply "Python Vision Practical Projects" in the background of "Xiaobai Learns Vision" public account to download 31 practical projects including image segmentation, mask detection, lane detection, vehicle counting, eyeliner addition, license plate recognition, character recognition, emotion detection, text content extraction, face recognition, etc., to assist in quickly learning computer vision.

Download 3: 20 Lectures on OpenCV Practical Projects

Reply "OpenCV Practical Projects 20 Lectures" in the background of "Xiaobai Learns Vision" public account to download 20 practical projects based on OpenCV to advance learning in OpenCV.

Discussion Group

Welcome to join the reader group of the public account to exchange ideas with peers. Currently, there are WeChat groups for SLAM, 3D vision, sensors, autonomous driving, computational photography, detection, segmentation, recognition, medical imaging, GAN, algorithm competitions, etc. (these will gradually be subdivided). Please scan the WeChat ID below to join the group, and note: "Nickname + School/Company + Research Direction", for example: "Zhang San + Shanghai Jiao Tong University + Vision SLAM". Please follow the format for notes, otherwise, you will not be approved. After successfully adding, you will be invited to related WeChat groups based on research direction. Please do not send advertisements in the group, otherwise, you will be removed. Thank you for your understanding~