Follow us for Golden Open Access

01

Authors

Liu Guofeng, Kong Weicheng, Qiao Tianhong, Sun Yuan, He Yong, Xia Pengcheng, Ren Wenjie

02

Institutions

Zhejiang University, Nanjing Medical University, Xinxiang Medical University

03

Citation

Liu G F, Xia P C, Kang W C, Qiao T H, Sun Y, Ren W J, He Y. 2025. 3D printing of hard/soft switchable hydrogels. Int. J. Extrem. Manuf. 7 045001.

Scan to access the full text

https://doi.org/10.1088/2631-7990/adbd97

Written by | Article Authors

1. Article Introduction

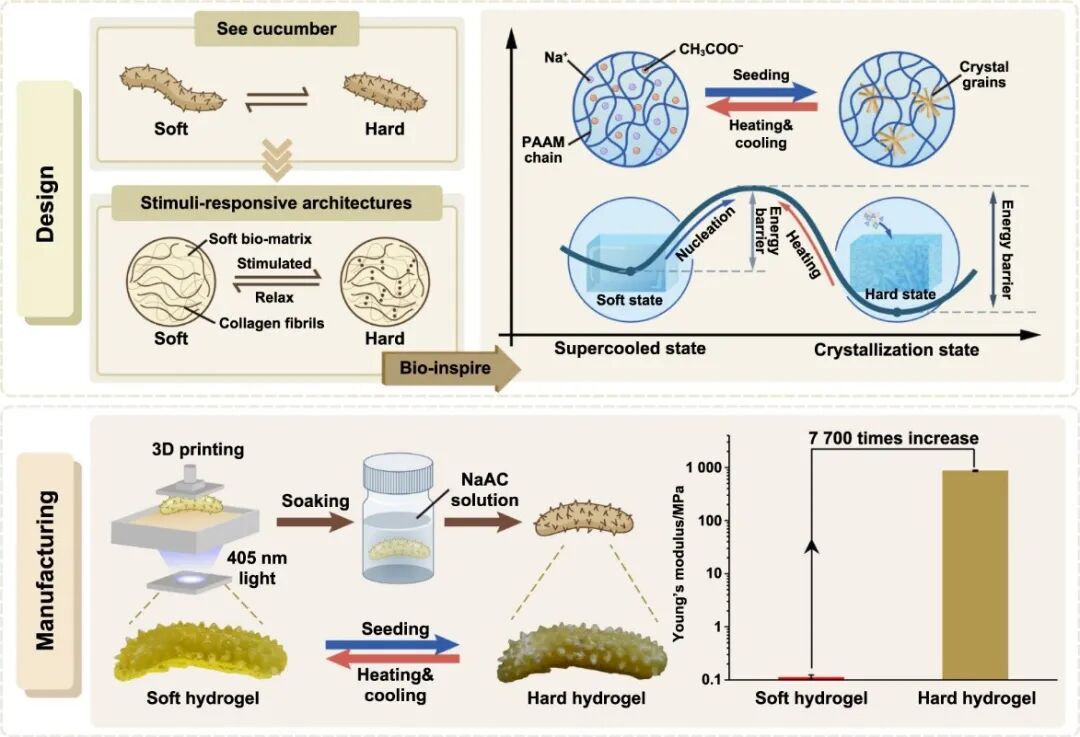

The core component of hydrogels is water, and their soft and wet characteristics are widely used in flexible electronics, soft robotics, and regenerative medicine. Currently, hydrogels can be soft (soft) and, after special treatment, can also be tough (tough), but it is difficult to achieve hardness (hard), which limits their application scenarios. Recently, Professor He Yong’s research group at the School of Mechanical Engineering, Zhejiang University proposed a hydrogel that can freely switch between soft and hard states by introducing a reversible phase change of supersaturated sodium acetate solution into the 3D printed hydrogel structure, granting it the ability to quickly and reversibly switch between soft and hard states, increasing the hydrogel’s hardness from the kPa level by nearly four orders of magnitude to the level of conventional hard plastics, and published an article titled “3D printing of hard/soft switchable hydrogels” in the SCI journal International Journal of Extreme Manufacturing.

Figure 1 Design and manufacturing principle diagram of 3D printed soft/hard switchable hydrogels inspired by sea cucumbers.

Video 1 Demonstration of soft/hard switching of 3D printed sea cucumber structure hydrogels.

