Soldering SMD components on a PCB is a true test of skill, with numerous chip pins and capacitors and resistors smaller than sand grains, issues like cold solder joints and short circuits frequently arise and are extremely difficult to detect. This requires high levels of technique and patience. More importantly, there are some small tips and details to pay attention to, and some points I had previously overlooked.

Soldering is second nature for many hardware veterans; I am just an average beginner, so please guide me, and I hope I don’t embarrass myself.

About the Soldering Iron

A temperature-adjustable soldering station seems essential; otherwise, how do you know how hot your soldering iron is? Haha~~~ With a soldering station, a chisel tip soldering iron has become standard (I find it quite frustrating to use a pointed soldering iron for SMD soldering), along with solder, a sponge, and flux, the soldering family is complete.

Here are a few points to note about using the soldering iron:

-

The soldering iron tip is easily damaged; always keep it tinned.

-

Avoid striking the soldering iron tip against hard objects to prevent deformation.

-

Set the temperature to about 350°C when soldering SMD components.

-

Avoid leaving the soldering iron heated for too long, as it can easily burn out (lower the temperature when not in use for a long time).

-

Don’t add too much water to the sponge; wring it out to keep it soft.

-

Avoid touching strange things with the soldering iron, or it will smell weird →_→.

Representation of SMD Resistor and Capacitor Values

Let’s briefly discuss the markings of SMD components; you must know that if you can’t understand the representation of resistor and capacitor values, you won’t even find the components!

Direct Marking Method

Direct marking method: Mark the resistance value directly on the surface of the SMD resistor using numbers and unit symbols, with the allowed error represented directly as a percentage. If no deviation is noted on the SMD resistor, it is ±20%. The direct marking method can use unit symbols to replace decimals, which is straightforward but only applicable to larger components and is not internationally standardized.

In other words, just write the value and unit directly, such as the common 100Ω, 4K7 (4.7K), 220uF, etc.

Three-Digit Code Method

Three-digit code method: This method uses a three-digit code on the SMD resistor to indicate the nominal value. The first two digits represent the significant figures, and the third digit represents the number of zeros. The deviation is usually indicated by a letter symbol.

For example, a resistor marked 103 means 10 followed by three zeros, which is 10000, or 10KΩ. Similarly, a resistor marked 331 means 330Ω. For capacitors, the unit is pF, so a capacitor marked 104 means 100000pF = 100nF = 0.1uF.

Special attention should be paid to the unit conversion for capacitors: pF is the smallest, followed by nF, then uF, and finally F. 1F = 10^6uF = 10^9nF = 10^12pF.

Next, I will explain some precautions for soldering different components based on some components I recently encountered.

