Today, we will use the Weintek touch screen to control the Mitsubishi D series inverter as an example.

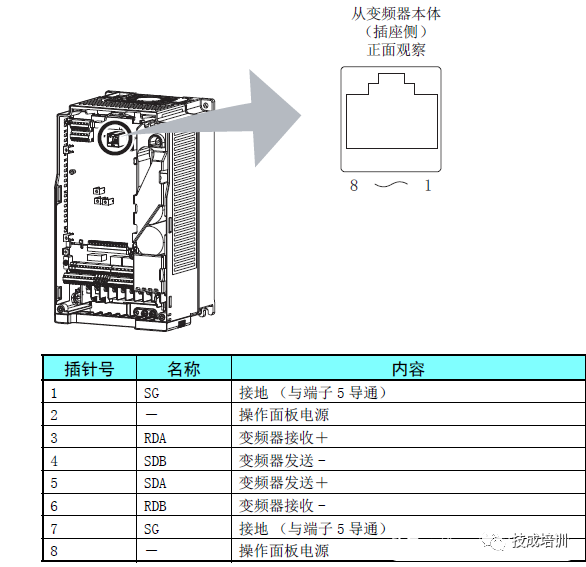

The touch screen controls the inverter using RS485 communication. Traditional RS485 uses two wires, but Mitsubishi automation products generally use a four-wire system, so we will use four wires for communication between the touch screen and the inverter.

On the inverter side, you need to set the relevant communication parameters, mainly the baud rate and parity bit.

It is important to note that Mitsubishi inverters do not default to MODBUS RTU protocol; parameter 549 needs to be set. The communication data must match between the touch screen and the inverter, otherwise, communication will fail.

On the touch screen side, we will add a MODBUS RTU slave.

The communication parameters of the inverter and the touch screenmust match, otherwise, communication will not work.

For the inverter to operate, it must receive a start signal and a speed signal. Therefore, we need to configure the screen to send the start signal and speed signal to the inverter. The addresses for the start and speed signals can be found in the inverter manual.

Above are the relevant address descriptions from the inverter manual. We only need toimplement the related start, stop, and speed settings on the screen.

1120 Inverter Manuals

16 Essential Inverter E-books

Disclaimer: This article is reprinted from the internet, and the copyright belongs to the original author. If there are copyright issues, please contact us for deletion. Thank you!

Recommended Reading: Siemens HMI (Touch Screen) Configuration and Application Technology, click on "Read the Original" below.