Recently, Tuosida’s 2024 annual report was released.

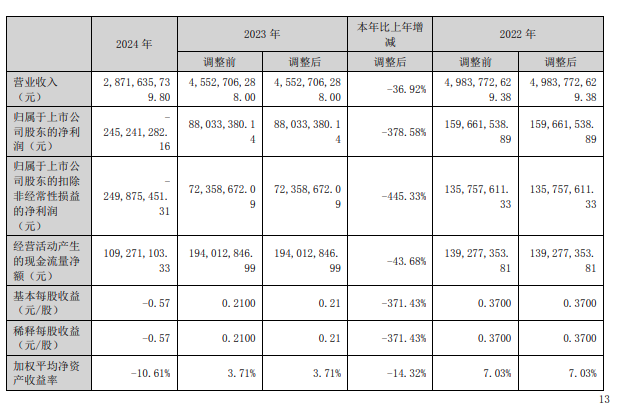

During the reporting period, the company achieved total operating revenue of 2.872 billion yuan, a year-on-year decrease of 36.92%;the net profit attributable to shareholders was -245 million yuan, a year-on-year decrease of 378.58%; the net profit excluding non-recurring gains and losses was -250 million yuan, a year-on-year decrease of 445.33%.This is the first time Tuosida has shown a “loss warning” since its listing.

By business segment, Tuosida’s intelligent energy and environmental management system business revenue was 1.229 billion yuan, a year-on-year decrease of 54.22%, which can be described as suffering a “severe blow”.

In the manufacturing sector, the injection molding machine, supporting equipment, and automatic feeding system business showed strong market resilience, achieving operating revenue of 511 million yuan, a year-on-year increase of 18.67%.

In contrast, the CNC machine tool business achieved operating revenue of 308 million yuan, a year-on-year decrease of 11.71%. During the reporting period, Tuosida sold approximately 270 five-axis CNC machine tools, with over 250 units shipped.

With the booming emergence of new industries such as humanoid robots and low-altitude aircraft, the demand for high-precision machine tools for component processing has exploded, and five-axis CNC machine tools, as “weapons” in the processing field, have entered a golden development period.Tuosida, with its strong technical capabilities and product quality, currently has a full order book.

Most notably,in the industrial robot and automation application system business, Tuosida achieved operating revenue of 755 million yuan, a year-on-year decrease of 22.05%, but the gross profit margin surged by 8.36 percentage points to 34.60%, significantly improving profitability quality.

Specifically, the industrial robot business performed well, with revenue of 275 million yuan, a year-on-year increase of 12.50%, and a gross profit margin of 47.53%, an increase of 3.93 percentage points from the previous year. Among them,self-produced multi-joint industrial robotsleveraged their process advantages accumulated in the 3C industry, achieving “speed and passion”, with revenue growth of 76.04%,and shipment volume exceeding 2000 units, with cumulative shipments surpassing 8000 units.

This success is attributed to the recovery of the injection molding industry, which drove the hot sales of Cartesian robots by 26.20%, as well as the strategic focus on reducing low-margin trading businesses and deepening high-value self-produced products.

Additionally, Tuosida’s automation application system business achieved operating revenue of 480 million yuan, a year-on-year decrease of 33.74%, but the gross profit margin increased by 6.81 percentage points compared to last year.This is due to its increased focus on the research and layout of “robot +” applications, reducing the proportion of personalized projects, and enhancing standardized production capacity.

From “Injection Molding Small Factory” to Robot “Chain Leader”

From a small manufacturer focused on auxiliary equipment around injection molding machines to now being recognized as the “chain leader” in the intelligent robot field of Guangdong Province’s strategic emerging industry cluster, Tuosida has achieved full-chain coverage from upstream precision component self-research, midstream industrial robot manufacturing, to downstream automation system customized integration, forming an industrial closed-loop advantage through continuous technical deepening and strategic layout.

Since launching its first robotic arm in 2010, reaching an annual shipment milestone of over 10,000 units in 2020; starting multi-joint robot research and development in 2015, and now accumulating nearly 10,000 units shipped, Tuosida has maintained a steady pace.

This year, “embodied intelligence” was first included in the “Government Work Report”, and Tuosida is also actively laying out, using motion control as an entry point,launching a new generation of integrated intelligent robot control platform called “Sense-Compute-Control” and achieving applications in industrial scenarios.This motion control platform plays a role similar to that of a “cerebellum and spine” in the integration of intelligence and embodiment.

In terms of industrial cooperation,last November, Huawei (Shenzhen) Global Embodied Intelligence Industry Innovation Center announced its operation and held a signing ceremony for selected partners, with Tuosida being one of them.

In addition to Huawei, Tuosida is also exploring the implementation of embodied intelligence scenarios in collaboration with partners such as Zhiyu and Alibaba Cloud.

In Conclusion

In the current context of slowing growth in the industrial robot industry and fierce competition, those companies that successfully navigate through cycles are like a prism, reflecting the wisdom and innovative resilience of Chinese manufacturing in the tide of the times.

In the red sea of stock competition, they solidify their fundamentals while also “looking up at the stars” to layout future tracks, seizing the high ground of cutting-edge technologies such as “embodied intelligence”. Only by using technological innovation as a spear and industrial ecology as a shield can they break through and find a way out in the fierce industry reshuffle.

Recommended Highlights

Contact Us