Chips

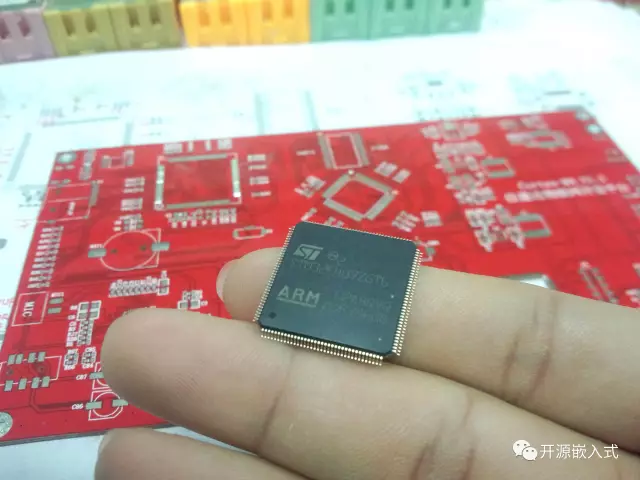

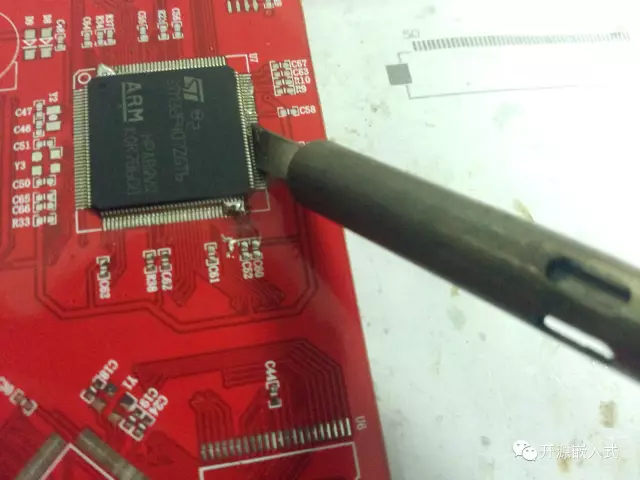

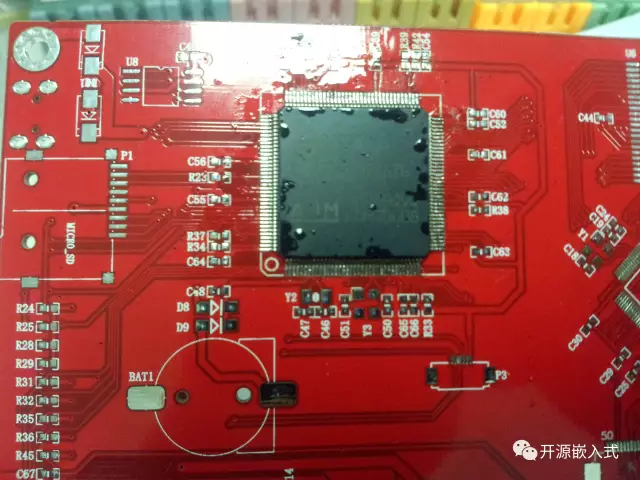

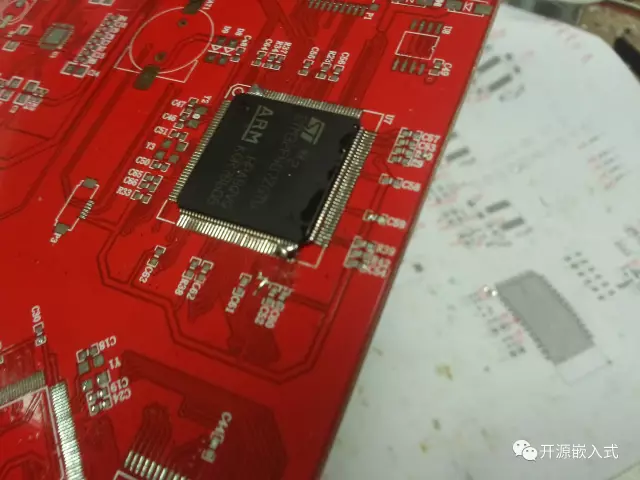

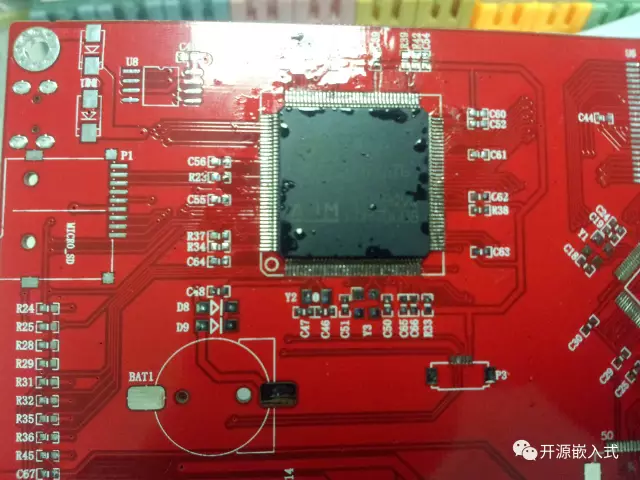

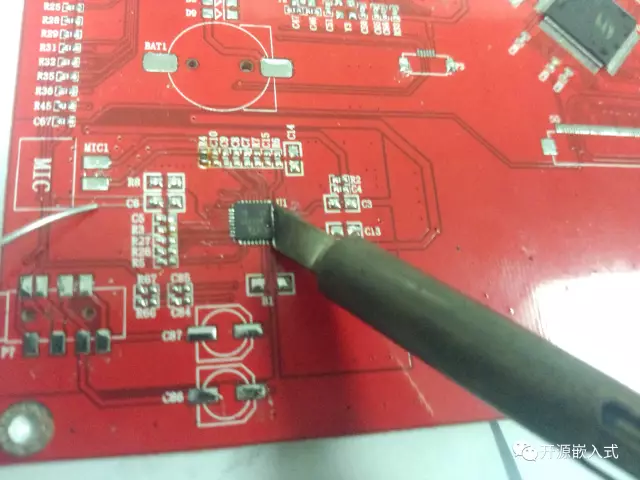

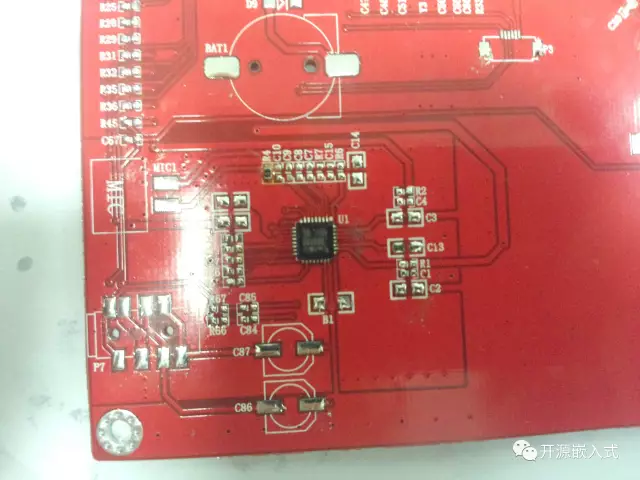

QFP Package

For SOP packaged chips with larger pin spacing, you can basically just scrape a bit of solder with a chisel tip soldering iron, and it’s not a big deal. Here, I will focus on soldering the densely pinned QFP package. First, fix the chip with the following steps:

-

Place the chip flat on the PCB; do not add solder to the pads, or the chip will not sit flat and is prone to cold solder joints.

