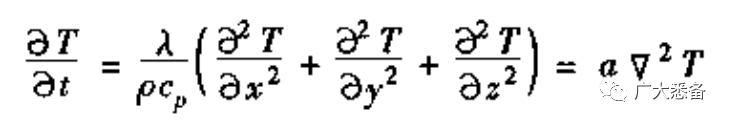

1. Technology and Applications of 3D Printed Molds3D printed molds, such as injection molds, have always been regarded as a promising application direction for metal 3D printing in the industry. There are three main reasons:(1) Complex cooling channels can almost only be achieved through 3D printing;(2) It must be combined with simulation, which is quite challenging;(3) The added value of molds can withstand the high price threat of 3D printing (forgive me for using this term), which can be analyzed through the cost-benefit analysis process of users.For example, the widely circulated diagram: The relative success of 3D molds is mainly due to the “one bad apple spoils the whole barrel” problem. An expensive mold may have low forming efficiency and quality due to several “deep pits and high protrusions” that cannot cool effectively and uniformly.Assuming a mold for an ABS plastic product has a lifespan of 500,000 cycles, with an original yield of 98%, if 3D technology improves efficiency by 10% and yield by 1%, then the number of qualified products over the entire lifespan of the mold will increase from 490,000 to 495,000. At the same time, time is saved by 10%, which could mean several days, allowing the production line to be freed up for further benefits.If we calculate the comprehensive benefits from the revenue of qualified products and the time saved, and if this benefit remains after 3D printing, then this surplus is the value. If the value is positive, it can be done; if negative, it cannot.However, 3D printed molds have two drawbacks:(1) Insufficient density, with defects on the order of tens of micrometers (pores, inclusions, etc.);(2) Limited material choices, with very uniform thermal conductivity.The topic of this article is the first issue: density. As for the second issue of thermal conductivity, I will briefly mention it; if interested, feel free to message me for further details:The mainstream materials currently used for 3D printed mold steel are 18Ni300 (MS1), H13, etc., with thermal conductivities generally ranging from 10W/mk to 20W/mk, which is quite low. However, there are no particularly good alternatives; among commonly used iron-based alloys, the highest is only about 100W/mk, with most below 30. Although 3D printing can provide higher and more uniform density distribution in cooling channels, the upper limit of cooling efficiency it can achieve is limited.In the article “Thermal Processes in the Melting Pool 1 – Derivation and Application of Analytical Solutions“, we used the heat conduction equation:

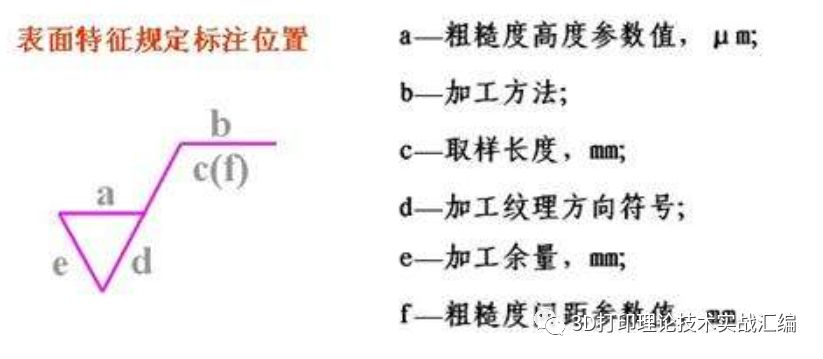

The relative success of 3D molds is mainly due to the “one bad apple spoils the whole barrel” problem. An expensive mold may have low forming efficiency and quality due to several “deep pits and high protrusions” that cannot cool effectively and uniformly.Assuming a mold for an ABS plastic product has a lifespan of 500,000 cycles, with an original yield of 98%, if 3D technology improves efficiency by 10% and yield by 1%, then the number of qualified products over the entire lifespan of the mold will increase from 490,000 to 495,000. At the same time, time is saved by 10%, which could mean several days, allowing the production line to be freed up for further benefits.If we calculate the comprehensive benefits from the revenue of qualified products and the time saved, and if this benefit remains after 3D printing, then this surplus is the value. If the value is positive, it can be done; if negative, it cannot.However, 3D printed molds have two drawbacks:(1) Insufficient density, with defects on the order of tens of micrometers (pores, inclusions, etc.);(2) Limited material choices, with very uniform thermal conductivity.The topic of this article is the first issue: density. As for the second issue of thermal conductivity, I will briefly mention it; if interested, feel free to message me for further details:The mainstream materials currently used for 3D printed mold steel are 18Ni300 (MS1), H13, etc., with thermal conductivities generally ranging from 10W/mk to 20W/mk, which is quite low. However, there are no particularly good alternatives; among commonly used iron-based alloys, the highest is only about 100W/mk, with most below 30. Although 3D printing can provide higher and more uniform density distribution in cooling channels, the upper limit of cooling efficiency it can achieve is limited.In the article “Thermal Processes in the Melting Pool 1 – Derivation and Application of Analytical Solutions“, we used the heat conduction equation: In the equation, λ represents thermal conductivity, which can be seen hanging at the front of the test piece; the temperature gradient (cooling rate, heating rate) is proportional to it, indicating its significant impact.Sometimes in 3D molds, we have to place the cooling channels as close to the surface as possible, but this proximity is limited.For example, some molds use beryllium copper or similar high thermal conductivity materials for rapid cooling. In this case, forcibly using 18Ni300 with optimized cooling channels may not keep up. This is an issue that the industry needs to pay attention to but may not be sufficiently aware of. Introducing materials that balance high hardness, high corrosion resistance, and better thermal conductivity into 3D printing will be key to further promoting the application of 3D molds.2. Knowledge Related to RoughnessTo understand the issue of mold surface finish, it is essential to supplement the basic knowledge of roughness measurement and evaluation.There are many evaluation methods for roughness, with Ra being the most commonly used. So what is Ra?R – Roughnessa – Average (Average)

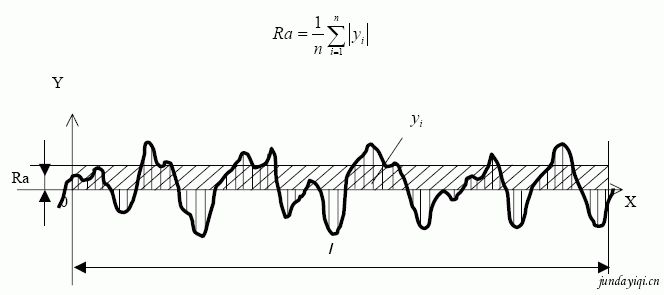

In the equation, λ represents thermal conductivity, which can be seen hanging at the front of the test piece; the temperature gradient (cooling rate, heating rate) is proportional to it, indicating its significant impact.Sometimes in 3D molds, we have to place the cooling channels as close to the surface as possible, but this proximity is limited.For example, some molds use beryllium copper or similar high thermal conductivity materials for rapid cooling. In this case, forcibly using 18Ni300 with optimized cooling channels may not keep up. This is an issue that the industry needs to pay attention to but may not be sufficiently aware of. Introducing materials that balance high hardness, high corrosion resistance, and better thermal conductivity into 3D printing will be key to further promoting the application of 3D molds.2. Knowledge Related to RoughnessTo understand the issue of mold surface finish, it is essential to supplement the basic knowledge of roughness measurement and evaluation.There are many evaluation methods for roughness, with Ra being the most commonly used. So what is Ra?R – Roughnessa – Average (Average) What does this diagram mean? To better explain this concept, let’s take an example of walking: you walk a distance that has ups and downs, pits, and bumps. We can plot the elevation changes of this path on a coordinate system. How do we evaluate whether this path is flat or not? There are many ways to describe the unevenness of this path:

What does this diagram mean? To better explain this concept, let’s take an example of walking: you walk a distance that has ups and downs, pits, and bumps. We can plot the elevation changes of this path on a coordinate system. How do we evaluate whether this path is flat or not? There are many ways to describe the unevenness of this path:

-

The highest point of this path is 5 meters, and the lowest point is 3 meters: by marking the maximum and minimum values;

-

The difference between the highest and lowest points: by describing it similarly to elevation;

-

The average height of this path is 2.8 meters: using the average method.

