For business cooperation, please contact QQ: 3350579506

For more exciting consultations, please follow Electrician 365 (diangong365) Electrician Home QQ Group:Group 1: 468193845 Group 2: 522898769

Often, technicians encounter this problem: why can’t my touch screen communicate with the PLC? For example, the following two issues:

1. The Weintek touch screen cannot communicate with the Siemens PLC, always prompting that the PLC is unresponsive. How should I set it up?

Solution Approach:

Ensure that the baud rate, data bits, and stop bits are the same, and the station number must not be the same, meaning that the PLC and the touch screen addresses cannot be identical. Then check if the communication line is normal…

2. How to determine if there is a communication failure between the touch screen and PLC through programming?

Solution Approach:

The usual method is to use heartbeat detection. Define a bool, and the HMI will set this point at a fixed frequency. After the PLC receives this point as an ON signal, it will reset it. If no ON signal is received within a certain time, say 5 seconds, it is considered a communication interruption.

The PLC sends the memory clock byte to the screen, and the screen uses a script to assign this byte’s value to another address within the PLC. Then the PLC checks whether the returned byte is the same for two scanning cycles; if it is the same, it indicates a communication interruption.

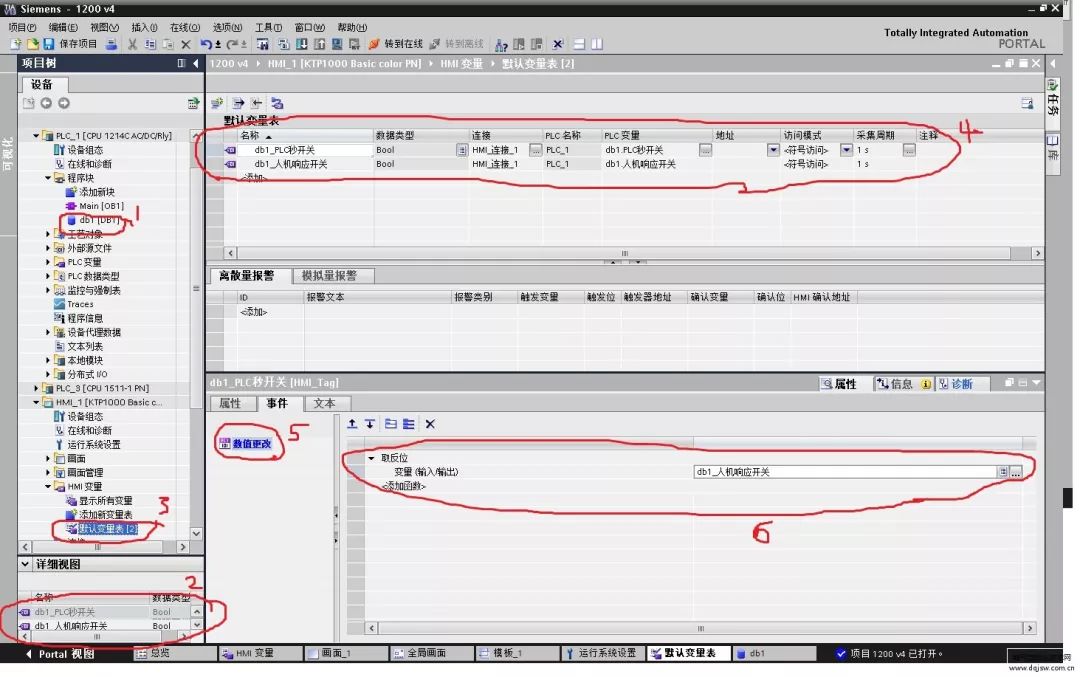

For example, see the image, and follow these steps:

1. Create a DB1 data block in the PLC, setting two digital switches: “PLC Second Switch” and “HMI Response Switch”;

2. Connect these two variables in the HMI variable;

3. In the properties of the HMI “PLC Second Switch” variable, under events, add “Invert”, allowing the “HMI Response Switch” variable to change with the “PLC Second Switch”;

4. In the PLC program block, program the “PLC Second Switch” to toggle every 0.5 seconds, then use the TON delay instruction to output “HMI communication failure” if there is no action on the “HMI Response Switch” within 1 second, because after the HMI communication exception, the “HMI Response Switch” will no longer change.

Good method, feel free to take it!~

Actually, any touch screen not communicating with the PLC in the market can be boiled down to confirming four issues:

1. Are the PLC parameters consistent with those in the project?

2. Is the communication line connected according to the wiring diagram?

3. Is the COM port set in the project correct when connecting to the screen?

4. If the parameters and lines are confirmed OK, check if there is a PLC program or address issue.

Method:

First, check the parameters:

1. Use the PLC programming software to connect to the PLC and test what the PLC parameters are, and see if they match the parameters set in the project.

2. Online simulation: Use our configuration software, connect the PLC with its communication cable to the computer, and simulate online to see if the project communicates. You can use a numeric input component or switch to operate it and check if the previous operations remain after turning off the simulator and then back on; if you directly get NC (not connected), it means there is no communication.

Testing the line:

Use a multimeter to test the connections according to the wiring diagram.

1. Touch screen parameters. Check the parameter settings of the touch screen.

There are a few parameters that need special attention:

1: Communication port settings – Be sure to confirm whether the PLC connects to COM1 or COM2 of the touch screen.

2: Device type – This is the most important; if the protocol is not selected correctly, there is no need to discuss the rest.

3: Connection method – Confirm whether the connection between the PLC and touch screen is RS485 or RS232C.

4: Interface parameters and PLC station number – Must be consistent with the settings in the PLC.

2. If the parameter settings are confirmed, next, check for line issues.

Confirm whether the RS485 or RS232C wiring is correct; the wiring methods for touch screens with various PLCs are different. This can refer to the Weikong (PLC and touch screen communication wiring methods help documentation) for guidance, which is the basic method for troubleshooting communication issues.

Next, let me teach you how to bypass touch screen issues – online simulation. When communication is down, some customers may speculate that it might be a touch screen issue or an interface issue. Online simulation is a way to bypass the touch screen and connect directly to the PLC with the computer.

Specific method:

1: Connect the PLC to the computer via RS232. Some PLCs have RS232 interfaces, while others do not; those without can connect to the computer via an adapter.

2: Create a simple new project. Place two components, one numeric display and one numeric input. Set the address to the address in the PLC.

3: The project parameter settings must match the settings in the PLC.

4: Click the online simulation function.

This way, you can clearly see if the PLC can communicate with the PC. If communication is successful, you can rule out issues on the PLC side and parameter settings.

Popular Recommendations

What do you know about the significance of wire colors in electrical equipment?

Calculation method for copper busbars in distribution cabinets: Estimate the copper busbar usage for GGD switch cabinets

Contactor control circuits? This article is sufficient

How to connect copper wire to aluminum wire? You will understand at a glance

The main protective role of equipotential bonding

Understand our distribution system

Detailed explanation of ‘Capacitance Method’ for checking wire breakpoints

How motors are wound (Beginner’s Edition)

From novice to expert: Measuring voltage and distinguishing between neutral and live wires with a multimeter

Secondary circuit schematic, expanded diagram, wiring diagram

(National Grid Training Exclusive) Circuit breaker control circuit

How is the compensation capacity of reactive power compensation devices calculated? Reactive power compensation capacity calculation coefficient table

Comprehensive understanding of leakage protection: Working principles and purchasing methods of leakage protectors [Illustrated]

From novice to expert: Checking new multimeters upon arrival

Strange occurrences when repairing LED bulbs

About the issue of LED dimming and flickering when turning off lights

Long press the QR code to follow us