-

Ensure the direction of pin one of the chip corresponds to the PCB (pin one is usually at the small circle or at the lower left corner of the silkscreen).

-

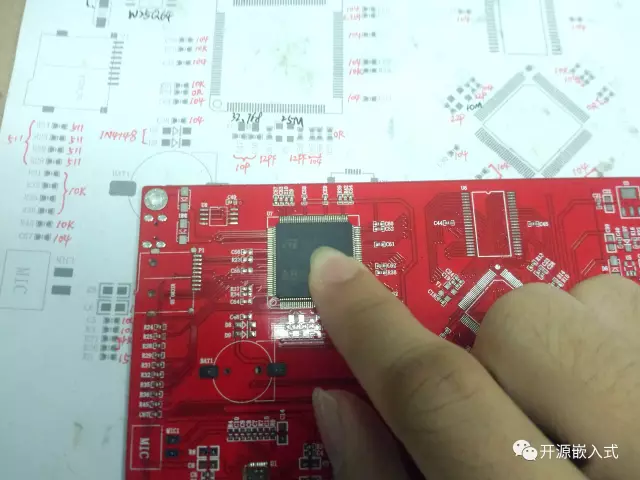

Align the chip’s pins with the pads; ensuring alignment on all four sides is quite challenging.

-

Solder a few pins on one edge of the chip with solder, check the alignment on all four sides; if not aligned, there is still a chance to adjust the chip position with the soldering iron.

-

Solder a few pins on the opposite edge.

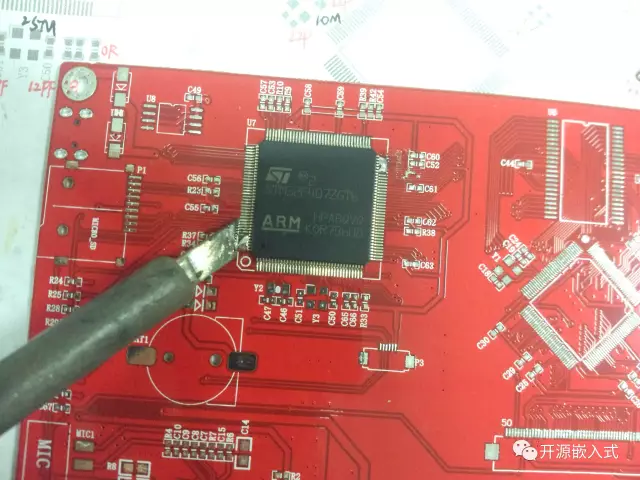

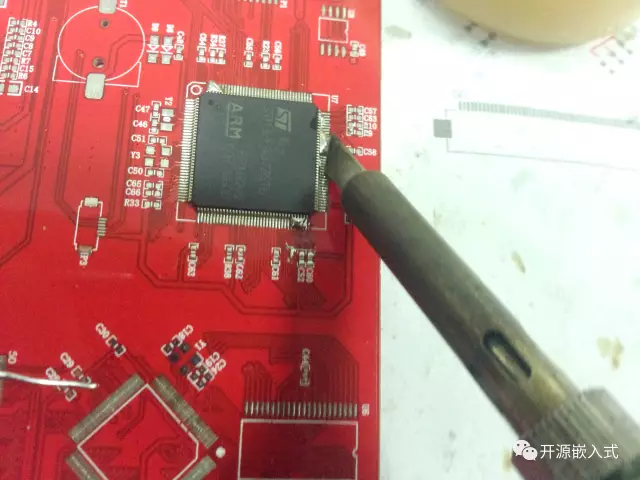

Once the chip is fixed, we can start soldering (many components follow the routine of “fix first, then solder”). While soldering, keep the following in mind:

-

Choose an edge that has not been soldered yet and start soldering.

-

Dip the soldering iron in flux and apply it to one side of the pins and pads.

-

Add solder from one side, trying to form a solder ball.

-

Use the soldering iron to draw solder to the other side; the pins that have been wetted with solder will naturally solder on.

-

Remove excess solder using the stickiness of the soldering iron tip.

-

Repeat the process for the remaining three sides.

-

After soldering all four sides, check for pin shorting or bridging, and re-solder if necessary.

In summary, when soldering chips, remember two points: 1. When soldering, add more solder first; it doesn’t matter if the pins are connected, separate them slowly after soldering. 2. Add more flux, as flux enhances the flow of solder, preventing it from being sticky like a lump of glue.

There is a video on YouTube specifically teaching how to solder QFP chips: Professional SMT Soldering: Hand Soldering Techniques – Surface Mount.