You guessed it: the third method is the definition of Ra, which is also the most commonly used description method because it represents an average and reflects the overall situation. However, it is not practical in every case; for example, when cycling, I pay close attention to the highest point of the segment; if it’s too high, I can’t climb it.

However, in processing, we cannot use meter-level measurement units and methods like measuring the ups and downs of a road. So how do we measure it? For example, the following image shows a photo of inclusions that have not corroded after polishing:

In the lower right corner, there is a 100um scale; how do we account for these inclusions or pits in roughness? How do we measure it?

3. Methods for Measuring Roughness

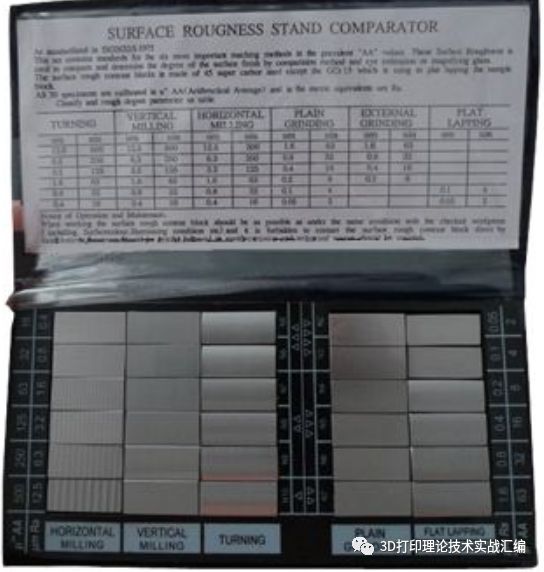

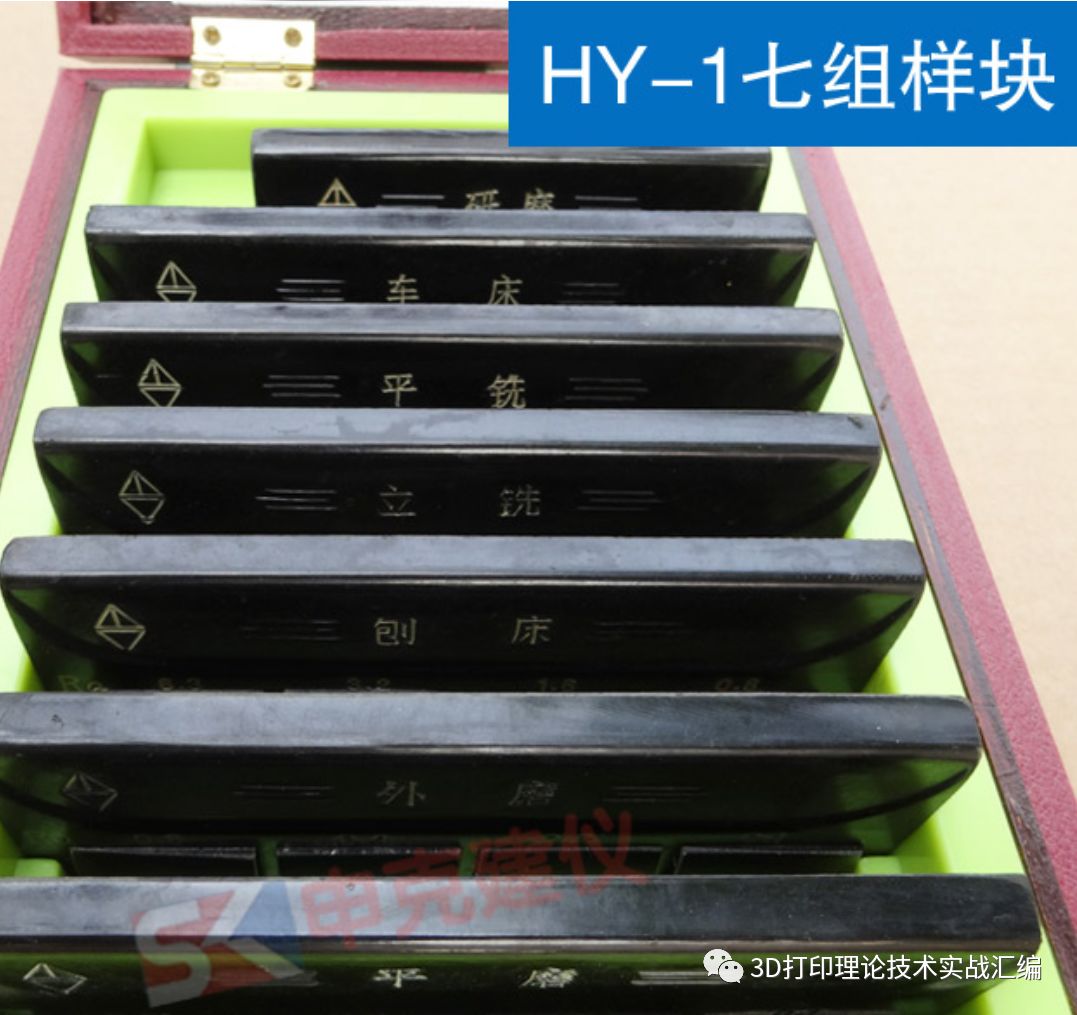

The first measurement method: Comparison Test Blocks

Comparison test blocks are essentially a type of gauge made to be judged by visual inspection and touch; various gauge brands are available, making them easy to purchase and use.

The second measurement method: Roughness Tester

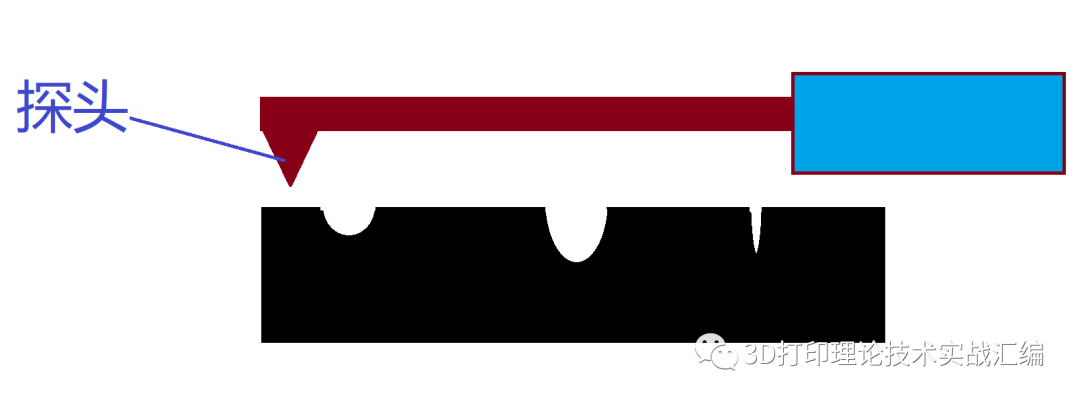

The roughness tester looks like this (a blue box fixed on a lifting frame):This instrument is also quite expensive, ranging from tens of thousands to hundreds of thousands. Its measurement principle is as follows: a probe moves across the surface of the workpiece, and the up-and-down oscillation of the probe can measure the values of protrusions and pits, which can then be processed to obtain roughness.

Its measurement principle is as follows: a probe moves across the surface of the workpiece, and the up-and-down oscillation of the probe can measure the values of protrusions and pits, which can then be processed to obtain roughness. In my experience, this instrument tends to give lower measurement results. The reason is the size of the probe: the probe is made of diamond-like materials, and its accuracy and the size of roughness it can measure are related to the probe’s dimensions. Such situations may occur:

In my experience, this instrument tends to give lower measurement results. The reason is the size of the probe: the probe is made of diamond-like materials, and its accuracy and the size of roughness it can measure are related to the probe’s dimensions. Such situations may occur:

However, most of the time, the application is sufficient.