2. Visual Analysis

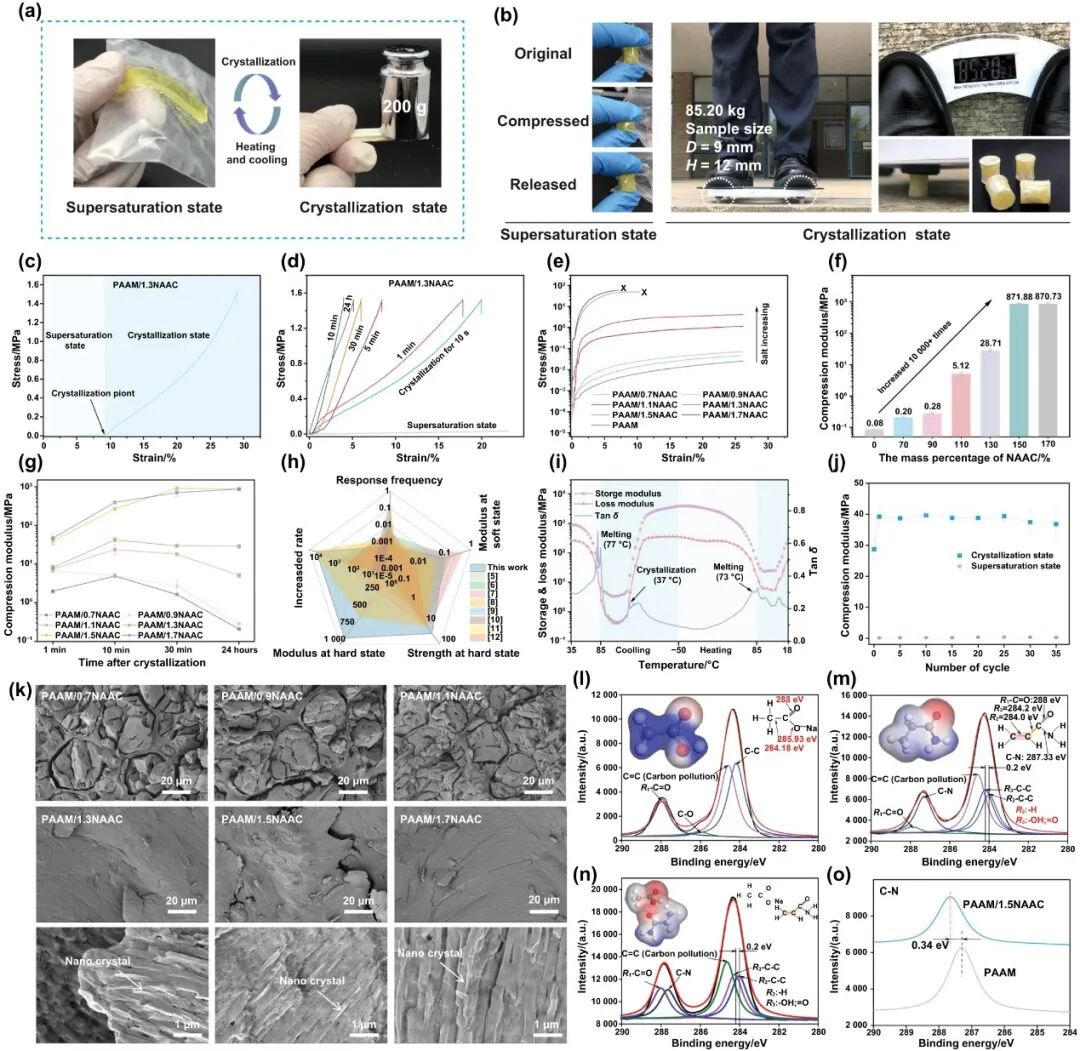

The innovation of this study lies in the proposal of a hydrogel that can freely switch between soft and hard states, incorporating a reversible phase change of supersaturated sodium acetate solution into the 3D printed hydrogel structure, granting it the ability to quickly and reversibly switch between soft and hard states. When the hydrated salt in the hydrogel is in a supersaturated state, the hydrogel exhibits soft characteristics, with an elastic modulus of only 80 kPa, and due to the presence of crystallization energy barriers, this soft state can be maintained stably at room temperature for a long time. By artificially introducing crystallization nuclei, the hydrogel crystallizes rapidly, forming a large number of nanoscale crystals uniformly distributed in the hydrogel matrix, achieving a controllable transition from the soft state to the hard state. During this process, the mechanical properties of the hydrogel are significantly enhanced, with its elastic modulus increasing dramatically to 1.2 GPa in a short time, an increase of 7700 times, which is significantly higher than previously reported hydrogels. The hardness reaches 86.5 Shore D, comparable to hard plastics. The strength increases to 81.7 MPa. By heating and then cooling, the hydrogel can reversibly return to its initial supersaturated state, i.e., the soft state. Moreover, this hydrogel can be shaped through 3D printing.