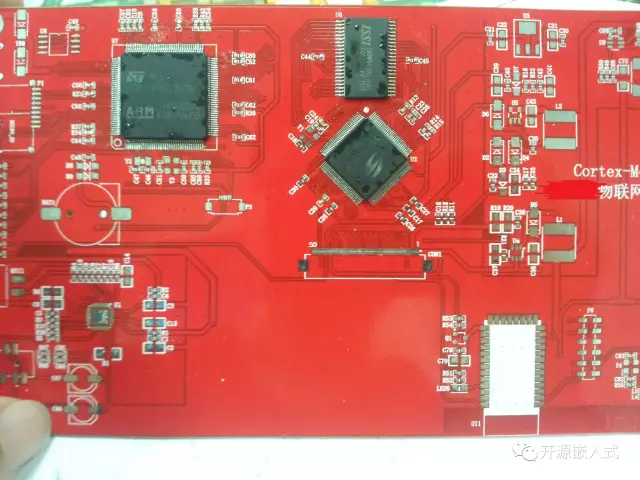

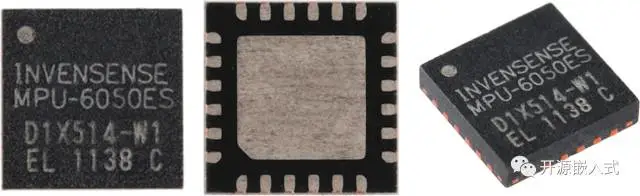

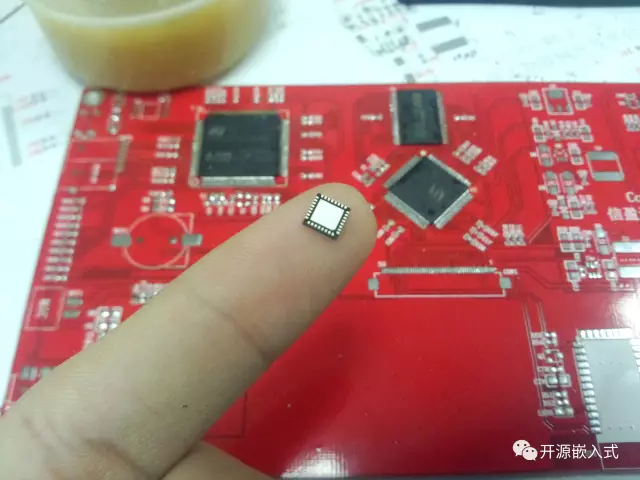

QFN Package

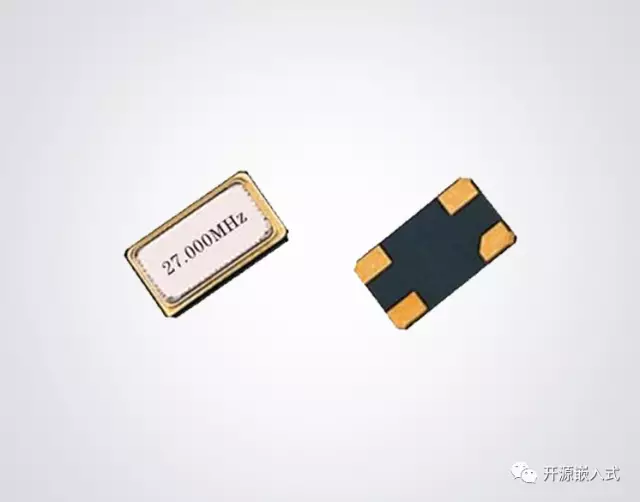

For QFN chips, which have no exposed pins (like the ESP8266), or for four-foot SMD crystal oscillators with contact points on the bottom, soldering with a soldering iron is quite difficult and unreliable. The correct method is to use a hot air gun (I was so excited the first time I used a hot air gun ~ (~ ̄▽ ̄)~). So how do you use it?

-

Apply a thin layer of solder on all pad connections and the central large pad.

-

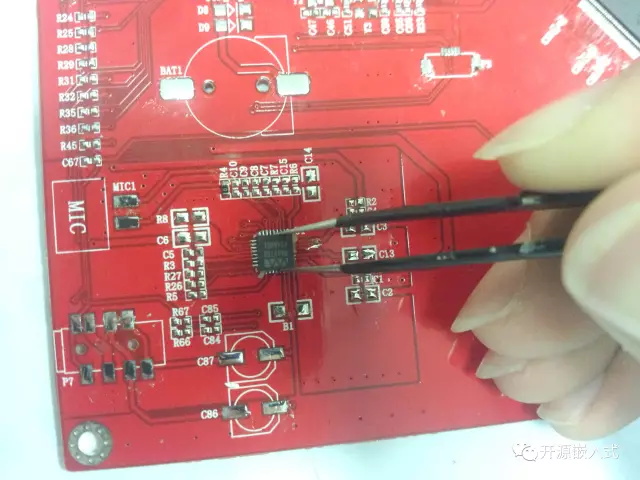

Using tweezers, hold the chip and apply flux to the bottom surface.

-

Place the chip on the pads and roughly align it.