Other methods: Brog’s recommended method

Measuring roughness can also be done using laser methods or other optical methods. This is quite advanced and generally not needed for ordinary use. However, I recommend the following method:

In my previous work experience, I developed another convenient and representative method for polishing 3D printed molds: metallographic method.

The implementation process is as follows:

Step 1: Polish the sample to achieve the following result

Step 2: Use image processing software to analyze the size of the particles (e.g., ImageJ);Step 3: Calculate the average particle size as the Ra value;Step 4: Take the maximum value as a reference for the highest achievable polishing level.This method is considered quite accurate because we are evaluating the surface of the mold, which is essentially a cross-section. We utilize the statistical results of this cross-section as the test value.Another feature of this method is its ease of implementation: a large number of photos can be processed and analyzed automatically by the program, making it efficient and cost-effective. Based on my experience, this is a recommended method for the industry,and everyone can consider applying it in their corporate standards. If you need support in this area, feel free to message me; I am happy to share my experiences. Of course, I have one request: if you successfully implement this, please allow me to publish the results to promote industry progress.5. Texture Characteristics of Roughness and Related IssuesDuring my time at my previous employer, I led the establishment of roughness measurement standards for 3D printed parts, which included various methods mentioned above. Surprisingly, the most frequently raised question was about the “comparison test block method”; why is that?Let’s take a look at the details of the comparison test block:

Step 2: Use image processing software to analyze the size of the particles (e.g., ImageJ);Step 3: Calculate the average particle size as the Ra value;Step 4: Take the maximum value as a reference for the highest achievable polishing level.This method is considered quite accurate because we are evaluating the surface of the mold, which is essentially a cross-section. We utilize the statistical results of this cross-section as the test value.Another feature of this method is its ease of implementation: a large number of photos can be processed and analyzed automatically by the program, making it efficient and cost-effective. Based on my experience, this is a recommended method for the industry,and everyone can consider applying it in their corporate standards. If you need support in this area, feel free to message me; I am happy to share my experiences. Of course, I have one request: if you successfully implement this, please allow me to publish the results to promote industry progress.5. Texture Characteristics of Roughness and Related IssuesDuring my time at my previous employer, I led the establishment of roughness measurement standards for 3D printed parts, which included various methods mentioned above. Surprisingly, the most frequently raised question was about the “comparison test block method”; why is that?Let’s take a look at the details of the comparison test block: The test block is made through turning, milling, grinding, etc., and everyone knows that the roughness values of various processing methods are different; these gauge blocks are naturally processed using these methods. The question arises:For example, after processing on a planer, the resulting texture is linear; although the micro-roughness dimensions are the same as the labeled Ra value, there are two issues to resolve:

The test block is made through turning, milling, grinding, etc., and everyone knows that the roughness values of various processing methods are different; these gauge blocks are naturally processed using these methods. The question arises:For example, after processing on a planer, the resulting texture is linear; although the micro-roughness dimensions are the same as the labeled Ra value, there are two issues to resolve:

-

How to measure the different texture shapes?

-

Can a roughness block made of metal measure plastic?

The roughness value only indicates a magnitude, for example, Ra3.2, which means the average roughness is 3.2um. Although the texture shapes are different, the tactile and visual sensations are mostly related to this value, so different textures can still be measured. The same goes for different materials: we only consider tactile and visual sensations.Roughness has two most important characteristics:

-

Magnitude

-

Texture Shape

For example: Many molds require specific textures; it is not always better to be smoother. For example, the matte effect of computer casing and the crosshatch pattern on plastic surfaces. In fact, achieving these regular and aesthetically pleasing textures often incurs huge costs in mold processing, sometimes accounting for a significant portion of the total mold cost. The processes involved include CNC, chemical etching, electrochemical etching, laser processing, etc.6. The “Highest Polishing Level” of 3D Printed MoldsIn the industry, 3D printed metal molds are often described using four grades: A, B, C, and D. However, from my observations of companies and professionals, even those who have been engaged in the 3D mold business for a long time often do not fully understand the nuances, leading to unnecessary troubles.The A, B, C, and D grades come from the standards set by the American Plastics Industry Association (SPI), and there are actually further subdivisions:

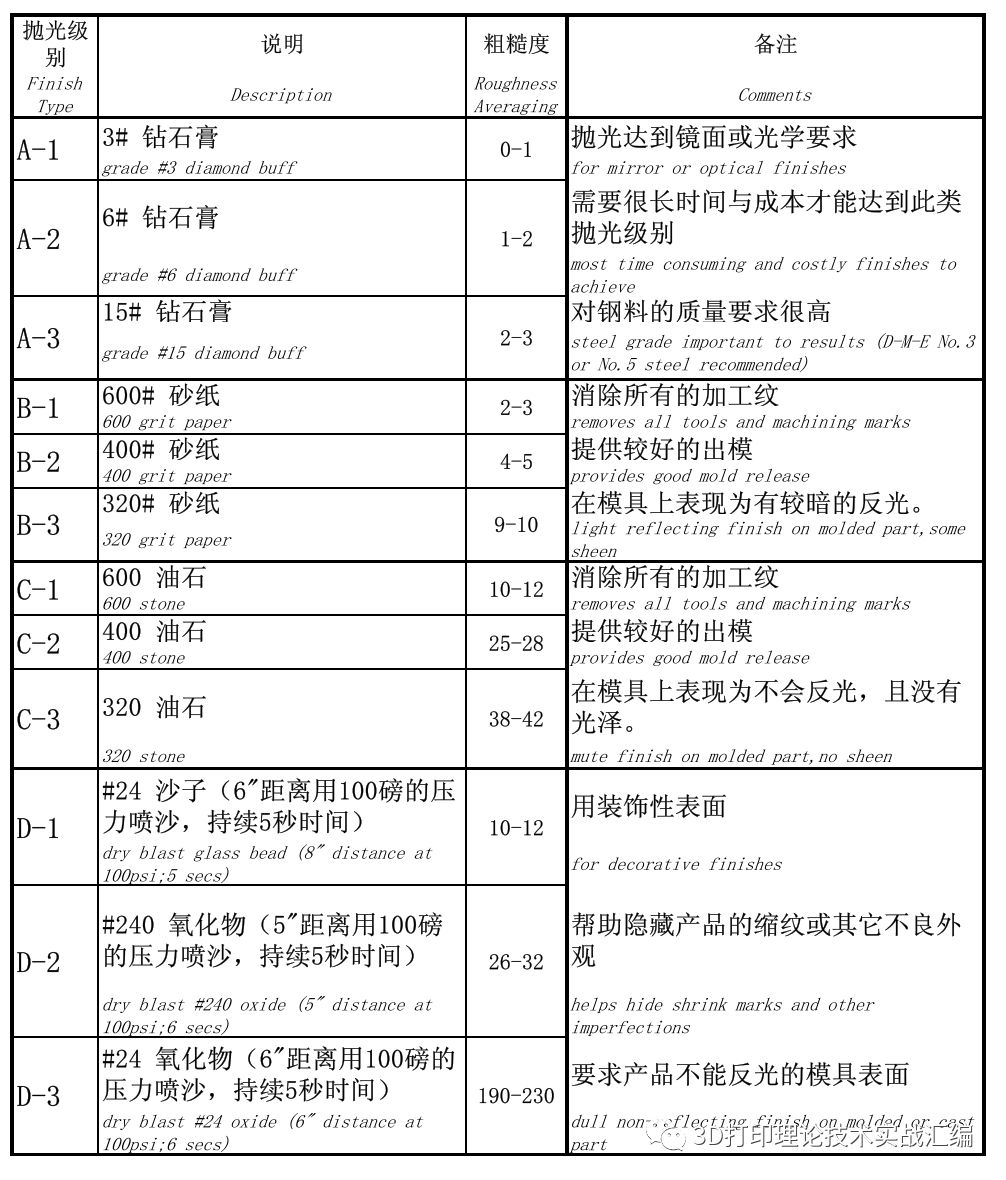

Many molds require specific textures; it is not always better to be smoother. For example, the matte effect of computer casing and the crosshatch pattern on plastic surfaces. In fact, achieving these regular and aesthetically pleasing textures often incurs huge costs in mold processing, sometimes accounting for a significant portion of the total mold cost. The processes involved include CNC, chemical etching, electrochemical etching, laser processing, etc.6. The “Highest Polishing Level” of 3D Printed MoldsIn the industry, 3D printed metal molds are often described using four grades: A, B, C, and D. However, from my observations of companies and professionals, even those who have been engaged in the 3D mold business for a long time often do not fully understand the nuances, leading to unnecessary troubles.The A, B, C, and D grades come from the standards set by the American Plastics Industry Association (SPI), and there are actually further subdivisions: In my previous work, someone once asked me:“If parts printed in 3D are polished with diamond paste, can’t they reach grade A?”Of course not; the polishing level of molds, for 3D printing, is more accurately termed:the “highest” polishing level of the mold.Why do I say this? 3D printed parts inherently have defects on the order of tens of micrometers. If we use coarse sandpaper for polishing, with a particle size of 100um, the areas where the sandpaper passes will be cut into tens of micrometers of “scratches”.These “scratches” are deep, thus covering the original defects of the 3D print, making them invisible even under a microscope.However, when we choose a finer polishing method, making the areas next to the pits shiny with minimal scratches, the defects of the 3D printed part will become apparent.It can be seen that even with finer polishing methods, it is impossible to “fill the pits”. Further polishing is meaningless, so from this perspective, the “mold polishing level” can be equivalently described as the “highest polishing level of the mold”,which is determined by the properties of the material itself.7. Polishing Levels of 3D MoldsIf we measure the highest polishing level using the metallographic image method I recommended earlier, what would happen?We know that the microscopic defects in metal 3D printing (SLM) are mostly on the order of tens of micrometers, and the process can be unstable, leading to larger defects as well. This means that in the polishing level table, it corresponds to at least grade C.However, if you use a probe-type measuring instrument, the result will be lower than this.From a scientifically rigorous perspective, many molds cannot be made using 3D printing. However, strangely, many molds