Figure 2 Mechanical properties of soft/hard switchable hydrogels and their mechanical enhancement mechanisms.

Video 2 Demonstration of soft/hard switching of 3D printed lattice structure hydrogels.

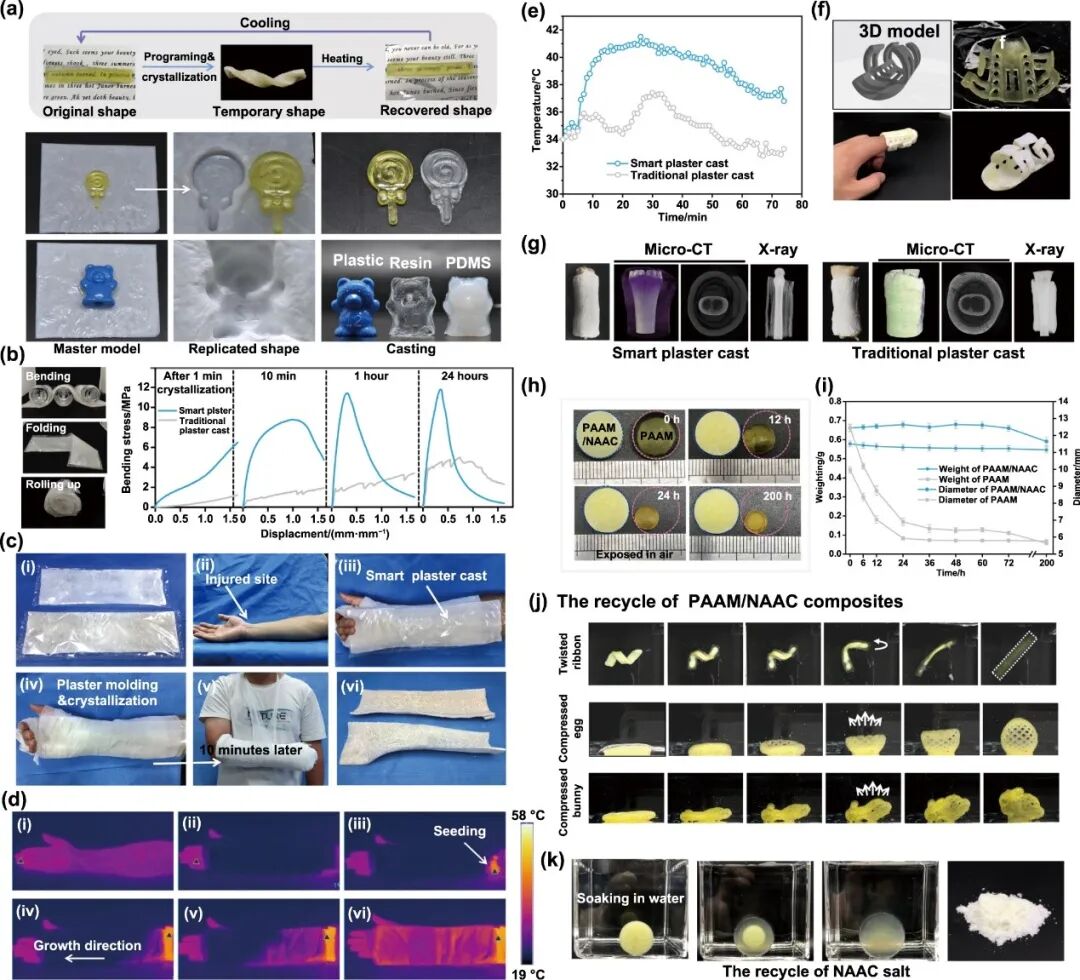

In response to emergency medical rescue scenarios, based on the advantages of soft/hard switching of hydrogels, this study developed a smart medical fixation bandage based on hydrogels, which can accurately conform to the shape of limbs in its soft state. After triggering crystallization, the material rapidly transforms into a rigid state, providing mechanical support superior to traditional plaster for fracture sites within 10 minutes. This bandage is portable, easy to operate, and responds quickly, making it a promising alternative to the cumbersome traditional plaster fixation techniques. Furthermore, this study extends the method of enhancing the mechanical properties of hydrogels through hydrated salts to various hydrated salt and hydrogel systems, validating the universality of this method.

Figure 3 Application of PAAM/NAAC composite materials in smart medical plaster bandages.

Video 3 Demonstration of the application of hydrogel smart medical plaster bandages.