-

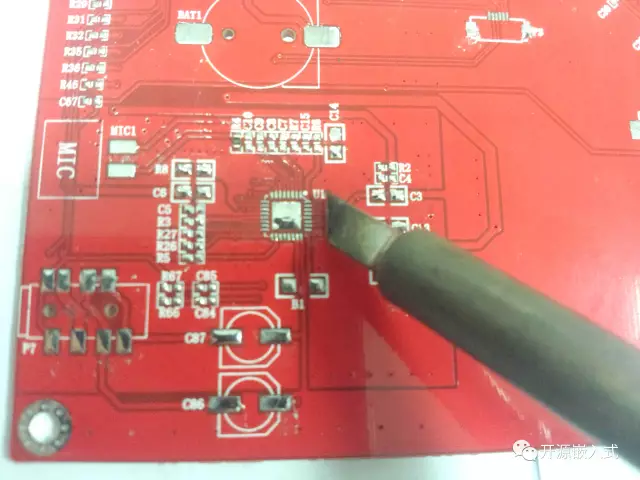

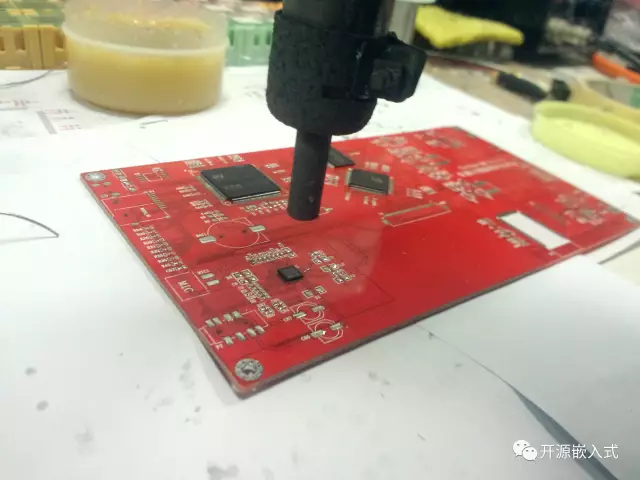

Set the hot air gun temperature to around 350°C with the lowest airspeed.

-

Hold the hot air gun vertically above the PCB at a height of about 8CM, first heat the area around the chip, then aim the gun at the chip.

-

The flux and solder will melt, and the chip will automatically adhere to the correct position due to surface tension.

-

Turn off the hot air gun and check the chip connection; be careful as the PCB will be hot.

-

Resolder around the chip if necessary.

Precautions:

-

The airspeed should not be too high, and the height should be appropriate; otherwise, it may blow the chip or nearby small capacitors and resistors away.

-

If the chip does not automatically adhere, you can use tweezers to assist in adjusting it or press it down slightly.

-

Do not add too much solder to the central pad; otherwise, the chip will push the solder outward, causing pin shorting.

-

The hot air gun is very hot, very hot, very hot, very hot, very hot!

Capacitors, Resistors, and Diodes

Capacitors, resistors, and other two-terminal components are the most common; a commonly used soldering method is: first add solder to one side of the pad, use tweezers to solder one side to fix it, and then solder the other side. The biggest advantage of this method is that it is easy to adjust the component’s position (because of the assistance of tweezers), so the soldered components look neat and tidy. However, the downside is obvious—efficiency is too low (also because you have to use tweezers). Especially when facing a PCB with many components, soldering one pin at a time seems a bit slow…