marked as “grade B” can be successfully produced with 3D printing. Why is that?Everyone knows that molds are secondary forming, and the defects in metal 3D printing are very evenly distributed and regular, resulting in pits after polishing. The contact and cooling of plastic with the mold do not necessarily create visible protrusions; it may even relate to the type of plastic used.Based on my experience, standard bright plastic surfaces can be produced using 3D printed molds without issues.However, optical components should not be considered this way. It is better to use 100% dense metal materials for processing.8. Improving Polishing LevelsDefects in 3D printing are extremely difficult to eliminate, but they can be reduced. This reduction process tests the quality control capabilities of a 3D mold manufacturing unit and their understanding of 3D printing technology.Most inclusions in 3D printing are oxides, with oxygen being prevalent during the powder manufacturing and printing processes, making it very difficult to eliminate. Concentrations of hundreds to thousands of ppm are common in 3D printing.In contrast, well-known cast and forged parts can achieve oxygen levels below 20ppm through processes like out-of-furnace refining. With fewer inclusions and subsequent forging processes that crush and elongate inclusions, their density can reach 100%.To improve the purity of 3D printed parts, we can only focus on several major aspects: the purity of raw materials, the purity of protective gases during printing, and the removal of debris. Each of these aspects presents significant challenges for 3D printing. Additionally, as mentioned in the article “Evaluation and Handling of Metal Powder Laser Reflection Issues”, green laser technology can help stabilize the melting pool, thereby reducing defects and improving the highest polishing level.Moreover, the quality control process is also extremely important. Repeatedly using raw materials to reduce costs can lead to a sharp decline in mold quality.9. The Issue of OverperformanceWhile insufficient performance is certainly concerning, overperformance is also undesirable. For example, in your company, have you explored the highest polishing level of molds printed with recycled powder materials used three times? Can this level of mold be used for a certain type of product? Is it necessary to mix in 50% new powder?Of course, mixing in new powder involves many other considerations, and polishing performance may not be the primary target characteristic. However, this contemplation about overperformance helps us establish a rational relationship between “product” and “technology”, and also aids 3D mold production organizations in scrutinizing their work more carefully.