4. Author Biography

He Yong, recipient of the National Outstanding Youth Science Fund, gold medal instructor of the National Internet+ College Student Innovation and Entrepreneurship Competition, chief science communication expert in Zhejiang Province. Currently a distinguished professor at Zhejiang University, deputy director of the National Key Laboratory of Fluid Power Basic Components and Mechatronic Systems, associate editor of the journal Bio-Design Manufacturing, and editorial board member of Biofabrication. Engaged in research on additive manufacturing and biomanufacturing, he has presided over six projects funded by the National Natural Science Foundation, including Outstanding Youth, Key Fund, and Joint Key Fund projects, and is a core member of the innovative group project “Research on Tissue Engineering and Regeneration of Motion Systems”. He has published two monographs on biological 3D printing, holds over 50 authorized invention patents, and has published more than 100 SCI papers in journals such as Science Translational Medicine, Nature Review Bioengineering, Science Advances, and Nature Communications, with an H-index of 65 and over 12,000 citations. He serves as an executive member of the Biomanufacturing Division of the Mechanical Engineering Society, vice chairman of the Advanced Manufacturing Division of the Biomaterials Society, and leader of the equipment group of the National Medical Additive Manufacturing Standard Committee, creating the EFL brand (Engineering for Life), dedicated to interdisciplinary research and the transformation of research results.

Recommended Reading

High-precision additive manufacturing of slippery hydrogels with anti-desiccation skin

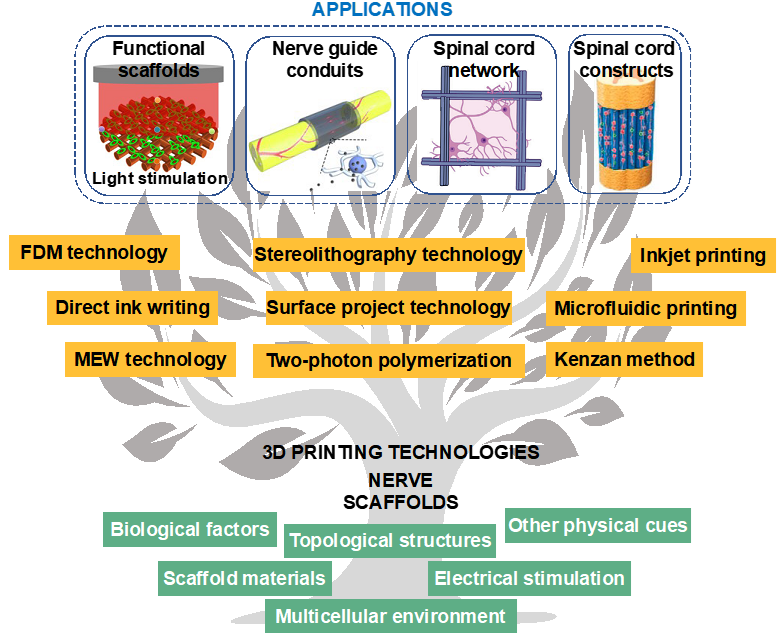

Research progress on 3D printed scaffolds for peripheral nerve regeneration and spinal cord injury repair

About the Journal

International Journal of Extreme Manufacturing (极端制造), abbreviated as IJEM, is dedicated to publishing high-quality and cutting-edge research results in the field of extreme manufacturing. Since its inception in 2019, the journal has been included in over 20 international databases such as SCIE, EI, and Scopus.The latest JCR impact factor is 16.1, ranking first in the engineering/manufacturing discipline. It is classified as a top journal in the engineering technology category by the Chinese Academy of Sciences and is included in the second phase of the Excellent Action Plan for Chinese Science and Technology Journals as a leading English journal.

Journal Website:

https://iopscience.iop.org/journal/2631-7990

http://ijemnet.com/

Journal Submission:

https://mc04.manuscriptcentral.com/ijem-caep

Author Benefits:

• Golden Open Access

• Fast review of original groundbreaking results through a green channel

• Online within 24 hours after acceptance

• Free global promotion

• Free high-quality image editing and standardized literature proofreading

Special Call for Papers

Call for Papers

Dynamic Cover

2024-06

2024-05

2024-04

2024-03

2024-02

2024-01

2023-04

2023-03

2023-02

2023-01

▶ More past issues click here ◀

WeChat ID丨IJEM-Editor

Scan to add the editor’s WeChat

Inviting you to join the Extreme Manufacturing group

Written by: Author Edited by: Liang Yu Reviewed by: Fan Keyan, Guan Lichao

This article aims to convey and share the latest scientific research information. If there are any copyright issues, please contact us promptly, and we will address them in a timely manner to protect your rights. Thank you to all the friends who have continuously followed and supported this public account!