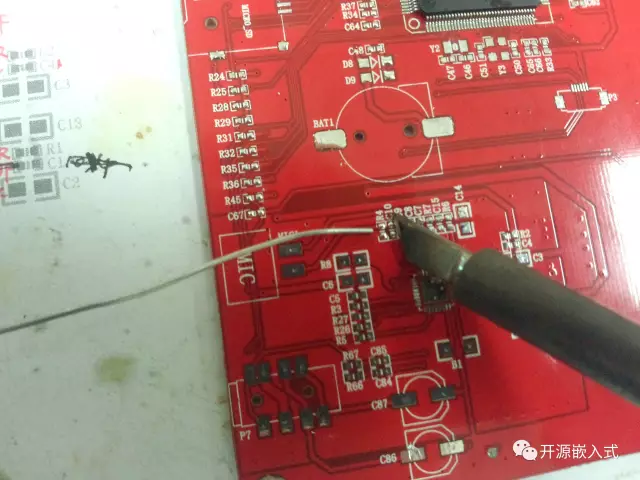

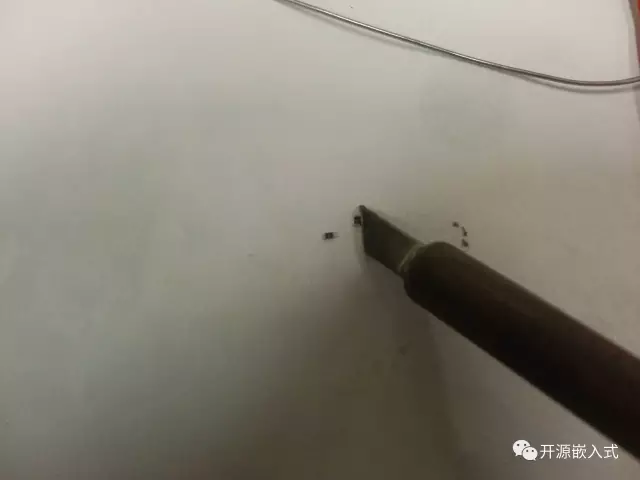

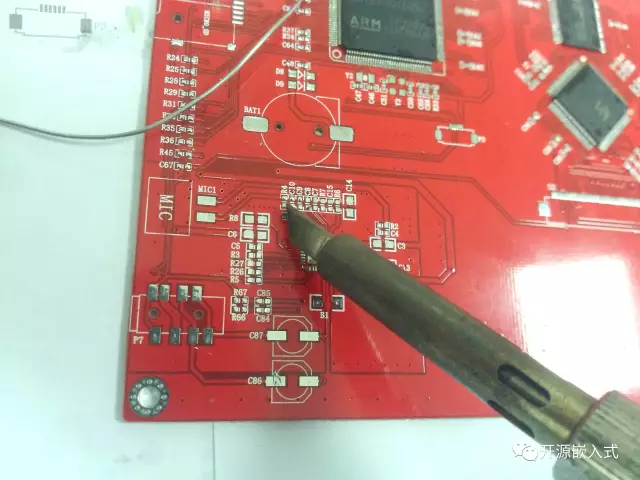

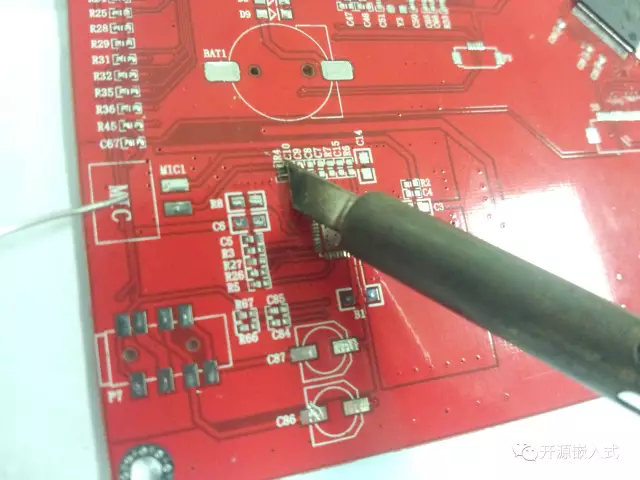

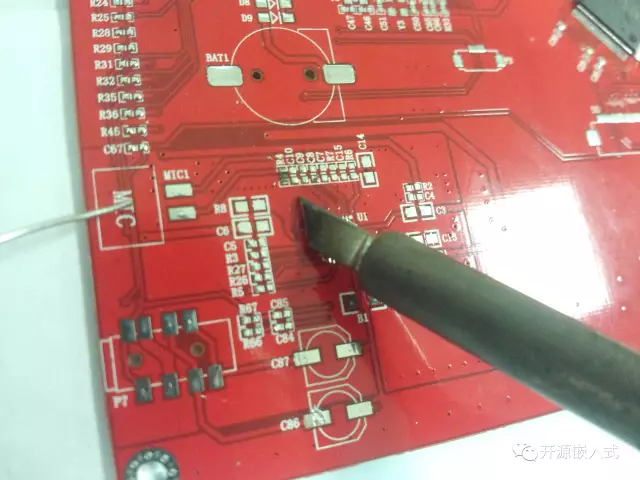

Now I use a quick soldering method called “soldering iron sticks to components,” sacrificing the neat arrangement of components for higher efficiency. This method was taught to me by the company’s senior engineers; it allows soldering both pins of a component simultaneously without using tweezers, effectively doubling the speed. The steps are as follows:

-

Add solder to both sides of the pads.

-

Shake off excess solder from the soldering iron, keeping a thin layer of solder covering the tip (the soldering iron must have solder to be sticky).

-

Place the component flat, and the soldering iron tip should contact the side of the component horizontally to stick it.

-

Move the soldering iron with the component to the pad position, heating both ends, and use the soldering iron tip to fine-tune the component’s position.

-

Remove the soldering iron in the direction of the component.

-

Solder the adjacent components from left to right one by one.

The key step in this method is to use the soldering iron to “stick” the component; the technique is to slowly approach the side of the component with the soldering iron and gently touch it. Note that the soldering iron tip must have solder to be sticky, but not too much solder; otherwise, the liquid surface tension will make it difficult to control the component. How to get a thin layer of solder on the soldering iron tip? First add solder, then shake it a bit in the direction of the soldering iron (imagine the hand motion of throwing a dart); in actual soldering, sponges are rarely used, and excess solder is typically shaken off directly, so this “shake” motion is crucial (the sponge can wipe off too much solder, which is not good; only use it when there is dirt, and shaking off is more natural).

Using tweezers can easily cause cold solder joints, while using solder to support the component can greatly reduce the probability of cold soldering.