In my previous work, someone once asked me:“If parts printed in 3D are polished with diamond paste, can’t they reach grade A?”Of course not; the polishing level of molds, for 3D printing, is more accurately termed:the “highest” polishing level of the mold.Why do I say this? 3D printed parts inherently have defects on the order of tens of micrometers. If we use coarse sandpaper for polishing, with a particle size of 100um, the areas where the sandpaper passes will be cut into tens of micrometers of “scratches”.These “scratches” are deep, thus covering the original defects of the 3D print, making them invisible even under a microscope.However, when we choose a finer polishing method, making the areas next to the pits shiny with minimal scratches, the defects of the 3D printed part will become apparent.It can be seen that even with finer polishing methods, it is impossible to “fill the pits”. Further polishing is meaningless, so from this perspective, the “mold polishing level” can be equivalently described as the “highest polishing level of the mold”,which is determined by the properties of the material itself.7. Polishing Levels of 3D MoldsIf we measure the highest polishing level using the metallographic image method I recommended earlier, what would happen?We know that the microscopic defects in metal 3D printing (SLM) are mostly on the order of tens of micrometers, and the process can be unstable, leading to larger defects as well. This means that in the polishing level table, it corresponds to at least grade C.However, if you use a probe-type measuring instrument, the result will be lower than this.From a scientifically rigorous perspective, many molds cannot be made using 3D printing. However, strangely, many molds marked as “grade B” can be successfully produced with 3D printing. Why is that?Everyone knows that molds are secondary forming, and the defects in metal 3D printing are very evenly distributed and regular, resulting in pits after polishing. The contact and cooling of plastic with the mold do not necessarily create visible protrusions; it may even relate to the type of plastic used.Based on my experience, standard bright plastic surfaces can be produced using 3D printed molds without issues.However, optical components should not be considered this way. It is better to use 100% dense metal materials for processing.8. Improving Polishing LevelsDefects in 3D printing are extremely difficult to eliminate, but they can be reduced. This reduction process tests the quality control capabilities of a 3D mold manufacturing unit and their understanding of 3D printing technology.Most inclusions in 3D printing are oxides, with oxygen being prevalent during the powder manufacturing and printing processes, making it very difficult to eliminate. Concentrations of hundreds to thousands of ppm are common in 3D printing.In contrast, well-known cast and forged parts can achieve oxygen levels below 20ppm through processes like out-of-furnace refining. With fewer inclusions and subsequent forging processes that crush and elongate inclusions, their density can reach 100%.To improve the purity of 3D printed parts, we can only focus on several major aspects: the purity of raw materials, the purity of protective gases during printing, and the removal of debris. Each of these aspects presents significant challenges for 3D printing. Additionally, as mentioned in the article “Evaluation and Handling of Metal Powder Laser Reflection Issues”, green laser technology can help stabilize the melting pool, thereby reducing defects and improving the highest polishing level.Moreover, the quality control process is also extremely important. Repeatedly using raw materials to reduce costs can lead to a sharp decline in mold quality.9. The Issue of OverperformanceWhile insufficient performance is certainly concerning, overperformance is also undesirable. For example, in your company, have you explored the highest polishing level of molds printed with recycled powder materials used three times? Can this level of mold be used for a certain type of product? Is it necessary to mix in 50% new powder?Of course, mixing in new powder involves many other considerations, and polishing performance may not be the primary target characteristic. However, this contemplation about overperformance helps us establish a rational relationship between “product” and “technology”, and also aids 3D mold production organizations in scrutinizing their work more carefully.