“Remote Data Acquisition for PLCs: Wireless Solutions Preventing Network Outages in Remote Workshops, Reducing Operational Costs by 80%!”

Hello, friends in the industrial control circle! Today, let’s talk about a painful topic—have you ever experienced debugging a PLC in the deep mountains, with such poor signal that you start to doubt life? Last month, I went to a mining area in Inner Mongolia and saw an old technician carrying a network cable over mountains, almost chased by wild dogs. I couldn’t bear to look at that beautiful scene…

▶ A Bloody Lesson

Last year, Mr. Wang from a chemical plant faced a setback: a remote pump station experienced daily network outages, requiring workers to visit the site 30 times a month, costing 120,000 just in fuel! Even worse, a hydropower station lost 1.8 million due to a rainstorm severing the fiber optic cable. Don’t laugh! If your equipment still relies on traditional wiring, it could become “blind as a bat” in no time.

▌ Three Major Advantages of Wireless Solutions (Proven Effective!)

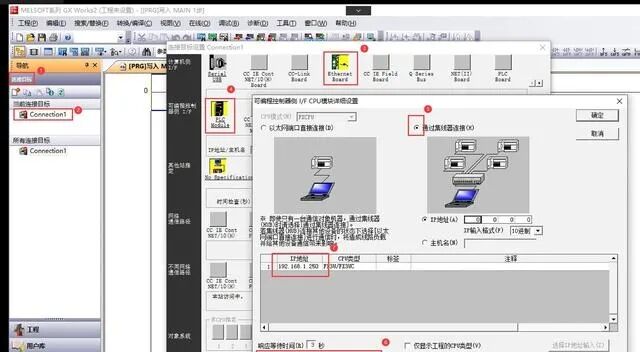

Physical Layer Drop Prevention: Install a “Wi-Fi Router” for the PLC

The Huachen Zhitong HINET gateway is a game changer! It directly converts RS485 to 4G, like inserting a SIM card into the PLC. During a recent test at a photovoltaic power station in Qinghai, data transmission was smooth even at 20 kilometers.

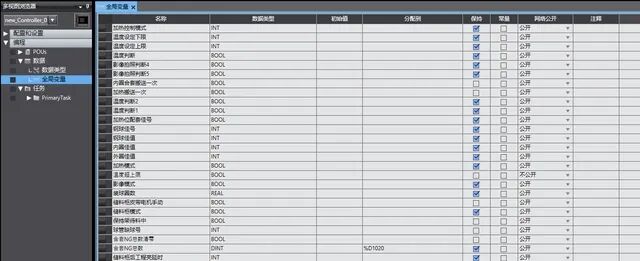

Protocol Translation Black Technology

What to do when PLCs from Siemens, Mitsubishi, and Omron speak different dialects? The gateway comes with “UN translation” capabilities, automatically switching between 112 industrial protocols. Just last week, we managed to get a mixed production line with five different brands of PLCs to communicate together!

Edge Computing Lifesaver

Is the signal intermittent? The 8G cache and breakpoint resume function are lifesavers! In a mining project, the network was down for 8 hours, yet not a second of data was lost. The boss immediately decided: “This thing is more stable than my NAS!”

▶ Comparison Table of Solutions (Copy and Paste Version)

❗ Pitfall Guide (Bloody Experience)

Never be lazy like Engineer Zhang and skip grounding! Last year, a factory burned 50 modules because of this. Remember the mantra: power grounding should be separate, and signal shielding must be twisted pair. By the way, when buying a gateway, make sure it has IP67 waterproofing—don’t ask me how I know…

▌ Economic Calculation

A 2000 yuan gateway vs. 50,000 yuan per emergency repair? A textile factory’s test data is shocking: fault response time dropped from 4 hours to 15 minutes, allowing the maintenance guy to finally leave work on time to date! Even better, they secured three additional out-of-province orders through remote diagnostics.

Five-Step Implementation Method (Step-by-Step Guide)

On-site signal scanning (just get a Network Analyzer)

Three questions for gateway selection: distance? bandwidth? protocol?

Explosion-proof certification is a must (a must-read for chemical companies!)

Simulate pressure testing (just flood it with data packets)

Build a remote maintenance platform (a mobile app for monitoring is great)

Soul-searching question: Is your factory still using spider web wiring? Are you still going crazy over PLCs in the deep mountains? Hurry up and like, save, and tag three friends in the comments to receive the “Industrial Wireless Pitfall Guide”! Finally, let me leave you with this: technological innovation is not a choice, it’s a matter of survival. Don’t let PLCs become “deaf and mute devices,” what do you think?