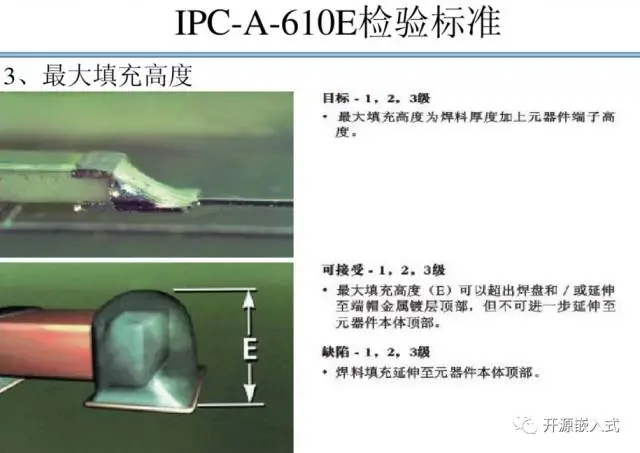

When using this soldering method, do not pursue speed blindly; while aiming for speed, ensure quality, and try to solder the components neatly—do not have cold solder joints. Additionally, the amount of solder should be well controlled; the solder should form a ball shape on both sides, which is considered too much. The just right amount should look like this (IPC standard):

For larger and higher SMD electrolytic capacitors and diodes, the soldering iron cannot heat both ends simultaneously; care must be taken not to add too much solder to the pads, or it will cause the component to sit unevenly.

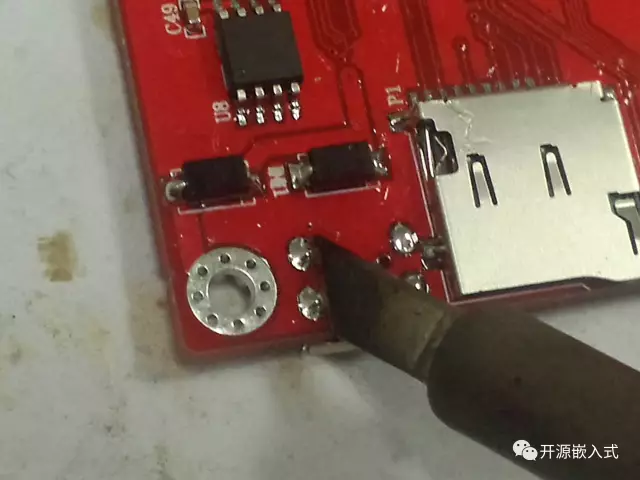

Socket Components

For sockets like USB, SD cards, and SIM cards, always solder the pins first, then solder the fixed pins, because if you fix the socket first and the position is not accurate, it cannot be adjusted. Be careful not to solder it crooked. For sockets with fixed holes, like Micro-USB, after soldering the pins, flip the board over and add solder to the back of the fixed hole to let the solder flow to the component side for fixing. This is because some Micro-USB sockets are not completely sealed, and when soldering the fixed part next to the component, solder can easily get into the socket and block it, making it impossible to insert the plug (in short, solder the holes from the back).

There is also a more troublesome type of ribbon socket called “FPC socket,” which has very dense pins and significant solder adhesion, requiring a lot of flux to manage. The typical flux is not very effective; I have damaged quite a few while soldering.

Finally, one last point: since socket components are frequently plugged and unplugged, they must be soldered securely. When soldering the fixed pins, you can slightly increase the soldering iron temperature and solder for a longer time, and for larger components (or those with a larger contact area with the pads), extend the heating time and increase the temperature to ensure a secure solder joint.

Soldering Order

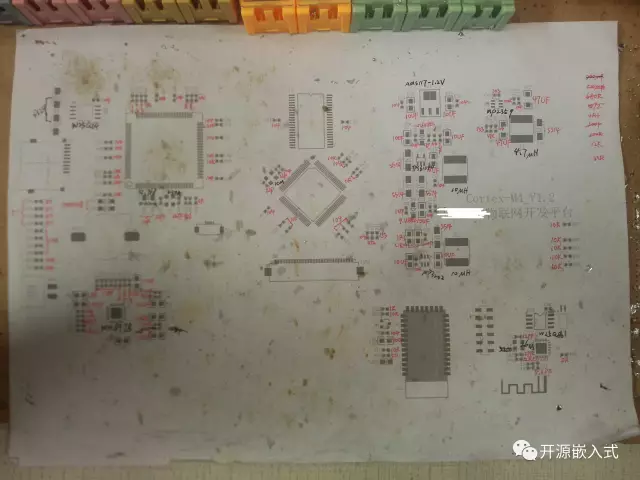

To solder a board more efficiently and reliably, certain principles must be followed (such as “small first, then large”). You cannot solder randomly or based on which component looks the best. Generally, my process upon receiving a PCB is as follows:

-

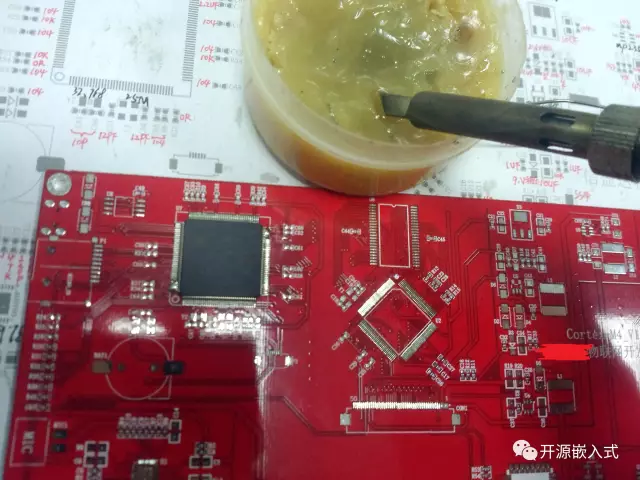

Print the PCB package diagram (the pattern printed on the board), and according to the circuit schematic, use a red pen to mark the sizes of each component and the chip models on the paper (this step can be skipped for small boards with fewer components).

-

Solder the power section, including various voltage regulators and conversion circuits, and after soldering, use a multimeter to check if the voltage at each point is normal (this step can be skipped for small boards).

-

Solder the main chips (MCU, Flash chips, device driver chips, etc.).

-

Solder smaller components like capacitors, resistors, and diodes.

-

Solder larger components like capacitors and diodes.

-

Solder peripheral components like switches, sockets, and antennas.

-

Power on for testing.

-

Clean the PCB with cleaning solution and lint-free cloth.

PS: For more complex PCBs, solder the power circuit first, check the voltage values at each point are normal, and then solder the digital circuit part. Work in modules, solder and test simultaneously to eliminate problems promptly and ensure correct circuit connections.

Of course, it doesn’t have to be done exactly this way; you should explore the most suitable order based on the differences in components and PCBs.

Common Soldering Issues

Uneven Solder Joints

Beginners often encounter uneven solder joints, which are not only unattractive but can also lead to cold solder joints and sharp points. Uneven solder joints are mainly caused by two reasons: first, the soldering iron temperature is insufficient, preventing the solder from melting completely; simply increase the soldering iron temperature. Second, the soldering time is too long, causing the flux to evaporate completely, resulting in dull and non-flowing solder; the solution is to add solder first, then remove the excess solder with the soldering iron.

Pin Shorting

When soldering components with closely spaced pins, such as chips, it is common to accidentally solder two or more pins together, making them difficult to separate. This is due to the soldering time being too long, causing the flux in the solder to evaporate, which results in loss of solder flow. Typically, solder wire contains flux, so you can add solder again and quickly remove the excess solder. A more direct approach is to add more flux or other flux to make the solder smooth.

Clearing Blocked Holes

It is quite troublesome when the solder holes for through-hole components are blocked; using a solder sucker for a long time may not work, or drilling may not work either. In fact, there is a simpler method—tap! Utilizing the fluidity and tension of the liquid along with Newton’s first law (inertia) can perfectly solve the problem. Here’s how to try:

-

Add solder to the solder pad side of the hole (that’s right, add more as it gets blocked!).

-

Continue heating the blob of solder that is blocking the hole with the soldering iron.

-

Hold the board with your left hand and keep heating with your right hand.

-

Lift and move both hands, raising the board.

-

Quickly move both hands to align the board with the edge of the table and tap it down forcefully, stopping the soldering iron before the board hits the table edge.

-

The melted solder will be “flung out” from the solder hole due to the impact.

Be careful not to be too violent; otherwise, you may easily damage the board. Remember, there is no solder hole that cannot be cleared with a single tap; if there is, just add more solder and tap again. PS: This method is not suitable for larger PCBs.

One application of this method is for desoldering through-hole components; previously, you would use a solder sucker to remove one pin at a time. Now you can simply add a large blob of solder to heat them all at once, then remove the component while it’s hot, and finally clear the solder holes. It’s convenient and quick.

There is also a video on YouTube specifically teaching desoldering techniques: Desoldering Techniques.

Some Small Details

-

Ensure the component and pad package sizes correspond; do not solder 0805 components onto 0603 pads.

-

To prevent unnecessary places on the PCB (like the company logo) from getting soldered, you can use masking tape to cover them before soldering.

-

Gather commonly used components in one place so you don’t have to rummage through the component box every time.

-

When taking small SMD components from the component box, pressing down with the tip of your right pinky can pick up several at once, which is much faster than using tweezers.

-

No other thoughts come to mind for now; I will add more if I think of anything…

Final Thoughts

I would like to thank the engineer for daring to hand over the product prototype to me for soldering; it seems that only under strict requirements can one discover their shortcomings and improve (so everyone should practice in real situations rather than just soldering for fun). Although I have encountered many new components, there is still much more to discover in the colorful world of electronics.

That’s all; the foreman is calling me to solder the boards…

Reference Articles:

Four Major Methods for Representing SMD Resistor Values

How to Read SMD Resistor Values and SMD Capacitor Values

Steps for Soldering SMD Resistors

Source: Hardware City

Disclaimer: This article is copyrighted by the original author and does not represent the views of the association. The articles promoted by the “Jiangxi Province Electronic Circuit Industry Association” are for sharing purposes only and do not represent the position of this account. If there are any copyright issues, please contact us for removal.